无机材料学报 ›› 2018, Vol. 33 ›› Issue (7): 749-755.DOI: 10.15541/jim20170461 CSTR: 32189.14.10.15541/jim20170461

范广新1, 刘泽萍1, 闻寅1, 刘宝忠2

收稿日期:2017-09-28

修回日期:2018-01-31

出版日期:2018-07-10

网络出版日期:2018-06-19

作者简介:范广新(1970-), 男, 博士, 副教授. E-mail: fangx@hpu.edu.cn

基金资助:FAN Guang-Xin1, LIU Ze-Ping1, WEN Yin1, LIU Bao-Zhong2

Received:2017-09-28

Revised:2018-01-31

Published:2018-07-10

Online:2018-06-19

About author:FAN Guang-Xin. E-mail: fangx@hpu.edu.cn

Supported by:摘要:

用硅烷偶联剂加热分解的简便方法对锂离子电池正极材料LiNi0.8Co0.15Al0.05O2(NCA)的表面进行处理, 利用XRD结合Rietveld精修、SEM、TEM、DSC、EIS和恒流充放电等方法对材料进行表征。结果显示, 硅烷偶联剂经450℃加热分解后得到的非晶态SiO2均匀包覆在材料表面, 包覆不改变 NCA的晶体结构, 但明显改善了材料性能。在60℃环境中, 0.2C、1C下包覆材料(简写为a-NCA)的放电比容量分别为176.4、158.9 mAh·g-1, 高于NCA的174.2、153.8 mAh·g-1; 50周循环后a-NCA的容量保持率为91.4 %, 远高于NCA的86.5 %; 同时, 经包覆后材料的热稳定性大幅度提高。其原因是包覆层抑制了NCA在循环过程中与电解液发生副反应, 有效降低了离子迁移的界面膜电阻, 并抑制了晶体结构变化。

中图分类号:

范广新, 刘泽萍, 闻寅, 刘宝忠. 硅烷偶联剂表面处理对LiNi0.8Co0.15Al0.05O2结构和性能的影响[J]. 无机材料学报, 2018, 33(7): 749-755.

FAN Guang-Xin, LIU Ze-Ping, WEN Yin, LIU Bao-Zhong. Surface Treatment on Structure and Property of LiNi0.8Co0.15Al0.05O2 by Silane Coupling Agent[J]. Journal of Inorganic Materials, 2018, 33(7): 749-755.

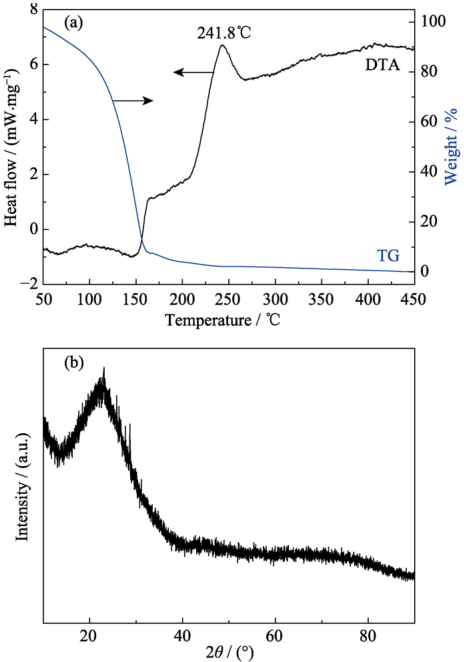

图1 硅烷偶联剂KH550在空气气氛中的TG-DTA曲线(a)及在450℃保温5 h热分解产物的XRD图谱(b)

Fig. 1 (a) TG-DTA curves of the KH550 silane coupling agent in air and (b) XRD pattern for thermal decomposition product of the silane coupling agent after heating at 450℃ for 5 h

| Sample | a/nm | c/nm | c/a | FWHM/(°) | |

|---|---|---|---|---|---|

| (003) | (104) | ||||

| NCA | 0.2869 | 1.4193 | 4.948 | 0.130 | 0.225 |

| a-NCA | 0.2869 | 1.4200 | 4.949 | 0.131 | 0.228 |

表1 NCA和a-NCA的结构参数

Table 1 Structural parameters of NCA and a-NCA

| Sample | a/nm | c/nm | c/a | FWHM/(°) | |

|---|---|---|---|---|---|

| (003) | (104) | ||||

| NCA | 0.2869 | 1.4193 | 4.948 | 0.130 | 0.225 |

| a-NCA | 0.2869 | 1.4200 | 4.949 | 0.131 | 0.228 |

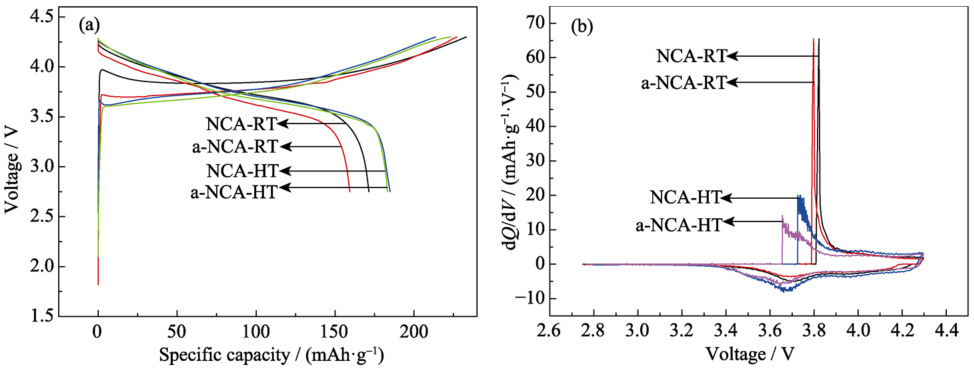

图7 NCA和a-NCA的首次充放电曲线 (a)及对应的微分容量曲线(b)

Fig. 7 (a) Initial charge-discharge curves and (b) the corresponding differential capacity (dQ/dV) of NCA and a-NCA

| Sample | 0.1C/(mAh·g-1) | 0.2C/(mAh·g-1) | 1C/(mAh·g-1) | Difference values of (Ni2+/Ni4+)/V | Capacity retention |

|---|---|---|---|---|---|

| NCA-RT | 171.5 | 164.7 | 146.0 | 0.11 | 94.7% |

| a-NCA-RT | 164.6 | 153.8 | 140.2 | 0.10 | 96.0% |

| NCA-HT | 184.9 | 174.2 | 153.8 | 0.05 | 86.5% |

| a-NCA-HT | 183.2 | 176.4 | 158.9 | 0.01 | 91.4% |

表2 NCA和a-NCA的电化学性能

Table 2 Electrochemical performances of NCA and a-NCA

| Sample | 0.1C/(mAh·g-1) | 0.2C/(mAh·g-1) | 1C/(mAh·g-1) | Difference values of (Ni2+/Ni4+)/V | Capacity retention |

|---|---|---|---|---|---|

| NCA-RT | 171.5 | 164.7 | 146.0 | 0.11 | 94.7% |

| a-NCA-RT | 164.6 | 153.8 | 140.2 | 0.10 | 96.0% |

| NCA-HT | 184.9 | 174.2 | 153.8 | 0.05 | 86.5% |

| a-NCA-HT | 183.2 | 176.4 | 158.9 | 0.01 | 91.4% |

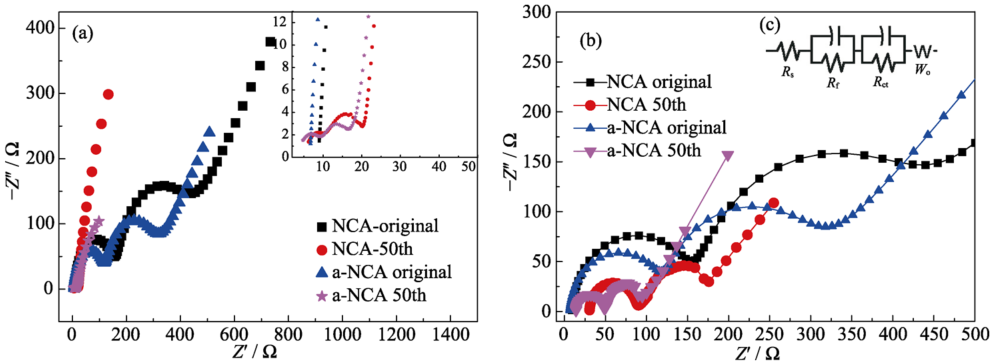

图9 NCA和a-NCA在(a)室温和(b)高温的交流阻抗图, (b)中的插图为等效电路

Fig. 9 EIS plots of NCA and a-NCA at (a) room temperature and (b) high temperature with inset in (b) showing the corresponding equivalent circuit diagram

| Sample | Condition | Rs/Ω | Rf/Ω | Rct/Ω | Wo/(×10-3, Ω) |

|---|---|---|---|---|---|

| NCA | Original | 8.6 | 136.4 | 211.9 | 2.0 |

| RT-50th | 7.5 | 8.3 | 126.1 | 2.8 | |

| HT-50th | 7.9 | 55.7 | 114.2 | 7.5 | |

| a-NCA | Original | 6.5 | 106.0 | 156.6 | 3.1 |

| RT-50th | 4.5 | 7.4 | 92.1 | 4.9 | |

| HT-50th | 6.2 | 21.4 | 75.5 | 8.6 |

表3 NCA和a-NCA循环前后的交流阻抗值

Table 3 Electrochemical AC impedance values of NCA and a-NCA

| Sample | Condition | Rs/Ω | Rf/Ω | Rct/Ω | Wo/(×10-3, Ω) |

|---|---|---|---|---|---|

| NCA | Original | 8.6 | 136.4 | 211.9 | 2.0 |

| RT-50th | 7.5 | 8.3 | 126.1 | 2.8 | |

| HT-50th | 7.9 | 55.7 | 114.2 | 7.5 | |

| a-NCA | Original | 6.5 | 106.0 | 156.6 | 3.1 |

| RT-50th | 4.5 | 7.4 | 92.1 | 4.9 | |

| HT-50th | 6.2 | 21.4 | 75.5 | 8.6 |

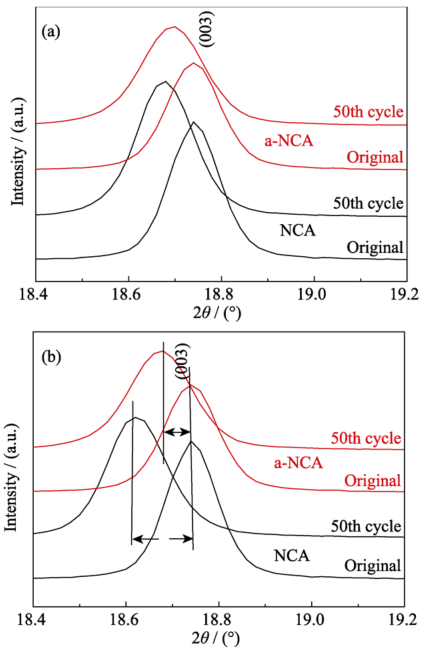

图11 NCA和a-NCA在室温(a)和高温(b)循环前后(003)峰的XRD图谱

Fig. 11 XRD patterns of (003) peak in original and the 50th cycle sample for NCA and a-NCA at room temperature (a) and high temperature (b)

| Condition | a/nm | Δa/a | c/nm | V/(×10-3, nm3) | |

|---|---|---|---|---|---|

| NCA | Original | 0.2869 | 1.4193 | 0.1011 | |

| RT-50th | 0.2858 | 0.39% | 1.4246 | 0.1007 | |

| HT-50th | 0.2841 | 0.96% | 1.4299 | 0.995 | |

| a-NCA | Original | 0.2869 | 1.4199 | 0.1012 | |

| RT-50th | 0.2862 | 0.26% | 1.4224 | 0.1008 | |

| HT-50th | 0.2857 | 0.43% | 1.4242 | 0.1001 |

表4 NCA和a-NCA室温和高温循环前后的结构参数

Table 4 Structural parameters of NCA and a-NCA before and after cycling at room temperature and high temperature

| Condition | a/nm | Δa/a | c/nm | V/(×10-3, nm3) | |

|---|---|---|---|---|---|

| NCA | Original | 0.2869 | 1.4193 | 0.1011 | |

| RT-50th | 0.2858 | 0.39% | 1.4246 | 0.1007 | |

| HT-50th | 0.2841 | 0.96% | 1.4299 | 0.995 | |

| a-NCA | Original | 0.2869 | 1.4199 | 0.1012 | |

| RT-50th | 0.2862 | 0.26% | 1.4224 | 0.1008 | |

| HT-50th | 0.2857 | 0.43% | 1.4242 | 0.1001 |

| [1] | NITTA N, WU F, LEE J T,et al.Li-ion battery materials: present and future. Mater. Today, 2015, 18(5): 252-264. |

| [2] | TRAN H Y, TÄUBERT C, WOHLFAHRT-MEHRENS M. Influence of the technical process parameters on structural mechanical and electrochemical properties of LiNi0.8Co0.15Al0.05O2 based electrodes - a review.Prog. Solid State Ch., 2014, 42(4): 118-127. |

| [3] | WANG H, LAI C, XIAO Y,et al.A new lithium-ion battery with LiNi0.8Co0.15Al0.05O2 cathode and lithium pre-doping hard carbon anode.Mater. Lett., 2015, 160: 250-254. |

| [4] | ZUO D, TIAN G, LI X,et al.Recent progress in surface coating of cathode materials for lithium ion secondary batteries.J. Alloys Comp., 2017, 706: 24-40. |

| [5] | XU Y, LI X, WANG Z,et al.Structure and electrochemical performance of TiO2-coated LiNi0.8Co0.15Al0.05O2 cathode materials.Mater. Lett., 2015, 143: 151-154. |

| [6] | LIU W, HU G, DU K,et al.Surface coating of LiNi0.8Co0.15Al0.05O2 with LiCoO2 by a molten salt method.Surf. Coat. Tech., 2013, 216: 267-272. |

| [7] | HUANG B, LI X, WANG Z,et al.A facile process for coating amorphous FePO4 onto LiNi0.8Co0.15Al0.05O2 and the effects on its electrochemical properties.Mater. Lett., 2014, 131: 210-213. |

| [8] | LEE D J, SCROSATI B, SUN Y K.Ni3(PO4)2-coated LiNi0.8Co0.15Al0.05O2 lithium battery electrode with improved cycling performance at 55℃.J. Power Sources, 2011, 196(18): 7742-7746. |

| [9] | HE X, DU C, SHEN B,et al.Electronically conductive Sb-doped SnO2 nanoparticles coated LiNi0.8Co0.15Al0.05O2 cathode material with enhanced electrochemical properties for Li-ion batteries.Electrochim. Acta, 2017, 236: 273-279. |

| [10] | CHEN C, TAO T, WANG Q,et al.High-performance lithium ion batteries using SiO2-coated LiNi0.5Co0.2Mn0.3O2 microspheres as cathodes.J. Alloys Comp., 2017, 709: 708-716. |

| [11] | FAN Y, WANG J, TANG Z,et al.Effects of the nanostructured SiO2 coating on the performance of LiNi0.5Mn1.5O4 cathode materials for high voltage Li-ion batteries.Electrochim. Acta, 2007, 52(11): 3870-3875. |

| [12] | LIANG L, HU G, JIANG F,et al.Electrochemical behaviours of SiO2-coated LiNi0.8Co0.1Mn0.1O2 cathode materials by a novel modification method.J. Alloys Comp., 2016, 657: 570-581. |

| [13] | ZHOU P, ZHANG Z, MENG H,et al.SiO2-coated LiNi0.915Co0.075Al0.01O2 cathode material for rechargeable Li-ion batteries.Nanoscale, 2016, 8(46): 19263-19269. |

| [14] | CHO W, KIM S M, SONG J H,et al.Improved electrochemical and thermal properties of nickel rich LiNi0.6Co0.2Mn0.2O2 cathode materials by SiO2 coating.J. Power Sources, 2015, 282: 45-50. |

| [15] | LI Y, ZHAO S.Electrochemical performance of SiO2-coated LiFePO4 cathode materials for lithium ion battery.J. Alloys Comp., 2011, 509(3): 957-960. |

| [16] | MALLAKPOUR S, MADANI M.A review of current coupling agents for modification of metal oxide nanoparticles.Prog. Org. Coat., 2015, 86: 194-207. |

| [17] | LIU HUAN-MIN, HUANG KE-LONG, XUE JIAN-JUN,et al.Study on the performance of LiCrxMn2-xO4 by surface treatment with silane coupling agent.Battery Bimonthly, 2004, 34(6): 403-405. |

| [18] | 王雪明. 硅烷偶联剂在金属预处理及有机涂层中的应用研究. 济南:山东大学硕士学位论文, 2005. |

| [19] | HUANG WEI, CAO XUE-JUAN, ZHU HONG-ZHOU,et al.Research on physic adsorption and photocatalytic activity of TiO2/SiO2 with different molar content of SiO2.J. Wuhan Univ. Technol., 2015, 37(9): 25-31. |

| [20] | CHO Y, CHO J.Significant improvement of LiNi0.8Co0.15Al0.05O2 cathodes at 60℃ by SiO2 dry coating for Li-ion batteries.J. Electrochem. Soc., 2010, 157(6): A625-A629. |

| [21] | SHI Y, ZHANG M, QIAN D,et al.Ultrathin Al2O3 coatings for improved cycling performance and thermal stability of LiNi0.5Co0.2Mn0.3O2 cathode material.Electrochim. Acta, 2016, 203: 154-161. |

| [22] | YIN S C, RHO Y H, SWAINSON I,et al.X-ray/neutron diffraction and electrochemical studies of lithium de/re-intercalation in Li1-xCo1/3Ni1/3Mn1/3O2 (x=0→1).Chem. Mater., 2006, 18(7): 1901-1910. |

| [23] | LIN C K, REN Y, AMINE K,et al.In situ high-energy X-ray diffraction to study overcharge abuse of 18650-size lithium-ion battery.J. Power Sources, 2013, 230: 32-37. |

| [1] | 万俊池, 杜路路, 张永上, 李琳, 刘建德, 张林森. Na4FexP4O12+x/C钠离子电池正极材料的结构演变及其电化学性能[J]. 无机材料学报, 2025, 40(5): 497-503. |

| [2] | 薛柯, 蔡长焜, 谢满意, 李舒婷, 安胜利. 固体氧化物燃料电池Pr1+xBa1-xFe2O5+δ阴极材料的制备及电化学性能研究[J]. 无机材料学报, 2025, 40(4): 363-371. |

| [3] | 苗鑫, 闫世强, 韦金豆, 吴超, 樊文浩, 陈少平. Te基热电器件反常界面层生长行为及界面稳定性研究[J]. 无机材料学报, 2024, 39(8): 903-910. |

| [4] | 陈正鹏, 金芳军, 李明飞, 董江波, 许仁辞, 徐韩昭, 熊凯, 饶睦敏, 陈创庭, 李晓伟, 凌意瀚. 双钙钛矿Sr2CoFeO5+δ阴极材料的制备及其中温固体氧化物燃料电池性能研究[J]. 无机材料学报, 2024, 39(3): 337-344. |

| [5] | 肖娅妮, 吕嘉南, 李振明, 刘铭扬, 刘伟, 任志刚, 刘弘景, 杨东旺, 鄢永高. Bi2Te3基热电材料的湿热稳定性研究[J]. 无机材料学报, 2023, 38(7): 800-806. |

| [6] | 李悦, 张旭良, 景芳丽, 胡章贵, 吴以成. 铈掺杂硼酸钙镧晶体的生长与性能研究[J]. 无机材料学报, 2023, 38(5): 583-588. |

| [7] | 万家宝, 张明辉, 苏怀宇, 曹枝军, 刘学超, 谢坚生, 王祥远, 时英辉, 王亮, 雷水金. GeO2-La2O3-TiO2玻璃的结构、热学和光学性质[J]. 无机材料学报, 2023, 38(10): 1230-1236. |

| [8] | 朱河圳, 王选朋, 韩康, 杨晨, 万睿哲, 吴黎明, 麦立强. 超高镍LiNi0.91Co0.06Al0.03O2@Ca3(PO4)2正极材料的储锂稳定性的提升机制[J]. 无机材料学报, 2022, 37(9): 1030-1036. |

| [9] | 刘芳芳, 传秀云, 杨扬, 李爱军. 氮/硫共掺杂对纤水镁石模板碳纳米管电化学性能的影响[J]. 无机材料学报, 2021, 36(7): 711-717. |

| [10] | 张亚萍,雷宇轩,丁文明,于濂清,朱帅霏. 双铁电复合材料的制备及其光电化学性能研究[J]. 无机材料学报, 2020, 35(9): 987-992. |

| [11] | 柏祥涛,班丽卿,庄卫东. 高镍三元正极材料的包覆与掺杂改性研究进展[J]. 无机材料学报, 2020, 35(9): 972-986. |

| [12] | 湛菁,徐昌藩,龙怡宇,李启厚. 聚丙烯酰胺凝胶法制备Bi2Mn4O10及其电化学性能[J]. 无机材料学报, 2020, 35(7): 827-833. |

| [13] | 郑坤, 罗永春, 邓安强, 杨洋, 张海民. A2B7型La0.3Y0.7Ni3.4-xMnxAl0.1储氢合金微观结构和电化学性能研究[J]. 无机材料学报, 2020, 35(5): 549-555. |

| [14] | 朱泽阳,魏济时,黄健航,董向阳,张鹏,熊焕明. 晶格空位ZnO纳米棒的制备及其在镍锌电池中的应用[J]. 无机材料学报, 2020, 35(4): 423-430. |

| [15] | 李学林, 朱建锋, 焦宇鸿, 黄家璇, 赵倩楠. 二氧化锰形貌对Ti3C2Tx@MnO2复合材料电化学性能的影响[J]. 无机材料学报, 2020, 35(1): 119-125. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||