Journal of Inorganic Materials ›› 2020, Vol. 35 ›› Issue (5): 593-600.DOI: 10.15541/jim20190213

Special Issue: 计算材料论文精选(2020)

Previous Articles Next Articles

ZHANG Yongzhen1,2,TONG Xiaoyan1,YAO Leijiang1( ),LI Bin1,BAI Guodong1,2

),LI Bin1,BAI Guodong1,2

Received:2019-05-09

Revised:2019-07-30

Published:2020-05-20

Online:2019-09-12

Supported by:CLC Number:

ZHANG Yongzhen, TONG Xiaoyan, YAO Leijiang, LI Bin, BAI Guodong. Acoustic Emission Pattern Recognition on Tensile Damage Process of C/SiC Composites Using an Improved Genetic Algorithm[J]. Journal of Inorganic Materials, 2020, 35(5): 593-600.

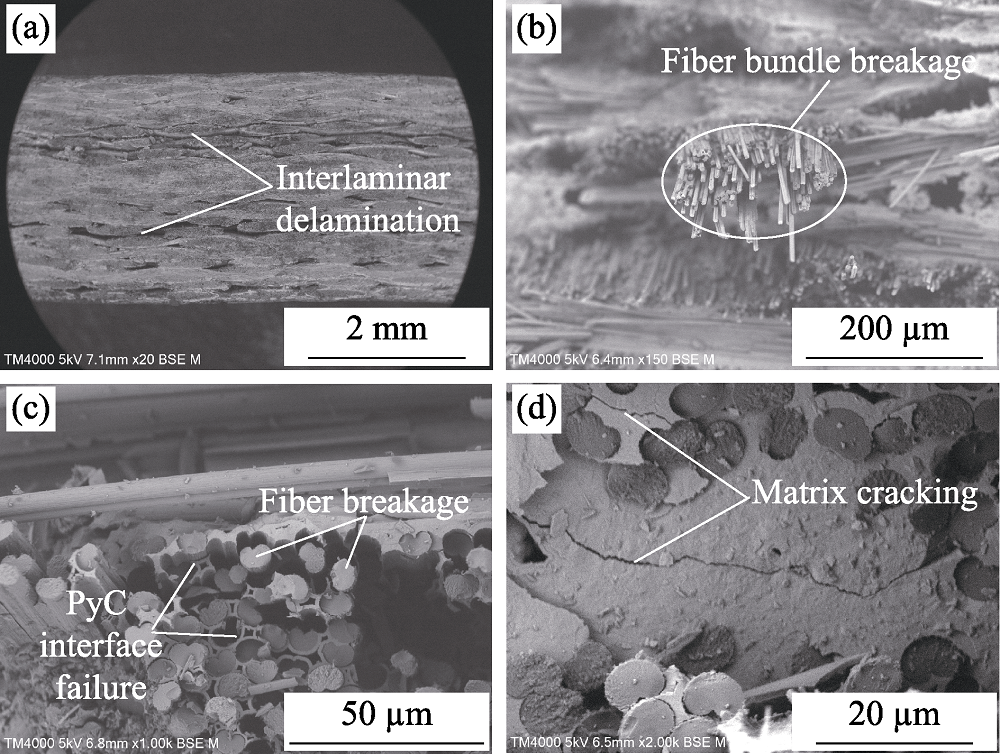

Fig. 7 Fracture SEM images of specimen (a) Interlaminar delamination; (b) Fiber bundle breakage; (c) Fiber breakage & PyC interface failure; (d) Matrix cracking

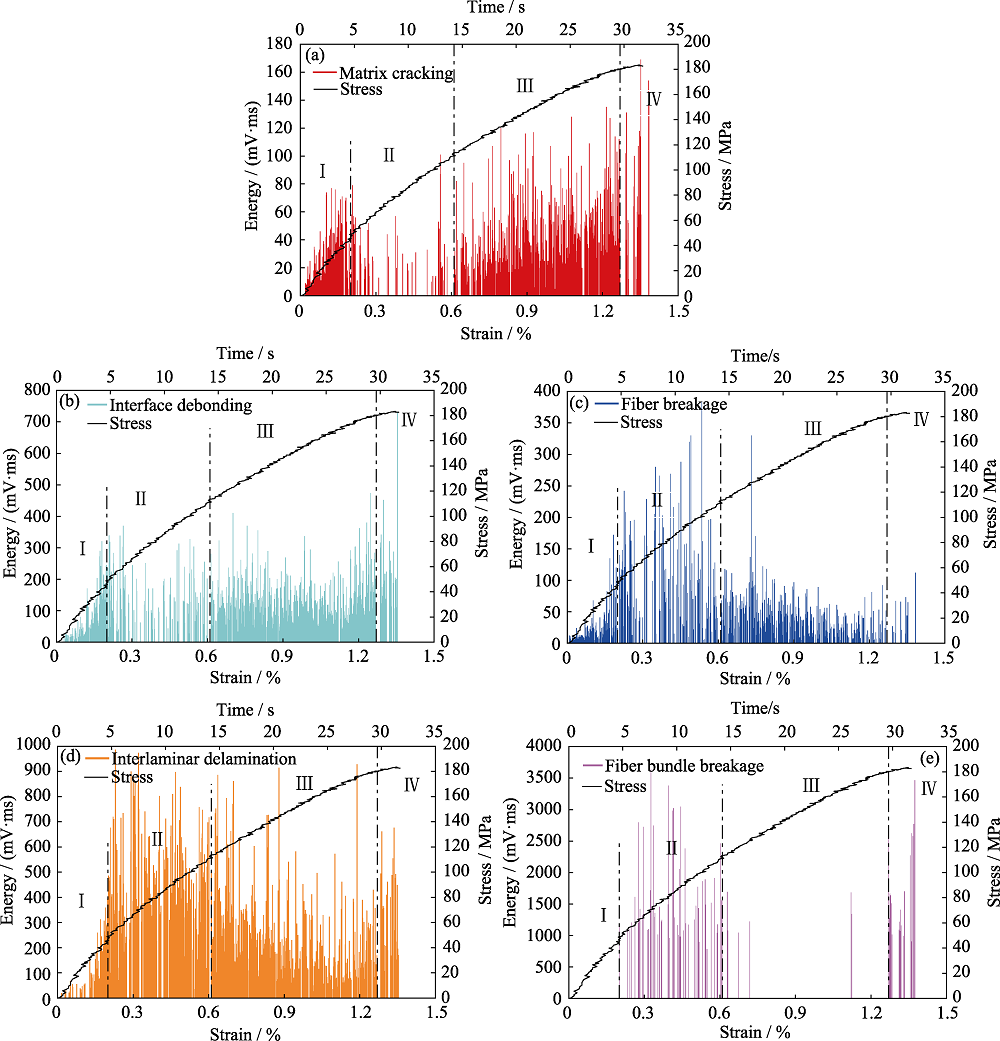

| Cluster | Count | Energy/ (mV·ms) | Amplitude/ mV | Average frequency/ kHz | Damage mode |

|---|---|---|---|---|---|

| 1 | 182 | 28 | 63 | 112 | Matrix cracking |

| 2 | 596 | 90 | 71 | 136 | Interface failure |

| 3 | 303 | 42 | 66 | 189 | Fiber breakage |

| 4 | 1463 | 237 | 77 | 167 | Interlaminar delamination |

| 5 | 10703 | 1628 | 82 | 188 | Fiber bundle breakage |

Table 1 Numerical values of the clustering centers

| Cluster | Count | Energy/ (mV·ms) | Amplitude/ mV | Average frequency/ kHz | Damage mode |

|---|---|---|---|---|---|

| 1 | 182 | 28 | 63 | 112 | Matrix cracking |

| 2 | 596 | 90 | 71 | 136 | Interface failure |

| 3 | 303 | 42 | 66 | 189 | Fiber breakage |

| 4 | 1463 | 237 | 77 | 167 | Interlaminar delamination |

| 5 | 10703 | 1628 | 82 | 188 | Fiber bundle breakage |

Fig. 10 Energy distributions of different damage modes during the tensile test (a) Matrix cracking; (b) Interface debonding; (c) Fiber breakage;(d) Interlaminar delamination; (e) Fiber bundle breakage

| [1] | NASLAIN R . Design, preparation and properties of non-oxide CMCs for application in engines and nuclear reactors: an overview. Composites Science and Technology, 2004,64(2):155-170. |

| [2] | CHRISTIN F . Design, fabrication, and application of thermostructural composites (TSC) like C/C, C/SiC, and SiC/SiC composites. Advanced Engineering Materials, 2002,4(12):903-912. |

| [3] | ZHANG LITONG, CHENG LAIFEI . Discussion on strategies of sustainable development of continuous fiber ceramic matrix composites. Acta Materiae Compositae Sinica, 2007,24(2):1-6. |

| [4] |

MORSCHER G N, MAILLET E . Nondestructive evaluation - use of acoustic emission for CMCs. Comprehensive Composite Materials II, 2018,5:308-324.

DOI URL PMID |

| [5] | ZARIF KARIMI N, MINAK G, KIANFAR P . Analysis of damage mechanisms in drilling of composite materials by acoustic emission. Composite Structures, 2015,131:107-114. |

| [6] | MAILLET E, BAKER C, MORSCHER G N , et al. Feasibility and limitations of damage identification in composite materials using acoustic emission. Composites Part A: Applied Science and Manufacturing, 2015,75:77-83. |

| [7] | MORIZET N, GODIN N, TANG J , et al. Classification of acoustic emission signals using wavelets and random forests: application to localized corrosion. Mechanical Systems & Signal Processing, 2016, 70- 71:1026-1037. |

| [8] |

MEI HUI, SUN YUYAO, ZHANG LIDONG , et al. Acoustic emission characterization of fracture toughness for fiber reinforced ceramic matrix composites. Materials Science and Engineering: A (Structural Materials: Properties, Microstructure and Processing), 2013,560:372-376.

DOI URL |

| [9] | MOMON S, GODIN N, REYNAUD P , et al. Unsupervised and supervised classification of AE data collected during fatigue test on CMC at high temperature. Composites Part A: Applied Science and Manufacturing, 2012,43(2):1-260. |

| [10] | TONG XIAOYAN, ZHANG JIALI, YAO LEIJIANG , et al. Cluster analysis of acoustic emission signals of 2D-C/SiC under tensile loading. Chinese Journal of Solid Mechanics, 2014,35(2):109-114. |

| [11] |

HUANG XIPENG, WANG BO, YANG CHENGPENG , et al. Evaluating damage evolution of three-dimension needled C/SiC composite based on acoustic emission signal analysis. Journal of Inorganic Materials, 2018,33(6):609-616.

DOI URL |

| [12] | HUANG XIPENG, WANG BO, YANG CHENGPENG , et al. Damage evolution of C/SiC composite materials with different densities based on acoustic emission signal analysis. Acta Materiae Compositae Sinica, 2019,36(2):425-433. |

| [13] | HARTIGAN J A, WONG M A . Algorithm AS 136: A k-means clustering algorithm. Journal of the Royal Statistical Society. Series C (Applied Statistics), 1979,28(1):100-108. |

| [14] | HOLLAND J H . Genetic algorithms and the optimal allocation of trials. Siam Journal on Computing, 1973,2(2):88-105. |

| [15] | TANG WENYAN . Research and Application of Genetic Algorithm in Structural Optimization. Dalian: Doctoral Thesis of Dalian University of Technology, 2002. |

| [16] | REN ZIWU, SAN YE . Improved adaptive genetic algorithm and its application research in parameter identification. Journal of System Simulation, 2006,18(1):41-43. |

| [17] |

MOEVUS M, GODIN N, R’MILI M , et al. Analysis of damage mechanisms and associated acoustic emission in two SiCf/[Si-B-C] composites exhibiting different tensile behaviours. Part II: Unsupervised acoustic emission data clustering. Composites Science and Technology, 2008,68(6):1258-1265.

DOI URL |

| [18] | ANASTASSOPOULOS A A, PHILIPPIDIS T P . Clustering methodology for the evaluation of acoustic emission from composites. Journal of Acoustic Emission, 1995,13(1/2):11-22. |

| [19] | ANASTASSOPOULOS A A, PHILIPPIDIS T P, PAIPETIS S A . Failure mechanism identification in composite materials by means of acoustic emission: Is it possible. Nondestructive testing, 1996: 143-149. |

| [20] |

DAVIES D L, BOULDIN D W . A cluster separation measure. IEEE Transactions on Pattern Analysis and Machine Intelligence. 1979,1(2):224-227.

URL PMID |

| [21] |

MILLIGAN G W, COOPER M C . An examination of procedures for determining the number of clusters in a data set. Psychometrika, 1985,50(2):159-179.

DOI URL PMID |

| [22] | CALINSKI T, HARABASZ J . A dendrite method for cluster analysis. Communications in Statistics, 1974,3(1):1-27. |

| [23] |

LI L, LOMOV S V, XIONG Y , et al. Cluster analysis of acoustic emission signals for 2D and 3D woven glass/epoxy composites. Composite Structures, 2014,116(1):286-299.

DOI URL |

| [24] |

ECH-CHOUDANY Y, ASSARAR M, SCIDA D , et al. Unsupervised clustering for building a learning database of acoustic emission signals to identify damage mechanisms in unidirectional laminates. Applied Acoustics, 2017,123:123-132.

DOI URL |

| [25] | YANG CHENGPENG, JIAO GUIQIONG, WANG BO . Uniaxial tensile stress-strain behavior and strength of plain woven C/SiC composite. Chinese Journal of Theoretical and Applied Mechanics, 2011,43(2):330-337. |

| [26] | GUAN GUOYANG, JIAO GUIQIONG, ZHANG ZENGGUANG . Uniaxial macro-mechanical property and failure mode of a 2D-woven C/SiC composite. Acta Materiae Compositae Sinica, 2005,22(4):81-85. |

| [27] |

CHANG YANJUN, JIAO GUIQIONG, TAO YONGQIANG , et al. Damage behavior of 2.5D-C/SiC composites under tensile loading. Journal of Inorganic Materials, 2008,23(3):509-514.

DOI URL |

| [28] | MEI HUI, CHENG LAIFEI, ZHANG LITONG , et al. Damage evolution and microstructural characterization of a cross-woven C/SiC composite under tensile loading. Journal of the Chinese Ceramic Society, 2007,35(2):137-143. |

| [29] |

WANG M, LAIRD C . Characterization of microstructure and tensile behavior of a cross-woven C/SiC composite. Acta Materialia, 1996,44(4):1371-1387.

DOI URL |

| [30] | FANG PENG, CHENG LAIFEI, ZHANG LITONG , et al. Acoustic emission characteristics of C/SiC composite during tensile test. Nondestructive Testing, 2006,28(7):358-361. |

| [31] | QIAO SHENGRU, DU SHUANGMING, JI GANGCHANG , et al. Damage mechanism of 3D-C/SiC composite. Journal of Mechanical Strength, 2004,26(3):307-312. |

| [32] |

NIE J, XU Y, ZHANG L , et al. Microstructure and tensile behavior of multiply needled C/SiC composite fabricated by chemical vapor infiltration. Journal of Materials Processing Technology, 2009,209(1):572-576.

DOI URL |

| [33] | WANG YIQIANG, ZHANG LITONG, CHENG LAIFEI . Effects of heat treatment on the tensile behavior and damage evolution of a 3D C/SiC composite. International Journal of Modern Physics B, 2010,24(15/16):2591-2596. |

| [34] | LI L B, SONG Y D, SUN Y C . Modeling the tensile behavior of cross-ply C/SiC ceramic-matrix composites. Mechanics of Composite Materials, 2015,51(3):359-376. |

| [1] | CHEN Yi, QIU Haipeng, CHEN Mingwei, XU Hao, CUI Heng. SiC/SiC Composite: Matrix Boron Modification and Mechanical Properties [J]. Journal of Inorganic Materials, 2025, 40(5): 504-510. |

| [2] | MU Shuang, MA Qin, ZHANG Yu, SHEN Xu, YANG Jinshan, DONG Shaoming. Oxidation Behavior of Yb2Si2O7 Modified SiC/SiC Mini-composites [J]. Journal of Inorganic Materials, 2025, 40(3): 323-328. |

| [3] | ZHANG Li, GUAN Haoyang, ZHENG Qining, HONG Zhiliang, WANG Jiaxuan, XING Ning, LI Mei, LIU Yongsheng, ZHANG Chengyu. Creep Properties and Damage Mechanisms of SiCf/SiC-SiYBC Prepared by Melt Infiltration [J]. Journal of Inorganic Materials, 2025, 40(1): 23-30. |

| [4] | WANG Xu, LI Xiang, KOU Huamin, FANG Wei, WU Qinghui, SU Liangbi. Effect of Doping with Different Concentrations of Y3+ Ions on the Properties of CaF2 Crystals [J]. Journal of Inorganic Materials, 2024, 39(9): 1029-1034. |

| [5] | QUAN Wenxin, YU Yiping, FANG Bing, LI Wei, WANG Song. Oxidation Behavior and Meso-macro Model of Tubular C/SiC Composites in High-temperature Environment [J]. Journal of Inorganic Materials, 2024, 39(8): 920-928. |

| [6] | JIANG Lingyi, PANG Shengyang, YANG Chao, ZHANG Yue, HU Chenglong, TANG Sufang. Preparation and Oxidation Behaviors of C/SiC-BN Composites [J]. Journal of Inorganic Materials, 2024, 39(7): 779-786. |

| [7] | WU Xiaochen, ZHENG Ruixiao, LI Lu, MA Haolin, ZHAO Peihang, MA Chaoli. Research Progress on In-situ Monitoring of Damage Behavior of SiCf/SiC Ceramic Matrix Composites at High Temperature Environments [J]. Journal of Inorganic Materials, 2024, 39(6): 609-622. |

| [8] | FANG Guangwu, XIE Haoyuan, ZHANG Huajun, GAO Xiguang, SONG Yingdong. Progress of Damage Coupling Mechanism and Integrated Design Method for CMC-EBC [J]. Journal of Inorganic Materials, 2024, 39(6): 647-661. |

| [9] | LI Guangyu, YUE Yifan, WANG Bo, ZHANG Chengyu, SUO Tao, LI Yulong. Damage of 2D-SiC/SiC Composites under Projectile Impact and Tensile Properties after Impact [J]. Journal of Inorganic Materials, 2024, 39(5): 494-500. |

| [10] | WU Jun, XU Peifei, JING Rui, ZHANG Dahai, FEI Qingguo. Experimental Study on Low-velocity Impact and Residual Strength of SiC/SiC Composite Laminates [J]. Journal of Inorganic Materials, 2024, 39(1): 51-60. |

| [11] | SHEN Xuanyi, MA Qin, XUE Yudong, LIAO Chunjin, ZHU Min, ZHANG Xiangyu, YANG Jinshan, DONG Shaoming. Effects of Multilayered Interfaces on Mechanical Damage of SiCf/SiC Composites [J]. Journal of Inorganic Materials, 2023, 38(8): 917-922. |

| [12] | JIN Sai, LIU Xiaogen, QI Shuang, ZHAO Runchang, LI Zhijun. Fused Silica Glass: Laser-induced Damage on Bending Strength Weakening and Safety Design [J]. Journal of Inorganic Materials, 2023, 38(6): 671-677. |

| [13] | WANG Huajin, KOU Huamin, WANG Yongzhe, JIANG Dapeng, ZHANG Bo, QIAN Xiaobo, WANG Jingya, ZHU Linling, ZENG Aijun, YANG Qiuhong, SU Liangbi. Irradiation Damage of CaF2 with Different Yttrium Concentrations under 193 nm Laser [J]. Journal of Inorganic Materials, 2023, 38(2): 219-224. |

| [14] | OUYANG Qin, WANG Yanfei, XU Jian, LI Yinsheng, PEI Xueliang, MO Gaoming, LI Mian, LI Peng, ZHOU Xiaobing, GE Fangfang, ZHANG Chonghong, HE Liu, YANG Lei, HUANG Zhengren, CHAI Zhifang, ZHAN Wenlong, HUANG Qing. Research Progress of SiC Fiber Reinforced SiC Composites for Nuclear Application [J]. Journal of Inorganic Materials, 2022, 37(8): 821-840. |

| [15] | WEI Tingting, GAO Xiguang, SONG Yingdong. Response of 2D SiC/SiC Composites Resistivity to Service Environments [J]. Journal of Inorganic Materials, 2022, 37(4): 420-426. |

| Viewed | ||||||

|

Full text |

|

|||||

|

Abstract |

|

|||||