Journal of Inorganic Materials ›› 2017, Vol. 32 ›› Issue (6): 571-580.DOI: 10.15541/jim20160461

• Orginal Article • Previous Articles Next Articles

LI Da-Chuan1,2, ZHAO Hua-Yu1, ZHONG Xing-Hua1, TAO Shun-Yan1

Received:2016-08-08

Revised:2016-09-26

Published:2017-06-20

Online:2017-05-27

About author:LI Da-Chuan. E-mail: dachuan_li@student.sic.ac.cn

Supported by:CLC Number:

LI Da-Chuan, ZHAO Hua-Yu, ZHONG Xing-Hua, TAO Shun-Yan. Research Progresses of Atmospheric Plasma Sprayed Splat[J]. Journal of Inorganic Materials, 2017, 32(6): 571-580.

| Radial position /mm | Average particle diameter /μm | Average particle velocity/(m·s-1) | Average particle temperature /K |

|---|---|---|---|

| +50 | 25.7 | 236 | 3310 |

| +40 | 26.3 | 247 | 3342 |

| +30 | 27.8 | 254 | 3392 |

| +20 | 30.3 | 248 | 3430 |

| +10 | 32.3 | 233 | 3420 |

| 0 | 36.5 | 228 | 3400 |

| -10 | 37.0 | 215 | 3340 |

| -20 | 38.2 | 209 | 3310 |

| -30 | 42.3 | 199 | 3294 |

| -40 | 44.3 | 191 | 3270 |

| -50 | 45.6 | 188 | 3250 |

Table 1 Average values of the particle size, velocity and temperature at different radial positions from the plasma jet center line[12]

| Radial position /mm | Average particle diameter /μm | Average particle velocity/(m·s-1) | Average particle temperature /K |

|---|---|---|---|

| +50 | 25.7 | 236 | 3310 |

| +40 | 26.3 | 247 | 3342 |

| +30 | 27.8 | 254 | 3392 |

| +20 | 30.3 | 248 | 3430 |

| +10 | 32.3 | 233 | 3420 |

| 0 | 36.5 | 228 | 3400 |

| -10 | 37.0 | 215 | 3340 |

| -20 | 38.2 | 209 | 3310 |

| -30 | 42.3 | 199 | 3294 |

| -40 | 44.3 | 191 | 3270 |

| -50 | 45.6 | 188 | 3250 |

Fig. 5 Comparison of cooling and solidification processes inside the splat deposited onto substrates at a temperature above (left) and below (right) transition temperature[34]

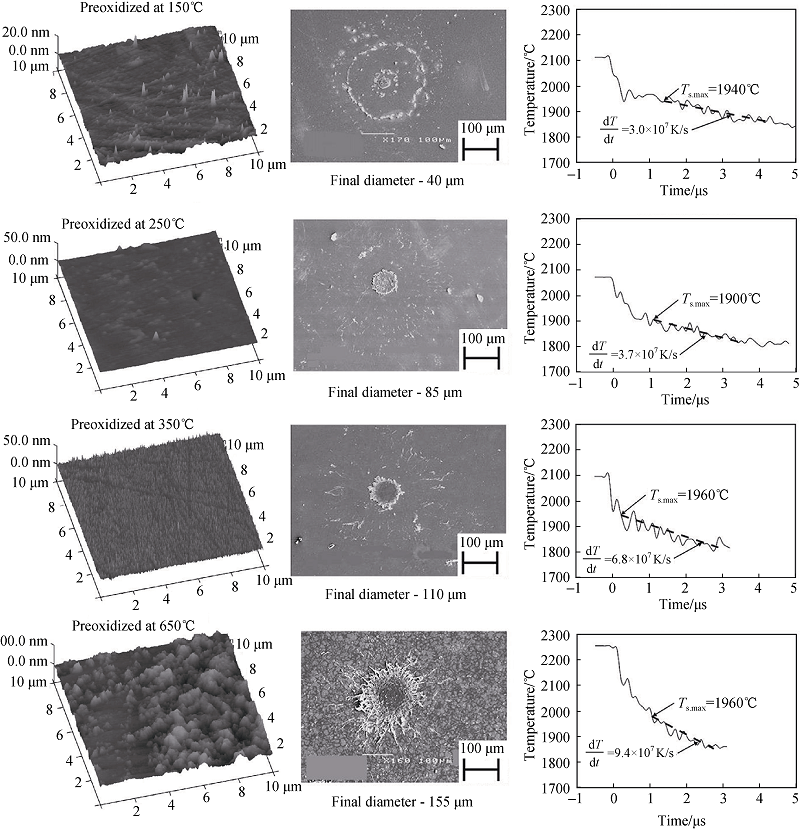

Fig. 7 Surface topologies of stainless steel surfaces either non-oxidized or preoxidized at different temperatures, images of nickel splats after solidification and cooling curves of splats[39]

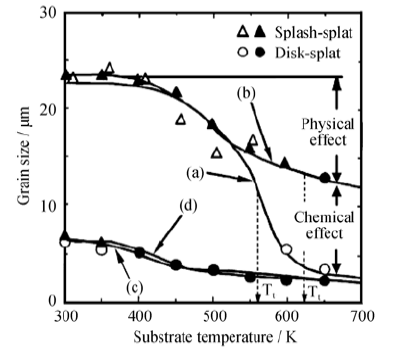

Fig. 8 Grain size in a cross-section of the splat obtained in different ambient pressures[28](a) on stainless steel in atmospheric pressure; (b) on gold-coated stainless steel in atmospheric pressure; (c) on stainless steel under low pressure; and (d) on gold-coated stainless steel under low pressure

| [1] | 徐滨士, 李长久, 刘世参, 等. 表面工程与热喷涂技术及其发展. 中国表面工程, 1998, 38(1): 3-9. |

| [2] | 徐滨士, 马世宁, 时小军, 等. 中国表面工程的发展. 中国机械工程, 1996, 7(5): 3-5. |

| [3] | 曹学强. 热障涂层新材料和新结构. 北京: 科学出版社, 2016. |

| [4] | 黄小鸥, 吴朝军. 适应产业结构调整,开发新型涂层产品. 第十七届国际热喷涂研讨会(ITSS'2014)暨第十八届全国热喷涂年会(CNTSC'2014), 成都&自贡, 中国, 2014: 1-5. |

| [5] | 中国表面工程协会热喷涂专业委员会. 中国热喷涂年鉴: 2015年版. 北京: 科学技术文献出版社, 2016. |

| [6] | FAUCHAIS P, HEBERLEIN J, BOULOS M.Thermal Spray Fundamentals: from Powder to Part. New York: Springer Science+Business Media, 2014. |

| [7] | FAUCHAIS P.Understanding plasma spraying.J. Phys. D Appl. Phys., 2004, 37(9): 86-108. |

| [8] | VARDELLE M, VARDELLE A, DUSSOUBS B, et al.Influence of injector geometry on particle trajectories: analysis of particle dynamics in the injector and plasma jet.Thermal Spray, Vols 1 and 2, 1998: 887-894. |

| [9] | LI H P, CHEN X.Three-dimensional simulation of a plasma jet with transverse particle and carrier gas injection.Thin Solid Films, 2001, 390(1/2): 175-180. |

| [10] | XIONG H B, ZHENG L L, SAMPATH S, et al.Three-dimensional simulation of plasma spray: effects of carrier gas flow and particle injection on plasma jet and entrained particle behavior.Int. J. Heat Mass Tran., 2004, 47(24): 5189-5200. |

| [11] | YUGESWARAN S, KOBAYASHI A, SELVAN B, et al.In-flight behavior of lanthanum zirconate (La2Zr2O7) particles in gas tunnel type plasma jet and its coating properties.Vacuum, 2013, 88: 139-143. |

| [12] | ELSEBAEI A, HEBERLEIN J, ELSHAER M, et al.Comparison of in-flight particle properties, splat formation, and coating microstructure for regular and nano-ysz powders.J. Therm Spray Techn., 2010, 19(1/2): 2-10. |

| [13] | OERLIKON METCO.Thermal spray materials guide. , April 2015. |

| [14] | KUMAR A, GU S, TABBARA H, et al.Study of impingement of hollow ZrO2 droplets onto a substrate.Surf. Coat. Tech., 2013, 220: 164-169. |

| [15] | KANOUFF M P, NEISER R A, ROEMER T J.Surface roughness of thermal spray coatings made with off-normal spray angles.J. Therm. Spray Techn., 1998, 7(2): 219-228. |

| [16] | LEIGH S H, BERNDT C C.Evaluation of off-angle thermal spray.Surf. Coat. Tech., 1997, 89(3): 213-224. |

| [17] | ALAVI S, PASSANDIDEH-FARD M, MOSTAGHIMI J.Simulation of semi-molten particle impacts including heat transfer and phase change.J. Therm. Spray Techn., 2012, 21(6): 1278-1293. |

| [18] | ZHU Z H, KAMNIS S, GU S.Numerical study of molten and semi-molten ceramic impingement by using coupled Eulerian and Lagrangian method.Acta Mater., 2015, 90: 77-87. |

| [19] | GOUTIER S, VARDELLE M, FAUCHAIS P.Comparison between metallic and ceramic splats: influence of viscosity and kinetic energy on the particle flattening.Surf. Coat. Tech., 2013, 235: 657-668. |

| [20] | CHEN D, WANG Y, BAI Y, et al.Effect of reynolds number of molten particle on splat formation in plasma spraying.J. Inorg. Mater., 2015, 30(1): 65-70. |

| [21] | GOUTIER S, VARDELLE M, LABBE J C, et al.Flattening and cooling of millimeter- and micrometer-sized alumina drops.J. Therm. Spray Techn., 2011, 20(1/2): 59-67. |

| [22] | ESCURE C, VARDELLE M, FAUCHAIS P.Experimental and theoretical study of the impact of alumina droplets on cold and hot substrates.Plasma Chem. Plasma P., 2003, 23(2): 185-221. |

| [23] | LI L, VAIDYA A, SAMPATH S, et al.Particle characterization and splat formation of plasma sprayed zirconia.J. Therm. Spray Techn., 2006, 15(1): 97-105. |

| [24] | WANG Y Z, HUA J J, LIU Z W, et al.Melting index characterization and thermal conductivity model of plasma sprayed YSZ coatings.J. Eur. Ceram. Soc., 2012, 32(14): 3701-3707. |

| [25] | FUKUMOTO M, HUANG Y.Flattening mechanism in thermal sprayed nickel particle impinging on flat substrate surface.J. Therm. Spray Techn., 1999, 8(3): 427-432. |

| [26] | MOREAU C, GOUGEON P, LAMONTAGNE M.Influence of substrate preparation on the flattening and cooling of plasma- sprayed particles.J. Therm. Spray Techn., 1995, 4(1): 25-33. |

| [27] | FAUCHAIS P, VARDELLE M, VARDELLE A, et al.Parameters controlling the generation and properties of plasma sprayed zirconia coatings.Plasma Chem. Plasma P., 1996, 16(1): 99-125. |

| [28] | FUKUMOTO M, NISHIOKA E, MATSUBARA T.Effect of interface wetting on flattening of freely fallen metal droplet onto flat substrate surface.J. Therm. Spray Techn., 2002, 11(1): 69-74. |

| [29] | FAUCHAIS P, FUKUMOTO M, VARDELLE A, et al.Knowledge concerning splat formation: an invited review.J. Therm. Spray Techn., 2004, 13(3): 337-360. |

| [30] | MCDONALD A, MOREAU C, CHANDRA S.Thermal contact resistance between plasma-sprayed particles and flat surfaces.Int. J. Heat Mass Tran., 2007, 50(9/10): 1737-1749. |

| [31] | TRAN A T T, HYLAND M M. The role of substrate surface chemistry on splat formation during plasma spray deposition by experiments and simulations.J. Therm. Spray Techn., 2010, 19(1/2): 11-23. |

| [32] | ZHENG Y Z, LI Q, ZHENG Z H,et al.Modeling the impact, flattening and solidification of a molten droplet on a solid substrate during plasma spraying.Appl. Surf. Sci., 2014, 317: 526-533. |

| [33] | FUKUMOTO M, OHGITANI D, YASUI T.Effect of substrate surface change on flattening behaviour of thermal sprayed particles.Mater Trans., 2004, 45(6): 1869-1873. |

| [34] | FUKUMOTO M, NISHIOKA E, MATSUBARA T.Flattening and solidification behavior of a metal droplet on a flat substrate surface held at various temperatures.Surf. Coat. Tech., 1999, 120: 131-137. |

| [35] | JIANG X Y, WAN Y P, HERMAN H, et al.Role of condensates and adsorbates on substrate surface on fragmentation of impinging molten droplets during thermal spray.Thin Solid Films, 2001, 385(1/2): 132-141. |

| [36] | LI C J, LI J L.Evaporated-gas-induced splashing model for splat formation during plasma spraying.Surf. Coat. Tech., 2004, 184(1): 13-23. |

| [37] | LI H, COSTIL S, LIAO H L, et al.Effects of surface conditions on the flattening behavior of plasma sprayed Cu splats.Surf. Coat. Tech., 2006, 200(18/19): 5435-5446. |

| [38] | TRAN A T T, HYLAND M M, SHINODA K, et al. Influence of substrate surface conditions on the deposition and spreading of molten droplets.Thin Solid Films, 2011, 519(8): 2445-2456. |

| [39] | MCDONALD A, MOREAU C, CHANDRA S.Effect of substrate oxidation on spreading of plasma-sprayed nickel on stainless steel.Surf. Coat. Tech., 2007, 202(1): 23-33. |

| [40] | PARIZI H B, ROSENZWEIG L, MOSTAGHIMI J, et al.Numerical simulation of droplet impact on patterned surfaces.J. Therm. Spray Techn., 2007, 16(5/6): 713-721. |

| [41] | SHINODA K, RAESSI M, MOSTAGHIMI J, et al.Effect of substrate concave pattern on splat formation of yttria-stabilized zirconia in atmospheric plasma spraying.J. Therm. Spray Techn., 2009, 18(4): 609-618. |

| [42] | KHAN A N, LU J, LIAO H.Effect of residual stresses on air plasma sprayed thermal barrier coatings.Surf. Coat. Tech., 2003, 168(2-3): 291-299. |

| [43] | CHRISTOULIS D K, PANTELIS D I, DE DAVE-FABREGUE N, et al. Effect of substrate temperature and roughness on the solidification of copper plasma sprayed droplets.Mat. Sci. Eng. a-Struct., 2008, 485(1/2): 119-129. |

| [44] | LI D C, ZHAO H Y, ZHONG X H, et al.Effect of the bond coating surface morphology on ceramic splat construction.J. Therm. Spray Techn., 2015, 24(8): 1450-1458. |

| [45] | SYED A A, DENOIRJEAN A, HANNOYER B, et al.Influence of substrate surface conditions on the plasma sprayed ceramic and metallic particles flattening.Surf. Coat. Tech., 2005, 200(7): 2317-2331. |

| [46] | SALIMIJAZI H R, PERSHIN L, COYLE T W, et al.Effect of droplet characteristics and substrate surface topography on the final morphology of plasma-sprayed zirconia single splats.J. Therm. Spray Techn., 2007, 16(2): 291-299. |

| [47] | LI C J, LI C X, YANG G J, et al.Examination of substrate surface melting-induced splashing during splat formation in plasma spraying.J. Therm. Spray Techn., 2006, 15(4): 717-724. |

| [48] | BROSSARD S, MUNROE P R, TRAN A T T, et al. Study of the splat microstructure, splat-substrate interface, and the effects of substrate heating on the splat formation for ni-cr particles plasma sprayed on to aluminum substrates.J. Therm. Spray Techn., 2010, 19(5): 1115-1130. |

| [1] | ZHU Wenjie, TANG Lu, LU Jichang, LIU Jiangping, LUO Yongming. Research Progress on Catalytic Oxidation of Volatile Organic Compounds by Perovskite Oxides [J]. Journal of Inorganic Materials, 2025, 40(7): 735-746. |

| [2] | HU Zhichao, YANG Hongyu, YANG Hongcheng, SUN Chengli, YANG Jun, LI Enzhu. Usage of the P-V-L Bond Theory in Regulating Properties of Microwave Dielectric Ceramics [J]. Journal of Inorganic Materials, 2025, 40(6): 609-626. |

| [3] | WU Qiong, SHEN Binglin, ZHANG Maohua, YAO Fangzhou, XING Zhipeng, WANG Ke. Research Progress on Lead-based Textured Piezoelectric Ceramics [J]. Journal of Inorganic Materials, 2025, 40(6): 563-574. |

| [4] | ZHANG Bihui, LIU Xiaoqiang, CHEN Xiangming. Recent Progress of Hybrid Improper Ferroelectrics with Ruddlesden-Popper Structure [J]. Journal of Inorganic Materials, 2025, 40(6): 587-608. |

| [5] | WU Jie, YANG Shuai, WANG Mingwen, LI Jinglei, LI Chunchun, LI Fei. Textured PT-based Piezoelectric Ceramics: Development, Status and Challenge [J]. Journal of Inorganic Materials, 2025, 40(6): 575-586. |

| [6] | JIANG Kun, LI Letian, ZHENG Mupeng, HU Yongming, PAN Qinxue, WU Chaofeng, WANG Ke. Research Progress on Low-temperature Sintering of PZT Ceramics [J]. Journal of Inorganic Materials, 2025, 40(6): 627-638. |

| [7] | TIAN Ruizhi, LAN Zhengyi, YIN Jie, HAO Nanjing, CHEN Hangrong, MA Ming. Microfluidic Technology Based Synthesis of Inorganic Nano-biomaterials: Principles and Progress [J]. Journal of Inorganic Materials, 2025, 40(4): 337-347. |

| [8] | ZHANG Jiguo, WU Tian, ZHAO Xu, YANG Fan, XIA Tian, SUN Shien. Improvement of Cycling Stability of Cathode Materials and Industrialization Process for Sodium-ion Batteries [J]. Journal of Inorganic Materials, 2025, 40(4): 348-362. |

| [9] | YIN Jie, GENG Jiayi, WANG Kanglong, CHEN Zhongming, LIU Xuejian, HUANG Zhengren. Recent Advances in 3D Printing and Densification of SiC Ceramics [J]. Journal of Inorganic Materials, 2025, 40(3): 245-255. |

| [10] | CHEN Guangchang, DUAN Xiaoming, ZHU Jinrong, GONG Qing, CAI Delong, LI Yuhang, YANG Donglei, CHEN Biao, LI Xinmin, DENG Xudong, YU Jin, LIU Boya, HE Peigang, JIA Dechang, ZHOU Yu. Advanced Ceramic Materials in Helicopter Special Structures: Research Progress and Application Prospect [J]. Journal of Inorganic Materials, 2025, 40(3): 225-244. |

| [11] | FAN Xiaobo, ZU Mei, YANG Xiangfei, SONG Ce, CHEN Chen, WANG Zi, LUO Wenhua, CHENG Haifeng. Research Progress on Proton-regulated Electrochemical Ionic Synapses [J]. Journal of Inorganic Materials, 2025, 40(3): 256-270. |

| [12] | HAIREGU Tuxun, GUO Le, DING Jiayi, ZHOU Jiaqi, ZHANG Xueliang, NUERNISHA Alifu. Research Progress of Optical Bioimaging Technology Assisted by Upconversion Fluorescence Probes in Tumor Imaging [J]. Journal of Inorganic Materials, 2025, 40(2): 145-158. |

| [13] | SUN Shujuan, ZHENG Nannan, PAN Haokun, MA Meng, CHEN Jun, HUANG Xiubing. Research Progress on Preparation Methods of Single-atom Catalysts [J]. Journal of Inorganic Materials, 2025, 40(2): 113-127. |

| [14] | TAO Guilong, ZHI Guowei, LUO Tianyou, OUYANG Peidong, YI Xinyan, LI Guoqiang. Progress on Key Technologies of Cavity-structured Thin Film Bulk Acoustic Wave Filter [J]. Journal of Inorganic Materials, 2025, 40(2): 128-144. |

| [15] | ZHOU Fan, TIAN Zhilin, LI Bin. Research Progress on Carbide Ultra-high Temperature Ceramic Anti-ablation Coatings for Thermal Protection System [J]. Journal of Inorganic Materials, 2025, 40(1): 1-16. |

| Viewed | ||||||

|

Full text |

|

|||||

|

Abstract |

|

|||||