Journal of Inorganic Materials ›› 2025, Vol. 40 ›› Issue (12): 1379-1386.DOI: 10.15541/jim20250080

• RESEARCH ARTICLE • Previous Articles Next Articles

YI Guogang1,2( ), WU Yaoying2, ZU Xihong2(

), WU Yaoying2, ZU Xihong2( )

)

Received:2025-02-24

Revised:2025-05-16

Published:2025-12-20

Online:2025-06-10

Contact:

ZU Xihong, professor. E-mail: xhzu@gdut.edu.cnAbout author:YI Guogang (1982-), male, professor. E-mail: tadd.yi@gdnhec.com

Supported by:CLC Number:

YI Guogang, WU Yaoying, ZU Xihong. Non-solvent and Low-temperature Preparation of Porous Silicon-carbon Anodes for Enhanced Lithium Storage[J]. Journal of Inorganic Materials, 2025, 40(12): 1379-1386.

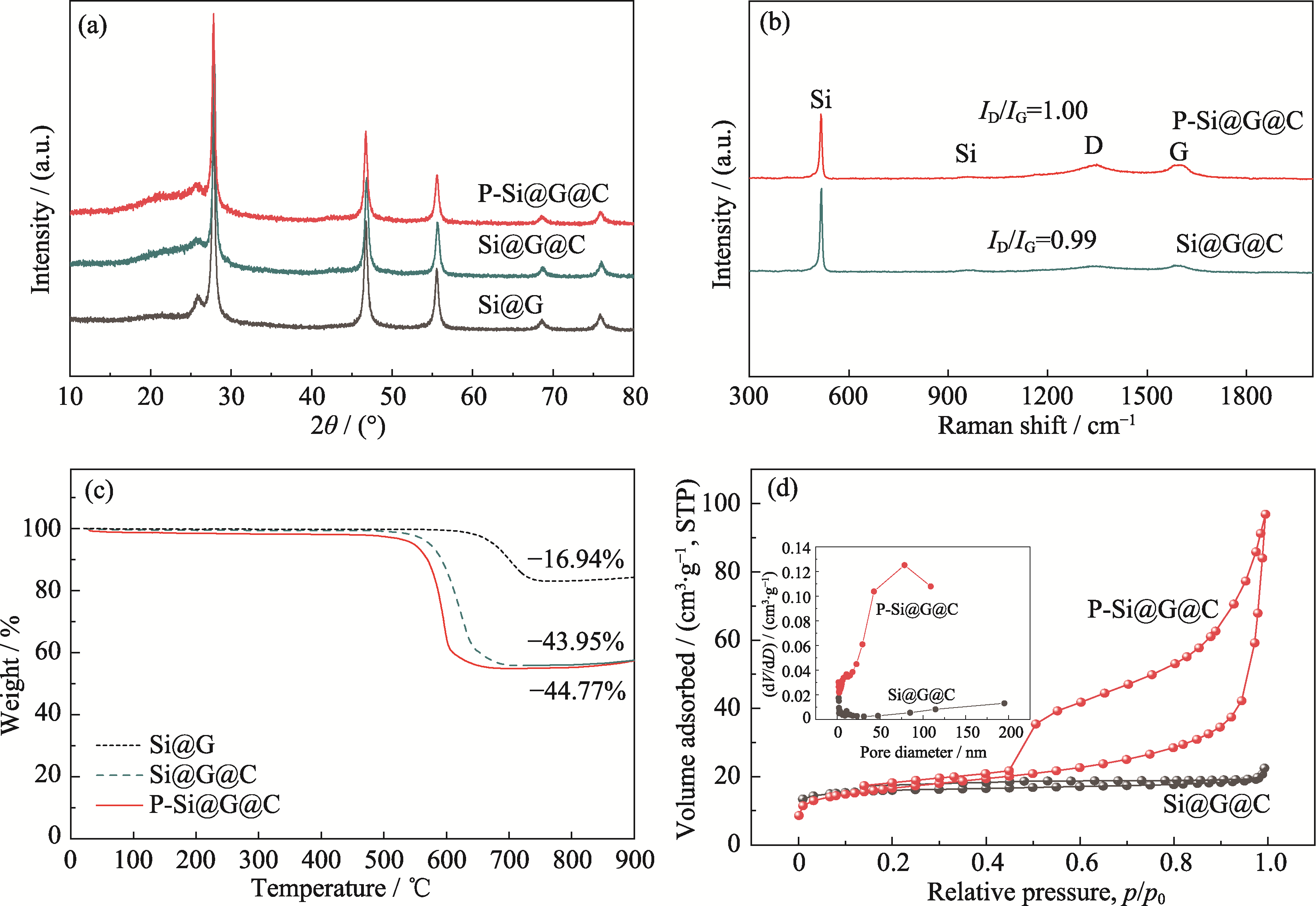

Fig. 3 Structure characterization of different composite materials (a) XRD patterns; (b) Raman spectra; (c) Thermogravimetric curves; (d) N2 adsorption-desorption isotherms

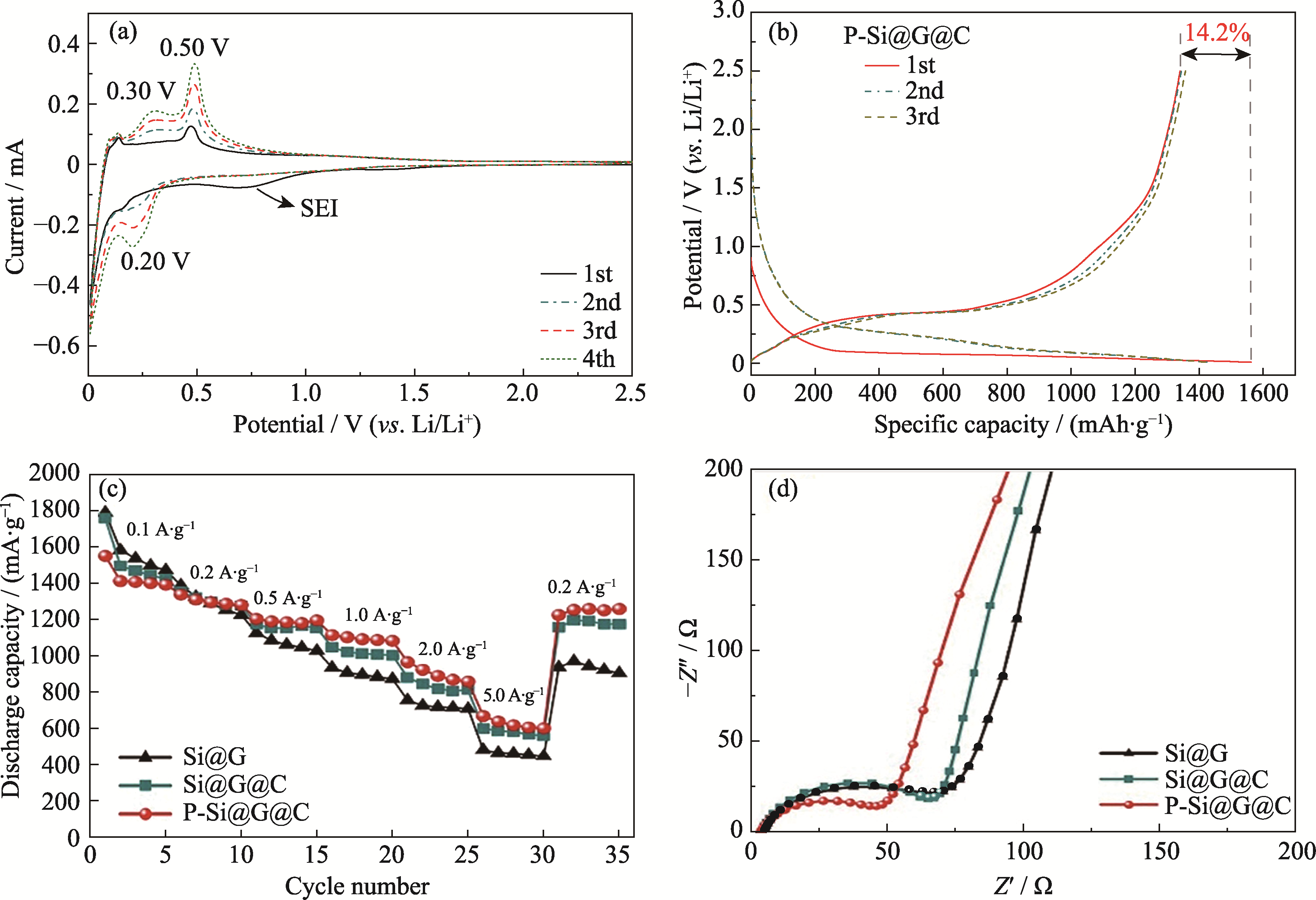

Fig. 5 Electrochemical performance of batteries with different anode materials (a) CV curves of initial 4 cycles of P-Si@G@C battery; (b) Charging-discharging curves of initial 3 cycles of P-Si@G@C battery; (c) Rate performances and (d) EIS spectra of Si@G, Si@G@C and P-Si@G@C batteries

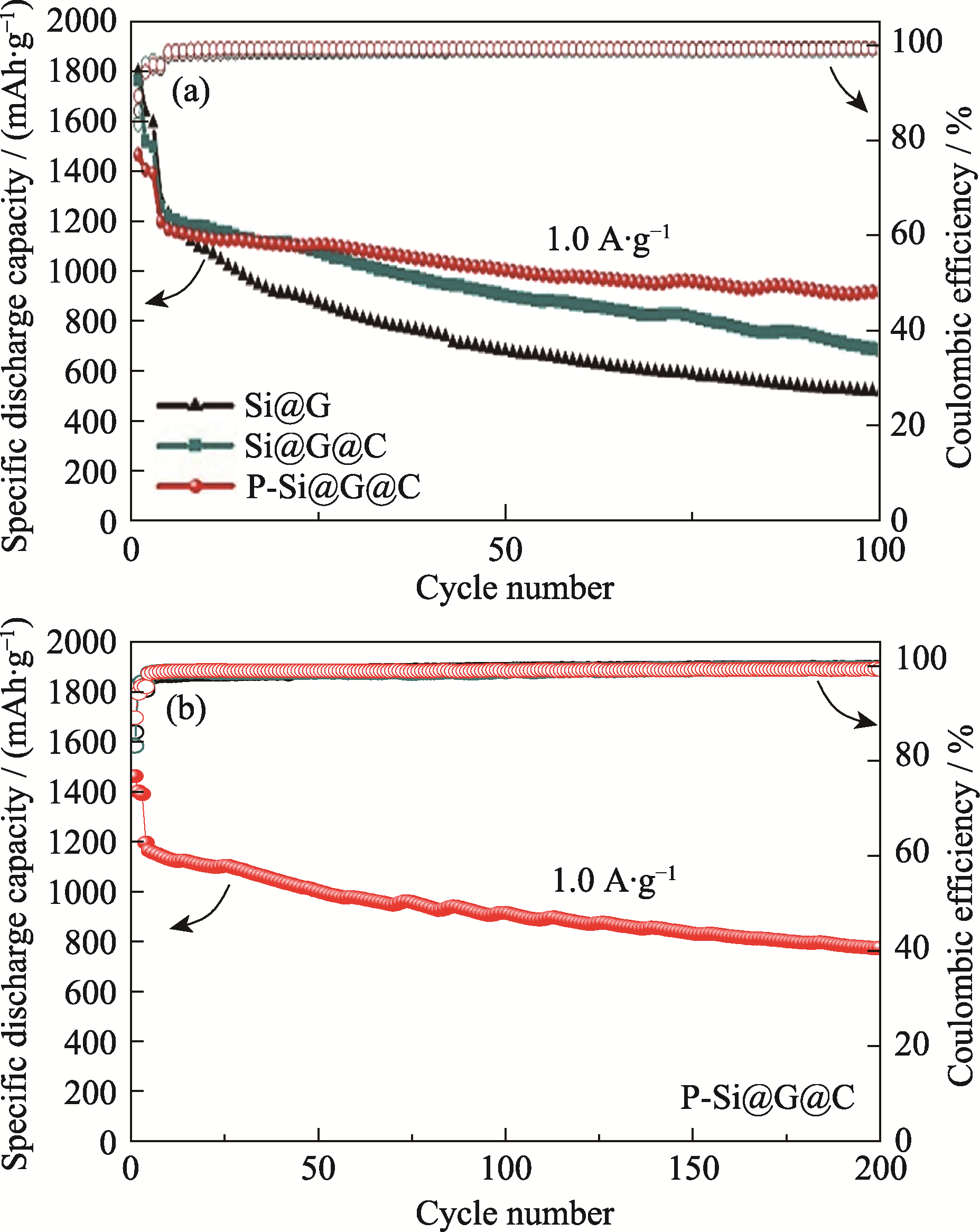

Fig. 6 (a) Cycling performances of Si@G, Si@G@C and P-Si@G@C batteries at 1.0 A·g-1 for 100 cycles; (b) Long cycling performance of P-Si@G@C battery at 1.0 A·g-1 for 200 cycles

| [38] |

LU J, LIU S, LIU J, et al. Millisecond conversion of photovoltaic silicon waste to binder-free high silicon content nanowires electrodes. Adv. Energy Mater., 2021, 11(40): 2102103.

DOI URL |

| [39] |

LIU G X, TIAN J X, WAN J, et al. Revealing the high salt concentration manipulated evolution mechanism on the lithium anode in quasi-solid-state lithium sulfur batteries. Angew. Chem. Int. Ed., 2022, 61(12): e202212744.

DOI URL |

| [40] |

ZHANG J H, LIU G X, ZHAI P B, et al. Stabilizing the interface of Li1.3Al0.3Ti1.7(PO4)3 and lithium electrodes via an interlayer strategy in solid-state batteries. Chem. Comm., 2025, 61(14): 2949.

DOI URL |

| [1] |

DING J W, JI D F, YUE Y Z, et al. Amorphous materials for lithium- ion and post-lithium-ion batteries. Small, 2024, 20(5): 2304270.

DOI URL |

| [2] |

JELLA G, PANDA D K, SAPKOTA N, et al. Electrochemical performance of polymer-derived silicon-oxycarbide/graphene nanoplatelet composites for high-performance Li-ion batteries. ACS Appl. Mater. Interf., 2023, 15(25): 30039.

DOI URL |

| [3] |

KIM M J, LEE I, LEE J W, et al. A novel structured Si-based composite with 2D structured graphite for high-performance lithium-ion batteries. Small, 2024, 20: 2405005.

DOI URL |

| [4] | SUN L, LIU Y X, SHAO R, et al. Recent progress and future perspective on practical silicon anode-based lithium ion batteries. Energy Storage Mater., 2022, 46: 482. |

| [5] | LI P, ZHAO G, ZHENG X, et al. Recent progress on silicon-based anode materials for practical lithium-ion battery applications. Energy Storage Mater., 2018, 15: 422. |

| [6] |

LIU W J, SU S X, WANG Y, et al. Constructing a stable conductive network for high-performance silicon-based anode in lithium-ion batteries. ACS Appl. Mater. Interf., 2024, 16: 10703.

DOI URL |

| [7] |

SHI H F, ZHANG W Y, WANG D H, et al. Facile preparation of silicon/carbon composite with porous architecture for advanced lithium-ion battery anode. J. Electroanal. Chem., 2023, 937: 117427.

DOI URL |

| [8] |

LI H, YAO B H, LI M, et al. Three-dimensional carbon nanotubes buffering interfacial stress of the silicon/carbon anodes for long-cycle lithium storage. ACS Appl. Mater. Interf., 2024, 16: 53665.

DOI URL |

| [9] |

GAO J F, LIU Y, CHEN J Q, et al. Fabrication of honeycomb-like amorphous carbon-encapsulated Si nanoparticles/graphene composite for superior lithium storage. J. Energy Storage, 2023, 74: 109351.

DOI URL |

| [10] |

GAO Y J, SONG S S, HE F, et al. Controllable synthesis of hollow dodecahedral Si@C core-shell structures for ultrastable lithium- ion batteries. Small, 2024, 20: 2406489.

DOI URL |

| [11] |

LI X Z, ZHANG M, YUAN S X, et al. Research progress of silicon/carbon anode materials for lithium-ion batteries: structure design and synthesis method. ChemElectroChem, 2020, 7: 4289.

DOI URL |

| [12] |

LUO W, CHEN X Q, XIA Y, et al. Surface and interface engineering of silicon-based anode materials for lithium-ion batteries. Adv. Energy Mater., 2017, 7: 1701083.

DOI URL |

| [13] |

SU N, QIU J S, WANG Z Y. F-doped carbon coated nano-Si anode with high capacity: preparation by gaseous fluorination and performance for lithium storage. J. Inorg. Mater., 2023, 38(8): 947.

DOI URL |

| [14] |

HU M F, HUANG L P, LI H, et al. Research progress on hard carbon anode for Li/Na-ion batteries. J. Inorg. Mater., 2024, 39(1): 32.

DOI URL |

| [15] | MA Q, ZHAO Z, ZHAO Y, et al. A self-driven alloying/dealloying approach to nanostructuring micro-silicon for high-performance lithium-ion battery anodes. Energy Storage Mater., 2021, 34: 768. |

| [16] |

ZHANG L, HUANG Q, LIAO X, et al. Scalable and controllable fabrication of CNTs improved yolk-shelled Si anodes with advanced in operando mechanical quantification. Energ. Environ. Sci., 2021, 14(6): 3502.

DOI URL |

| [17] |

TAO H, FAN L Z, SONG W L, et al. Hollow core-shell structured Si/C nanocomposites as high-performance anode materials for lithium-ion batteries. Nanoscale, 2014, 6(6): 3138.

DOI PMID |

| [18] | LIU N, LIU J, JIA D, et al. Multi-core yolk-shell like mesoporous double carbon-coated silicon nanoparticles as anode materials for lithium-ion batteries. Energy Storage Mater., 2019, 18: 165. |

| [19] |

SU H, LI X, LIU C, et al. Scalable synthesis of micrometer-sized porous silicon/carbon composites for high-stability lithium-ion battery anodes. Chem. Eng. J., 2023, 451: 138394.

DOI URL |

| [20] |

SUN Y Q, ZU X H, LIU B W, et al. Low-cost integrated silicon-carbon anode based on Si-Cu bonds and asphalt-derived carbon towards high-performance lithium-ion battery. ACS Appl. Energy Mater., 2023, 6: 11376.

DOI URL |

| [21] |

KONG X, XI Z, JIANG Y, et al. Fe-NC decorated fibrous network-wrapped biomass SiOx/C with gradient conductive structure for high performance Li-ion battery anodes. Chem. Eng. J., 2023, 477: 147178.

DOI URL |

| [22] |

PEI Y, WANG Y, CHANG A Y, et al. Nanofiber-in-microfiber carbon/silicon composite anode with high silicon content for lithium-ion batteries. Carbon, 2023, 203: 436.

DOI URL |

| [23] |

HU L, LUO B, WU C, et al. Yolk-shell Si/C composites with multiple Si nanoparticles encapsulated into double carbon shells as lithium-ion battery anodes. J. Energy Chem., 2019, 32: 124.

DOI |

| [24] |

ZHANG L, HU X, CHEN C, et al. In operando mechanism analysis on nanocrystalline silicon anode material for reversible and ultrafast sodium storage. Adv. Mater., 2017, 29: 1604708.

DOI URL |

| [25] |

ZHAO M, MCCORMACK A, KESWANI M. The formation mechanism of gradient porous Si in a contactless electrochemical process. J Mater. Chem. C, 2016, 4(19): 4204.

DOI URL |

| [26] |

DONG H, FU X, WANG J, et al. In-situ construction of porous Si@C composites with LiCl template to provide silicon anode expansion buffer. Carbon, 2021, 173: 687.

DOI URL |

| [27] |

CHAE S, XU Y, YI R, et al. A micrometer-sized silicon/carbon composite anode synthesized by impregnation of petroleum pitch in nanoporous silicon. Adv. Mater., 2021, 33(40): 2103095.

DOI URL |

| [28] |

MU T, ZUO P, LOU S, et al. A two-dimensional nitrogen-rich carbon/silicon composite as high performance anode material for lithium ion batteries. Chem. Eng. J., 2018, 341: 37.

DOI URL |

| [29] |

LI X, YANG D, HOU X, et al. Scalable preparation of mesoporous silicon@C/graphite hybrid as stable anodes for lithium-ion batteries. J. Alloys Compd., 2017, 728: 1.

DOI URL |

| [30] |

SHIN H J, HWANG J Y, KWON H J, et al. Sustainable encapsulation strategy of silicon nanoparticles in microcarbon sphere for high-performance lithium-ion battery anode. ACS Sustain. Chem. Eng., 2020, 8(37): 14150.

DOI URL |

| [31] |

LI P, HWANG J Y, SUN Y K. Nano/microstructured silicon-graphite composite anode for high-energy-density Li-ion battery. ACS Nano, 2019, 13(2): 2624.

DOI PMID |

| [32] |

ZHANG H, ZHANG X, JIN H, et al. A robust hierarchical 3D Si/CNTs composite with void and carbon shell as Li-ion battery anodes. Chem. Eng. J., 2019, 360: 974.

DOI URL |

| [33] |

WEI Q, CHEN Y M, HONG X J, et al. Novel bread-like nitrogen-doped carbon anchored nano-silicon as high-stable anode for lithium-ion batteries. Appl. Surf. Sci., 2020, 511: 145609.

DOI URL |

| [34] | XIN X, ZHOU X, WANG F, et al. A 3D porous architecture of Si/graphene nanocomposite as high-performance anode materials for Li-ion batteries. J. Mater. Chem. A, 2012, 22(16): 7724. |

| [35] |

PAN Q, ZUO P, LOU S, et al. Micro-sized spherical silicon@carbon@graphene prepared by spray drying as anode material for lithium-ion batteries. J. Alloys Compd., 2017, 723: 434.

DOI URL |

| [36] |

FU L, XU A, SONG Y, et al. Pinecone-like silicon@carbon microspheres covered by Al2O3 nano-petals for lithium-ion battery anode under high temperature. Electrochim. Acta, 2021, 387: 138461.

DOI URL |

| [37] |

GAO R, TANG J, YU X, et al. In situ synthesis of MOF-derived carbon shells for silicon anode with improved lithium-ion storage. Nano Energy, 2020, 70: 104444.

DOI URL |

| [1] | WEN Shenhao, PENG Dezhao, LIN Zheyu, GUO Xia, HUANG Peixin, ZHANG Zhizhen. Interface Engineering for the Anode in Solid-state Lithium Batteries Based on LLZTO Electrolyte [J]. Journal of Inorganic Materials, 2025, 40(9): 1013-1021. |

| [2] | TAN Bowen, GENG Shuanglong, ZHANG Kai, ZHENG Bailin. Composition-gradient Design of Silicon Electrodes to Mitigate Mechanochemical Coupling Degradation [J]. Journal of Inorganic Materials, 2025, 40(7): 772-780. |

| [3] | ZHANG Yuting, LI Xiaobin, LIU Zunyi, LI Ning, ZHAO Yu. Composite Yolk-shell NiCo2V2O8@TiO2@NC Material as Anode for Lithium-ion Batteries [J]. Journal of Inorganic Materials, 2025, 40(11): 1221-1228. |

| [4] | LIU Pengdong, WANG Zhen, LIU Yongfeng, WEN Guangwu. Research Progress on the Application of Silicon Slurry in Lithium-ion Batteries [J]. Journal of Inorganic Materials, 2024, 39(9): 992-1004. |

| [5] | YANG Zhuo, LU Yong, ZHAO Qing, CHEN Jun. X-ray Diffraction Rietveld Refinement and Its Application in Cathode Materials for Lithium-ion Batteries [J]. Journal of Inorganic Materials, 2023, 38(6): 589-605. |

| [6] | SU Nana, HAN Jingru, GUO Yinhao, WANG Chenyu, SHI Wenhua, WU Liang, HU Zhiyi, LIU Jing, LI Yu, SU Baolian. ZIF-8-derived Three-dimensional Silicon-carbon Network Composite for High-performance Lithium-ion Batteries [J]. Journal of Inorganic Materials, 2022, 37(9): 1016-1022. |

| [7] | WANG Yang, FAN Guangxin, LIU Pei, YIN Jinpei, LIU Baozhong, ZHU Linjian, LUO Chengguo. Microscopic Mechanism of K+ Doping on Performance of Lithium Manganese Cathode for Li-ion Battery [J]. Journal of Inorganic Materials, 2022, 37(9): 1023-1029. |

| [8] | ZHU Hezhen, WANG Xuanpeng, HAN Kang, YANG Chen, WAN Ruizhe, WU Liming, MAI Liqiang. Enhanced Lithium Storage Stability Mechanism of Ultra-high Nickel LiNi0.91Co0.06Al0.03O2@Ca3(PO4)2 Cathode Materials [J]. Journal of Inorganic Materials, 2022, 37(9): 1030-1036. |

| [9] | FENG Kun, ZHU Yong, ZHANG Kaiqiang, CHEN Zhang, LIU Yu, GAO Yanfeng. Boehmite Nanosheets-coated Separator with Enhanced Performance for Lithium-ion Batteries [J]. Journal of Inorganic Materials, 2022, 37(9): 1009-1015. |

| [10] | CHEN Ying, LUAN Weiling, CHEN Haofeng, ZHU Xuanchen. Multi-scale Failure Behavior of Cathode in Lithium-ion Batteries Based on Stress Field [J]. Journal of Inorganic Materials, 2022, 37(8): 918-924. |

| [11] | WANG Yutong, ZHANG Feifan, XU Naicai, WANG Chunxia, CUI Lishan, HUANG Guoyong. Research Progress of LiTi2(PO4)3 Anode for Aqueous Lithium-ion Batteries [J]. Journal of Inorganic Materials, 2022, 37(5): 481-492. |

| [12] | LI Kunru, HU Xinghui, ZHANG Zhengfu, GUO Yuzhong, HUANG Ruian. Three-dimensional Porous Biogenic Si/C Composite for High Performance Lithium-ion Battery Anode Derived from Equisetum Fluviatile [J]. Journal of Inorganic Materials, 2021, 36(9): 929-935. |

| [13] | WANG Ying, ZHANG Wenlong, XING Yanfeng, CAO suqun, DAI Xinyi, LI Jingze. Performance of Amorphous Lithium Phosphate Coated Lithium Titanate Electrodes in Extended Working Range of 0.01-3.00 V [J]. Journal of Inorganic Materials, 2021, 36(9): 999-1005. |

| [14] | WANG Yanan, LI Hua, WANG Zhengkun, LI Qingfeng, LIAN Chen, HE Xin. Progress on Failure Mechanism of Lithium Ion Battery Caused by Diffusion Induced Stress [J]. Journal of Inorganic Materials, 2020, 35(10): 1071-1087. |

| [15] | Jian-Huang KE, Kai XIE, Yu HAN, Wei-Wei SUN, Shi-Qiang LUO, Jin-Feng LIU. Morphology Controlling of the High-voltage Cathode Materials with Different Co-solvents [J]. Journal of Inorganic Materials, 2019, 34(6): 618-624. |

| Viewed | ||||||

|

Full text |

|

|||||

|

Abstract |

|

|||||