Journal of Inorganic Materials ›› 2022, Vol. 37 ›› Issue (3): 267-277.DOI: 10.15541/jim20210705

Special Issue: 增材制造专题(2022)

• REVIEW • Previous Articles Next Articles

YANG Yong1,2( ), GUO Xiaotian1,3, TANG Jie1,2, CHANG Haotian1,3, HUANG Zhengren1,2, HU Xiulan3(

), GUO Xiaotian1,3, TANG Jie1,2, CHANG Haotian1,3, HUANG Zhengren1,2, HU Xiulan3( )

)

Received:2021-11-15

Revised:2021-12-23

Published:2022-03-20

Online:2022-01-06

Contact:

HU Xiulan, professor. E-mail: whoxiulan@163.com

About author:YANG Yong (1974-), male, professor. E-mail: yangyong@mail.sic.ac.cn

Supported by:CLC Number:

YANG Yong, GUO Xiaotian, TANG Jie, CHANG Haotian, HUANG Zhengren, HU Xiulan. Research Progress and Prospects of Non-oxide Ceramic in Stereolithography Additive Manufacturing[J]. Journal of Inorganic Materials, 2022, 37(3): 267-277.

| Material | Absorbance (d/μm, λ/nm) | Refractive index (d/μm, λ/nm) |

|---|---|---|

| Al2O3[ | 0.044 (10, 405) | 1.787 (2.3, 365) |

| ZrO2[ | 0.003 (10, 405) | Low |

| ZTA[ | Low | Low |

| SiO2[ | Low | 1.564 (2.25, 365) |

| SiC[ | 0.479 (10, 405) | 2.553 (12.25, 467-691) |

| Si3N4[ | 0.180 (5, 405) | 2.023 (-, 632.8) |

| TiO2[ | Low | 2.493 (-, 632.8) |

| BN[ | High | High |

Table 1 Refractive index and absorbance of ceramic materials

| Material | Absorbance (d/μm, λ/nm) | Refractive index (d/μm, λ/nm) |

|---|---|---|

| Al2O3[ | 0.044 (10, 405) | 1.787 (2.3, 365) |

| ZrO2[ | 0.003 (10, 405) | Low |

| ZTA[ | Low | Low |

| SiO2[ | Low | 1.564 (2.25, 365) |

| SiC[ | 0.479 (10, 405) | 2.553 (12.25, 467-691) |

| Si3N4[ | 0.180 (5, 405) | 2.023 (-, 632.8) |

| TiO2[ | Low | 2.493 (-, 632.8) |

| BN[ | High | High |

| Material | Flexural strength/MPa | Elasticity modulus/GPa | Fracture toughness/ (MPa·m1/2) |

|---|---|---|---|

| RB-SiC[ | ≥330 | ≥340 | ≥4.1 |

| S-SiC[ | 349-431 | 308-342 | 3.77 |

| RB-SiC[ | (305±15) | - | - |

| RB-SiC*[ | 210.4 | - | - |

| (Cf)/SiC*[ | 262.6 | - | - |

Table 2 Structure and properties of SiC ceramics obtained by different manufacturing methods

| Material | Flexural strength/MPa | Elasticity modulus/GPa | Fracture toughness/ (MPa·m1/2) |

|---|---|---|---|

| RB-SiC[ | ≥330 | ≥340 | ≥4.1 |

| S-SiC[ | 349-431 | 308-342 | 3.77 |

| RB-SiC[ | (305±15) | - | - |

| RB-SiC*[ | 210.4 | - | - |

| (Cf)/SiC*[ | 262.6 | - | - |

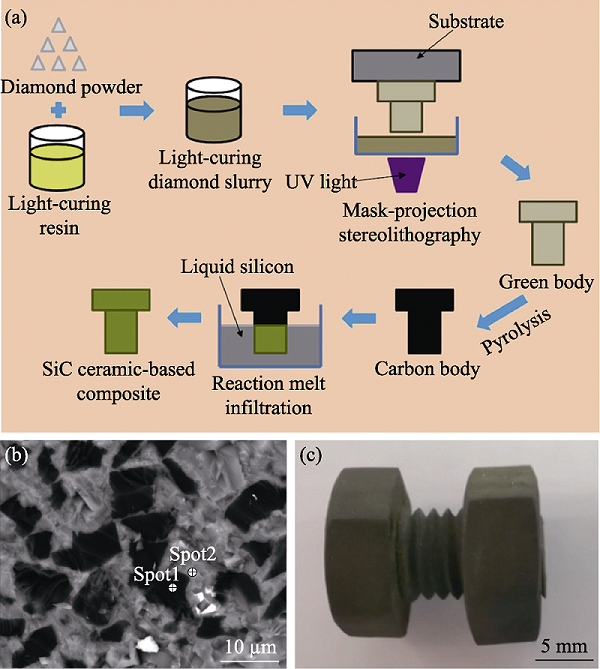

Fig. 4 Preparation of SiC ceramic-based composite by stereolithography[52] (a) Prepared schematic of SiC ceramic-based composite by stereolithography; (b) SEM image of SiC ceramic-based composite with a diamond volume fraction of 15%; (c) SiC ceramic-based composite

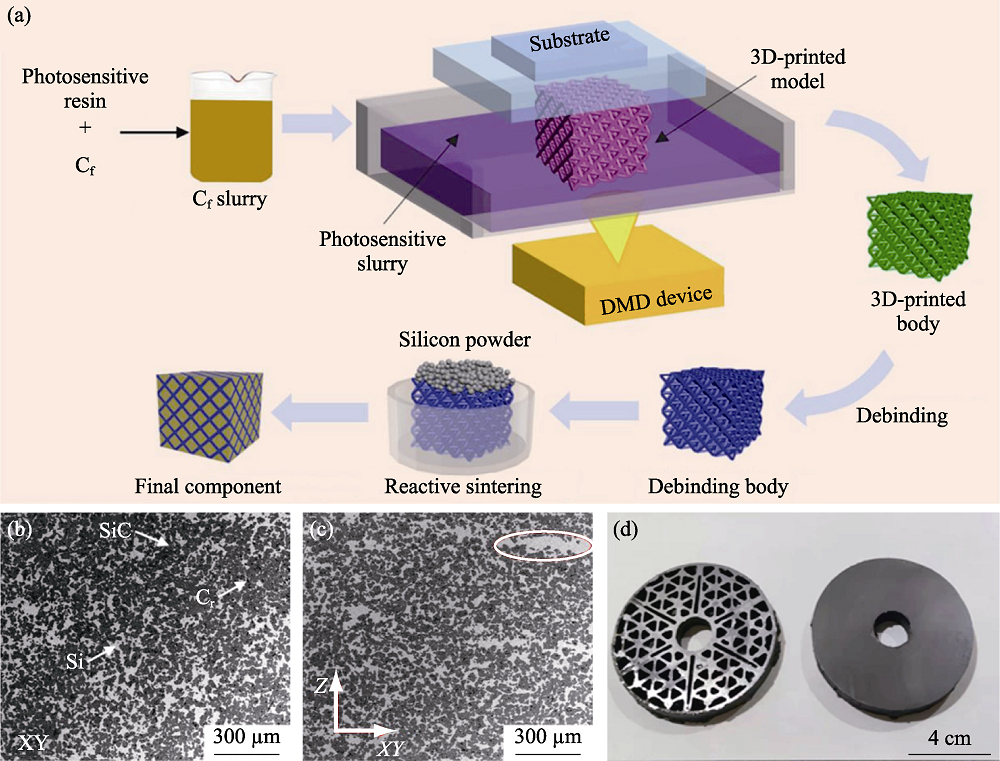

Fig. 5 Preparation of Cf/SiC ceramic composites by digital light processing technology and liquid silicon infiltration process[46] (a) Prepared schematic of SiC composites; (b, c) SEM images of cross section and horizontal plane of Cf/SiC composite; (d) Sintered Cf/SiC composites

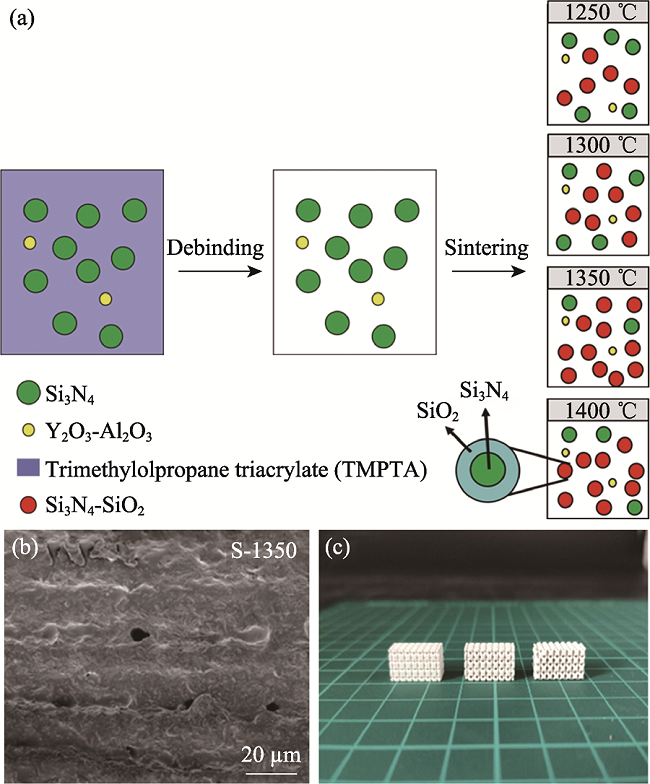

Fig. 6 Preparation of Si3N4-SiO2 ceramics by digital light processing (DLP) technology[58] (a) Schematic synthetic reaction process of oxidation of silicon nitride at high temperature; (b) SEM image of fracture surface of Si3N4-SiO2 ceramics sintered at 1350 ℃; (c) Si3N4-SiO2 ceramics with lattice structure

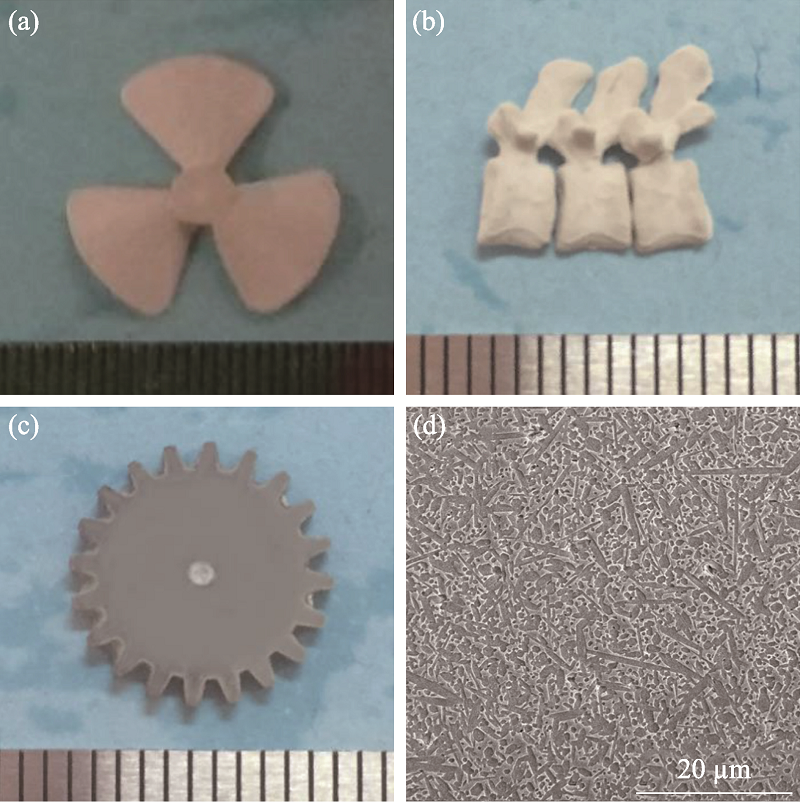

Fig. 7 Fabrication of complex shaped ceramic parts with surface- oxidized Si3N4 powder via digital light processing based stereolithography method[60] (a) Green Si3N4 body of a blade; (b) Green Si3N4 body of a vertebrae; (c) Sintered body of a Si3N4 gear; (d) SEM image of sintered body of a Si3N4 gear

| Material | Technology | Resin+photoinitiator | Dispersant | Powder | Cured thickness /μm | Solid content/% (in volume) | Bending strength /MPa | Ref. |

|---|---|---|---|---|---|---|---|---|

| SiC | DLP | HDDA+DVE-3+ TPO | KOS110 | 15 μm SiC | 78 | 30 | - | [ |

| SiC | DLP | HDDA+TMPTA+TPO | KOS110+ 17000 | 15 μm SiC+ ~40 nm SiC | - | 45 | 165.2 | [ |

| SiC | DLP | ACMO+HDDA+ TMPTA+BAPO | 4200 | 10 μm SiC | ≈60 | 40 | 50.18 | [ |

| Al2O3-Si3N4 | SLA | TMPTA+HDDA+ Irgacure 184 | PEG200+ glycerol | 1 μm Al2O3+ 200 nm Si3N4 | 40 | 47 | - | [ |

| SiO2-Si3N4 | DLP | TMPTA+Irgacure 184 | - | 3.45 μm Si3N4+ Y2O3+Al2O3 | 50-60 | 50 | (77±5) | [ |

| Si3N4 | DLP | HDDA+TMPTA+819 | Copolymer | 200 nm oxidized Si3N4 | 51 | - | - | [ |

| Si3N4 | DLP | EA+819+HDDA+184 | Darvan | 800 nm (KH-560)Si3N4 | 50 | 45 | - | [ |

Table 3 Comparison of molding and sintering performances in stereolithography of high refractive index and high absorbance ceramics

| Material | Technology | Resin+photoinitiator | Dispersant | Powder | Cured thickness /μm | Solid content/% (in volume) | Bending strength /MPa | Ref. |

|---|---|---|---|---|---|---|---|---|

| SiC | DLP | HDDA+DVE-3+ TPO | KOS110 | 15 μm SiC | 78 | 30 | - | [ |

| SiC | DLP | HDDA+TMPTA+TPO | KOS110+ 17000 | 15 μm SiC+ ~40 nm SiC | - | 45 | 165.2 | [ |

| SiC | DLP | ACMO+HDDA+ TMPTA+BAPO | 4200 | 10 μm SiC | ≈60 | 40 | 50.18 | [ |

| Al2O3-Si3N4 | SLA | TMPTA+HDDA+ Irgacure 184 | PEG200+ glycerol | 1 μm Al2O3+ 200 nm Si3N4 | 40 | 47 | - | [ |

| SiO2-Si3N4 | DLP | TMPTA+Irgacure 184 | - | 3.45 μm Si3N4+ Y2O3+Al2O3 | 50-60 | 50 | (77±5) | [ |

| Si3N4 | DLP | HDDA+TMPTA+819 | Copolymer | 200 nm oxidized Si3N4 | 51 | - | - | [ |

| Si3N4 | DLP | EA+819+HDDA+184 | Darvan | 800 nm (KH-560)Si3N4 | 50 | 45 | - | [ |

| [1] |

HALLORAN J W. Ceramic stereolithography: additive manufacturing for ceramics by photopolymerization. Annual Review of Materials Research, 2016, 46(1): 19-40.

DOI URL |

| [2] |

DUFAUD O, CORBEL S. Oxygen diffusion in ceramic suspensions for stereolithography. Chemical Engineering Journal, 2003, 92(1): 55-62.

DOI URL |

| [3] |

WU H D, CHENG Y L, LIU W, et al. Effect of the particle size and the debinding process on the density of alumina ceramics fabricated by 3D printing based on stereolithography. Ceramics International, 2016, 42(15): 17290-17294.

DOI URL |

| [4] |

LI W L, LIU W W, QI F, et al. Determination of micro-mechanical properties of additive manufactured alumina ceramics by nanoindentation and scratching. Ceramics International, 2019, 45(8): 10612-10618.

DOI URL |

| [5] |

SCHWENTENWEIN M, HOMA J. Additive manufacturing of dense alumina ceramics. International Journal of Applied Ceramic Technology, 2015, 12(1): 1-7.

DOI URL |

| [6] |

ZHANG K Q, XIE C, WANG G, et al. High solid loading, low viscosity photosensitive Al2O3 slurry for stereolithography based additive manufacturing. Ceramics International, 2019, 45(1): 203-208.

DOI URL |

| [7] |

WU X Q, LIAN Q, LI D C, et al. Effects of soft-start exposure on the curing characteristics and flexural strength in ceramic projection stereolithography process. Journal of the European Ceramic Society, 2019, 39(13): 3788-3796.

DOI URL |

| [8] |

XU X H, ZHOU S X, WU J F, et al. Preparation of highly dispersive solid microspherical α-Al2O3 powder with a hydrophobic surface for stereolithography-based 3d printing technology. Ceramics International, 2020, 46(2): 1895-1906.

DOI URL |

| [9] |

LI X B, ZHONG H, ZHANG J X, et al. Fabrication of zirconia all-ceramic crown via DLP-based stereolithography. International Journal of Applied Ceramic Technology, 2020, 17(3): 844-853.

DOI URL |

| [10] |

FU X S, ZOU B, XING H Y, et al. Effect of printing strategies on forming accuracy and mechanical properties of ZrO2 parts fabricated by SLA technology. Ceramics International, 2019, 45(14): 17630-17637.

DOI URL |

| [11] |

HE R X, LIU W, WU Z W, et al. Fabrication of complex-shaped zirconia ceramic parts via a DLP-stereolithography-based 3D printing method. Ceramics International, 2018, 44(3): 3412-3416.

DOI URL |

| [12] |

LI X B, ZHONG H, ZHANG J X, et al. Dispersion and properties of zirconia suspensions for stereolithography. International Journal of Applied Ceramic Technology, 2020, 17(1): 239-247.

DOI URL |

| [13] |

SUN J X, BINNER J, BAI J M. Effect of surface treatment on the dispersion of nano zirconia particles in non-aqueous suspensions for stereolithography. Journal of the European Ceramic Society, 2019, 39(4): 1660-1667.

DOI URL |

| [14] |

WU H D, LIU W, HE R X, et al. Fabrication of dense zirconia- toughened alumina ceramics through a stereolithography-based additive manufacturing. Ceramics International, 2017, 43(1): 968-972.

DOI URL |

| [15] |

LIU X Y, ZOU B, XING H Y, et al. The preparation of ZrO2-Al2O3 composite ceramic by SLA-3D printing and sintering processing. Ceramics International, 2020, 46(1): 937-944.

DOI URL |

| [16] |

XING H Y, ZOU B, LIU X Y, et al. Effect of particle size distribution on the preparation of ZTA ceramic paste applying for stereolithography 3D printing. Powder Technology, 2020, 359: 314-322.

DOI URL |

| [17] |

WANG Y Y, WANG Z Y, LIU S H, et al. Additive manufacturing of silica ceramics from aqueous acrylamide based suspension. Ceramics International, 2019, 45(17): 21328-21332.

DOI URL |

| [18] |

CHARTIER T, BADEV A, ABOULIATIM Y, et al. Stereolithography process: influence of the rheology of silica suspensions and of the medium on polymerization kinetics-cured depth and width. Journal of the European Ceramic Society, 2012, 32(8): 1625-1634.

DOI URL |

| [19] |

BAE C J, KIM D, HALLORAN J W. Mechanical and kinetic studies on the refractory fused silica of integrally cored ceramic mold fabricated by additive manufacturing. Journal of the European Ceramic Society, 2019, 39(2): 618-623.

DOI URL |

| [20] |

LASGORCEIX M, CHAMPION E, CHARTIER T. Shaping by microstereolithography and sintering of macro-micro-porous silicon substituted hydroxyapatite. Journal of the European Ceramic Society, 2016, 36(4): 1091-1101.

DOI URL |

| [21] |

WANG Z, HUANG C Z, WANG J, et al. Development of a novel aqueous hydroxyapatite suspension for stereolithography applied to bone tissue engineering. Ceramics International, 2019, 45(3): 3902-3909.

DOI URL |

| [22] |

PFAFFINGER M, HARTMANN M, SCHWENTENWEIN M, et al. Stabilization of tricalcium phosphate slurries against sedimentation for stereolithographic additive manufacturing and influence on the final mechanical properties. International Journal of Applied Ceramic Technology, 2017, 14(4): 499-506.

DOI URL |

| [23] |

CHEN Z W, LIU C B, LI J J, et al. Mechanical properties and microstructures of 3D printed bulk cordierite parts. Ceramics International, 2019, 45(15): 19257-19267.

DOI URL |

| [24] |

HE R J, ZHOU N P, ZHANG K Q, et al. Progress and challenges towards additive manufacturing of SiC ceramic. Journal of Advanced Ceramics, 2021, 10(4): 637-674.

DOI URL |

| [25] |

SEFIU A R, DING Y X, SHU F X, et al. Photopolymerization- based additive manufacturing of ceramics: a systematic review. Journal of Advanced Ceramics, 2021, 10(3): 442-471.

DOI URL |

| [26] | LIU Y, CHEN Z W. Research progress in photopolymerization- based 3D printing technology of ceramics. Journal of Materials Engineering, 2020(9): 1-12. |

| [27] | TANG J, YANG Y, HUANG Z R. Research progress of silicon carbide ceramic slurry based 3D printing. Materials Reports, 35(S01): 8. |

| [28] |

GRIFFITH M L, HALLORAN J W. Scattering of ultraviolet radiation in turbid suspensions. Journal of Applied Physics, 1997, 81(6): 2538-2546.

DOI URL |

| [29] |

DING G J, HE R J, ZHANG K Q, et al. Stereolithography-based additive manufacturing of gray-colored SiC ceramic green body. Journal of the American Ceramic Society, 2019, 102(12): 7198-7209.

DOI URL |

| [30] | WU K C, SEEFELDT K F, SOLOMON M J, et al. Prediction of ceramic stereolithography resin sensitivity from theory and measurement of diffusive photon transport. Journal of Applied Physics, 2005, 98(2): 10. |

| [31] |

BURGER R, WENDLAND W L. Sedimentation and suspension flows: historical perspective and some recent developments. Journal of Engineering Mathematics, 2001, 41(2/3): 101-116.

DOI URL |

| [32] |

CHEN Z W, LI Z Y, LI J J, et al. 3D printing of ceramics: a review. Journal of the European Ceramic Society, 2019, 39(4): 661-687.

DOI URL |

| [33] |

WANG M, XIE C, HE R J, et al. Polymer-derived silicon nitride ceramics by digital light processing based additive manufacturing. Journal of the American Ceramic Society, 2019, 102(9): 5117-5126.

DOI URL |

| [34] |

DE HAZAN Y, PENNER D. SiC and SiOC ceramic articles produced by stereolithography of acrylate modified polycarbosilane systems. Journal of the European Ceramic Society, 2017, 37(16): 5205-5212.

DOI URL |

| [35] |

TANG J, GUO X T, CHANG H T, et al. The preparation of SiC ceramic photosensitive slurry for rapid stereolithography. Journal of the European Ceramic Society, 2021, 41(15): 7516-7524.

DOI URL |

| [36] |

VRANCKENAND K C, POSSEMIERS K, VAN DER VOORT P, et al. Surface modification of silica gels with aminoorganosilanes. Colloids and Surfaces A: Physicochemical and Engineering Aspects, 1995, 98(3): 235-241.

DOI URL |

| [37] | LIU D, MALGHAN S G. Role of polyacrylate in modifying interfacial properties and stability of silicon nitride particles in aqueous suspensions. Colloids & Surfaces A Physicochemical & Engineering Aspects, 1996, 110(1): 37-45. |

| [38] |

XIAO C X, NI Q, CHEN HAN, et al. Effect of polyvinylpyrrolidone on rheology of aqueous SiC suspensions dispersed with poly(aspartic acid). Colloids and Surfaces A: Physicochemical and Engineering Aspects, 2012, 399: 108-111.

DOI URL |

| [39] |

LIU G W, ZHANG X Z, YANG J, et al. Recent advances in joining of SiC-based materials (monolithic SiC and SiCf/SiC composites): joining processes, joint strength, and interfacial behavior. Journal of Advanced Ceramics, 2019, 8(1): 19-38.

DOI URL |

| [40] |

CHEN X W, CHENG G F, ZHANG J M, et al. Residual stress variation in SiCf/SiC composite during heat treatment and its effects on mechanical behavior. Journal of Advanced Ceramics, 2020, 9(5): 567-575.

DOI URL |

| [41] |

EOM J H, KIM Y W, RAJU S. Processing and properties of macroporous silicon carbide ceramics: a review. Journal of Asian Ceramic Societies, 2013, 1(3): 220-242.

DOI URL |

| [42] | ZHAO R C, BAO J X. Lightweight structure and mirror blank formation of the SiC ceramic mirror with large caliber. Optics & Optoelectronic Technology, 2014, 12(6): 65-69. |

| [43] |

WU H B, YAN Y J, LIU G L, et al. Effects of grain grading on microstructures and mechanical behaviors of pressureless solid-state-sintered SiC. International Journal of Applied Ceramic Technology, 2015, 12(5): 976-984.

DOI URL |

| [44] | LI Y, GAO J Q, YANG J F. Preparation of complicated SiC green bodies via aqueous slip casting. Key Engineering Materials, 2010, 434-435: 88-91. |

| [45] |

BAI X J, DING G J, ZHANG K Q, et al. Stereolithography additive manufacturing and sintering approaches of SiC ceramics. Open Ceramics, 2021, 5: 100046.

DOI URL |

| [46] |

ZHANG H, YANG Y, HU K H, et al. Stereolithography-based additive manufacturing of lightweight and high-strength Cf/SiC ceramics. Additive Manufacturing, 2020, 34: 101199.

DOI URL |

| [47] |

DING G J, HE R J, ZHANG K Q, et al. Dispersion and stability of SiC ceramic slurry for stereolithography. Ceramics International, 2020, 46(4): 4720-4729.

DOI URL |

| [48] |

DING G J, HE R J, ZHANG K Q, et al. Stereolithography 3D printing of SiC ceramic with potential for lightweight optical mirror. Ceramics International, 2020, 46(11, Part B): 18785-18790.

DOI URL |

| [49] |

HU C Q, CHEN Y F, YANG T S, et al. Effect of SiC powder on the properties of SiC slurry for stereolithography. Ceramics International, 2021, 47(9): 12442-12449.

DOI URL |

| [50] |

CAO J W, IDREES M, TIAN G Q, et al. Complex SiC-based structures with high specific strength fabricated by vat photopolymerization and one-step pyrolysis. Additive Manufacturing, 2021, 48: 102430.

DOI URL |

| [51] |

TIAN X Y, ZHANG W G, LI D C, et al. Reaction-bonded SiC derived from resin precursors by stereolithography. Ceramics International, 2012, 38(1): 589-597.

DOI URL |

| [52] |

CHEN R G, LIAN Q, HE X N, et al. A stereolithographic diamond-mixed resin slurry for complex SiC ceramic structures. Journal of the European Ceramic Society, 2021, 41(7): 3991-3999.

DOI URL |

| [53] |

XING H Y, ZOU B, WANG X F, et al. Fabrication and characterization of SiC whiskers toughened Al2O3 paste for stereolithography 3D printing applications. Journal of Alloys and Compounds, 2020, 828(5): 154347.

DOI URL |

| [54] |

ZORAN K, VLADIMIR D K. Silicon nitride: the engineering material of the future. Journal of Materials Science, 2012, 47(2): 535-552.

DOI URL |

| [55] | HAMPSHIRE S. Silicon nitride ceramics-review of structure, processing and properties. Journal of Achievements of Materials and Manufacturing Engineering, 2007, 24(1): 2685-2689. |

| [56] |

RILEY F L. Silicon nitride and related materials. Journal of the American Ceramic Society, 2000, 83(2): 245-265.

DOI URL |

| [57] |

XING H Y, ZOU B, LIU X Y, et al. Fabrication strategy of complicated Al2O3-Si3N4 functionally graded materials by stereolithography 3D printing. Journal of the European Ceramic Society, 2020, 40(15): 5797-5809.

DOI URL |

| [58] |

CHEN R F, DUAN W Y, WANG G, et al. Preparation of broadband transparent Si3N4-SiO2 ceramics by digital light processing (DLP) 3D printing technology. Journal of the European Ceramic Society, 2021, 41(11): 5495-5504.

DOI URL |

| [59] |

LI X B, ZHANG J X, DUAN Y S, et al. Rheology and curability characterization of photosensitive slurries for 3D printing of Si3N4 ceramics. Applied Sciences, 2020, 10: 6438.

DOI URL |

| [60] |

HUANG R J, JIANG Q G, WU H D, et al. Fabrication of complex shaped ceramic parts with surface-oxidized Si3N4 powder via digital light processing based stereolithography method. Ceramics International, 2019, 45(4): 5158-5162.

DOI URL |

| [61] | SHEN X, GAO Y A, XU Z. Research and application of silane coupling agents. Shanghai Journal of Biomedical Engineering, 2006, 27(1): 14-17. |

| [62] |

LIU Y, ZHAN L N, HE Y, et al. Stereolithographical fabrication of dense Si3N4 ceramics by slurry optimization and pressure sintering. Ceramics International, 2020, 46(2): 2063-2071.

DOI URL |

| [63] |

TIAN Z, YANG Y P, WANG Y, et al. Fabrication and properties of a high porosity H-BN-SiO2 ceramics fabricated by stereolithography- based 3D printing. Materials Letters, 2019, 236: 144-147.

DOI URL |

| [64] |

SHI B H, SHANG Y Y, ZHANG P, et al. Dynamic capillary-driven additive manufacturing of continuous carbon fiber composite. Matter, 2020, 2(6): 1594-1604.

DOI URL |

| [1] | ZHU Wenjie, TANG Lu, LU Jichang, LIU Jiangping, LUO Yongming. Research Progress on Catalytic Oxidation of Volatile Organic Compounds by Perovskite Oxides [J]. Journal of Inorganic Materials, 2025, 40(7): 735-746. |

| [2] | WEI Zhifan, CHEN Guoqing, ZU Yufei, LIU Yuan, LI Minghao, FU Xuesong, ZHOU Wenlong. ZrB2-HfSi2 Ceramics: Microstructure and Formation Mechanism of Core-rim Structure [J]. Journal of Inorganic Materials, 2025, 40(7): 817-825. |

| [3] | HU Zhichao, YANG Hongyu, YANG Hongcheng, SUN Chengli, YANG Jun, LI Enzhu. Usage of the P-V-L Bond Theory in Regulating Properties of Microwave Dielectric Ceramics [J]. Journal of Inorganic Materials, 2025, 40(6): 609-626. |

| [4] | WU Qiong, SHEN Binglin, ZHANG Maohua, YAO Fangzhou, XING Zhipeng, WANG Ke. Research Progress on Lead-based Textured Piezoelectric Ceramics [J]. Journal of Inorganic Materials, 2025, 40(6): 563-574. |

| [5] | ZHANG Bihui, LIU Xiaoqiang, CHEN Xiangming. Recent Progress of Hybrid Improper Ferroelectrics with Ruddlesden-Popper Structure [J]. Journal of Inorganic Materials, 2025, 40(6): 587-608. |

| [6] | WU Jie, YANG Shuai, WANG Mingwen, LI Jinglei, LI Chunchun, LI Fei. Textured PT-based Piezoelectric Ceramics: Development, Status and Challenge [J]. Journal of Inorganic Materials, 2025, 40(6): 575-586. |

| [7] | JIANG Kun, LI Letian, ZHENG Mupeng, HU Yongming, PAN Qinxue, WU Chaofeng, WANG Ke. Research Progress on Low-temperature Sintering of PZT Ceramics [J]. Journal of Inorganic Materials, 2025, 40(6): 627-638. |

| [8] | CUI Ning, ZHANG Yuxin, WANG Lujie, LI Tongyang, YU Yuan, TANG Huaguo, QIAO Zhuhui. Single-phase Formation Process and Carbon Vacancy Regulation of (TiVNbMoW)Cx High-entropy Ceramics [J]. Journal of Inorganic Materials, 2025, 40(5): 511-520. |

| [9] | TIAN Ruizhi, LAN Zhengyi, YIN Jie, HAO Nanjing, CHEN Hangrong, MA Ming. Microfluidic Technology Based Synthesis of Inorganic Nano-biomaterials: Principles and Progress [J]. Journal of Inorganic Materials, 2025, 40(4): 337-347. |

| [10] | ZHANG Jiguo, WU Tian, ZHAO Xu, YANG Fan, XIA Tian, SUN Shien. Improvement of Cycling Stability of Cathode Materials and Industrialization Process for Sodium-ion Batteries [J]. Journal of Inorganic Materials, 2025, 40(4): 348-362. |

| [11] | YIN Jie, GENG Jiayi, WANG Kanglong, CHEN Zhongming, LIU Xuejian, HUANG Zhengren. Recent Advances in 3D Printing and Densification of SiC Ceramics [J]. Journal of Inorganic Materials, 2025, 40(3): 245-255. |

| [12] | CHEN Guangchang, DUAN Xiaoming, ZHU Jinrong, GONG Qing, CAI Delong, LI Yuhang, YANG Donglei, CHEN Biao, LI Xinmin, DENG Xudong, YU Jin, LIU Boya, HE Peigang, JIA Dechang, ZHOU Yu. Advanced Ceramic Materials in Helicopter Special Structures: Research Progress and Application Prospect [J]. Journal of Inorganic Materials, 2025, 40(3): 225-244. |

| [13] | FAN Xiaobo, ZU Mei, YANG Xiangfei, SONG Ce, CHEN Chen, WANG Zi, LUO Wenhua, CHENG Haifeng. Research Progress on Proton-regulated Electrochemical Ionic Synapses [J]. Journal of Inorganic Materials, 2025, 40(3): 256-270. |

| [14] | HAIREGU Tuxun, GUO Le, DING Jiayi, ZHOU Jiaqi, ZHANG Xueliang, NUERNISHA Alifu. Research Progress of Optical Bioimaging Technology Assisted by Upconversion Fluorescence Probes in Tumor Imaging [J]. Journal of Inorganic Materials, 2025, 40(2): 145-158. |

| [15] | SUN Shujuan, ZHENG Nannan, PAN Haokun, MA Meng, CHEN Jun, HUANG Xiubing. Research Progress on Preparation Methods of Single-atom Catalysts [J]. Journal of Inorganic Materials, 2025, 40(2): 113-127. |

| Viewed | ||||||

|

Full text |

|

|||||

|

Abstract |

|

|||||