Journal of Inorganic Materials ›› 2025, Vol. 40 ›› Issue (9): 971-980.DOI: 10.15541/jim20250031

Special Issue: 【结构材料】陶瓷基复合材料(202512)

• RESEARCH ARTICLE • Previous Articles Next Articles

CHEN Bin( ), REN Ke(

), REN Ke( ), WANG Yiguang

), WANG Yiguang

Received:2025-01-21

Revised:2025-03-11

Published:2025-09-20

Online:2025-03-19

Contact:

REN Ke, assistant professor. E-mail:renke@bit.edu.cn

About author:CHEN Bin (1999-), male, Master candidate. E-mail: 1839412972@qq.com

Supported by:CLC Number:

CHEN Bin, REN Ke, WANG Yiguang. Evolution of Mechanical Properties of Mini-SiCf/SiC Composites at High Temperatures over a Long Period of Time[J]. Journal of Inorganic Materials, 2025, 40(9): 971-980.

| Fiber | Diameter/ μm | C/Si | Oxygen/ % (in atom) | Density/ (g·cm-3) | Linear density/(g·m-1) |

|---|---|---|---|---|---|

| Cansas-Ⅱ | 13±1 | 1.61 | <0.8 | 2.7±0.1 | 0.2 |

Table 1 General properties of Cansas-II SiC fibers

| Fiber | Diameter/ μm | C/Si | Oxygen/ % (in atom) | Density/ (g·cm-3) | Linear density/(g·m-1) |

|---|---|---|---|---|---|

| Cansas-Ⅱ | 13±1 | 1.61 | <0.8 | 2.7±0.1 | 0.2 |

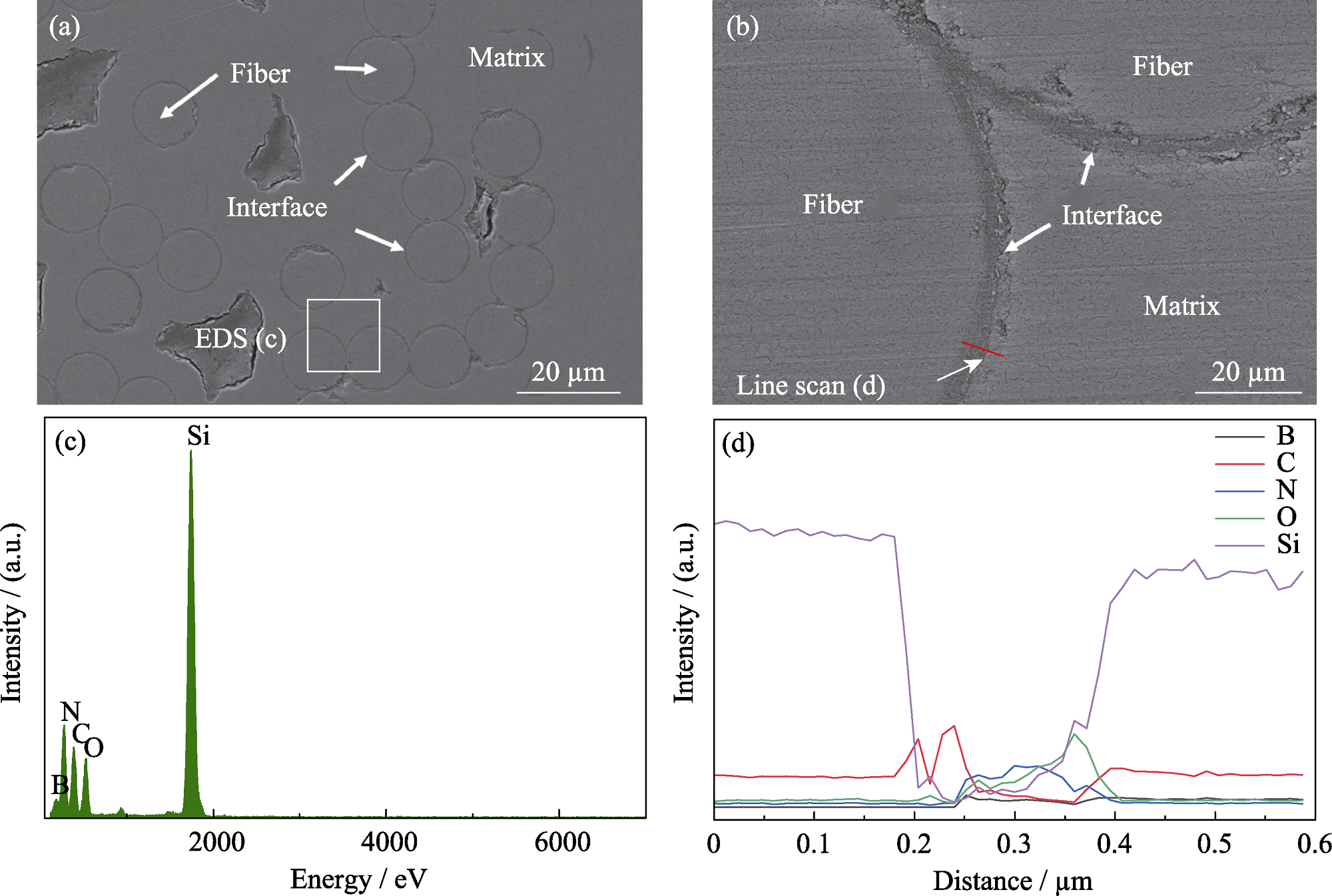

Fig. 2 Cross-sectional morphologies and EDS analyses of mini-SiCf/SiC composites (a) Low magnification; (b) High magnification; (c) EDS results of white square marked in (a); (d) Line scan results of red line shown in (b) Colorful figures are available on website

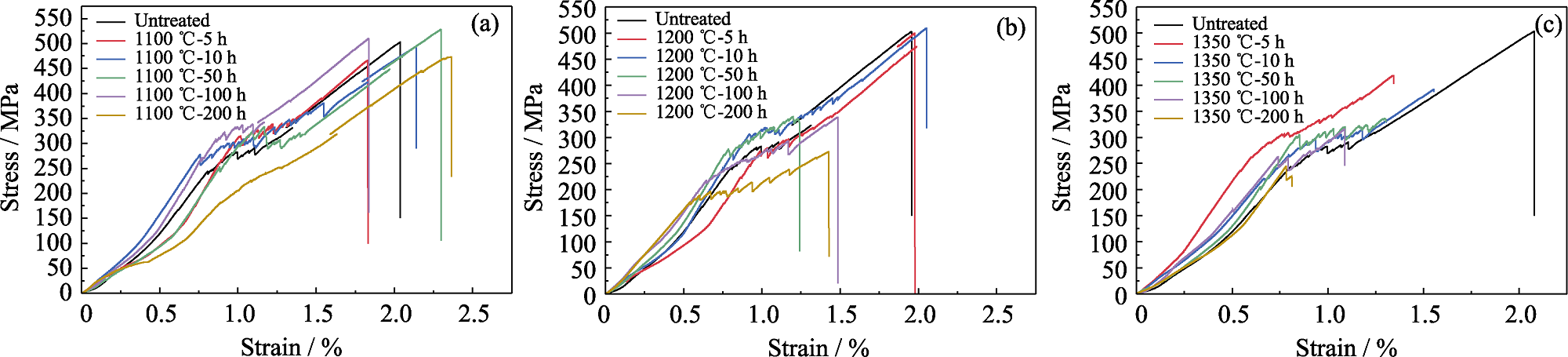

Fig. 3 Stress-strain curves of mini-SiCf/SiC composites after heat treatment at 1100 (a), 1200 (b), and 1350 ℃ (c) for different periods Colorful figures are available on website

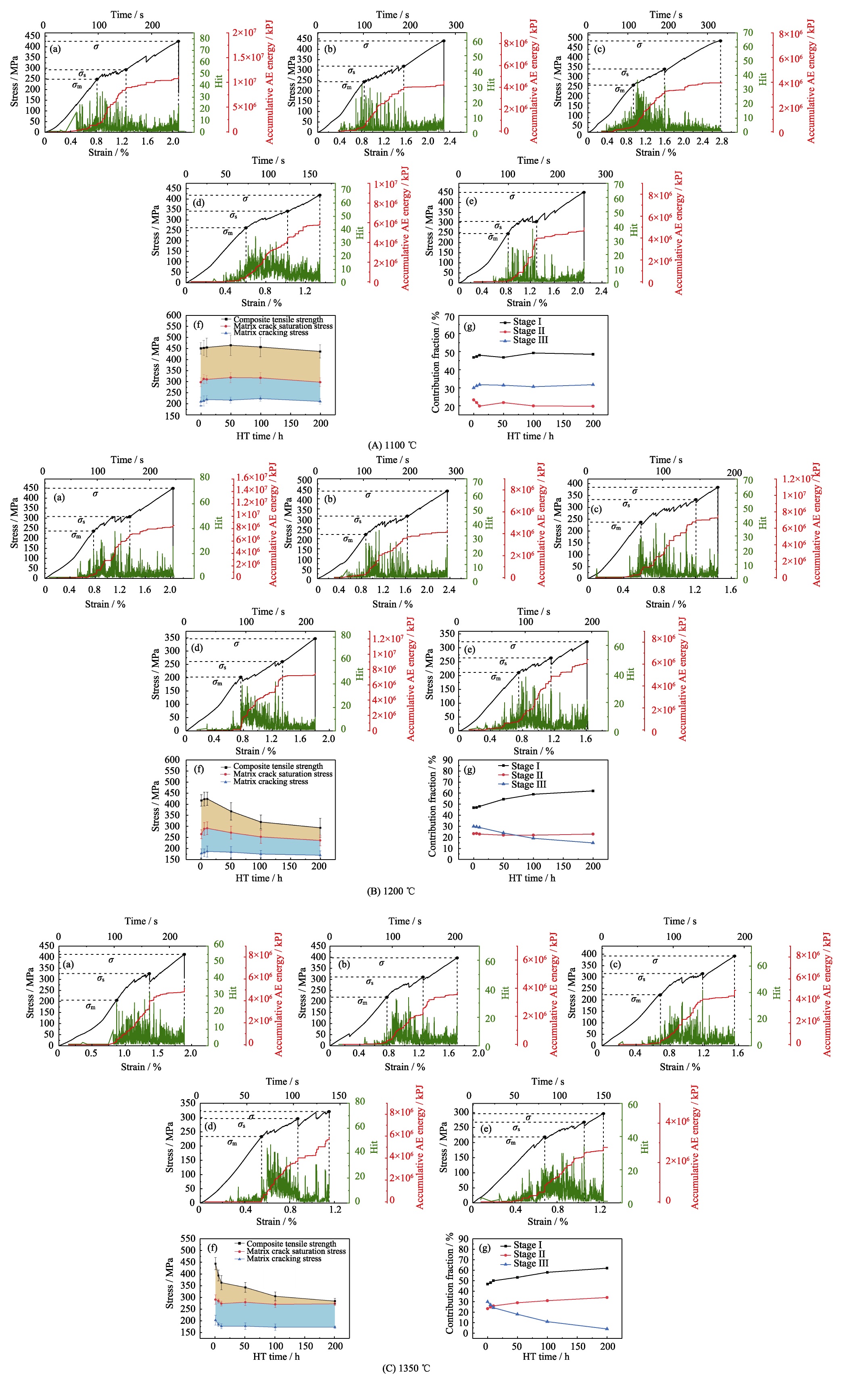

Fig. 4 Tensile stress-strain curves and acoustic emission test results of mini-SiCf/SiC composites after heat treatment at 1100 (A), 1200 (B), and 1350 ℃ (C) for different periods, change trend of the stress of each stage and the contribution fraction of each stage (a-e) Tensile stress-strain curves and acoustic emission test results for 5 (a), 10 (b), 50 (c), 100 (d), and 200 h (e); (f) Change trend of the stress of each stage; (g) Contribution fraction of each stage. Colorful figures are available on website

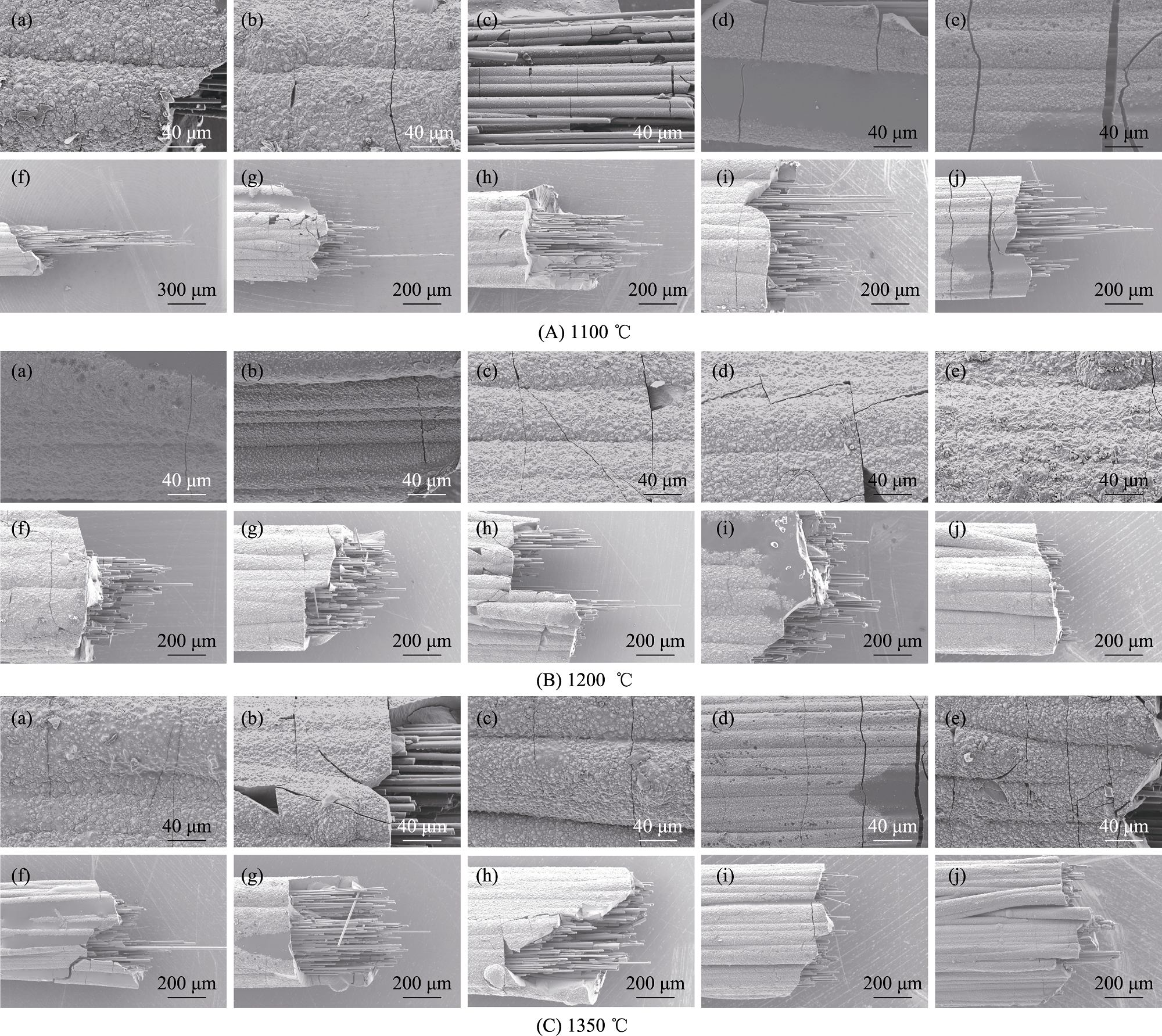

Fig. 5 Morphologies of matrix fracture and fiber pull-out of mini-SiCf/SiC composites after heat treatment at 1100 (A), 1200 (B), 1350 ℃ (C) for different periods (a, f) 5 h; (b, g) 10 h; (c, h) 50 h; (d, i) 100 h; (e, j) 200 h

| HT time/h | SMCS/μm |

|---|---|

| 5 | 254±12 |

| 10 | 247±15 |

| 50 | 253±13 |

| 100 | 246±12 |

| 200 | 248±17 |

Table 2 SMCS after tensile test of mini-SiCf/SiC composites after heat treatment at 1100 ℃ for different periods

| HT time/h | SMCS/μm |

|---|---|

| 5 | 254±12 |

| 10 | 247±15 |

| 50 | 253±13 |

| 100 | 246±12 |

| 200 | 248±17 |

| HT time/h | SMCS/μm |

|---|---|

| 5 | 243±16 |

| 10 | 239±15 |

| 50 | 231±18 |

| 100 | 197±16 |

| 200 | 184±13 |

Table 3 SMCS after tensile test of mini-SiCf/SiC composites after heat treatment at 1200 ℃ for different periods

| HT time/h | SMCS/μm |

|---|---|

| 5 | 243±16 |

| 10 | 239±15 |

| 50 | 231±18 |

| 100 | 197±16 |

| 200 | 184±13 |

| HT time/h | SMCS/μm |

|---|---|

| 5 | 187±20 |

| 10 | 176±15 |

| 50 | 159±17 |

| 100 | 146±13 |

| 200 | 138±12 |

Table 4 SMCS after tensile test of mini-SiCf/SiC composites after heat treatment at 1350 ℃ for different periods

| HT time/h | SMCS/μm |

|---|---|

| 5 | 187±20 |

| 10 | 176±15 |

| 50 | 159±17 |

| 100 | 146±13 |

| 200 | 138±12 |

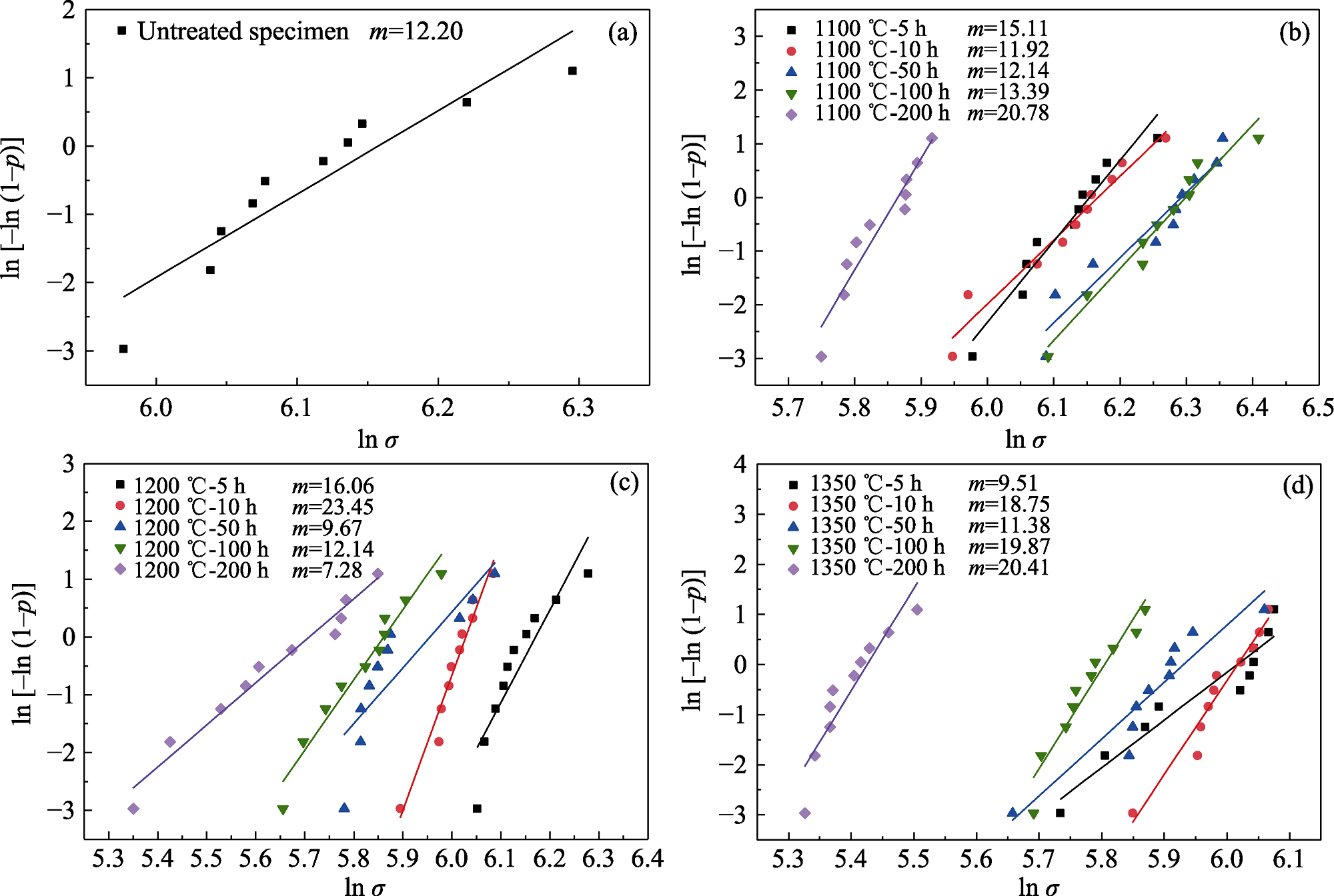

Fig. 6 Weibull distributions of tensile strengths of mini-SiCf/SiC composites after heat treatment at different temperature (a) Untreated specimen; (b) 1100 ℃; (c) 1200 ℃; (d) 1350 ℃

| HT time/h | m | ||

|---|---|---|---|

| 1100 ℃ | 1200 ℃ | 1350 ℃ | |

| 5 | 15.11 | 16.06 | 9.51 |

| 10 | 11.92 | 23.45 | 18.75 |

| 50 | 12.14 | 9.67 | 11.38 |

| 100 | 13.39 | 12.14 | 19.87 |

| 200 | 20.78 | 7.28 | 20.41 |

Table 5 Weibull modulus (m) of distributions of different mini-SiCf/SiC composites after tensile test

| HT time/h | m | ||

|---|---|---|---|

| 1100 ℃ | 1200 ℃ | 1350 ℃ | |

| 5 | 15.11 | 16.06 | 9.51 |

| 10 | 11.92 | 23.45 | 18.75 |

| 50 | 12.14 | 9.67 | 11.38 |

| 100 | 13.39 | 12.14 | 19.87 |

| 200 | 20.78 | 7.28 | 20.41 |

| [1] | LV X X, QI Z, YANG J H, et al. The effect of boron nitride interphase on the thermal stability of SiC fibers. Journal of Alloys and Compounds, 2020, 844: 156193. |

| [2] | 张立同. 纤维增韧碳化硅陶瓷复合材料:模拟, 表征与设计. 北京: 化学工业出版社, 2009. |

| [3] | SHEN X Y, MA Q, XUE Y D, et al. Effects of multilayered interfaces on mechanical damage of SiCf/SiC composites. Journal of Inorganic Materials, 2023, 38(8): 917. |

| [4] | GUAN H Y, ZHANG L, JING K K, et al. Interfacial mechanical properties of the domestic 3rd generation 2.5D SiCf/SiC composite. Journal of Inorganic Materials, 2024, 39(3): 259. |

| [5] | YOU B J, LI B, LI X Q, et al. Thermal shock damage and in-plane shear performance degradation of 2D SiCf/SiC at medium temperature. Journal of Inorganic Materials, 2024, 39(12): 1367. |

| [6] | NASLAIN R. Design, preparation and properties of non-oxide CMCs for application in engines and nuclear reactors: an overview. Composites Science and Technology, 2004, 64(2): 155. |

| [7] | WICAKSONO S, CHAI G B. A review of advances in fatigue and life prediction of fiber-reinforced composites. Proceedings of the Institution of Mechanical Engineers, Part L: Journal of Materials: Design and Applications, 2013, 227(3): 179. |

| [8] |

YUAN Q, SONG Y C. Research and development of continuous SiC fibers and SiCf/SiC composities. Journal of Inorganic Materials, 2016, 31(11): 1157.

DOI |

| [9] | WANG P, LIU F, WANG H, et al. A review of third generation SiC fibers and SiCf/SiC composites. Journal of Materials Science & Technology, 2019, 35(12): 2743. |

| [10] | UDAYAKUMAR A, GANESH A S, RAJA S, et al. Effect of intermediate heat treatment on mechanical properties of SiCf/SiC composites with BN interphase prepared by ICVI. Journal of the European Ceramic Society, 2011, 31(6): 1145. |

| [11] | MA X, YIN X, CAO X, et al. Effect of heat treatment on the mechanical properties of SiCf/BN/SiC fabricated by CVI. Ceramics International, 2016, 42(2): 3652. |

| [12] | ZHAO S, ZHOU X, YU J, et al. Effect of heat treatment on microstructure and mechanical properties of PIP-SiC/SiC composites. Materials Science and Engineering: A, 2013, 559: 808. |

| [13] | ZHAO S, ZHOU X, YU J. Effect of heat treatment on the mechanical properties of PIP-SiC/SiC composites fabricated with a consolidation process. Ceramics International, 2014, 40(3): 3879. |

| [14] | NASLAIN R, LAMON J, PAILLER R, et al. Micro/mini composites: a useful approach to the design and development of non-oxide CMCs. Composites Part A: Applied Science and Manufacturing, 1999, 30(4): 537. |

| [15] | QIAO S R, HAN D, LUO G Q. Mini-composites C/SiC tensile strength at elevated temperature in vacuum. Key Engineering Materials, 2005, 297: 435. |

| [16] | PADMAVATHI N, KUMARI S, PRASAD V V B, et al. Processing of carbon-fiber reinforced (SiC+ZrC) mini-composites by soft-solution approach and their characterization. Ceramics International, 2009, 35(8): 3447. |

| [17] | FLORES O, BORDIA R K, NESTLER D, et al. Ceramic fibers based on SiC and SiCN systems: current research, development, and commercial status. Advanced Engineering Materials, 2014, 16(6): 621. |

| [18] | GONCZY S T, SPRANDEL R C, FABER K T. Tensile tests of miniature fiber reinforced ceramic composites for screening process-property relations//SINGH J P. Proceedings of the 21st Annual Conference on Composites, Advanced Ceramics, Materials, and Structures—A:Ceramic Engineering and Science Proceedings. Hoboken: John Wiley & Sons, Inc., 1997: 729. |

| [19] |

赵文青, 齐哲, 吕晓旭, 等. 界面层对CVI-mini SiCf/SiC复合材料力学性能的影响. 材料工程, 2021, 49(7): 71.

DOI |

| [20] | HAN X, GAO X, SONG Y. Effect of heat treatment on the microstructure and mechanical behavior of SiCf/SiC mini-composites. Materials Science and Engineering: A, 2019, 746: 94. |

| [21] | SUZUKI H, TAKEMOTO M, ONO K. A study of fracture dynamics in a model composite by acoustic emission signal processing. Journal of Acoustic Emission, 1993, 11(3): 117. |

| [22] | HUANG X P, WANG B, YANG C P, et al. Evaluating damage evolution of three-dimension needled C/SiC composite based on acoustic emission signal analysis. Journal of Inorganic Materials, 2018, 33(6): 609. |

| [23] | MEI H, CHENG L. Thermal cycling response behavior of ceramic matrix composites under load and displacement constraints. Materials Science and Engineering: A, 2008, 486(1/2): 235. |

| [24] | YANG X F, KNOWLES K M. On the first-matrix-cracking stress in unidirectional fiber-reinforced brittle materials. Journal of Materials Research, 1993, 8(2): 371. |

| [25] | LARA-CURZIO E, RUSS C M. On the matrix cracking stress and the redistribution of internal stresses in brittle-matrix composites. Materials Science and Engineering: A, 1998, 250(2): 270. |

| [26] | WANG Y Q, ZHANG L T. Tensile behaviour and damage evolution of a C/SiC minicomposite fabricated by chemical vapour infiltration. Advanced Composites Letters, 2010, 19(2): 85. |

| [27] | SU K, CHEN Z, LI L, et al. Effects of single-phase and co-deposited inter-phases on mechanical hysteresis behavior in T700TM mini-Cf/SiC composites. International Journal of Fatigue, 2023, 168: 107473. |

| [28] | 福建立亚新材有限公司. Cansas 3300系列连续碳化硅纤维: Q/LY 20010––2001. 福建立亚新材有限公司企业标准, 2021. |

| [29] | CHEN X, SUN Z, NIU X, et al. Evolution of the structure and mechanical performance of Cansas-II SiC fibres after thermal treatment. Ceramics International, 2021, 47(19): 27217. |

| [1] | WU Xiaochen, ZHENG Ruixiao, LI Lu, MA Haolin, ZHAO Peihang, MA Chaoli. Research Progress on In-situ Monitoring of Damage Behavior of SiCf/SiC Ceramic Matrix Composites at High Temperature Environments [J]. Journal of Inorganic Materials, 2024, 39(6): 609-622. |

| [2] | SHEN Xuanyi, MA Qin, XUE Yudong, LIAO Chunjin, ZHU Min, ZHANG Xiangyu, YANG Jinshan, DONG Shaoming. Effects of Multilayered Interfaces on Mechanical Damage of SiCf/SiC Composites [J]. Journal of Inorganic Materials, 2023, 38(8): 917-922. |

| [3] | WU Shuang, GOU Yanzi, WANG Yongshou, SONG Quzhi, ZHANG Qingyu, WANG Yingde. Effect of Heat Treatment on Composition, Microstructure and Mechanical Property of Domestic KD-SA SiC Fibers [J]. Journal of Inorganic Materials, 2023, 38(5): 569-576. |

| [4] | ZHANG Yachen, MENG Jia, CAI Kun, SHENG Xiaochen, LE Jun, SONG Lixin. Bending Failure Mechanism Study of Si-Cr-Ti High Temperature Oxidation Resistance Coating via Acoustic Emission Technique [J]. Journal of Inorganic Materials, 2021, 36(11): 1185-1192. |

| [5] | LI Longbin, XUE Yudong, HU Jianbao, YANG Jinshan, ZHANG Xiangyu, DONG Shaoming. Influence of SiC Nanowires on the Damage Evolution of SiCf/SiC Composites [J]. Journal of Inorganic Materials, 2021, 36(10): 1111-1117. |

| [6] | WEI Yuquan,YANG Yong,LIU Meng,LI Qile,HUANG Zhengren. Effect of High Temperature Heat Treatment on Phase Composition and Microstructure of SiBCN/HfC Ceramic Composites [J]. Journal of Inorganic Materials, 2020, 35(8): 931-938. |

| [7] | ZHANG Yongzhen, TONG Xiaoyan, YAO Leijiang, LI Bin, BAI Guodong. Acoustic Emission Pattern Recognition on Tensile Damage Process of C/SiC Composites Using an Improved Genetic Algorithm [J]. Journal of Inorganic Materials, 2020, 35(5): 593-600. |

| [8] | FU Ya-Kang,WENG Jie,LIU Yao-Wen,ZHANG Ke-Hong. hBMP-2 Contained Composite Coatings on Titanium Mesh Surface: Preparation and hBMP-2 Release [J]. Journal of Inorganic Materials, 2020, 35(2): 173-178. |

| [9] | LÜ Xiaoxu, JIANG Zhuyu, ZHOU Yiran, QI Zhe, ZHAO Wenqing, JIAO Jian. Effect of BN/SiC Multilayered Interphases on Mechanical Properties of SiC Fibers and Minicomposites by PIP [J]. Journal of Inorganic Materials, 2020, 35(10): 1099-1104. |

| [10] | WANG Dan-Dan, TIAN Wu-Bian, DING Jian-Xiang, MA Ai-Bin, ZHANG Pei-Gen, HE Wei, SUN Zheng-Ming. Ag/Ti3AlC2 Composites Prepared by Equal Channel Angular Pressing Followed by Heat Treatment [J]. Journal of Inorganic Materials, 2020, 35(1): 46-52. |

| [11] | LIAO Chun-Jing, DONG Shao-Ming, JIN Xi-Hai, HU Jian-Bao, ZHANG Xiang-Yu, WU Hui-Xia. Deposition Temperature and Heat Treatment on Silicon Nitride Coating Deposited by LPCVD [J]. Journal of Inorganic Materials, 2019, 34(11): 1231-1237. |

| [12] | HUANG Xi-Peng, WANG Bo, YANG Cheng-Peng, PAN Wen-Ge, LIU Xiao-Ying. Evaluating Damage Evolution of Three-dimension Needled C/SiC Composite Based on Acoustic Emission Signal Analysis [J]. Journal of Inorganic Materials, 2018, 33(6): 609-616. |

| [13] | WANG Hao, LUO Yong-Chun, DENG An-Qiang, ZHAO Lei, JIANG Wan-Ting. Annealing Temperature on Structural and Electrochemical Property of Mg-free La-Y-Ni Based A2B7-type Hydrogen Storage Alloys [J]. Journal of Inorganic Materials, 2018, 33(4): 434-440. |

| [14] | LI Shu-Ling, YUAN Xian-Xia, KONG Hai-Chuan, XU Jin, MA Zi-Feng. Fe-PPy-TsOH/C as Cathode Catalyst for Proton Exchange Membrane Fuel Cells [J]. Journal of Inorganic Materials, 2017, 32(4): 393-399. |

| [15] | ZHU Ping, CAI Ting, HAN Gao-Yi, XIONG Ji-Jun. Preparation and Electrochemical Performance of PPy/GO-RuO2 Film Electrode for Micro-supercapacitor [J]. Journal of Inorganic Materials, 2015, 30(5): 505-510. |

| Viewed | ||||||

|

Full text |

|

|||||

|

Abstract |

|

|||||