无机材料学报 ›› 2019, Vol. 34 ›› Issue (8): 851-856.DOI: 10.15541/jim20180418 CSTR: 32189.14.10.15541/jim20180418

收稿日期:2018-09-10

修回日期:2018-12-24

出版日期:2019-08-20

网络出版日期:2019-05-29

作者简介:林德宝(1990-), 男, 博士研究生. E-mail: <email>depaul@shu.edu.cn</email>

基金资助:

LIN De-Bao,FAN Ling-Cong,DING Mao-Mao,XIE Jian-Jun,LEI Fang,SHI Ying( )

)

Received:2018-09-10

Revised:2018-12-24

Published:2019-08-20

Online:2019-05-29

Supported by:摘要:

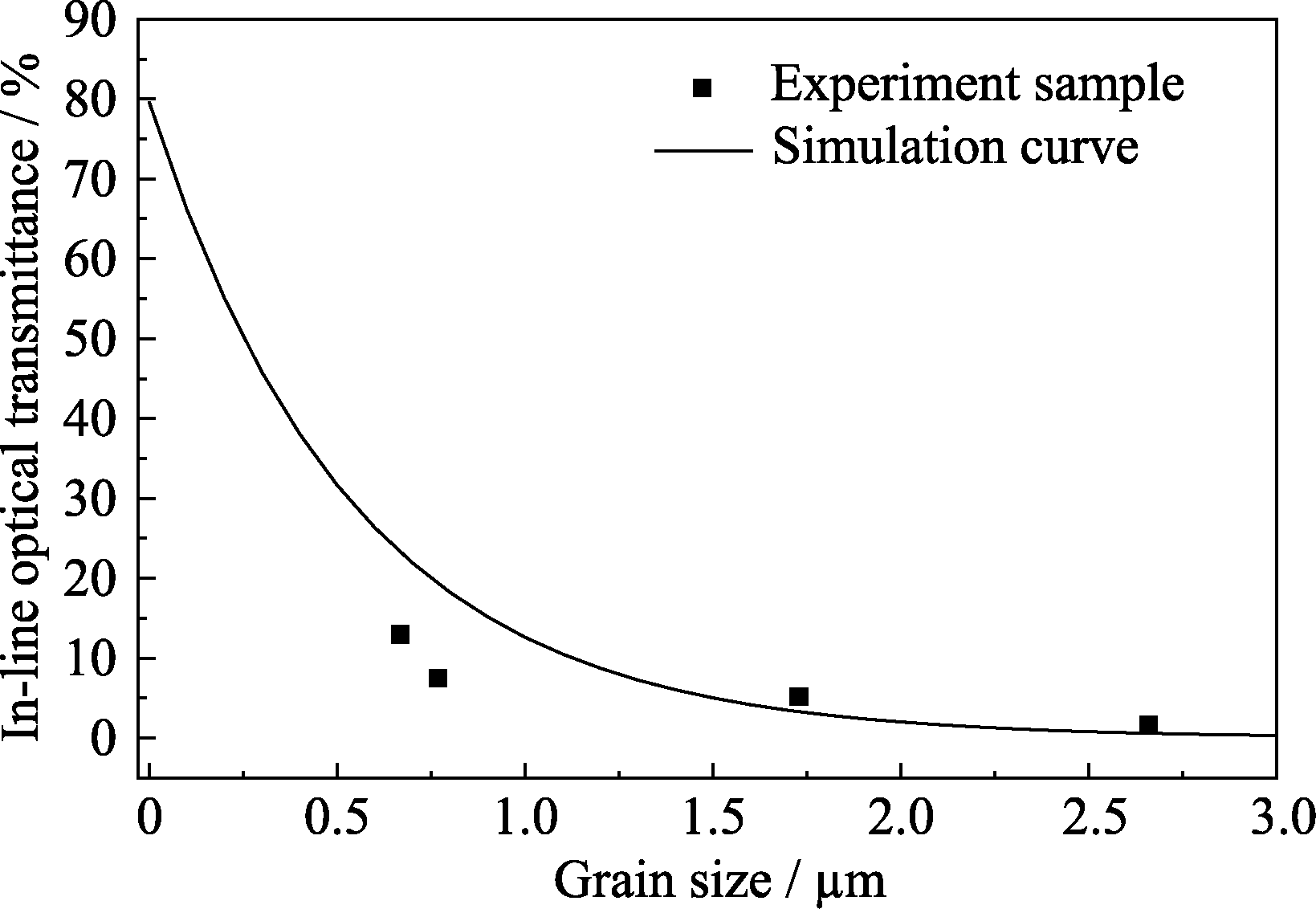

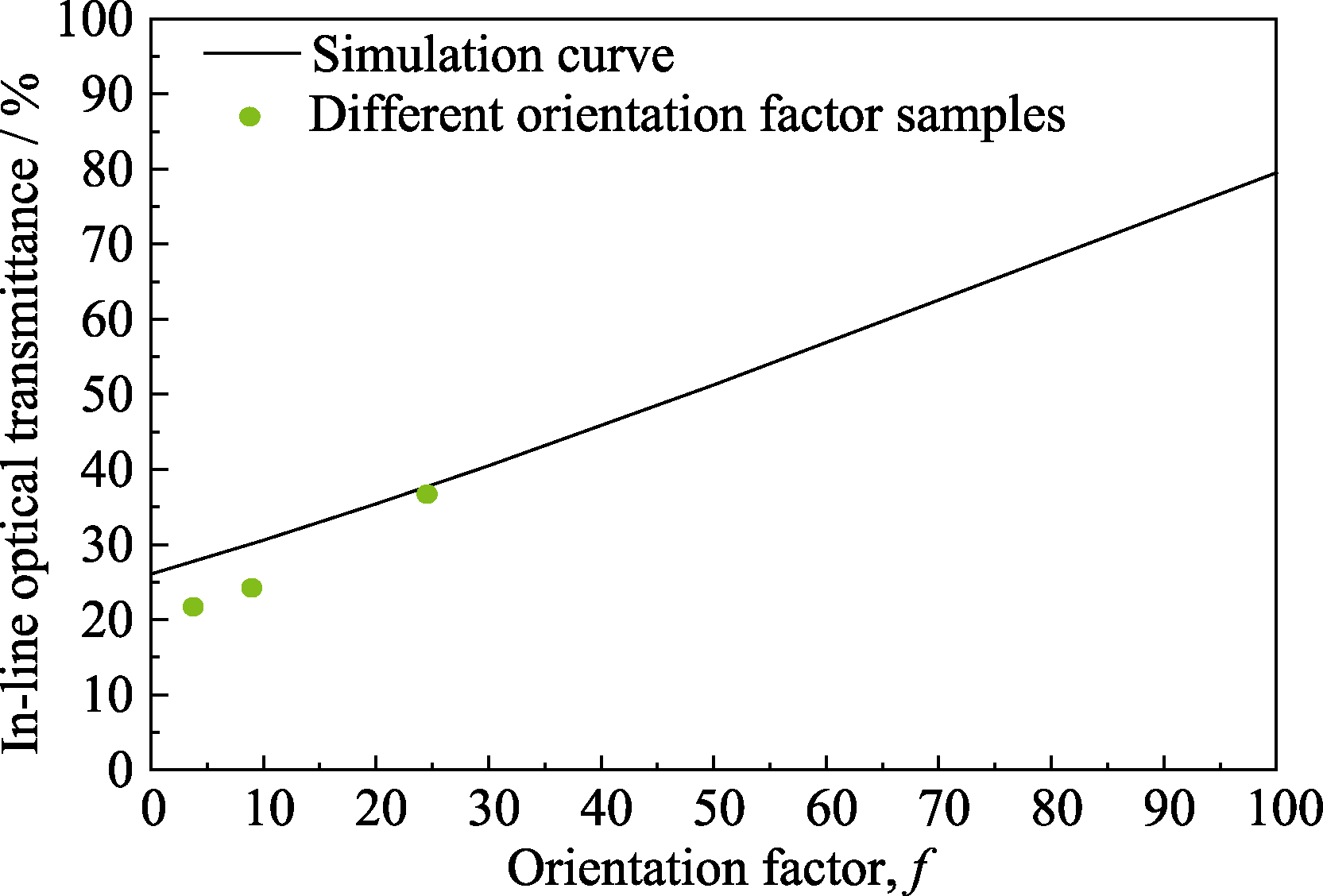

本研究以ZnO透明陶瓷为研究对象, 基于Mie理论及Rayleigh-Debye近似散射理论, 建立了单轴六方晶系透明陶瓷的双折射散射与其直线光学透过率之间关联的理论模型, 阐明了ZnO透明陶瓷光学直线透过率随晶粒尺寸减小、陶瓷织构度的提升而增大的关系。采用强磁场下的注浆成型工艺结合优化放电等离子体烧结参数, 实现了ZnO透明陶瓷显微结构的有效调控, 使得制备的ZnO透明陶瓷符合模型要求。实验结果表明: 当ZnO陶瓷平均晶粒尺寸从1.72 μm减小至0.66 μm时, 其600 nm处的直线透过率从5.1%提高到12.9%; 对于亚微米级ZnO陶瓷(平均晶粒尺寸0.35 μm), 当陶瓷织构度从4.0%提高到24.7%时(XRD计算), 样品光学直线透过率从21.6%提升到36.6%。所获得实验结果与构建的理论模型计算结果吻合, 证实了所构建的模型。

中图分类号:

林德宝, 范灵聪, 丁毛毛, 谢建军, 雷芳, 施鹰. 氧化锌透明陶瓷光学透过模型构建与实验验证[J]. 无机材料学报, 2019, 34(8): 851-856.

LIN De-Bao, FAN Ling-Cong, DING Mao-Mao, XIE Jian-Jun, LEI Fang, SHI Ying. Optical Transmittance Model Construction for ZnO Transparent Ceramic and Experimental Verification[J]. Journal of Inorganic Materials, 2019, 34(8): 851-856.

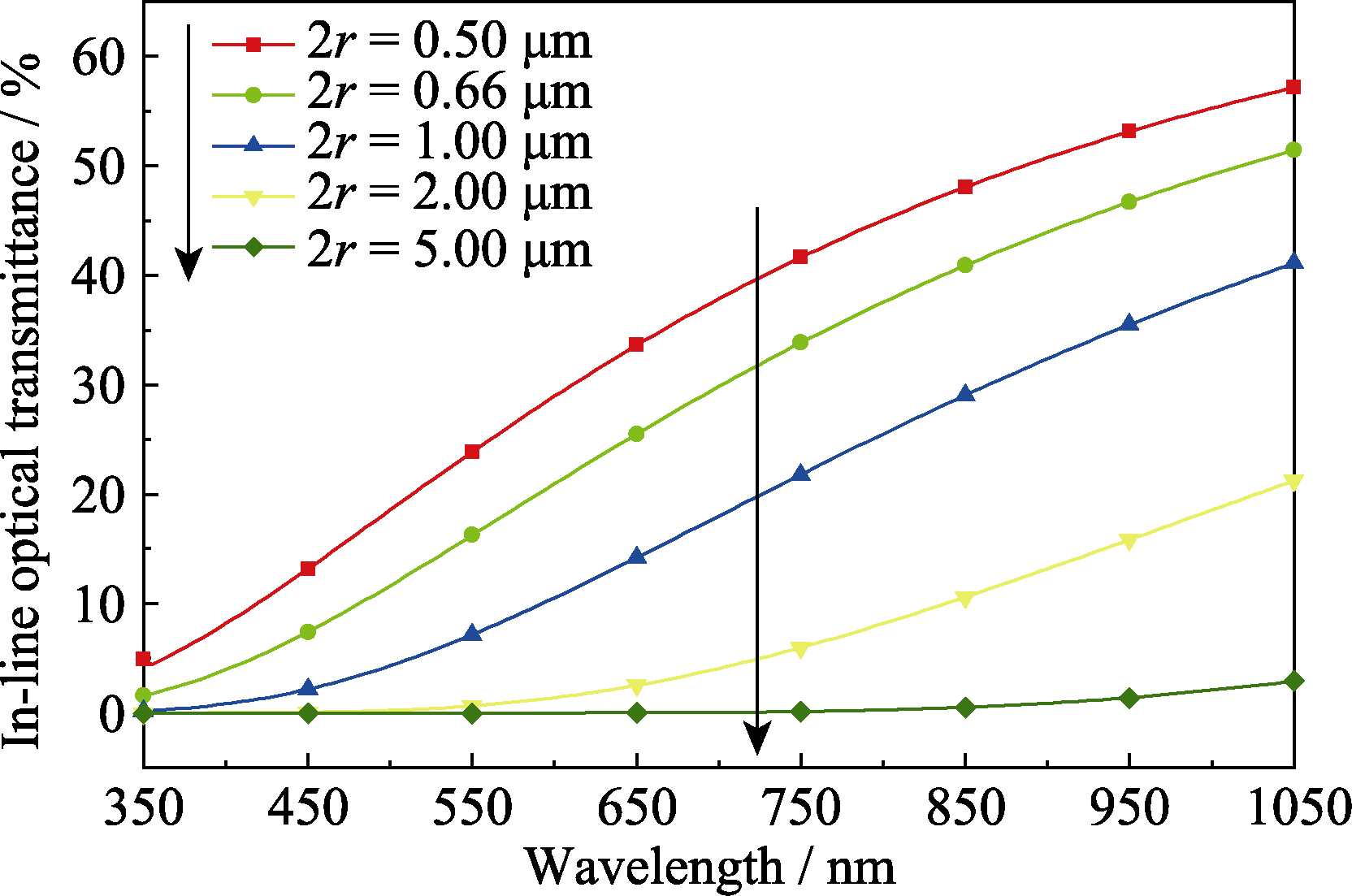

图2 以RGD散射模型计算不同晶粒尺寸ZnO陶瓷的直线透过率

Fig. 2 Variation of in-line transmission of ZnO ceramic calculated from the RGD scatting model from different grain sizes

图3 不同晶粒尺寸下ZnO陶瓷的直线透过率模拟计算结果与实际对比

Fig. 3 Comparation of in-line optical transmittance of ZnO ceramics with different grain sizes between calculated values from the RGD scattering model and ZnO samples by SPS processing

图4 在晶粒尺寸为(a) 2.65、(b) 1.72、(c) 0.76 和(d) 0.66 μm时ZnO陶瓷样品及其断面形貌

Fig. 4 Photographs of ZnO ceramics and corresponding fracture morphologies with grain sizes of (a) 2.65, (b) 1.72, (c) 0.76 and (d) 0.66 μm

| 2θ/(°) | (hkl) | Intensity/% | Angel α with (001) plane/(°) | 2θ/(°) | (hkl) | Intensity/% | Angel α with (001) plane/(°) |

|---|---|---|---|---|---|---|---|

| 31.769 | 100 | 17.33 | 90 | 66.378 | 200 | 1.22 | 90 |

| 34.421 | 002 | 13.37 | 0 | 67.961 | 112 | 6.99 | 52.60 |

| 36.252 | 101 | 30.40 | 61.61 | 69.098 | 201 | 3.34 | 74.88 |

| 47.538 | 102 | 6.99 | 42.77 | 72.561 | 004 | 0.61 | 0 |

| 56.602 | 110 | 9.73 | 90 | 76.953 | 202 | 1.22 | 61.61 |

| 62.862 | 103 | 8.81 | 31.66 |

表1 ZnO标准PDF卡片衍射峰位强度对比表

Table 1 Comparation of ZnO ceramics and standard pattern for ZnO measured by XRD (normalized intensity)

| 2θ/(°) | (hkl) | Intensity/% | Angel α with (001) plane/(°) | 2θ/(°) | (hkl) | Intensity/% | Angel α with (001) plane/(°) |

|---|---|---|---|---|---|---|---|

| 31.769 | 100 | 17.33 | 90 | 66.378 | 200 | 1.22 | 90 |

| 34.421 | 002 | 13.37 | 0 | 67.961 | 112 | 6.99 | 52.60 |

| 36.252 | 101 | 30.40 | 61.61 | 69.098 | 201 | 3.34 | 74.88 |

| 47.538 | 102 | 6.99 | 42.77 | 72.561 | 004 | 0.61 | 0 |

| 56.602 | 110 | 9.73 | 90 | 76.953 | 202 | 1.22 | 61.61 |

| 62.862 | 103 | 8.81 | 31.66 |

| θ=90-α/(°) | 0 | 30 | 45 | 60 | 90 |

|---|---|---|---|---|---|

| (<15) | (15-37.5) | (37.5-52.5) | (52.5-75) | (75-90) | |

| sinθ | 0 | 0.5 | 0.707 | 0.866 | 1 |

| P0 | P01(28.3%) | P02(42.0%) | P03(7.0%) | P04(8.8%) | P05(14.0%) |

表2 ZnO标准PDF卡片衍射峰位对应角度计算假设

Table 2 Hypothesis calculation of standard pattern for ZnO

| θ=90-α/(°) | 0 | 30 | 45 | 60 | 90 |

|---|---|---|---|---|---|

| (<15) | (15-37.5) | (37.5-52.5) | (52.5-75) | (75-90) | |

| sinθ | 0 | 0.5 | 0.707 | 0.866 | 1 |

| P0 | P01(28.3%) | P02(42.0%) | P03(7.0%) | P04(8.8%) | P05(14.0%) |

| θ/(°) f | 0 | 30 | 45 | 60 | 90 | μ(f) |

|---|---|---|---|---|---|---|

| (<15) | (15-37.5) | (37.5-52.5) | (52.5-75) | (75-90) | ||

| 0 | 28.28% | 41.95% | 6.99% | 8.81% | 13.98% | 0.4752 |

| 4.0% | 31.13% | 40.62% | 5.69% | 7.46% | 15.09% | 0.4588 |

| 9.2% | 34.57% | 43.65% | 6.13% | 5.58% | 10.07% | 0.4106 |

| 24.8% | 46.62% | 39.03% | 4.34% | 4.34% | 5.67% | 0.3201 |

表3 不同织构度下ZnO织构化函数数值与织构度间的关系

Table 3 Hypothesis calculation of standard pattern for ZnO

| θ/(°) f | 0 | 30 | 45 | 60 | 90 | μ(f) |

|---|---|---|---|---|---|---|

| (<15) | (15-37.5) | (37.5-52.5) | (52.5-75) | (75-90) | ||

| 0 | 28.28% | 41.95% | 6.99% | 8.81% | 13.98% | 0.4752 |

| 4.0% | 31.13% | 40.62% | 5.69% | 7.46% | 15.09% | 0.4588 |

| 9.2% | 34.57% | 43.65% | 6.13% | 5.58% | 10.07% | 0.4106 |

| 24.8% | 46.62% | 39.03% | 4.34% | 4.34% | 5.67% | 0.3201 |

图7 不同织构度下ZnO陶瓷的直线透过率(600 nm处)模拟计算结果与实际SPS样品值对比

Fig. 7 Comparation of in-line optical transmittance of ZnO ceramics calculated from the RGD scattering model with orientation factor at 600 nm

| [1] |

COBLE R L . Sintering alumina: effect of atmospheres. Journal of the American Ceramic Society, 1962,45(3):123-127.

DOI URL |

| [2] | MAO XIAOJIAN, WANG SHIWEI, SHIMA S , et al. Transparent polycrystalline alumina ceramics with orientated optical axes. Journal of the American Ceramic Society, 2008,91(10):3431-3433. |

| [3] |

APETZ ROLF, MICHEL P B BRUGGEN . Transparent alumina: a light-scattering model. Journal of the American Ceramic Society, 2003,86(3):480-486.

DOI URL |

| [4] | KRELL ANDREAS, BLANK PAUL, MA HONGWEI , et al. Transparent sintered corundum with high hardness and strength. Journal of the American Ceramic Society, 2010,86(1):12-18. |

| [5] | KRELL ANDREAS, KLIMAKE JENS, HUTZLER THOMAS , et al. Advanced spinel and sub-μm Al2O3 for transparent armour applications. Journal of the European Ceramic Society, 2009,29(2):275-281. |

| [6] |

BERNARD-GRANGER GUILLAUME, GUIZARD CHRISTIAN . Influence of MgO or TiO2 doping on the sintering path and on the optical properties of a submicronic alumina material. Journal of the American Ceramic Society, 2008,91(5):1703-1706.

DOI URL |

| [7] | LUCKEY D . A fast inorganic scintillator. Nuclear Instruments & Methods, 1968,62(1):119-120. |

| [8] | GOROKHOVA E I, ERON’KO S B, KUL’KOV A M , et al. Development and study of ZnO: in optical scintillation ceramic. Journal of Optical Technology C/c of Opticheskii Zhurnal, 2015,82(12):837. |

| [9] | RODNYO P A, CHERNENKO K A, GOROKHOVA E I , et al. Novel scintillation material-ZnO transparent ceramics. IEEE Transactions on Nuclear Science, 2012,59(5):2152-2155. |

| [10] | PRAKASAM MYTHILI, VIRAPHONG OUDOMSACK, MICHAU DOMINIQUE , et al. Critical parameters to obtain Yb3+ doped Lu2O3 and ZnO transparent ceramics. Ceramics International, 2014,40(1):1859-1864. |

| [11] | GOROKHOVA E I, RODNYIP A, LOKSHIN E P , et al. Structural, optical, and scintillation characteristics of ZnO ceramics. Journal of Optical Technology C/c of Opticheskii Zhurnal, 2011,78(11):753-760. |

| [12] | 赵宇 . 镓掺杂氧化锌纳米晶透明陶瓷的制备. 长春: 吉林大学硕士学位论文, 2008. |

| [13] | QIN JIEMING, ZHANG YING, CAO JIANMING , et al. Characterization of the transparent n-type ZnO ceramic with low resistivity prepared under high pressure. Acta Physics Sinica, 2011,60(3):431-435. |

| [14] | HULST HC, TWERSKY V . Light Scattering by Small Particles. Hoboken: John Wiley, 1957. |

| [15] |

BARBER P W, WANG D S . Rayleigh-Gans-Debye applicability to scattering by nonspherical particles: corrigenda. Applied Optics, 1978,17(5):797.

DOI URL |

| [16] |

BOND W L . Measurement of the refractive indices of several crystals. Journal Of Applied Physics, 1965,36(5):1674-1677.

DOI URL |

| [17] |

WEN T C SHETTY D K KRELL A . On the effect of birefringence on light transmission in polycrystalline magnesium fluoride. Journal of the American Ceramic Society, 2015,98(3):829-837.

DOI URL |

| [18] | WEN TZUCHIEN . Effect of grain size on optical transmittance of birefringent polycrystalline ceramics. Salt Lake City: The University of Utah, 2016. |

| [19] |

YOICHI SATO, JUN AKIYAMA, TAKUNORI TAIRA . Orientation control of micro-domains in anisotropic laser ceramics. Optical Materials Express, 2013,3(6):829-841.

DOI URL |

| [20] |

SUZUKI T S . Control of texture in ZnO by slip casting in a strong magnetic field and heating, Chemistry Letters, 2002,31(12):1204-1205.

DOI URL |

| [1] | 吴琼, 沈炳林, 张茂华, 姚方周, 邢志鹏, 王轲. 铅基织构压电陶瓷研究进展[J]. 无机材料学报, 2025, 40(6): 563-574. |

| [2] | 吴杰, 杨帅, 王明文, 李景雷, 李纯纯, 李飞. 铅基织构压电陶瓷的发展历程、现状与挑战[J]. 无机材料学报, 2025, 40(6): 575-586. |

| [3] | 高天宇, 刘东, 赵思雪, 邓伟, 张波萍, 朱立峰. 温度稳定性优异的K0.5Na0.5NbO3基压电陶瓷及其1-3型换能器[J]. 无机材料学报, 2025, 40(3): 297-304. |

| [4] | 徐昊, 钱伟, 花银群, 叶云霞, 戴峰泽, 蔡杰. 皮秒激光加工的微织构对碳化硅润湿性的影响[J]. 无机材料学报, 2023, 38(8): 923-930. |

| [5] | 产思义, 屠菊萍, 黄珂, 邵思武, 杨志亮, 刘鹏, 刘金龙, 陈良贤, 魏俊俊, 安康, 郑宇亭, 李成明. 2英寸MPCVD光学级均匀金刚石膜的制备研究[J]. 无机材料学报, 2023, 38(12): 1413-1419. |

| [6] | 万家宝, 张明辉, 苏怀宇, 曹枝军, 刘学超, 谢坚生, 王祥远, 时英辉, 王亮, 雷水金. GeO2-La2O3-TiO2玻璃的结构、热学和光学性质[J]. 无机材料学报, 2023, 38(10): 1230-1236. |

| [7] | 肖舒琳, 戴中华, 李定妍, 张凡博, 杨利红, 任晓兵. 氧化镧掺杂铌酸钾钠陶瓷的电、光性能研究[J]. 无机材料学报, 2022, 37(5): 520-526. |

| [8] | 向晖, 全慧, 胡艺媛, 赵炜骞, 徐波, 殷江. 类石墨烯单层结构ZnO和GaN的压电特性对比研究[J]. 无机材料学报, 2021, 36(5): 492-496. |

| [9] | 张清明, 朱敏, 周晓霞. CuO/ZnO复合电催化剂的制备及其还原CO2制合成气[J]. 无机材料学报, 2021, 36(11): 1145-1153. |

| [10] | 张东硕,蔡昊,高凯茵,马子川. Zn2SiO4-ZnO-生物炭复合物的制备及其可见光催化H2O2降解甲硝唑[J]. 无机材料学报, 2020, 35(8): 923-930. |

| [11] | 姚西媛, 李克智, 任俊杰, 张守阳. 混合前驱体制备高织构三维C/C复合材料的微观结构及疲劳行为[J]. 无机材料学报, 2020, 35(5): 589-592. |

| [12] | 朱泽阳,魏济时,黄健航,董向阳,张鹏,熊焕明. 晶格空位ZnO纳米棒的制备及其在镍锌电池中的应用[J]. 无机材料学报, 2020, 35(4): 423-430. |

| [13] | 张伟,高鹏,侯成义,李耀刚,张青红,王宏志. 基于ZnO复合材料的芯片式pH和温度传感器[J]. 无机材料学报, 2020, 35(4): 416-422. |

| [14] | 张之明,方晓生. ZnO纳米棒/ZnCo2O4纳米片异质结的制备及其光电探测性能[J]. 无机材料学报, 2019, 34(9): 991-996. |

| [15] | 祝志祥,张强,朱思宇,卢成嘉,刘艺,杨佳,吴超峰,曹林洪,王轲,高志鹏,朱承治. 脉冲电场下ZnO压敏陶瓷动态击穿过程研究[J]. 无机材料学报, 2019, 34(7): 715-720. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||