Journal of Inorganic Materials ›› 2018, Vol. 33 ›› Issue (2): 198-205.DOI: 10.15541/jim20170582

• Orginal Article • Previous Articles Next Articles

LI Hong-Xia

Received:2016-07-30

Revised:2016-12-05

Published:2018-02-26

Online:2018-01-26

Supported by:CLC Number:

LI Hong-Xia. Development Overview of Refractory Materials[J]. Journal of Inorganic Materials, 2018, 33(2): 198-205.

Fig. 1 Microstructure and effects of temperature on thermal conductivity of developed ceramic fiber enforced nano-SiO2- fumed-corundum insulation composite materials[41]

| Developed composite plate | Developed plate with nano-sized pores | A Company | B Company | Porextherm plate with nano-sized pores | |

|---|---|---|---|---|---|

| Thermal conductivity (1000℃)/(W·m-1·K-1) | 0.087 | 0.063 | 0.050(800℃) | — | 0.062 |

| Bulk density/(g·cm-3) | 0.55-0.65 | 0.35-0.4 | 0.30-0.35 | — | 0.35-0.45 |

| Service temperature/℃ | 1800 | 1100 | 850 | 650 | 1100 |

| Linear change/% (1000℃, 24 h) | ~1.5 | <2 | — | — | <2 |

Table 1 Properties of developed insulation composite material with micro/nano-sized pores[42]

| Developed composite plate | Developed plate with nano-sized pores | A Company | B Company | Porextherm plate with nano-sized pores | |

|---|---|---|---|---|---|

| Thermal conductivity (1000℃)/(W·m-1·K-1) | 0.087 | 0.063 | 0.050(800℃) | — | 0.062 |

| Bulk density/(g·cm-3) | 0.55-0.65 | 0.35-0.4 | 0.30-0.35 | — | 0.35-0.45 |

| Service temperature/℃ | 1800 | 1100 | 850 | 650 | 1100 |

| Linear change/% (1000℃, 24 h) | ~1.5 | <2 | — | — | <2 |

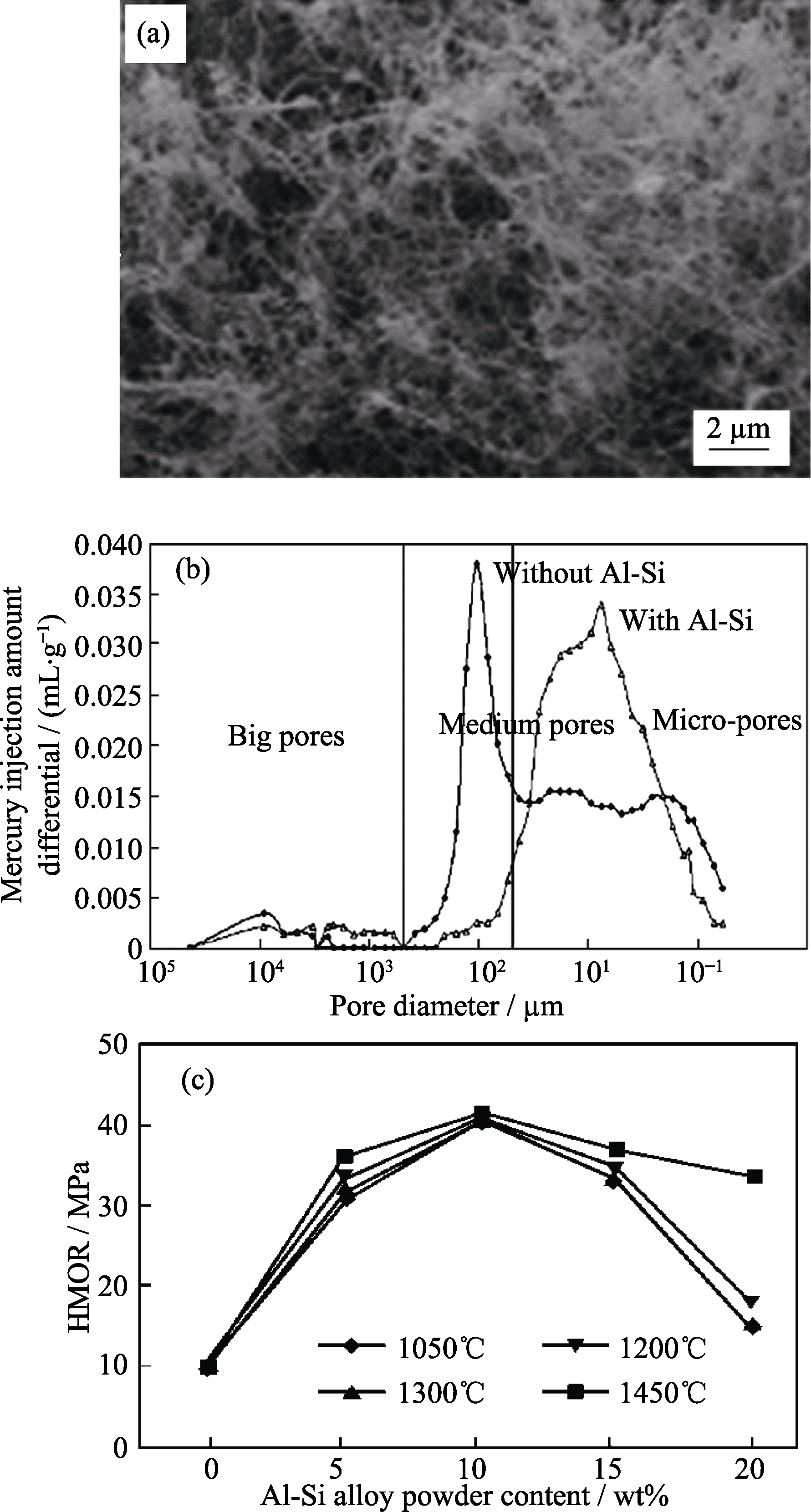

Fig. 5 The influence of Al-Si alloy antioxidant additives on the microstructure and properties of Al2O3-C refractories[44] (a) Fibrous substance formed by antioxidant reaction; (b) Narrowing influence on the pores distribution; (c) Effect on HMOR

| [1] | 李红霞. 高温工业的发展与耐火材料的技术进步. 耐火材料, 2006, 40(增刊): 4-8. |

| [2] | 陈肇友, 李红霞. 镁资源的综合利用及镁质耐火材料的发展. 耐火材料, 2005, 39(1): 6-15. |

| [3] | LI H X, LIU G Q.Current situation and development of refractories for clean steel production.China’s Refractories, 2013, 22(3): 1-6. |

| [4] | 吴小贤, 李红霞, 刘国齐, 等. 高能球磨合成纳米碳包覆α-Al2O3复合粉体. 无机材料学报, 2013, 28(3): 261-266. |

| [5] | 刘辉敏, 李红霞, 洪彦若, 等. 复合结构长水口热应力有限元分析. 硅酸盐学报, 2009, 31(12): 2000-2006. |

| [6] | SONG Y Y, LIU G Q, LI H X, et al. Influence of ladle purging plug airway on flow properties of liquid steel. Advanced Materials Research, 2012, 472-475: 2581-2587. |

| [7] | LI H X, YANG B, LIU G Q, et al.Gradient Functional Refractories for High Efficient Con-casting (invited). Proceedings of the 6th International Congress on the Science and Technology of Steelmaking(I), Beijing, China, 2015: 4-8. |

| [8] | 张洪哲, 李富朝, 孙庚辰, 等. 高风温长寿热风炉用高效小孔径格子砖的设计及选材. 耐火材料, 2015, 49(5): 376-380. |

| [9] | 王佳平, 金广湘, 王勇峰, 等.新型复相氮化物结合碳化硅耐火材料在干熄炉斜道区的应用和分析. 西安: 2016年(第十届)焦化节能环保及干熄焦技术研讨会论文集, 2016: 96-101. |

| [10] | YIN H J, ZHANG T, WU A J, et al. Effect of M-ZrO2 on sintering behavior and thermal shock resistance of dense Cr2O3 material. Advanced Materials Research, 2011, 199-200: 1928-1931. |

| [11] | 孙红刚, 陈杰, 范志辉, 等. 新型高铬砖在GE气化炉的试用研究. 大氮肥, 2011, 34(增刊2): 108-111. |

| [12] | 耿可明, 王金相. Cr2O3在水煤浆气化炉过程中的行为. 耐火材料, 2015, 49(1): 68-71. |

| [13] | 李红霞, 王金相. 水泥窑用碱性耐火材料无铬化的技术进展. 中国水泥, 2004, 10: 79-82. |

| [14] | LI H X, LIU J, FENG H X, et al.Development and application of chrome-free refractory materials for RH degasser.China's Refractories, 2014, 23(4): 1-5, 12. |

| [15] | GE H B, WANG G, YUAN B, et al.Fabrication and microstructure of porous SiC ceramics using suspension emulsions as pore-forming agents.Ceramics International, 2014, 40(8): 11705-11711. |

| [16] | WU H B, HUANG Z R, WANG G, et al.Alumina heat insulator through composite poring mechanisms.International Journal of Applied Ceramic Technology, 2015, 11(6): 1061-1067. |

| [17] | 徐殿利. 2016年全国耐火材料行业生产运行情况及2017年耐火材料市场预测分析. 北京: 2017年耐火材料行业协会年会报告会, 2017: 1-8. |

| [18] | 江东亮, 袁渭康, 钱锋, 等. 我国高耗能工业高温热工装备节能科技发展战略研究. 北京: 科学出版社, 2017: 50-55. |

| [19] | 李红霞, 杨彬. 中国石墨资源和产业状况概述. 郑州: 耐火原料学术交流会论文集, 2011: 1-11. |

| [20] | 刘俊光, 魏同. 我国耐火材料工业节能降耗技术及发展方向. 太原: 新形势下全国耐火原料发展战略研讨会论文集, 2014: 193-194. |

| [21] | HEMRICK J G, HAYDE H W, ANGELINI, et al. Refractories for industrial processing: opportunities for improved energy efficiency.Industrial Technologies Program, 2005, 1: 4-6. |

| [22] | HEMRICK J G.Improved refractories=energy saving.American Ceramic Society Bulletin, 2013, 92(7): 32-35. |

| [23] | HEADRICK W L.Towards a “greener” future with advanced refractories.American Ceramic Society Bulletin, 2013, 92(7): 28-31. |

| [24] | SEMLER C E.Refractories—the world most important but least known products.American Ceramic Society Bulletin, 2014, 93(2): 34-39. |

| [25] | GUIRE E D.State raw materials 2013-overview and frontiers.American Ceramic Society Bulletin, 2013, 92(6): 24-28. |

| [26] | CERAME-UNIE.The Ceramic Industry Roadmap. Paving the Way to 2050, 2012, 1: 40-45. |

| [27] | COHEN L.Challenge and opportunities for refractory manufacturers in the UK.Refractories Engineer, 2013, 11: 12-17. |

| [28] | JARVIS D R.An overview of the current 2013 global refractories industry.International Ceramic Review, 2013, 62(4): 262-266. |

| [29] | XU D L, CUI Y S, YANG K, et al.On the future of Chinese cement industry.Cement and Concrete Research, 2015, 78: 2-13. |

| [30] | 殷瑞钰. 高效率、低成本洁净钢“制造平台”集成技术及其动态运行. 钢铁, 2012, 47(1): 1-12. |

| [31] | LI HONGXIA.Development of Refractory Industry in China with Restricts of Resource, Energy and Environment Factors. Proceedings of UNITECR 2011, Kyoto, Japan, 2011: 122-123. |

| [32] | 李红霞. 经济下行时中国耐火材料行业发展的思考. 耐火材料, 2012, 46(5): 321-324. |

| [33] | JAKOBSEN D, GOTSCHEL I, ROOSEN A.Manufacture of multilayer composite with optimized thermal and chemical properties via the tape casting process.Refractories Worldforum, 2016, 8(2): 86-94. |

| [34] | 蔡斌利, 李红霞, 赵世贤, 等. 水煤浆气化炉中O2分压和Cr2O3稳定性的热力学计算. 耐火材料, 2016, 50(6): 411-415. |

| [35] | YANG W G, LIU G Q, LI H X, et al.Thermal Stress Distribution in Stopper by Finite Element Analysis. Proceedings of UNITECR 2013, Columbia, Canada, 2013: 154-158. |

| [36] | 李红霞. 对耐火材料的性能调控及设计的一些思考. 耐火材料, 2013, 47(增刊1): 1-2. |

| [37] | SEMLER C E.Review of advances in refractories.International Ceramic Review, 2011, 2: 77-81. |

| [38] | SUGITA K.The past and future of refractories technology.International Ceramic Review, 2012, 1: 8-12. |

| [39] | SEMLER C E.The advancement of refractories technology never stops.Refractories Worldforum, 2014, 6(4): 27-31. |

| [40] | PHILIP A.An introduction to Alkaline Silicate wool products. Proceedings of the Institute of Industrial Engineers Asian Conference 2013, Taipei, 2013: 100-105. |

| [41] | 孙小飞, 王刚, 袁波. 高铝纤维复合SiO2质纳米微孔隔热材料研究. 耐火材料, 2014, 48(6): 406-408. |

| [42] | LI H X.Some design consideration of advanced refractories.Refractories Worldforum, 2017, 9(4): 99-105. |

| [43] | 张琪. 隔热材料抗冰晶石蒸汽侵蚀机理研究. 洛阳: 中钢集团洛阳耐火材料研究院硕士学位论文, 2016. |

| [44] | 刘国齐. Al2O3-Al-C功能耐火材料的热变化和应用研究. 北京: 北京科技大学博士学位论文, 2006. |

| [45] | 吴小贤. 含纳米碳新型低碳铝碳耐火材料研究. 北京: 北京科技大学博士学位论文, 2013. |

| [1] | ZHU Wenjie, TANG Lu, LU Jichang, LIU Jiangping, LUO Yongming. Research Progress on Catalytic Oxidation of Volatile Organic Compounds by Perovskite Oxides [J]. Journal of Inorganic Materials, 2025, 40(7): 735-746. |

| [2] | HU Zhichao, YANG Hongyu, YANG Hongcheng, SUN Chengli, YANG Jun, LI Enzhu. Usage of the P-V-L Bond Theory in Regulating Properties of Microwave Dielectric Ceramics [J]. Journal of Inorganic Materials, 2025, 40(6): 609-626. |

| [3] | WU Qiong, SHEN Binglin, ZHANG Maohua, YAO Fangzhou, XING Zhipeng, WANG Ke. Research Progress on Lead-based Textured Piezoelectric Ceramics [J]. Journal of Inorganic Materials, 2025, 40(6): 563-574. |

| [4] | ZHANG Bihui, LIU Xiaoqiang, CHEN Xiangming. Recent Progress of Hybrid Improper Ferroelectrics with Ruddlesden-Popper Structure [J]. Journal of Inorganic Materials, 2025, 40(6): 587-608. |

| [5] | WU Jie, YANG Shuai, WANG Mingwen, LI Jinglei, LI Chunchun, LI Fei. Textured PT-based Piezoelectric Ceramics: Development, Status and Challenge [J]. Journal of Inorganic Materials, 2025, 40(6): 575-586. |

| [6] | JIANG Kun, LI Letian, ZHENG Mupeng, HU Yongming, PAN Qinxue, WU Chaofeng, WANG Ke. Research Progress on Low-temperature Sintering of PZT Ceramics [J]. Journal of Inorganic Materials, 2025, 40(6): 627-638. |

| [7] | TIAN Ruizhi, LAN Zhengyi, YIN Jie, HAO Nanjing, CHEN Hangrong, MA Ming. Microfluidic Technology Based Synthesis of Inorganic Nano-biomaterials: Principles and Progress [J]. Journal of Inorganic Materials, 2025, 40(4): 337-347. |

| [8] | ZHANG Jiguo, WU Tian, ZHAO Xu, YANG Fan, XIA Tian, SUN Shien. Improvement of Cycling Stability of Cathode Materials and Industrialization Process for Sodium-ion Batteries [J]. Journal of Inorganic Materials, 2025, 40(4): 348-362. |

| [9] | YIN Jie, GENG Jiayi, WANG Kanglong, CHEN Zhongming, LIU Xuejian, HUANG Zhengren. Recent Advances in 3D Printing and Densification of SiC Ceramics [J]. Journal of Inorganic Materials, 2025, 40(3): 245-255. |

| [10] | CHEN Guangchang, DUAN Xiaoming, ZHU Jinrong, GONG Qing, CAI Delong, LI Yuhang, YANG Donglei, CHEN Biao, LI Xinmin, DENG Xudong, YU Jin, LIU Boya, HE Peigang, JIA Dechang, ZHOU Yu. Advanced Ceramic Materials in Helicopter Special Structures: Research Progress and Application Prospect [J]. Journal of Inorganic Materials, 2025, 40(3): 225-244. |

| [11] | FAN Xiaobo, ZU Mei, YANG Xiangfei, SONG Ce, CHEN Chen, WANG Zi, LUO Wenhua, CHENG Haifeng. Research Progress on Proton-regulated Electrochemical Ionic Synapses [J]. Journal of Inorganic Materials, 2025, 40(3): 256-270. |

| [12] | HAIREGU Tuxun, GUO Le, DING Jiayi, ZHOU Jiaqi, ZHANG Xueliang, NUERNISHA Alifu. Research Progress of Optical Bioimaging Technology Assisted by Upconversion Fluorescence Probes in Tumor Imaging [J]. Journal of Inorganic Materials, 2025, 40(2): 145-158. |

| [13] | SUN Shujuan, ZHENG Nannan, PAN Haokun, MA Meng, CHEN Jun, HUANG Xiubing. Research Progress on Preparation Methods of Single-atom Catalysts [J]. Journal of Inorganic Materials, 2025, 40(2): 113-127. |

| [14] | TAO Guilong, ZHI Guowei, LUO Tianyou, OUYANG Peidong, YI Xinyan, LI Guoqiang. Progress on Key Technologies of Cavity-structured Thin Film Bulk Acoustic Wave Filter [J]. Journal of Inorganic Materials, 2025, 40(2): 128-144. |

| [15] | ZHOU Fan, TIAN Zhilin, LI Bin. Research Progress on Carbide Ultra-high Temperature Ceramic Anti-ablation Coatings for Thermal Protection System [J]. Journal of Inorganic Materials, 2025, 40(1): 1-16. |

| Viewed | ||||||

|

Full text |

|

|||||

|

Abstract |

|

|||||