Journal of Inorganic Materials ›› 2022, Vol. 37 ›› Issue (9): 1009-1015.DOI: 10.15541/jim20220050

• RESEARCH ARTICLE • Previous Articles Next Articles

FENG Kun1,2( ), ZHU Yong1, ZHANG Kaiqiang1, CHEN Zhang1, LIU Yu2(

), ZHU Yong1, ZHANG Kaiqiang1, CHEN Zhang1, LIU Yu2( ), GAO Yanfeng1(

), GAO Yanfeng1( )

)

Received:2022-01-27

Revised:2022-03-22

Published:2022-09-20

Online:2022-04-07

Contact:

GAO Yanfeng, professor. E-mail: yfgao@shu.edu.cn;>About author:FENG Kun, male, Master candidate. E-mail: fengkun@shu.edu.cn

Supported by:CLC Number:

FENG Kun, ZHU Yong, ZHANG Kaiqiang, CHEN Zhang, LIU Yu, GAO Yanfeng. Boehmite Nanosheets-coated Separator with Enhanced Performance for Lithium-ion Batteries[J]. Journal of Inorganic Materials, 2022, 37(9): 1009-1015.

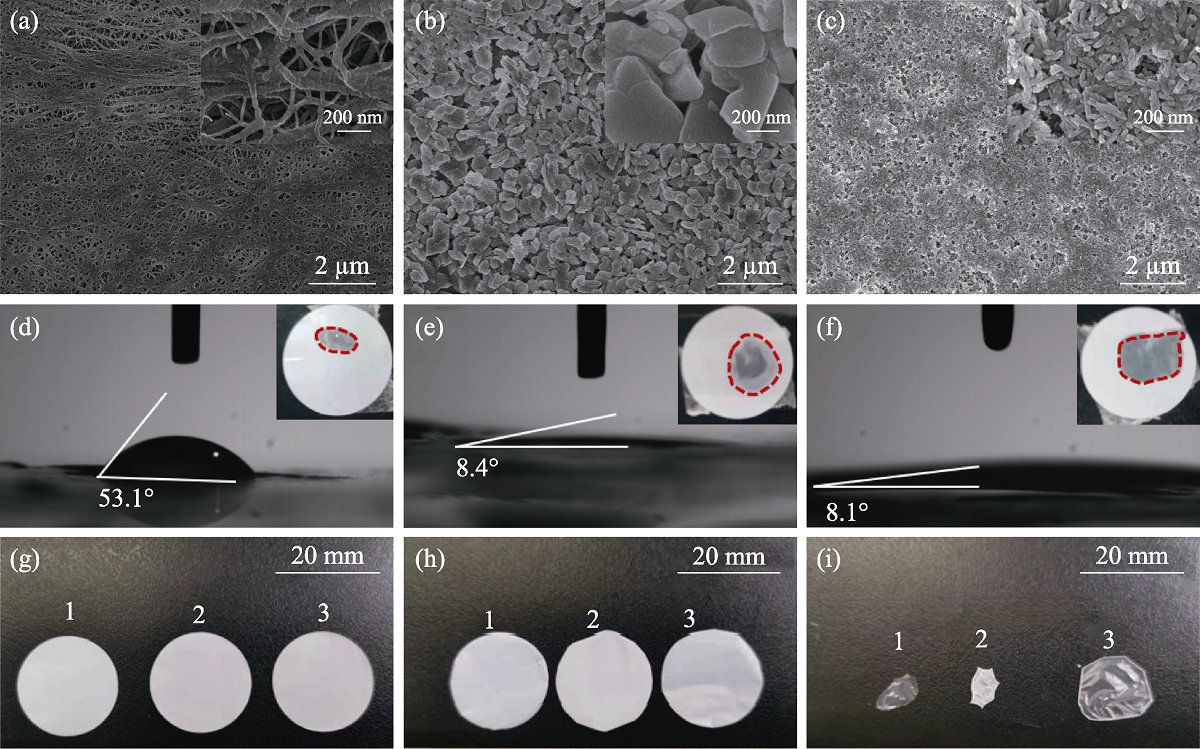

Fig. 2 Physical properties of PE, PE-AlOOHNP and PE-AlOOHNS Surface SEM images of (a) PE, (b) PE-AlOOHNP and (c) PE-AlOOHNS; Electrolyte contact angles of (d) PE, (e) PE-AlOOHNP and (f) PE-AlOOHNS with insets showing pictures of the electrolyte-wetted separators; (g) Initial photo of the separators at 25 ℃; Photos of the separators after heat treatment at (h) 130 ℃ and (i) 150 ℃ for 30 min (1: PE, 2: PE-AlOOHNP, 3: PE-AlOOHNS)

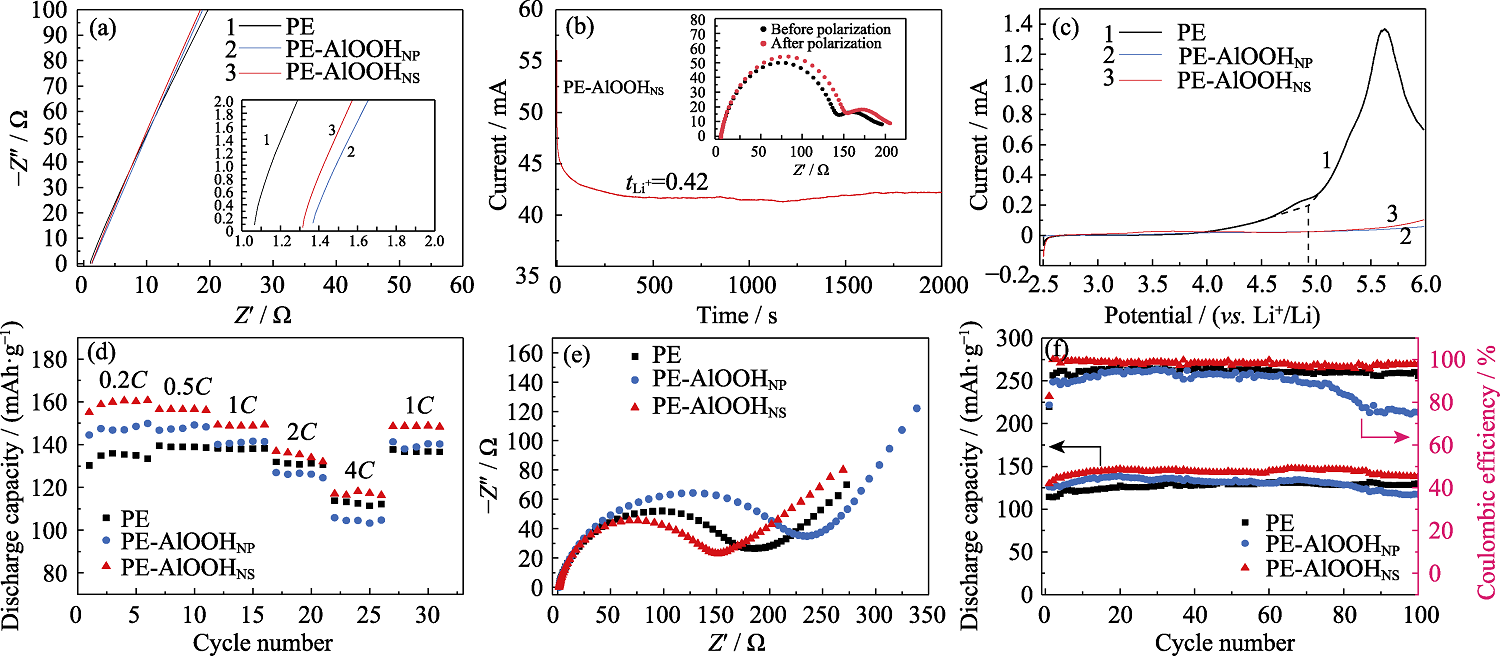

Fig. 3 (a)Nyquist plots of SS/SS cells assembled with different separators; (b) Chronoamperometry profile of Li/PE-AlOOHNS/Li cell with inset showing EIS plots before and after polarization; (c) LSV curves of SS/Li cells assembled with different separators; (d) Rate capabilities, (e) EIS spectra and (f) cycle performances of LFP/Li cells with different separators Colorful figures are available on website

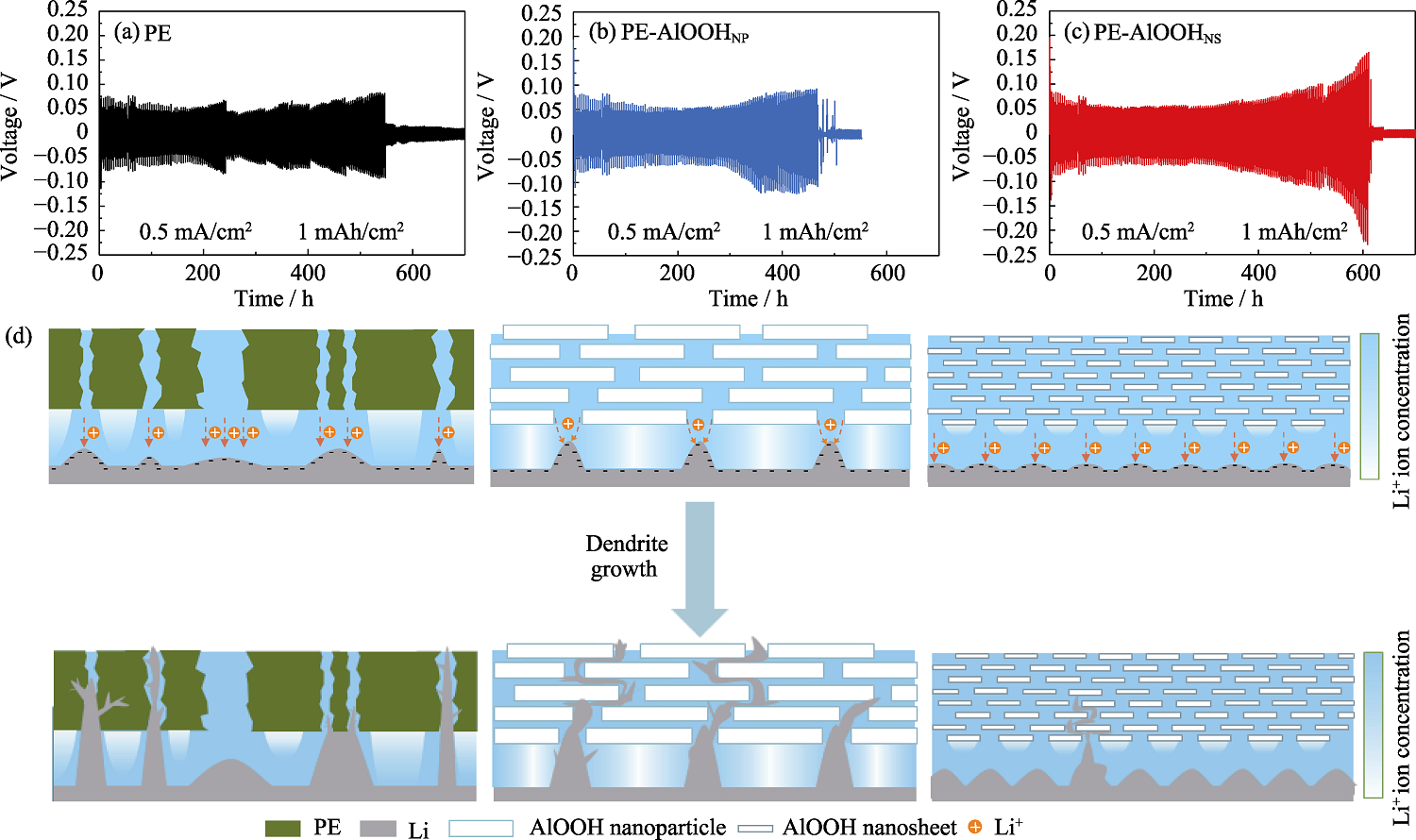

Fig. 4 Voltage profiles of Li/Li symmetric cells assembled with (a) PE, (b) PE-AlOOHNP and (c) PE-AlOOHNS, and (d) schematic illustration of suppressing lithium dendrite formation

| Thickness/μm | Porosity/% | Electrolyte uptake /% | Bulk resistance /Ω | Ionic conductivity /(mS·cm-1) | Lithium-ion transference number | |

|---|---|---|---|---|---|---|

| PE | 9 | 39.6 | 84.6 | 1.06 | 0.43 | 0.15 |

| PE-AlOOHNP | 12 | 42.4 | 112.5 | 1.37 | 0.45 | 0.39 |

| PE-AlOOHNS | 12 | 46.6 | 138.9 | 1.31 | 0.47 | 0.42 |

Table S1 Physical parameters of different separators

| Thickness/μm | Porosity/% | Electrolyte uptake /% | Bulk resistance /Ω | Ionic conductivity /(mS·cm-1) | Lithium-ion transference number | |

|---|---|---|---|---|---|---|

| PE | 9 | 39.6 | 84.6 | 1.06 | 0.43 | 0.15 |

| PE-AlOOHNP | 12 | 42.4 | 112.5 | 1.37 | 0.45 | 0.39 |

| PE-AlOOHNS | 12 | 46.6 | 138.9 | 1.31 | 0.47 | 0.42 |

| [1] |

PENG L, WANG X, DAI J, et al. A reinforced ceramic-coated separator by overall-covered modification of electron-insulated polypyrrole for the safe performance of lithium-ion batteries. Materials Chemistry Frontiers, 2021, 5(4): 1884-1894.

DOI URL |

| [2] | LEE J, LEE C L, PARK K, et al. Synthesis of an Al2O3-coated polyimide nanofiber mat and its electrochemical characteristics as a separator for lithium ion batteries. Journal of Power Sources, 2014, 248: 1211-1217. |

| [3] |

YUAN B, WEN K, CHEN D, et al. Composite separators for robust high rate lithium ion batteries. Advanced Functional Materials, 2021, 31(32): 2101420.

DOI URL |

| [4] |

HASSOUN J, PANERO S, REALE P, et al. A new, safe, high-rate and high-energy polymer lithium-ion battery. Advanced Materials, 2009, 21(47): 4807-4810.

DOI URL |

| [5] |

DING Y, CANO Z P, YU A, et al. Automotive Li-ion batteries: current status and future perspectives. Electrochemical Energy Reviews, 2019, 2(1): 1-28.

DOI URL |

| [6] | HUANG X, HE R, LI M, et al. Functionalized separator for next-generation batteries. Materials Today, 2020, 41: 143-155. |

| [7] |

FRANCIS C F J, KYRATZIS I L, BEST A S. Lithium-ion battery separators for ionic-liquid electrolytes: a review. Advanced Materials, 2020, 32(18): 1904205.

DOI URL |

| [8] | ZHANG X, SUN Q, ZHEN C, et al. Recent progress in flame-retardant separators for safe lithium-ion batteries. Energy Storage Materials, 2021, 37: 628-647. |

| [9] |

ZHANG S S. A review on the separators of liquid electrolyte Li-ion batteries. Journal of Power Sources, 2007, 164(1): 351-364.

DOI URL |

| [10] |

ZHANG H, SHENG L, BAI Y, et al. Amino-functionalized Al2O3 particles coating separator with excellent lithium-ion transport properties for high-power density lithium-ion batteries. Advanced Engineering Materials, 2020, 22(11): 1901545.

DOI URL |

| [11] |

JIANG H, LIN X, WEI C, et al. Scalable synthesis of nano-sized Bi for separator modifying in 5V-class lithium metal batteries and potassium ion batteries anodes. Small, 2021, 18(4): 2104264.

DOI URL |

| [12] |

XIANG H, CHEN J, LI Z, et al. An inorganic membrane as a separator for lithium-ion battery. Journal of Power Sources, 2011, 196(20): 8651-8655.

DOI URL |

| [13] | GAO H. The low-crystallinity PVDF/PMMA/PEG/TiO2 type polymer diaphragm prepared by phase inversion method. International Journal of Electrochemical Science, 2018, 13: 10751-10765. |

| [14] | CHEN H, LIN Q, XU Q, et al. Plasma activation and atomic layer deposition of TiO2 on polypropylene membranes for improved performances of lithium-ion batteries. Journal of Membrane Science, 2014, 458: 217-224. |

| [15] |

LIANG J, CHEN Q, LIAO X, et al. A nano-shield design for separators to resist dendrite formation in lithium-metal batteries. Angewandte Chemie International Edition, 2020, 59(16): 6561-6566.

DOI URL |

| [16] |

JEONG H S, LEE S Y. Closely packed SiO2 nanoparticles/poly (vinylidene fluoride-hexafluoropropylene) layers-coated polyethylene separators for lithium-ion batteries. Journal of Power Sources, 2011, 196(16): 6716-6722.

DOI URL |

| [17] | KIM P S, LE MONG A, KIM D. Thermal, mechanical, and electrochemical stability enhancement of Al2O3 coated polypropylene/ polyethylene/polypropylene separator via poly(vinylidene fluoride)-poly(ethoxylated pentaerythritol tetraacrylate) semi-interpenetrating network binder. Journal of Membrane Science, 2020, 612: 118481. |

| [18] | ZHANG Z, LAI Y, ZHANG Z, et al. Al2O3-coated porous separator for enhanced electrochemical performance of lithium sulfur batteries. Electrochimica Acta, 2014, 129: 55-61. |

| [19] |

XIAO W, SONG J, HUANG L, et al. PVA-ZrO2 multilayer composite separator with enhanced electrolyte property and mechanical strength for lithium-ion batteries. Ceramics International, 2020, 46(18): 29212-29221.

DOI URL |

| [20] |

WANG Y, WANG Q, WEI X, et al. A novel three-dimensional boehmite nanowhiskers network-coated polyethylene separator for lithium-ion batteries. Ceramics International, 2021, 47(7): 10153-10162.

DOI URL |

| [21] | WANG Y, WANG Q, LAN Y, et al. Aqueous aluminide ceramic coating polyethylene separators for lithium-ion batteries. Solid State Ionics, 2020, 345: 115188. |

| [22] |

CHOI E S, LEE S Y. Particle size-dependent, tunable porous structure of a SiO2/poly (vinylidene fluoride-hexafluoropropylene)- coated poly (ethylene terephthalate) nonwoven composite separator for a lithium-ion battery. Journal of Materials Chemistry, 2011, 21(38): 14747-14754.

DOI URL |

| [23] | QI X, ZHANG Z, TU C, et al. Covalent grafting interface engineering to prepare highly efficient and stable polypropylene/ mesoporous SiO2 separator for Li-ion batteries. Applied Surface Science, 2021, 541: 148405. |

| [24] | ZHANG X, CHEN Y, YU B, et al. Lithiophilic 3D VN@N-rGO as a multifunctional interlayer for dendrite-free and ultrastable lithium-metal batteries. ACS Applied Materials & Interfaces, 2021, 13(17): 20125-20136. |

| [25] |

ZHANG S S, FAN X, WANG C. Preventing lithium dendrite- related electrical shorting in rechargeable batteries by coating separator with a Li-killing additive. Journal of Materials Chemistry A, 2018, 6(23): 10755-10760.

DOI URL |

| [26] |

WANG J, LIU Y, CAI Q, et al. Hierarchically porous silica membrane as separator for high-performance lithium-ion batteries. Advanced Materials, 2022, 34(3): 2107957.

DOI URL |

| [27] | ZHANG Y, QIU Z, WANG Z, et al. Functional polyethylene separator with impurity entrapment and faster Li+ ions transfer for superior lithium-ion batteries. Journal of Colloid and Interface Science, 2022, 607: 742-751. |

| [28] |

ZHANG X, HUI Z, KING S, et al. Tunable porous electrode architectures for enhanced Li-ion storage kinetics in thick electrodes. Nano Letters, 2021, 21(13): 5896-5904.

DOI URL |

| [29] | CHEN X, ZHANG R, ZHAO R, et al. A “dendrite-eating” separator for high-areal-capacity lithium-metal batteries. Energy Storage Materials, 2020, 31: 181-186. |

| [30] | QIU Z, YUAN S, WANG Z, et al. Construction of silica- oxygen-borate hybrid networks on Al2O3-coated polyethylene separators realizing multifunction for high-performance lithium ion batteries. Journal of Power Sources, 2020, 472: 228445. |

| [31] | YANG Y, ZHANG J. Layered nanocomposite separators enabling dendrite-free lithium metal anodes at ultrahigh current density and cycling capacity. Energy Storage Materials, 2021, 37: 135-142. |

| [1] | TAN Bowen, GENG Shuanglong, ZHANG Kai, ZHENG Bailin. Composition-gradient Design of Silicon Electrodes to Mitigate Mechanochemical Coupling Degradation [J]. Journal of Inorganic Materials, 2025, 40(7): 772-780. |

| [2] | LIU Pengdong, WANG Zhen, LIU Yongfeng, WEN Guangwu. Research Progress on the Application of Silicon Slurry in Lithium-ion Batteries [J]. Journal of Inorganic Materials, 2024, 39(9): 992-1004. |

| [3] | WEN Zhipeng, WEI Yi, HOU Xianghua, GUO Jiawen, LI Qu, ZHU Manqing, ZHANG Jiahao, PAN Kai, WU Lian. Research Progress of Bentonite-based Functional Materials in Electrochemical Energy Storage [J]. Journal of Inorganic Materials, 2024, 39(12): 1301-1315. |

| [4] | YANG Zhuo, LU Yong, ZHAO Qing, CHEN Jun. X-ray Diffraction Rietveld Refinement and Its Application in Cathode Materials for Lithium-ion Batteries [J]. Journal of Inorganic Materials, 2023, 38(6): 589-605. |

| [5] | SU Nana, HAN Jingru, GUO Yinhao, WANG Chenyu, SHI Wenhua, WU Liang, HU Zhiyi, LIU Jing, LI Yu, SU Baolian. ZIF-8-derived Three-dimensional Silicon-carbon Network Composite for High-performance Lithium-ion Batteries [J]. Journal of Inorganic Materials, 2022, 37(9): 1016-1022. |

| [6] | WANG Yang, FAN Guangxin, LIU Pei, YIN Jinpei, LIU Baozhong, ZHU Linjian, LUO Chengguo. Microscopic Mechanism of K+ Doping on Performance of Lithium Manganese Cathode for Li-ion Battery [J]. Journal of Inorganic Materials, 2022, 37(9): 1023-1029. |

| [7] | ZHU Hezhen, WANG Xuanpeng, HAN Kang, YANG Chen, WAN Ruizhe, WU Liming, MAI Liqiang. Enhanced Lithium Storage Stability Mechanism of Ultra-high Nickel LiNi0.91Co0.06Al0.03O2@Ca3(PO4)2 Cathode Materials [J]. Journal of Inorganic Materials, 2022, 37(9): 1030-1036. |

| [8] | CHEN Ying, LUAN Weiling, CHEN Haofeng, ZHU Xuanchen. Multi-scale Failure Behavior of Cathode in Lithium-ion Batteries Based on Stress Field [J]. Journal of Inorganic Materials, 2022, 37(8): 918-924. |

| [9] | XIA Qian, SUN Shihao, ZHAO Yiliang, ZHANG Cuiping, RU Hongqiang, WANG Wei, YUE Xinyan. Effect of Boron Carbide Particle Size Distribution on the Microstructure and Properties of Reaction Bonded Boron Carbide Ceramic Composites by Silicon Infiltration [J]. Journal of Inorganic Materials, 2022, 37(6): 636-642. |

| [10] | WANG Yutong, ZHANG Feifan, XU Naicai, WANG Chunxia, CUI Lishan, HUANG Guoyong. Research Progress of LiTi2(PO4)3 Anode for Aqueous Lithium-ion Batteries [J]. Journal of Inorganic Materials, 2022, 37(5): 481-492. |

| [11] | LI Kunru, HU Xinghui, ZHANG Zhengfu, GUO Yuzhong, HUANG Ruian. Three-dimensional Porous Biogenic Si/C Composite for High Performance Lithium-ion Battery Anode Derived from Equisetum Fluviatile [J]. Journal of Inorganic Materials, 2021, 36(9): 929-935. |

| [12] | WANG Ying, ZHANG Wenlong, XING Yanfeng, CAO suqun, DAI Xinyi, LI Jingze. Performance of Amorphous Lithium Phosphate Coated Lithium Titanate Electrodes in Extended Working Range of 0.01-3.00 V [J]. Journal of Inorganic Materials, 2021, 36(9): 999-1005. |

| [13] | WANG Yanan, LI Hua, WANG Zhengkun, LI Qingfeng, LIAN Chen, HE Xin. Progress on Failure Mechanism of Lithium Ion Battery Caused by Diffusion Induced Stress [J]. Journal of Inorganic Materials, 2020, 35(10): 1071-1087. |

| [14] | Jian-Huang KE, Kai XIE, Yu HAN, Wei-Wei SUN, Shi-Qiang LUO, Jin-Feng LIU. Morphology Controlling of the High-voltage Cathode Materials with Different Co-solvents [J]. Journal of Inorganic Materials, 2019, 34(6): 618-624. |

| [15] | GUO Rong-Nan, HAN Wei-Qiang. Effects of Structure and Properties of Polar Polymeric Binders on Lithium-ion Batteries [J]. Journal of Inorganic Materials, 2019, 34(10): 1021-1029. |

| Viewed | ||||||

|

Full text |

|

|||||

|

Abstract |

|

|||||