Journal of Inorganic Materials ›› 2015, Vol. 30 ›› Issue (11): 1139-1147.DOI: 10.15541/jim20150158

• Orginal Article • Previous Articles Next Articles

WANG Xiao-Feng1, SUN Yue-Hua1, PENG Chao-Qun1, WANG Ri-Chu1, ZHANG Dou2, MA Chao2

Received:2015-04-03

Revised:2015-05-27

Published:2015-11-20

Online:2015-10-20

About author:WANG Xiao-Feng. E-mail: wangxiaofeng@csu.edu.cn

Supported by:CLC Number:

WANG Xiao-Feng, SUN Yue-Hua, PENG Chao-Qun, WANG Ri-Chu, ZHANG Dou, MA Chao. Suspensions Designed for Direct Ink Writing[J]. Journal of Inorganic Materials, 2015, 30(11): 1139-1147.

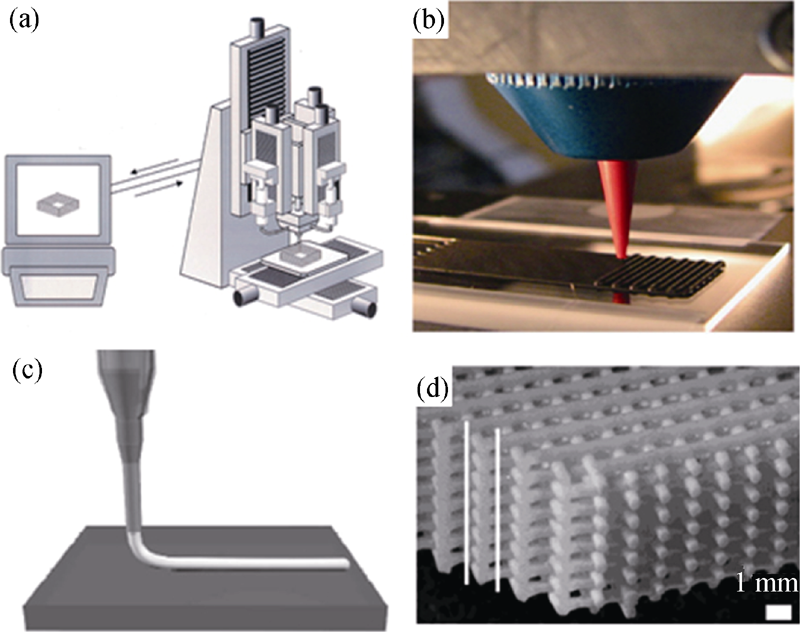

Fig. 1 Direct ink writing (robocasting) (a) Schematic view[1] and (b) optical image of direct ink writing[26]; (c) schematic view of filament fluid[1]; (d) optical image of a 3-D periodic structure[25]

| Self-solidification suspensions | Tailoring routes for rheological properties of suspensions | Minimum feature size in 3D structures | References |

|---|---|---|---|

| Colloidal gel suspensions | Changing pH values | 100 μm | [25, 35-36] |

| Tailoring ionic concentrations | 30 μm | [37] | |

| Adding oppositive polyelectrolyte | 200 μm | [13, 38] | |

| Biphasic suspensions | Changing inter environment of suspensions with homopolymer and copolymer, e.g. ionic concentrations | < 100 μm | [39] |

| Controlling the hydrophilicity/hydrophobicity between particles and solvent | - | [39] | |

| Using powder with different isoelectric points (IEP) | - | [39] |

Table 1 Self-solidification suspensions designed for direct ink writing[13, 25, 35-39]

| Self-solidification suspensions | Tailoring routes for rheological properties of suspensions | Minimum feature size in 3D structures | References |

|---|---|---|---|

| Colloidal gel suspensions | Changing pH values | 100 μm | [25, 35-36] |

| Tailoring ionic concentrations | 30 μm | [37] | |

| Adding oppositive polyelectrolyte | 200 μm | [13, 38] | |

| Biphasic suspensions | Changing inter environment of suspensions with homopolymer and copolymer, e.g. ionic concentrations | < 100 μm | [39] |

| Controlling the hydrophilicity/hydrophobicity between particles and solvent | - | [39] | |

| Using powder with different isoelectric points (IEP) | - | [39] |

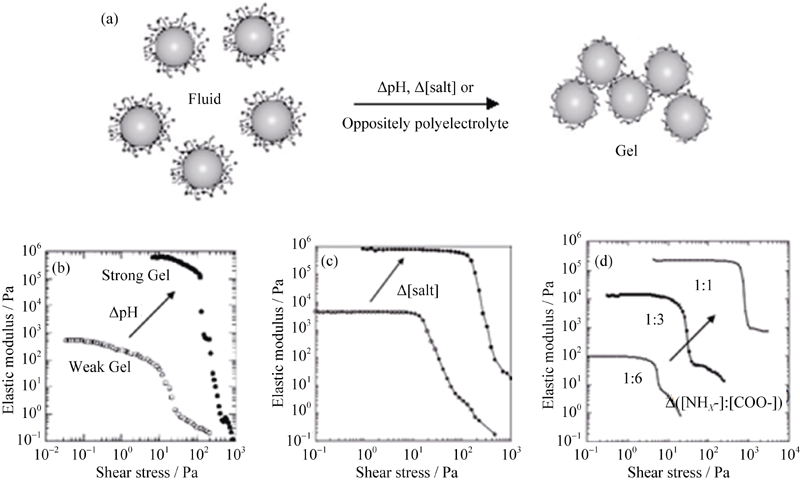

Fig. 3 Fluid-to-gel transition of colloidal inks that occur upon changing pH, ionic strength or adding oppositely charged polyelectrolyte (a) Schematic view[25, 36]; (b) Shear elastic modulus versus shear stress for concentrated silica gels of varying strength through changing pH [25]; (c) Equilibrium elastic modulus of BaTiO3 nanoparticle inks with different salt additions[37]; (d) Ink elasticity varying [NHx+]: [COO-] ratios[38]

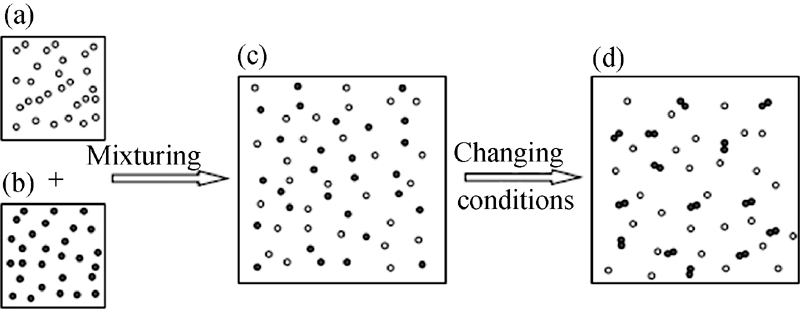

Fig. 4 Schematic image of biphasic suspensions Two stably dispersed suspensions (a, b) are mixed (c), and then conditions are changed to trigger the flocculation of one suspension but still another suspensions flowing (d)

| External conditions for solidification of suspensions | Assistant-solidification suspensions | Minimum feature size in 3D structures | References |

|---|---|---|---|

| Fast evaporation of solvent in suspensions | Colloidal suspensions with shear thinning behavior | 500 μm | [17] |

| Suspensions composited of nanoparticles and organic solvent | 1 μm | [42-43] | |

| Solubility divergence between solvent in suspensions and liquid in deposition reservoir | polyelectrolyte complexes (PECs) | 500 μm 30 μm 1 μm | [30, 43-44] |

| Polymerization of organic monomer under ultraviolet irradiation | Silk fibroin solution | 5 μm | [45] |

| Sol-Gel suspension | 0.3 μm | [46] | |

| Organic monomer solution | 5 μm | [31] | |

| Suspensions containing organic monomer | — | [47] |

Table 2 Assistant-solidification suspensions designed for direct ink writing[17, 30-31, 42-47]

| External conditions for solidification of suspensions | Assistant-solidification suspensions | Minimum feature size in 3D structures | References |

|---|---|---|---|

| Fast evaporation of solvent in suspensions | Colloidal suspensions with shear thinning behavior | 500 μm | [17] |

| Suspensions composited of nanoparticles and organic solvent | 1 μm | [42-43] | |

| Solubility divergence between solvent in suspensions and liquid in deposition reservoir | polyelectrolyte complexes (PECs) | 500 μm 30 μm 1 μm | [30, 43-44] |

| Polymerization of organic monomer under ultraviolet irradiation | Silk fibroin solution | 5 μm | [45] |

| Sol-Gel suspension | 0.3 μm | [46] | |

| Organic monomer solution | 5 μm | [31] | |

| Suspensions containing organic monomer | — | [47] |

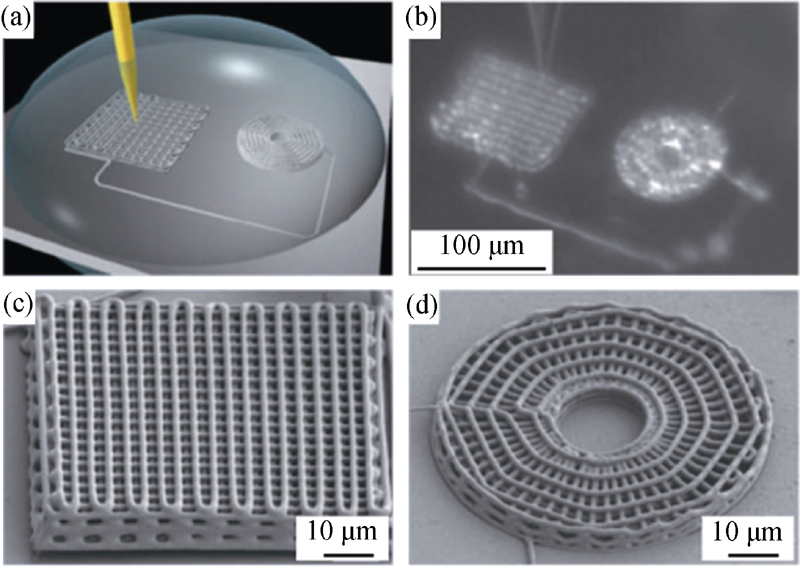

Fig. 5 Direct ink writing of three-dimensional microperiodic structures (a) Schematic diagram of direct ink writing with deposition reservoir; (b) Optical image acquired in situ during deposition; (c) Three-dimensional periodic structure with a face-centred tetragonal geometry; (d) Three- dimensional radial array[30]

| [1] | LEWIS J A.Colloidal processing of ceramics.Journal of the American Ceramic Society, 2000, 83(10): 2341-2359. |

| [2] | LEWIS J A, GRATSON G M.Direct writing in three dimensions.Materials Today, 2004, 7(7): 32-39. |

| [3] | LEWIS J A, SMAY J E, STUECKER J, et al.Direct ink writing of three-dimensional ceramic structures. Journal of the American Ceramic Society, 2006, 89(12): 3599-3609. |

| [4] | ALLAHVERDI M, DANFORTH S C, JAFARI M, et al.Processing of advanced electroceramic components by fused deposition technique.Journal of the European Ceramic Society, 2001, 21(10): 1485-1490. |

| [5] | SAFARI A, AKDOGAN E K.Rapid prototyping of novel piezoelectric composites.Ferroelectrics, 2006, 331(1): 153-179. |

| [6] | TRESSLER J F, ALKOY S, DOGAN A, et al.Functional composites for sensors, actuators and transducers.Composites. Part A: Applied Science and Manufacturing, 1999, 30(4): 477-482. |

| [7] | LI Y, LI L, LI B.Direct ink writing of 3-3 piezoelectric composite.Journal of Alloys and Compounds, 2015, 620(25): 125-128. |

| [8] | SAN MARCHI C, KOUZELI M, RAO R, et al.Alumina-aluminum interpenetrating-phase composites with three-dimensional periodic architecture.Scripta Materialia, 2003, 49(9): 861-866. |

| [9] | RAO M P, SANCHEZ-HERENCIA A J, BELTZ G E, et al. Laminar ceramics that exhibit a threshold strength.Science, 1999, 286(5437): 102-105. |

| [10] | SOUNDARARAJAN R, KUHN G, ATISIVAN R, et al.Processing of mullite-aluminum composites.Journal of the American Ceramic Society, 2001, 84(3): 509-513. |

| [11] | EQTESADI S, MOTEALLEH A, MIRANDA P, et al.Robocasting of 45S5 bioactive glass scaffolds for bone tissue engineering.Journal of the European Ceramic Society, 2014, 34(1): 107-118. |

| [12] | MAAZOUZ Y, MONTUFAR E B, GUILLEM-MARTI J, et al.Robocasting of biomimetic hydroxyapatite scaffolds using self-setting inks.Journal of Materials Chemistry B, 2014, 2(33): 5378-5386. |

| [13] | MICHNA S, WU W, LEWIS J A.Concentrated hydroxyapatite inks for direct-write assembly of 3-D periodic scaffolds.Biomaterials, 2005, 26(28): 5632-5639. |

| [14] | JOANNOPOULOS J D, VILLENEUVE P R, FAN S.Photonic crystals: putting a new twist on light. Nature, 1997, 386(6621): 143-149. |

| [15] | SHEN W, LI M, YE C, et al.Direct-writing colloidal photonic crystal microfluidic chips by inkjet printing for label-free protein detection.Lab on a Chip, 2012, 12(17): 3089-3095. |

| [16] | VLASOV Y A, BO X Z, STURM J C, et al.On-chip natural assembly of silicon photonic bandgap crystals.Nature, 2001, 414(6861): 289-293. |

| [17] | CESARANO III J.A review of robocasting technology.Materials Research Symposium Proceedings, 1999, 542: 133-139. |

| [18] | CESARANO III J, BAER T A, CALVERT P. Recent Developments in Freeform Fabrication of Dense Ceramics from Slurry Deposition. Albuquerque, NM: Sandia National Labs., 1997, SAND97-2857C. |

| [19] | ZEIN I, HUTMACHER D W, TAN K C, et al.Fused deposition modeling of novel scaffold architectures for tissue engineering applications. Biomaterials, 2002, 23(4): 1169-1185. |

| [20] | AGARWALA M K, BANDYOPADHYAY A, WEEREN R, et al.FDC, rapid fabrication of structural components.American Ceramic Society Bulletin, 1996, 75(11): 60-65. |

| [21] | RANGARAJAN S, QI G, VENKATARAMAN N, et al.Powder processing, rheology, and mechanical properties of feedstock for fused deposition of Si3N4 ceramics.Journal of the American Ceramic Society, 2000, 83(7): 1663-1669. |

| [22] | SACHS E, CIMA M, WILLIAMS P, et al.Three dimensional printing: rapid tooling and prototypes directly from a CAD model.Journal of Manufacturing Science and Engineering, 1992, 114(4): 481-488. |

| [23] | LEE K W, WANG S, LU L, et al.Fabrication and characterization of poly (propylene fumarate) scaffolds with controlled pore structures using 3-dimensional printing and injection molding. Tissue Engineering, 2006, 12(10): 2801-2811. |

| [24] | SACHS E, CIMA M, BREDT J, et al.CAD-casting: direct fabrication of ceramic shells and cores by three-dimensional printing.Manufacturing Review (USA), 1992, 5(2): 117-126. |

| [25] | SMAY J E, CESARANO J, LEWIS J A.Colloidal inks for directed assembly of 3-D periodic structures.Langmuir, 2002, 18(14): 5429-5437. |

| [26] | AHN B Y, SHOJI D, HANSEN C J, et al.Printed origami structures.Advanced Materials, 2010, 22(20): 2251-2254. |

| [27] | LI QI, LI BO, ZHOU JI, et al.Robocasting: a novel avenue for engineering complex 3D structures.Journal of Inorganic Materials, 2005, 20(1): 13-20. |

| [28] | CESARANO J, SEGALMAN R, CALVERT P.Robocasting provides moldless fabrication from slurry deposition.Ceramic Industry, 1998, 148(4): 94-102. |

| [29] | STUECKER J N, CESARANO J, HIRSCHFELD D A.Control of the viscous behavior of highly concentrated mullite suspensions for robocasting. Journal of Materials Processing Technology, 2003, 142(2): 318-325. |

| [30] | GRATSON G M, XU M, LEWIS J A.Microperiodic structures: direct writing of three-dimensional webs.Nature, 2004, 428(6981): 386. |

| [31] | BARRY R A, SHEPHERD R F, HANSON J N, et al.Direct-write assembly of 3D hydrogel scaffolds for guided cell growth.Advanced Materials, 2009, 21(23): 2407-2410. |

| [32] | HERSCHEL W H, BULKLEY R.Konsistenzmessungen von gummi-benzollösungen.Kolloid-Zeitschrift, 1926, 39(4): 291-300. |

| [33] | CHANNELL G M, ZUKOSKI C F.Shear and compressive rheology of aggregated alumina suspensions. AIChE Journal, 1997, 43(7): 1700-1708. |

| [34] | TRAPPE V, PRASAD V, CIPELLETTI L, et al.Jamming phase diagram for attractive particles.Nature, 2001, 411(6839): 772-775. |

| [35] | SMAY J E, CESARANO J, TUTTLE B A, et al.Directed colloidal assembly of linear and annular lead zirconate titanate arrays.Journal of the American Ceramic Society, 2004, 87(2): 293-295. |

| [36] | SMAY J E, CESARANO III J, TUTTLE B A, et al.Piezoelectric properties of 3-X periodic Pb(ZrxTi1-x)O3-polymer composites.Journal of Applied Physics, 2002, 92(10): 6119-6127. |

| [37] | LI Q, LEWIS J A.Nanoparticle inks for directed assembly of three-dimensional periodic structures.Advanced Materials, 2003, 15(19): 1639-1643. |

| [38] | RAO R B, KRAFCIK K L, MORALES A M, et al.Microfabricated deposition nozzles for direct-write assembly of three-dimensional periodic structures.Advanced Materials, 2005, 17(3): 289-293. |

| [39] | LEWIS J A, LI Q, RAO R. Biphasic Inks. U.S. Patent 8187500.2012-5-29. |

| [40] | GRAULE T J, GAUCKLER L J, BAADER F H.Direct coagulation casting-a new green shaping technique PT. 1. processing principles.Industrial Ceramics, 1996, 16(1): 31-34. |

| [41] | RHODES S K, LAMBETH R H, GONZALES J, et al.Cationic comb polymer superdispersants for colloidal silica suspensions. Langmuir, 2009, 25(12): 6787-6792. |

| [42] | AHN B Y, DUOSS E B, MOTALA M J, et al.Omnidirectional printing of flexible, stretchable, and spanning silver microelectrodes.Science, 2009, 323(5921): 1590-1593. |

| [43] | GRATSON G M, LEWIS J A.Phase behavior and rheological properties of polyelectrolyte inks for direct-write assembly.Langmuir, 2005, 21(1): 457-464. |

| [44] | XU M, LEWIS J A.Phase behavior and rheological properties of polyamine-rich complexes for direct-write assembly.Langmuir, 2007, 23(25): 12752-12759. |

| [45] | GHOSH S, PARKER S T, WWANG X, et al.Direct-write assembly of microperiodic silk fibroin scaffolds for tissue engineering applications.Advanced Functional Materials, 2008, 18(13): 1883-1889. |

| [46] | DUOSS E B, TWARDOWSKI M, LEWIS J A.Sol-Gel inks for direct-write assembly of functional oxides.Advanced Materials, 2007, 19(21): 3485-3489. |

| [47] | SHEPHERD R F, PANDA P, BAO Z, et al.Stop-flow lithography of colloidal, glass, and silicon microcomponents.Advanced Materials, 2008, 20(24): 4734-4739. |

| [48] | CESARANO III J, KING B H, DENHAM H B. Recent Developments in Robocasting of Ceramics and Multimaterial Deposition. Albuquerque, NM: Sandia National Labs., 1998, SAND98-2195C. |

| [49] | 高濂, 孙静, 刘阳桥. 纳米粉体的分散及表面改性. 北京: 化学工业出版社, 2003: 65-90. |

| [50] | PHILIPP B, DAUTZENBERG H, LINOW K J, et al.Polyelectrolyte complexes-recent developments and open problems.Progress in Polymer Science, 1989, 14(1): 91-172. |

| [51] | AHN B Y, LORANG D J, DUOSS E B, et al.Direct-write assembly of microperiodic planar and spanning ITO microelectrodes.Chemical Communications, 2010, 46(38): 7118-7120. |

| [52] | SUN JING-BO, LI BO, HUANG XUE-GUANG, et al.Direct-write assembly of ceramic three-dimensional structures based on photosensitive inks.Journal of Inorganic Materials, 2009, 24(6): 1147-1150. |

| [53] | SUN JING-BO, LI BO, CAI KUN-PENG, et al.TiO2 photolysis device fabricated by direct ink write assembly.Journal of Inorganic Materials, 2011, 26(3): 300-304. |

| [54] | CAI KUN-PENG, LI YA-YUN, SUN ZHEN-XIN, et al.Preparation of 3D ceramic meshes by direct-write method and modulation of its photocatalytic properties by structure design.Journal of Inorganic Materials, 2012, 27(1): 1-5. |

| [1] | ZHU Wenjie, TANG Lu, LU Jichang, LIU Jiangping, LUO Yongming. Research Progress on Catalytic Oxidation of Volatile Organic Compounds by Perovskite Oxides [J]. Journal of Inorganic Materials, 2025, 40(7): 735-746. |

| [2] | HU Zhichao, YANG Hongyu, YANG Hongcheng, SUN Chengli, YANG Jun, LI Enzhu. Usage of the P-V-L Bond Theory in Regulating Properties of Microwave Dielectric Ceramics [J]. Journal of Inorganic Materials, 2025, 40(6): 609-626. |

| [3] | WU Qiong, SHEN Binglin, ZHANG Maohua, YAO Fangzhou, XING Zhipeng, WANG Ke. Research Progress on Lead-based Textured Piezoelectric Ceramics [J]. Journal of Inorganic Materials, 2025, 40(6): 563-574. |

| [4] | ZHANG Bihui, LIU Xiaoqiang, CHEN Xiangming. Recent Progress of Hybrid Improper Ferroelectrics with Ruddlesden-Popper Structure [J]. Journal of Inorganic Materials, 2025, 40(6): 587-608. |

| [5] | WU Jie, YANG Shuai, WANG Mingwen, LI Jinglei, LI Chunchun, LI Fei. Textured PT-based Piezoelectric Ceramics: Development, Status and Challenge [J]. Journal of Inorganic Materials, 2025, 40(6): 575-586. |

| [6] | JIANG Kun, LI Letian, ZHENG Mupeng, HU Yongming, PAN Qinxue, WU Chaofeng, WANG Ke. Research Progress on Low-temperature Sintering of PZT Ceramics [J]. Journal of Inorganic Materials, 2025, 40(6): 627-638. |

| [7] | TIAN Ruizhi, LAN Zhengyi, YIN Jie, HAO Nanjing, CHEN Hangrong, MA Ming. Microfluidic Technology Based Synthesis of Inorganic Nano-biomaterials: Principles and Progress [J]. Journal of Inorganic Materials, 2025, 40(4): 337-347. |

| [8] | ZHANG Jiguo, WU Tian, ZHAO Xu, YANG Fan, XIA Tian, SUN Shien. Improvement of Cycling Stability of Cathode Materials and Industrialization Process for Sodium-ion Batteries [J]. Journal of Inorganic Materials, 2025, 40(4): 348-362. |

| [9] | YIN Jie, GENG Jiayi, WANG Kanglong, CHEN Zhongming, LIU Xuejian, HUANG Zhengren. Recent Advances in 3D Printing and Densification of SiC Ceramics [J]. Journal of Inorganic Materials, 2025, 40(3): 245-255. |

| [10] | CHEN Guangchang, DUAN Xiaoming, ZHU Jinrong, GONG Qing, CAI Delong, LI Yuhang, YANG Donglei, CHEN Biao, LI Xinmin, DENG Xudong, YU Jin, LIU Boya, HE Peigang, JIA Dechang, ZHOU Yu. Advanced Ceramic Materials in Helicopter Special Structures: Research Progress and Application Prospect [J]. Journal of Inorganic Materials, 2025, 40(3): 225-244. |

| [11] | FAN Xiaobo, ZU Mei, YANG Xiangfei, SONG Ce, CHEN Chen, WANG Zi, LUO Wenhua, CHENG Haifeng. Research Progress on Proton-regulated Electrochemical Ionic Synapses [J]. Journal of Inorganic Materials, 2025, 40(3): 256-270. |

| [12] | HAIREGU Tuxun, GUO Le, DING Jiayi, ZHOU Jiaqi, ZHANG Xueliang, NUERNISHA Alifu. Research Progress of Optical Bioimaging Technology Assisted by Upconversion Fluorescence Probes in Tumor Imaging [J]. Journal of Inorganic Materials, 2025, 40(2): 145-158. |

| [13] | SUN Shujuan, ZHENG Nannan, PAN Haokun, MA Meng, CHEN Jun, HUANG Xiubing. Research Progress on Preparation Methods of Single-atom Catalysts [J]. Journal of Inorganic Materials, 2025, 40(2): 113-127. |

| [14] | TAO Guilong, ZHI Guowei, LUO Tianyou, OUYANG Peidong, YI Xinyan, LI Guoqiang. Progress on Key Technologies of Cavity-structured Thin Film Bulk Acoustic Wave Filter [J]. Journal of Inorganic Materials, 2025, 40(2): 128-144. |

| [15] | ZHOU Fan, TIAN Zhilin, LI Bin. Research Progress on Carbide Ultra-high Temperature Ceramic Anti-ablation Coatings for Thermal Protection System [J]. Journal of Inorganic Materials, 2025, 40(1): 1-16. |

| Viewed | ||||||

|

Full text |

|

|||||

|

Abstract |

|

|||||