无机材料学报 ›› 2024, Vol. 39 ›› Issue (2): 145-152.DOI: 10.15541/jim20230425 CSTR: 32189.14.10.15541/jim20230425

所属专题: 【结构材料】陶瓷基复合材料(202506); 【信息功能】MAX、MXene及其他二维材料(202506)

刘艳艳1,2( ), 谢曦1, 刘增乾1,2(

), 谢曦1, 刘增乾1,2( ), 张哲峰1,2(

), 张哲峰1,2( )

)

收稿日期:2023-09-19

修回日期:2023-11-02

出版日期:2023-11-10

网络出版日期:2023-11-10

通讯作者:

刘增乾, 研究员. E-mail: zengqianliu@imr.ac.cn;作者简介:刘艳艳(1994-), 女, 博士研究生. E-mail: yyliu18s@imr.ac.cn

基金资助:

LIU Yanyan1,2( ), XIE Xi1, LIU Zengqian1,2(

), XIE Xi1, LIU Zengqian1,2( ), ZHANG Zhefeng1,2(

), ZHANG Zhefeng1,2( )

)

Received:2023-09-19

Revised:2023-11-02

Published:2023-11-10

Online:2023-11-10

Contact:

LIU Zengqian, professor. E-mail: zengqianliu@imr.ac.cn;About author:LIU Yanyan (1994-), female, PhD candidate. E-mail: yyliu18s@imr.ac.cn

Supported by:摘要:

由于原子间存在共价键、金属键与离子键的混合键合状态, MAX相陶瓷兼具金属和陶瓷材料的性能特点, 并且常与金属之间表现出良好的润湿性, 有助于形成强界面结合, 独特的层状原子结构使MAX相陶瓷表现出良好的断裂韧性、阻尼与自润滑性能。因此, 作为金属基复合材料的增强相, MAX相陶瓷具有显著优势, 本文着重介绍相关研究进展。目前, MAX相陶瓷增强金属基复合材料主要通过搅拌铸造、粉末冶金和熔体浸渗等途径制备, 得到的复合材料表现出优于金属基体的强度、硬度与模量, 同时还具备良好的耐磨、导电、抗电弧侵蚀等性能。此外, 借助真空抽滤、冰模板等工艺可实现超细片状MAX相陶瓷粉体的择优定向排列, 然后利用金属熔体浸渗多孔陶瓷骨架, 可获得具有类贝壳结构的MAX相陶瓷增强金属基仿生复合材料, 进一步提升材料的强韧性能。MAX相陶瓷增强金属基复合材料在承载、电接触等应用领域具有显著优势和广阔前景。

中图分类号:

刘艳艳, 谢曦, 刘增乾, 张哲峰. MAX相陶瓷增强金属基复合材料: 制备、性能与仿生设计[J]. 无机材料学报, 2024, 39(2): 145-152.

LIU Yanyan, XIE Xi, LIU Zengqian, ZHANG Zhefeng. Metal Matrix Composites Reinforced by MAX Phase Ceramics: Fabrication, Properties and Bioinspired Designs[J]. Journal of Inorganic Materials, 2024, 39(2): 145-152.

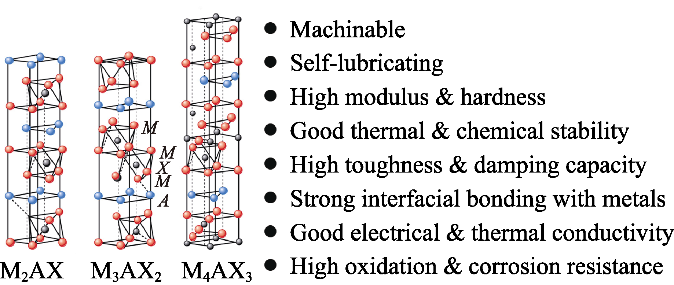

图1 MAX相陶瓷的原子结构与性能优势[6]

Fig. 1 Atomic structures and advantageous properties of MAX phase ceramics[6] With permission from Ref. [6] Copyright 2011, Annual Reviews

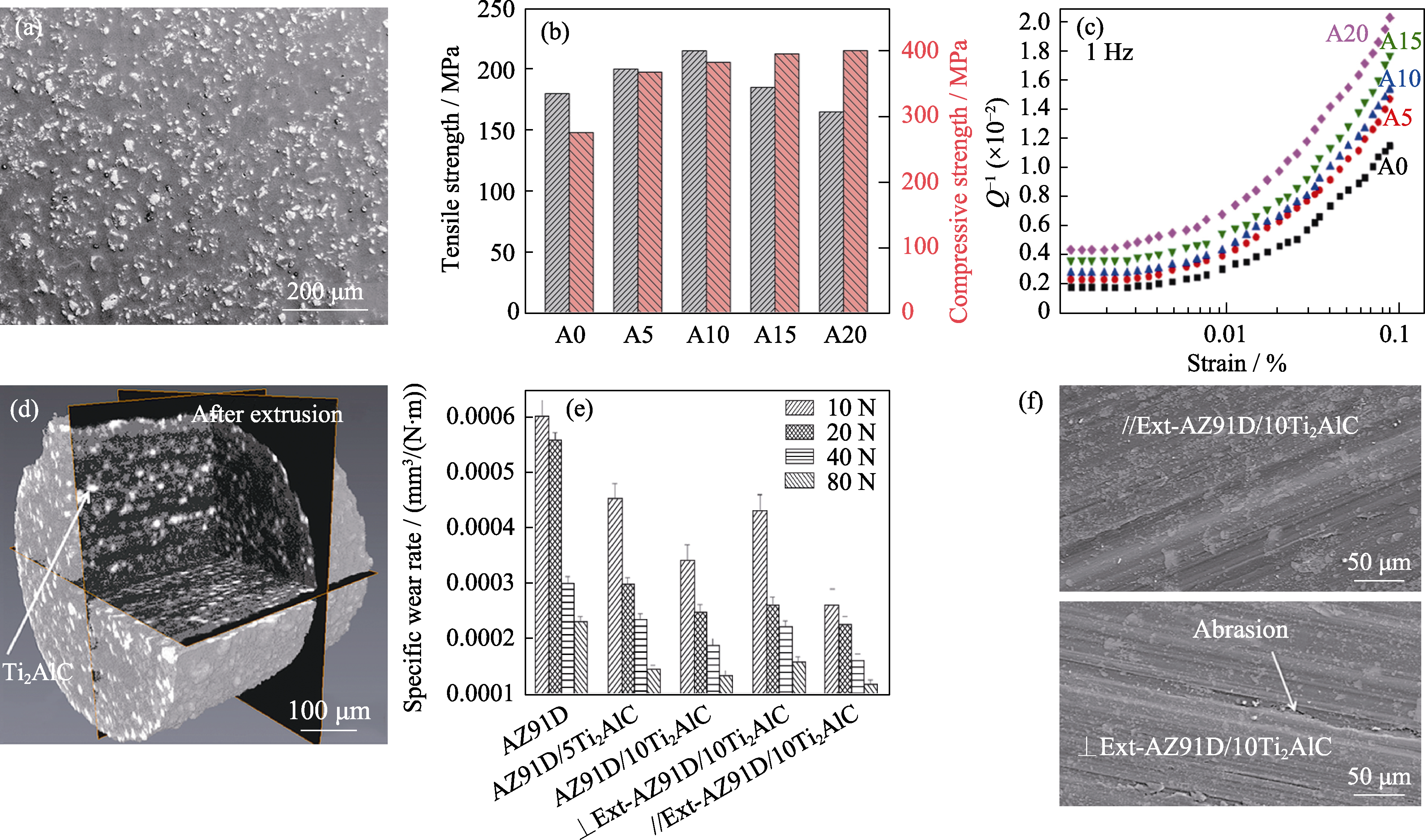

图2 搅拌铸造工艺制备的AZ91D-Ti2AlC复合材料的微观结构与力学、阻尼及磨损性能

Fig. 2 Structure and mechanical, damping and friction properties of AZ91D-Ti2AlC composites fabricated by stir casting technique (a) Representative structure of as-cast AZ91D-Ti2AlC composite with white regions showing Ti2AlC phase[13]; (b) Tensile and compressive strengths of the as-cast composites with different Ti2AlC contents (A0‒A20 denoting the volume fraction of Ti2AlC from 0 to 20%)[13]; (c) Variations in the internal friction (Q-1) with strain amplitude[16]; (d) 3D structure of AZ91D-Ti2AlC composite after hot extrusion[14]; (e) Specific wear rates of as-cast and extruded composites compared to the AZ91D matrix under different applied loads[15]; (f) Wear morphologies of extruded composite after sliding along parallel (∥) and perpendicular (⊥) directions with respect to the extrusion axis[15] (a, b) Adapted with permission from Ref. [13] Copyright 2017, Elsevier; (c) Adapted with permission from Ref. [16] Copyright 2019, Elsevier; (d) Adapted with permission from Ref. [14] Copyright 2018, Elsevier; (e, f) Adapted with permission from Ref. [15] Copyright 2019, Elsevier

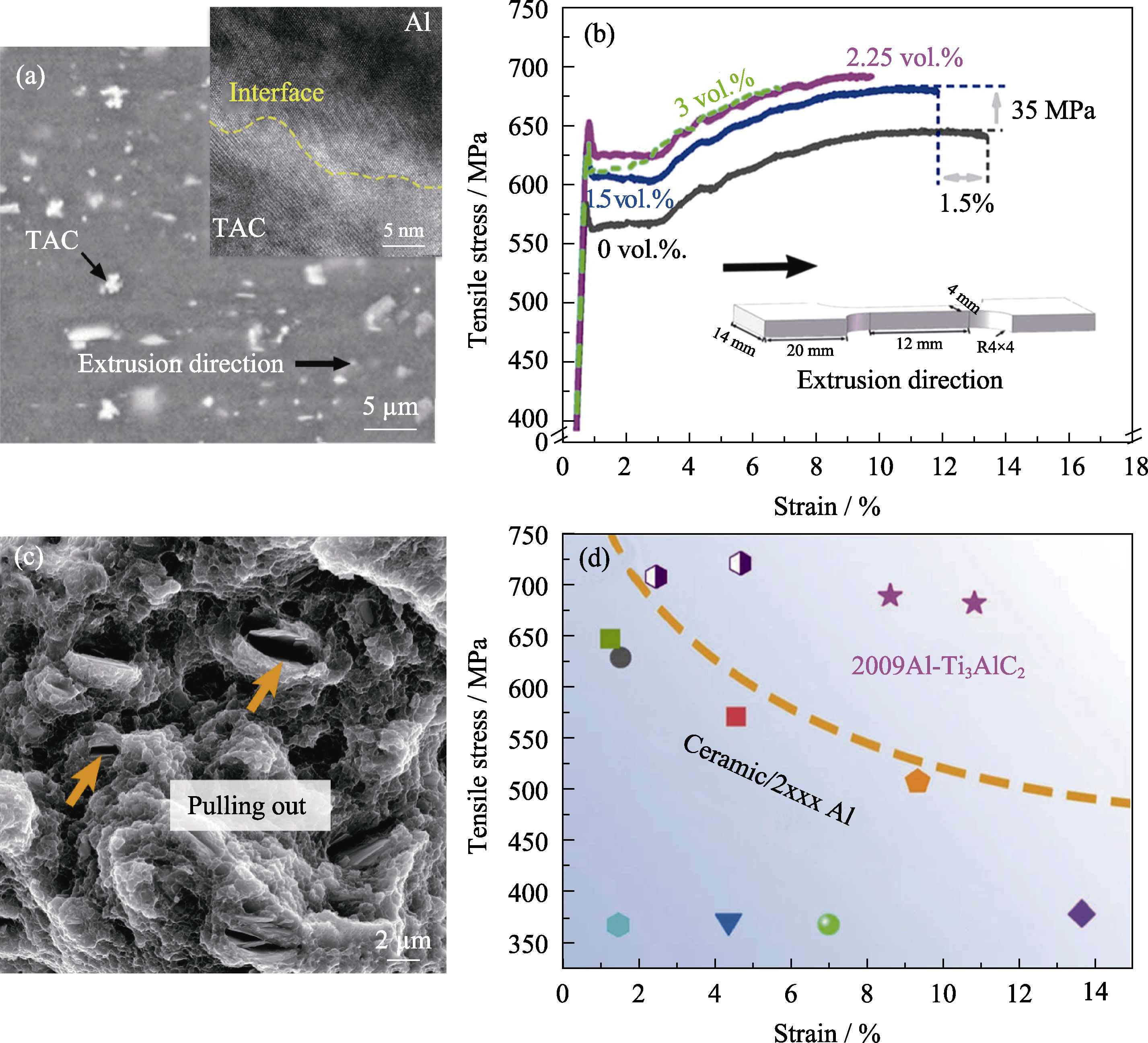

图3 粉末冶金工艺制备的2009Al-Ti3AlC2复合材料的微观结构、力学性能与断后形貌[17]

Fig. 3 Structure, mechanical properties, and fracture morphologies of 2009Al-Ti3AlC2 composites made by powder metallurgy technique[17] (a) Structure of 2009Al-Ti3AlC2 composite after extrusion and inverse fast Fourier transformation image of interface between Ti3AlC2 particle and Al alloy matrix. TAC: Ti3AlC2; (b) Tensile stress-strain curves of the composites with different Ti3AlC2 contents; (c) Fracture morphologies of composite after tensile fracture; (d) Comparison of tensile strength and ductility of 2009Al-Ti3AlC2 composites with other 2xxx Al alloy composites reinforced by ceramics. Adapted with permission from Ref. [17] Copyright 2023, Springer

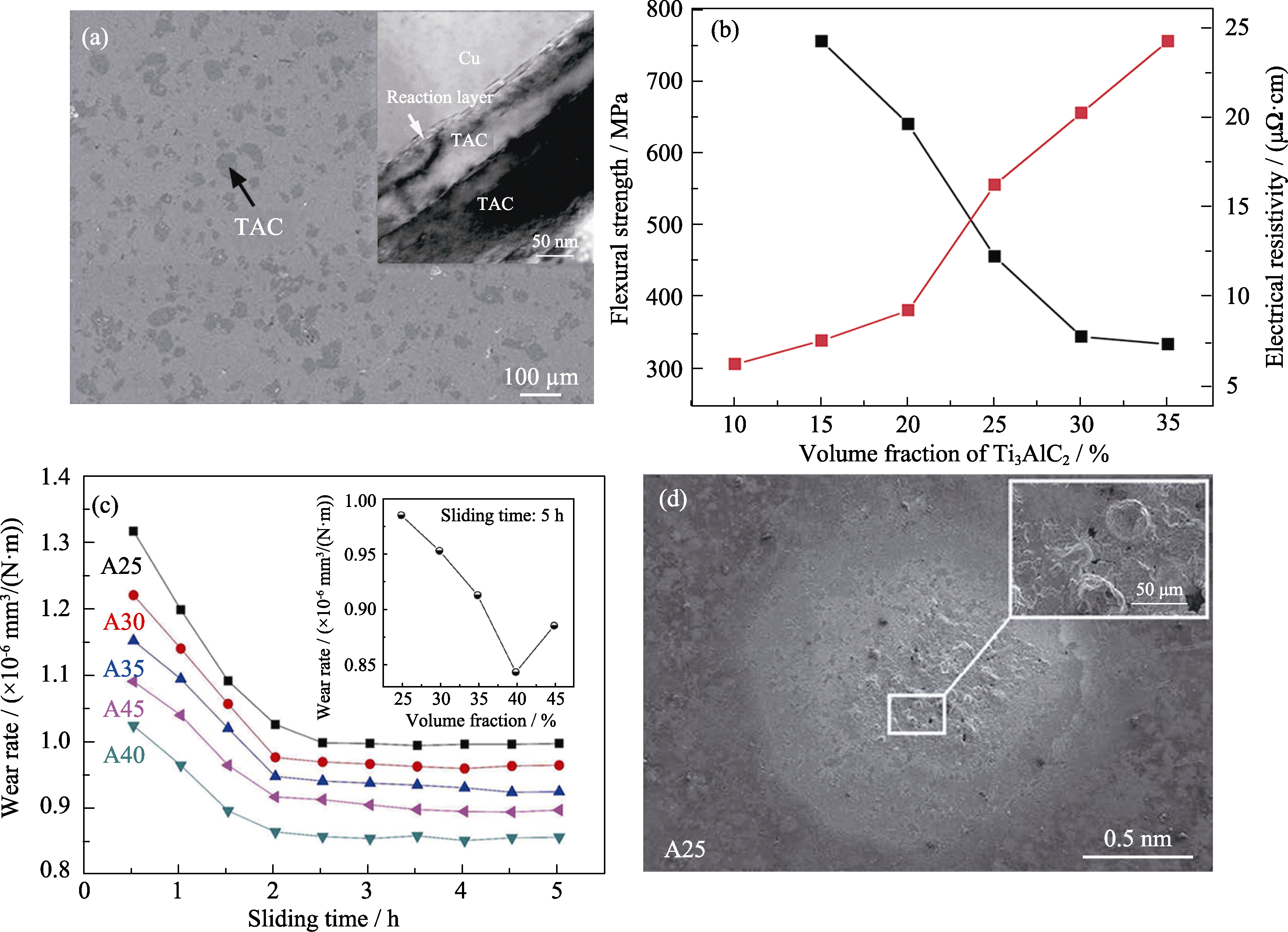

图4 粉末冶金工艺制备的Cu-Ti3AlC2复合材料的微观结构、力学性能与功能性质

Fig. 4 Structural, mechanical and functional charateristics of Cu-Ti3AlC2 composites fabricated by powder metallurgy technique (a) Structure of Cu-Ti3AlC2 composite and its reaction layer between Ti3AlC2 (TAC) and Cu phases[20]; (b) Variations in the flexural strength and electrical resistivity of the composites as a function of the volume fraction of Ti3AlC2 phase[20]; (c) Wear rate of the composites against increasing sliding time with inset showing the dependence of wear rate on the volume fraction of Ti3AlC2 phase at a sliding time of 5 h[22]; (d) Surface morphology of Cu-25% Ti3AlC2 composite after arc erosion[20]. (a, b, d) Adapted with permission from Ref. [20] Copyright 2017, Taylor & Francis. The inset in (a) is adapted with permission from Ref. [21] Copyright 2007, Elsevier. (c) Adapted with permission from Ref. [22] Copyright 2019, Springer

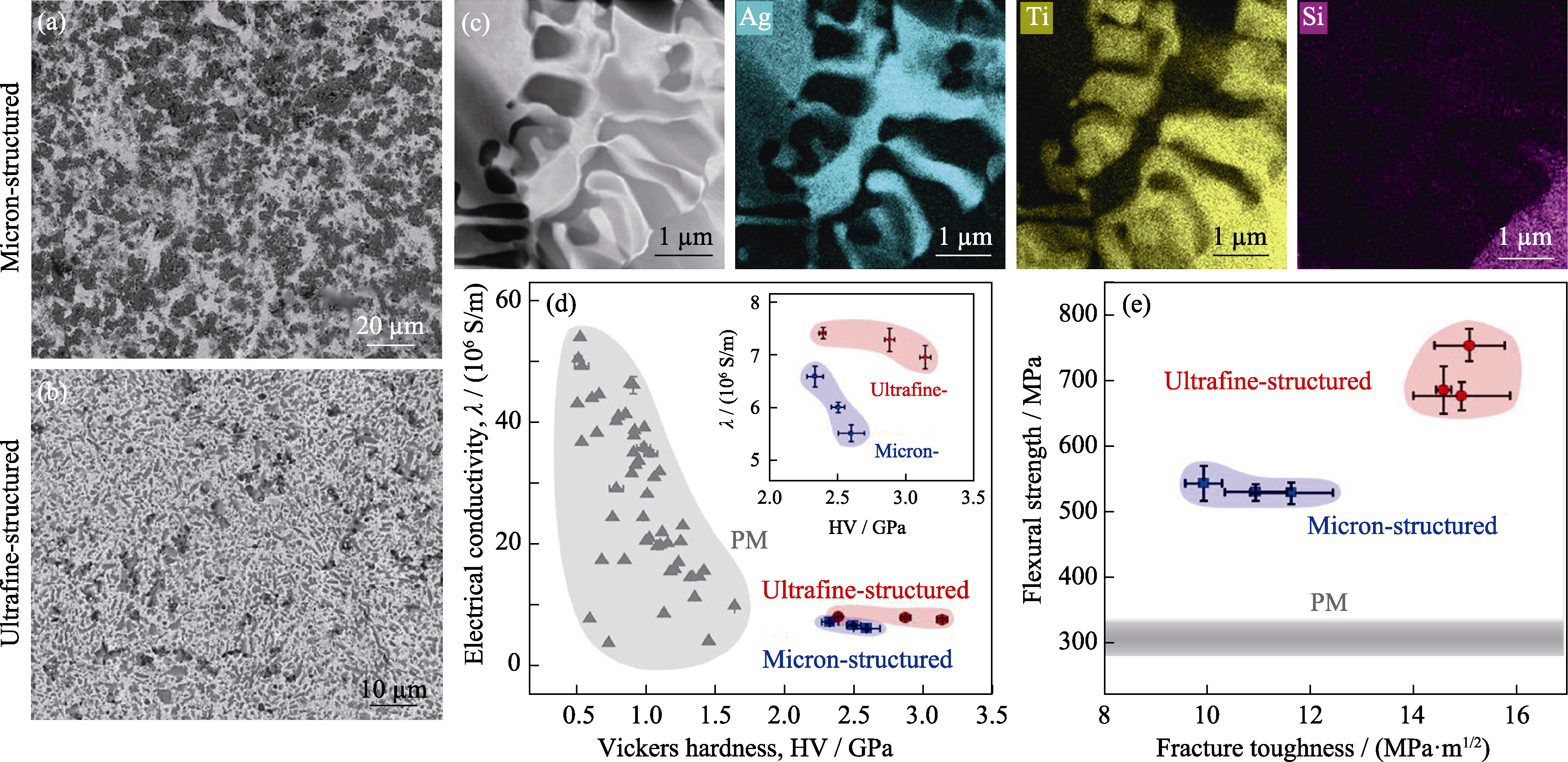

图5 熔体浸渗工艺制备的Ag-Ti3SiC2复合材料的微观结构及力学与导电性能[27]

Fig. 5 Structural, mechanical and electrical characteristics of Ag-Ti3AlC2 composites made by melt infiltration technique[27] (a, b) Structures of melt infiltrated Ag-Ti3AlC2 composites with different structural dimensions of micron- (a) and ultrafine (b) length scales with dark regions showing Ti3SiC2 phase; (c) Chemical characteristics of the micron-structured Ag-Ti3AlC2 composite; (d, e) Electrical conductivity versus Vickers hardness (d) and flexural strength versus fracture toughness (e) of the melt infiltrated Ag-Ti3AlC2 composites with other Ag-MAX phase composites fabricated by powder metallurgy technique. Adapted with permission from Ref. [27] Copyright 2023, Tsinghua University Press

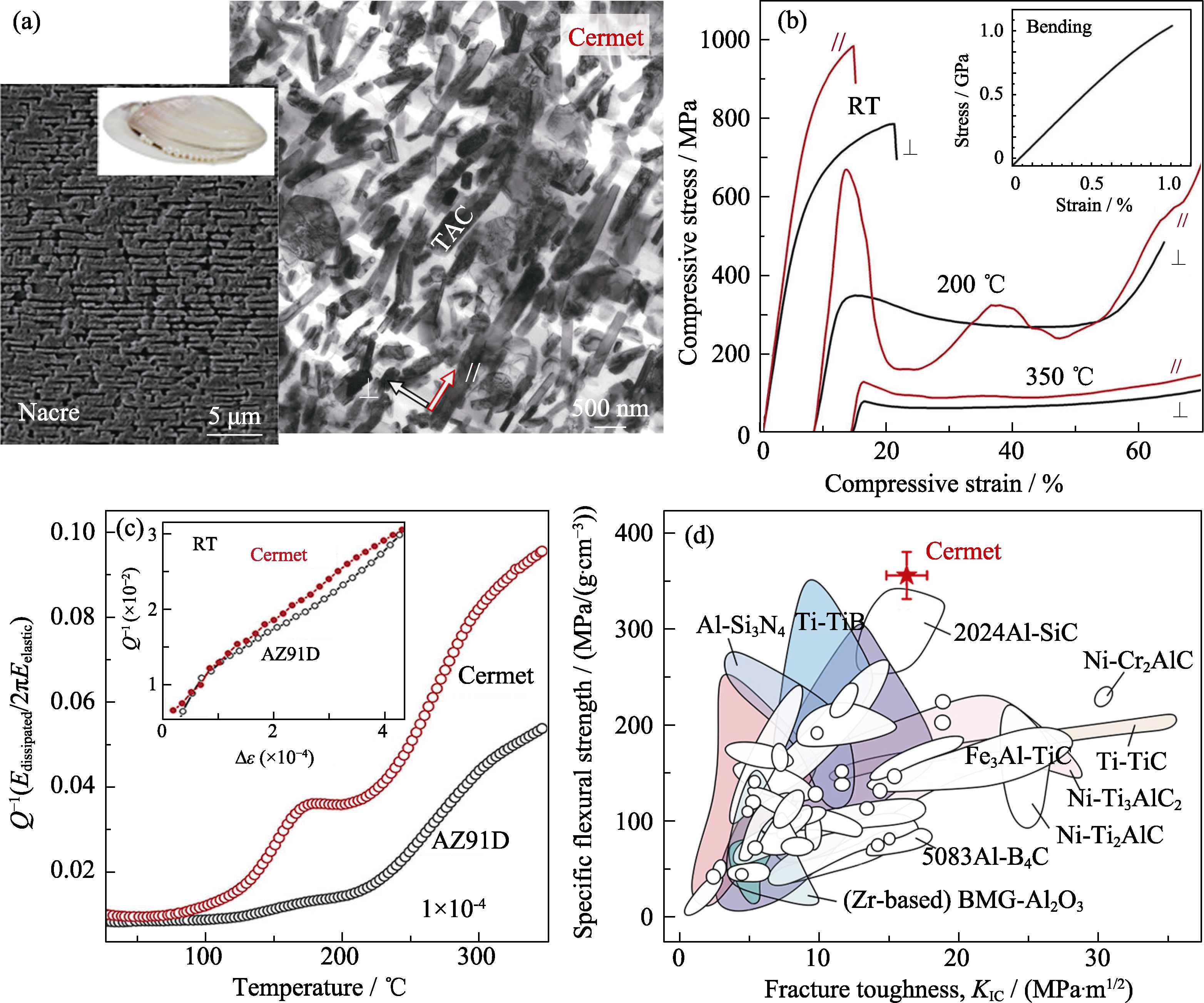

图6 具有微观类贝壳结构的Ti3AlC2增强镁基仿生复合材料的微观结构及力学与阻尼性能[29]

Fig. 6 Structure, mechanical properties, and damping characteristics of nacre-like Mg-Ti3AlC composites[29] (a) Structure of nacre-like composite compared to natural nacre (of Sinanodonta woodiana shell, TAC: Ti3AlC2); (b) Compressive stress-strain curves of the nacre-like composite at different temperatures when loading parallel and perpendicular to its layered structure with inset showing bending stress-strain curve of the composite at room temperature (RT); (c) Variations in the internal friction (Q-1) with temperature and strain amplitude for the composite compared to the AZ91D alloy matrix; (d) Comparison of the specific flexural strength, i.e., flexural strength normalized by density, and fracture toughness of the composite with other materials. The structure of natural nacre in (a) is adapted with permission from Ref. [30] Copyright 2016, Elsevier. (a-d) Adapted with permission from Ref. [29] Copyright 2023, Elsevier

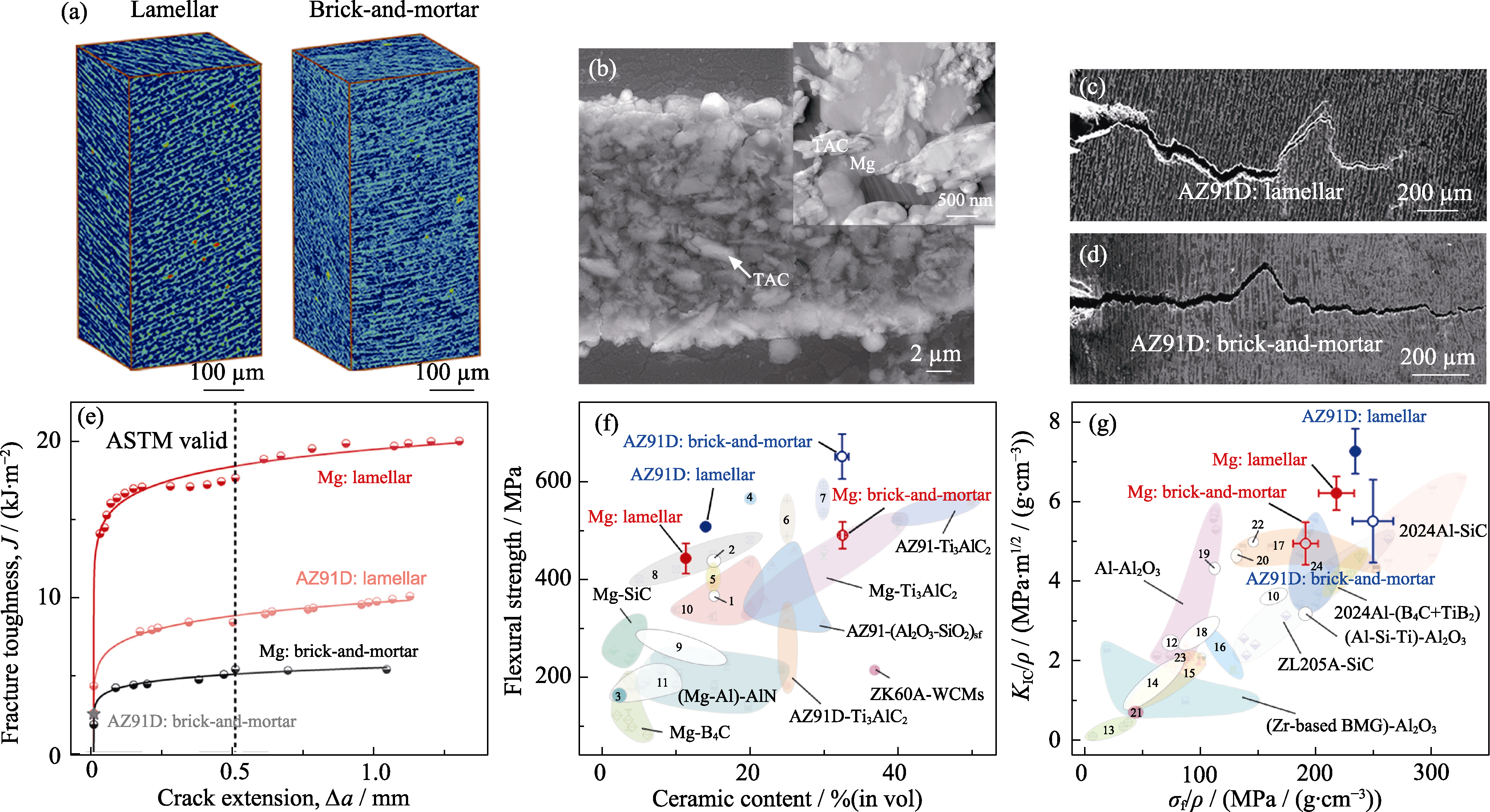

图7 利用冰模板技术结合熔体浸渗工艺制备的多级类贝壳结构Ti3AlC2增强镁基仿生复合材料的微观结构与力学性能[31]

Fig. 7 Microstructure and mechanical properties of the hierarchical nacre-like Mg-Ti3AlC2 composites made by ice templating and melt infiltration techniques[31] (a) 3D structures of the composites with hierarchical nacre-like lamellar and brick-and-mortar architectures; (b) Ultrafine structure of the composite showing the preferential alignment of Ti3AlC2 platelets and full filling interspaces between platelets and metal phase in the ceramic-rich layer; (c, d) Deflected cracking paths in the composites with lamellar (c) and brick-and-mortar (d) architectures; (e) Rising R-curve behavior of the composites demonstrating stable crack propagation; (f) Variation in the flexural strength as a function of ceramic content in Mg and Mg-alloy composites reinforced with various kinds of ceramics; (g) Comparison of fracture toughness and flexural strength normalized by density for various metal-ceramic composites with nacre-like architectures. Adapted with permission from Ref. [31] Copyright 2023, Springer Nature

| [1] |

MORTENSEN A, LLORCA J. Metal matrix composites. Annual Review of Materials Research, 2010, 40: 243.

DOI URL |

| [2] |

MIRACLE D B. Metal matrix composites-from science to technological significance. Composites Science and Technology, 2005, 65(15/16): 2526.

DOI URL |

| [3] |

YU W H, SING S L, CHUA C N, et al. Particle-reinforced metal matrix nanocomposites fabricated by selective laser melting: a state of the art review. Progress in Materials Science, 2019, 104: 330.

DOI URL |

| [4] | MACKE A, SCHULTZ B F, ROHATGI P. Metal matrix composites offer the automotive industry an opportunity to reduce vehicle weight, improve performance. Advanced Materials & Processes, 2012, 170: 19. |

| [5] | SUN Z M. Progress in research and development on MAX phases: a family of layered ternary compounds. Progress in Materials Science, 2011, 56: 143. |

| [6] |

BARSOUM M W, RADOVIC M. Elastic and mechanical properties of the MAX phases. Annual Review of Materials Research, 2011, 41: 195.

DOI URL |

| [7] |

EKLUND P, BECKERS M, JANSSON U, et al. The Mn+1AXn phases: materials science and thin-film processing. Thin Solid Films, 2010, 518: 1851.

DOI URL |

| [8] |

GONZALEZ-JULIAN J. Processing of MAX phases: from synthesis to applications. Journal of the American Ceramic Society, 2021, 104(2): 659.

DOI URL |

| [9] |

HU W Q, HUANG Z Y, WANG Y B, et al. Layered ternary MAX phases and their MX particulate derivative reinforced metal matrix composite: a review. Journal of Alloys and Compounds, 2021, 856: 157313.

DOI URL |

| [10] |

GUPTA S, BARSOUM M W. On the tribology of the MAX phases and their composites during dry sliding: a review. Wear, 2011, 271: 1878.

DOI URL |

| [11] |

CHEN W T, YU W B, MA C S, et al. A review of novel ternary nano-layered MAX phases reinforced AZ91D magnesium composite. Journal of Magnesium and Alloys, 2022, 10(6): 1457.

DOI URL |

| [12] |

GRIESELER R, CAMARGO M K, HOPFELD M, et al. Copper- MAX-phase composite coatings obtained by electro-co-deposition: a promising material for electrical contacts. Surface and Coatings Technology, 2017, 321: 219.

DOI URL |

| [13] |

YU W B, WANG X J, ZHAO H B, et al. Microstructure, mechanical properties and fracture mechanism of Ti2AlC reinforced AZ91D composites fabricated by stir casting. Journal of Alloys and Compounds, 2017, 702: 199.

DOI URL |

| [14] |

YU W B, ZHAO H B, WANG X J, et al. Synthesis and characterization of textured Ti2AlC reinforced magnesium composite. Journal of Alloys and Compounds, 2018, 730: 191.

DOI URL |

| [15] | YU W B, CHEN D Q, TIAN L, et al. Self-lubricate and anisotropic wear behavior of AZ91D magnesium alloy reinforced with ternary Ti2AlC MAX phases. Journal of Materials Science & Technology, 2019, 35: 275. |

| [16] |

YU W B, LI X B, VALLET M, et al. High temperature damping behavior and dynamic Young’s modulus of magnesium matrix composite reinforced by Ti2AlC MAX phase particles. Mechanics of Materials, 2019, 129: 246.

DOI URL |

| [17] |

LI X N, LI P Y, LIU Z Q, et al. Microstructure and mechanical properties of Ti3AlC2 reinforced Al-4.5Cu-1.5Mg composites fabricated by powder metallurgy. Journal of Materials Science, 2023, 58: 2570.

DOI |

| [18] | SUN H F, LI X W, ZHANG P, et al. The microstructure and tensile properties of the Ti2AlC reinforced TiAl composites fabricated by powder metallurgy. Materials Science & Engineering A, 2014, 611: 257. |

| [19] |

WANG W Z, SOKOL M, KOTA S, et al. Reaction paths and microstructures of nickel and Ti2AlC mixtures hot pressed and annealed in the 1050-1350 ℃ temperature range. Journal of Alloys and Compounds, 2020, 828: 154193.

DOI URL |

| [20] |

HUANG X C, FENG Y, QIAN G, et al. Physical, mechanical, and ablation properties of Cu-Ti3AlC2 composites with various Ti3AlC2 contents. Materials Science and Technology, 2018, 34(6): 757.

DOI URL |

| [21] |

ZHANG J, WANG J Y, ZHOU Y C. Structure stability of Ti3AlC2 in Cu and microstructure evolution of Cu-Ti3AlC2 composites. Acta Materialia, 2007, 55: 4381.

DOI URL |

| [22] |

ZHAO H, FENG Y, QIAN G, et al. Effect of Ti3AlC2 content on electrical friction and wear behaviors of Cu-Ti3AlC2 composites. Tribology Letters, 2019, 67: 96.

DOI |

| [23] | SHU S L, QIU F, LU S J, et al. Phase transitions and compression properties of Ti2AlC/TiAl composites fabricated by combustion synthesis reaction. Materials Science & Engineering A, 2012, 539: 344. |

| [24] | AI T T, LIU F, FENG X M, et al. Processing, microstructural characterization and mechanical properties of in situ Ti3AlC2/TiAl3 composite by hot pressing. Materials Science & Engineering A, 2014, 610: 297. |

| [25] |

LI L, ORTIZ C. A natural 3D interconnected laminated composite with enhanced damage resistance. Advanced Functional Materials, 2015, 25(23): 3463.

DOI URL |

| [26] |

ROY S, GIBMEIER J, KOSTOV V, et al. Internal load transfer in a metal matrix composite with a three-dimensional interpenetrating structure. Acta Materialia, 2011, 59(4): 1424.

DOI URL |

| [27] | GUO Y, XIE X, LIU Z Q, et al. Wear-resistant Ag-MAX phase 3D interpenetrating-phase composites: processing, structure and properties. Nano Research, DOI: 10.1007/s12274-023-6015-1. |

| [28] |

WEGST U G K, BAI H, SAIZ E, et al. Bioinspired structural materials. Nature Materials, 2015, 14: 23.

DOI PMID |

| [29] |

LIU Y Y, XIE X, LIU Z Q, et al. A strong, lightweight, and damping cermet material with a nacre-like ultrafine 3D interpenetrated architecture. Materials Today, 2023, 62: 62.

DOI URL |

| [30] |

JIAO D, LIU Z Q, ZHU Y K, et al. Mechanical behavior of mother-of-pearl and pearl with flat and spherical laminations. Materials Science and Engineering: C, 2016, 68: 9.

DOI URL |

| [31] |

LIU Y Y, XIE X, LIU Z Q, et al. Strong and tough magnesium- MAX phase composites with nacre-like lamellar and brick-and- mortar architectures. Communications Materials, 2023, 4: 30.

DOI |

| [32] |

GUPTA S, FILIMONOV D, PALANISAMY T, et al. Ta2AlC and Cr2AlC Ag-based composites - new solid lubricant materials for use over a wide temperature range against Ni-based superalloys and alumina. Wear, 2007, 262: 1479.

DOI URL |

| [33] |

AGNE M T, RADOVIC M, BENTZEL G W, et al. Stability of V2AlC with Al in 800-100 ℃ temperature range and in situ synthesis of V2AlC/Al composites. Journal of Alloys and Compounds, 2016, 666: 279.

DOI URL |

| [1] | 陈义, 邱海鹏, 陈明伟, 徐昊, 崔恒. SiC/SiC复合材料基体硼改性方法及其力学性能研究[J]. 无机材料学报, 2025, 40(5): 504-510. |

| [2] | 崔宁, 张玉新, 王鲁杰, 李彤阳, 于源, 汤华国, 乔竹辉. (TiVNbMoW)Cx高熵陶瓷的单相形成过程与碳空位调控[J]. 无机材料学报, 2025, 40(5): 511-520. |

| [3] | 李紫薇, 弓伟露, 崔海峰, 叶丽, 韩伟健, 赵彤. 前驱体法制备(Zr, Hf, Nb, Ta, W)C-SiC复相陶瓷及性能研究[J]. 无机材料学报, 2025, 40(3): 271-280. |

| [4] | 高晨光, 孙晓亮, 陈君, 李达鑫, 陈庆庆, 贾德昌, 周玉. 基于湿法纺丝技术的SiBCN-rGO陶瓷纤维的组织结构、力学和吸波性能[J]. 无机材料学报, 2025, 40(3): 290-296. |

| [5] | 穆浩洁, 张源江, 喻彬, 付秀梅, 周世斌, 李晓东. ZrO2掺杂Y2O3-MgO纳米复相陶瓷的制备及性能研究[J]. 无机材料学报, 2025, 40(3): 281-289. |

| [6] | 李伟, 许志明, 苟燕子, 尹森虎, 余艺平, 王松. SiC纤维烧结陶瓷的制备及其性能研究[J]. 无机材料学报, 2025, 40(2): 177-183. |

| [7] | 范武刚, 曹雄, 周响, 李玲, 赵冠楠, 张兆泉. 8YSZ陶瓷在模拟压水堆水环境中的耐腐蚀性能[J]. 无机材料学报, 2024, 39(7): 803-809. |

| [8] | 王伟明, 王为得, 粟毅, 马青松, 姚冬旭, 曾宇平. 以非氧化物为烧结助剂制备高导热氮化硅陶瓷的研究进展[J]. 无机材料学报, 2024, 39(6): 634-646. |

| [9] | 孙海洋, 季伟, 王为民, 傅正义. TiB-Ti周期序构复合材料设计、制备及性能研究[J]. 无机材料学报, 2024, 39(6): 662-670. |

| [10] | 蔡飞燕, 倪德伟, 董绍明. 高熵碳化物超高温陶瓷的研究进展[J]. 无机材料学报, 2024, 39(6): 591-608. |

| [11] | 刘国昂, 王海龙, 方成, 黄飞龙, 杨欢. B4C含量对(Ti0.25Zr0.25Hf0.25Ta0.25)B2-B4C陶瓷力学性能及抗氧化性能的影响[J]. 无机材料学报, 2024, 39(6): 697-706. |

| [12] | 粟毅, 史扬帆, 贾成兰, 迟蓬涛, 高扬, 马青松, 陈思安. 浆料浸渍辅助PIP工艺制备C/HfC-SiC复合材料的微观结构及性能研究[J]. 无机材料学报, 2024, 39(6): 726-732. |

| [13] | 李雷, 程群峰. 高性能MXenes纳米复合材料研究进展[J]. 无机材料学报, 2024, 39(2): 153-161. |

| [14] | 徐向明, Husam N ALSHAREEF. MXetronics—MXene电子学[J]. 无机材料学报, 2024, 39(2): 171-178. |

| [15] | 李腊, 沈国震. 二维MXenes材料在柔性光电探测器中的应用展望[J]. 无机材料学报, 2024, 39(2): 186-194. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||