Journal of Inorganic Materials ›› 2022, Vol. 37 ›› Issue (3): 241-254.DOI: 10.15541/jim20210590

Special Issue: 2022年度中国知网高下载论文

• REVIEW • Previous Articles Next Articles

CAO Jiwei1,2( ), WANG Pei1,2, LIU Zhiyuan1,2, LIU Changyong1,2, WU Jiamin3,4(

), WANG Pei1,2, LIU Zhiyuan1,2, LIU Changyong1,2, WU Jiamin3,4( ), CHEN Zhangwei1,2(

), CHEN Zhangwei1,2( )

)

Received:2021-09-26

Revised:2021-10-18

Published:2022-03-20

Online:2021-11-01

Contact:

WU Jiamin, associate professor. E-mail: jiaminwu@hust.edu.cn; CHEN Zhangwei, professor. E-mail: chen@szu.edu.cn

About author:CAO Jiwei (1989-), male, PhD. E-mail: caojiwei@szu.edu.cn

Supported by:CLC Number:

CAO Jiwei, WANG Pei, LIU Zhiyuan, LIU Changyong, WU Jiamin, CHEN Zhangwei. Research Progress on Powder-based Laser Additive Manufacturing Technology of Ceramics[J]. Journal of Inorganic Materials, 2022, 37(3): 241-254.

Fig. 3 ZrO2 ceramic parts and their morphologies prepared by SLS combined with isostatic pressing[28] (a, d) ZrO2 ceramic green bodies and their morphologies printed by SLS; (b) Warm isostatic pressure equipment; (c, e) ZrO2 ceramics and their microstructures after warm isostatic pressing sintering. SLS: Selective laser sintering; WIP: Warm isostatic pressing

Fig. 4 Preparation process of SiC ceramics and its composite parts by SLS[33,36-37] (a-d) Reaction sintering of Cf/SiC ceramic matrix composites by SLS technology; (e-h) SLS preparation process of SiC/SiC ceramics PF: Phenolic resin; Cf: Carbon fiber; SLS: Selective laser sintering; LSI: Liquid silicon infiltration; PIP: Precusor infiltration pyrolysis

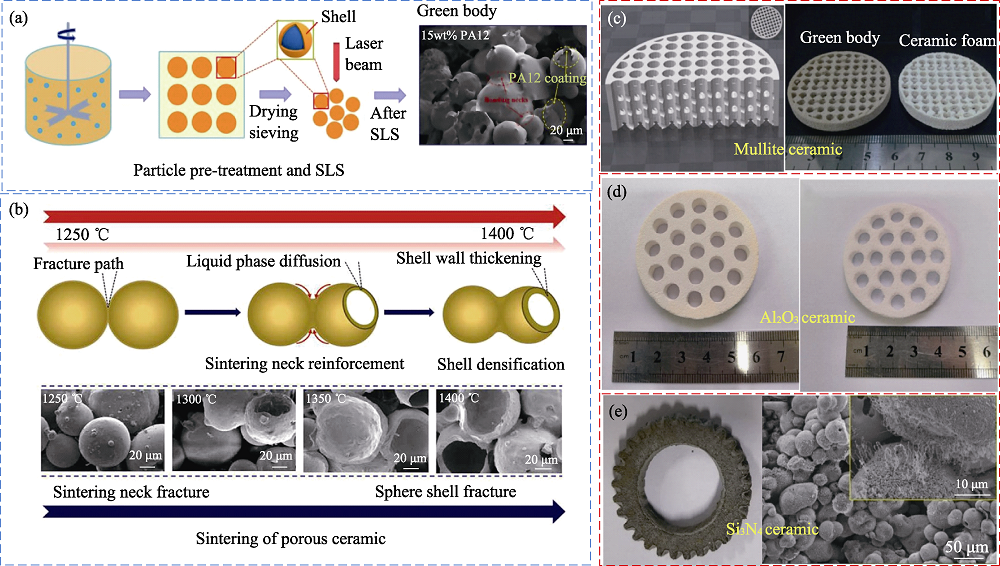

Fig. 5 Methods of porous ceramic by SLS technology[38,39,40,41] (a) Pre-treatment of ceramic particles and SLS; (b) Sintering of porous ceramic;(c) Porous mullite ceramic; (d) Porous Al2O3 ceramic; (e) Porous Si3N4 ceramic; SLS: Selective laser sintering

Fig. 6 Application of porous ceramic by SLS technology in biomedicine (a, b) CC-PLLA porous skull scaffolds and their mechanical properties[43]; (c, d) Porous biological ceramic scaffolds and their micromorphologies[48] SLS: Selective laser sintering

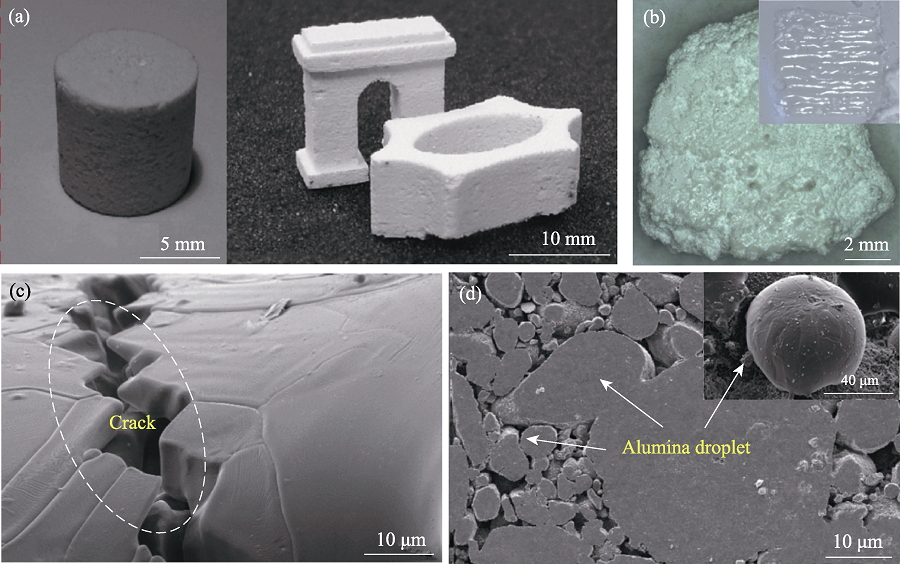

Fig. 8 Ceramics and their microdefects printed by selective laser melting[51,52] (a) ZrO2 sample; (b, c) Al2O3 samples and cracks; (d) Un-melted alumina balls

Fig. 9 Formation of closed pores and pits of ceramic by SLM[54] (a) SLM printing process and Al2O3/GdAlO3/ZrO2 ternary eutectic ceramics; (b) Formation process of the closed pores and pits

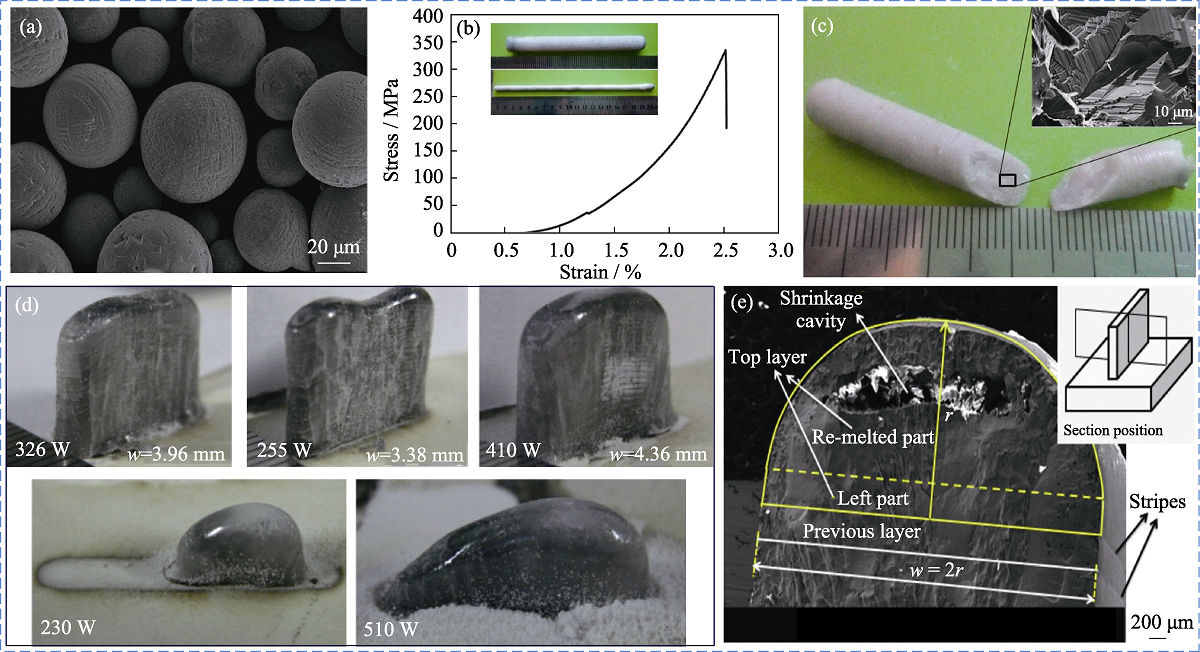

Fig. 11 Ceramic printed by LENS[62,67] (a) Al2O3 spherical particles; (b, c) Large-sized cylindrical Al2O3 ceramic, stress-strain curve and fracture morphology of Al2O3 ceramic; (d) Single-bead wall part fabricated with different laser power; (e) Typical geometry of the cross-section of a single-bead wall part

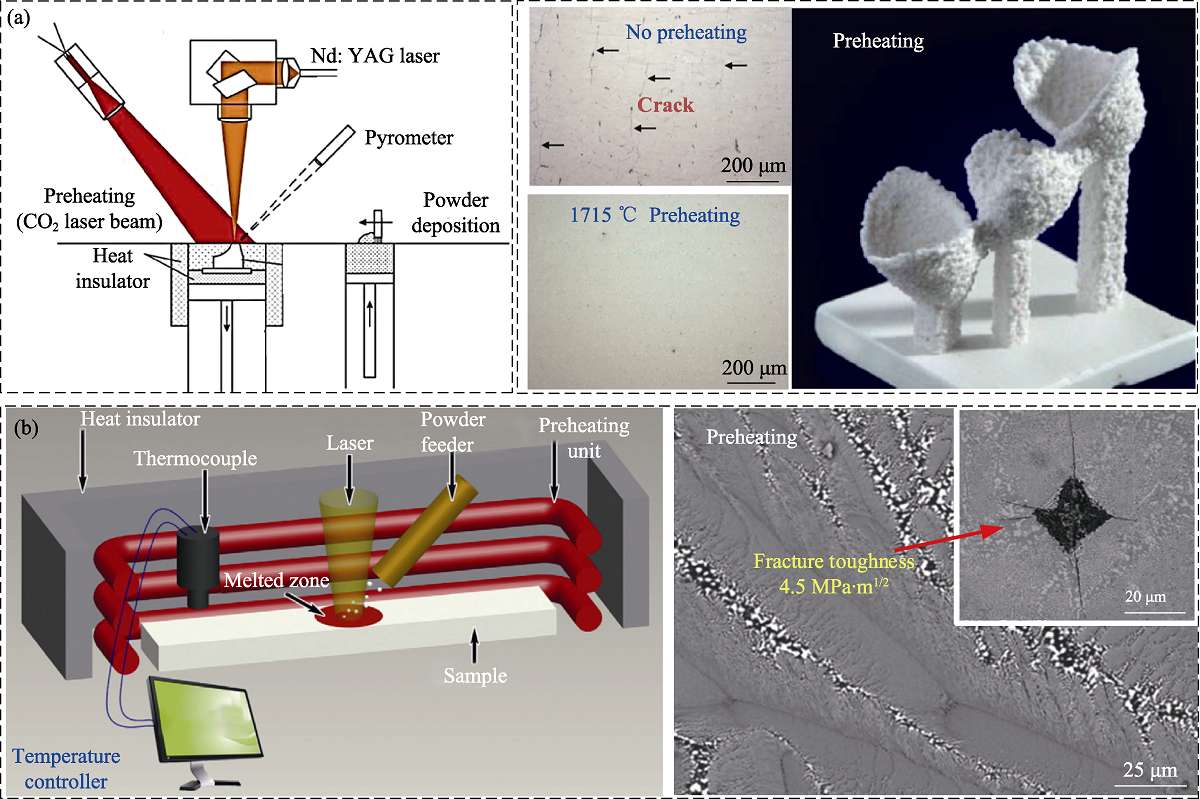

Fig. 13 CO2 laser preheating method, induction preheating method and prepared ceramics (a) CO2 laser preheating method and ZrO2/Al2O3 ceramic prepared by SLM[77]; (b) Induction preheating method and ZrO2/Al2O3 ceramic prepared by LENS[75]

| Technology | Raw materials | Post-treatment | Dimensional accuracy | Ref. | |

|---|---|---|---|---|---|

| PBF | SLS | Al2O3, ZrO2, Si3N4, SiC, Cf/SiC, Si3N4-SiC/SiO2, mullite, porous bio-ceramics such as PA-PEEK, HA-PC, CC-PLLA, etc. | Debinding, isostatic pressing/infiltration pyrolysis, pressureless sintering/reactive sintering | High | [ |

| SLM | Al2O3, ZrO2, ZrO2/Al2O3, MoSi2-Si3N4, ZrB2/ZrC, Al2O3-based eutectic ceramics | None | Low | [ | |

| DED | LENS | Al2O3, ZrO2/Al2O3, Al2O3-based eutectic ceramics | None | Low | [ |

Table 1 Comparation of powder-based laser additive manufacturing technologies of ceramics

| Technology | Raw materials | Post-treatment | Dimensional accuracy | Ref. | |

|---|---|---|---|---|---|

| PBF | SLS | Al2O3, ZrO2, Si3N4, SiC, Cf/SiC, Si3N4-SiC/SiO2, mullite, porous bio-ceramics such as PA-PEEK, HA-PC, CC-PLLA, etc. | Debinding, isostatic pressing/infiltration pyrolysis, pressureless sintering/reactive sintering | High | [ |

| SLM | Al2O3, ZrO2, ZrO2/Al2O3, MoSi2-Si3N4, ZrB2/ZrC, Al2O3-based eutectic ceramics | None | Low | [ | |

| DED | LENS | Al2O3, ZrO2/Al2O3, Al2O3-based eutectic ceramics | None | Low | [ |

| [1] |

CHEN Z, LI Z, LI J, et al. 3D printing of ceramics: a review. Journal of the European Ceramic Society, 2019, 39(4): 661-687.

DOI URL |

| [2] |

RASAKI S A, XIONG D, XIONG S, et al. Photopolymerization- based additive manufacturing of ceramics: a systematic review. Journal of Advanced Ceramics, 2021, 10(3): 442-471.

DOI URL |

| [3] |

LU Z, CAO J, SONG Z, et al. Research progress of ceramic matrix composite parts based on additive manufacturing technology. Virtual and Physical Prototyping, 2019, 14(4): 333-348.

DOI URL |

| [4] |

PFEIFFER S, FLORIO K, PUCCIO D, et al. Direct laser additive manufacturing of high performance oxide ceramics: a state-of-the-art review. Journal of the European Ceramic Society, 2021, 41(13): 6087-6014.

DOI URL |

| [5] | DECKARD C R. Method and Apparatus for Producing Parts by Selective Sintering. U.S. Patent. No.4863538. 1989.09.05. |

| [6] | LAKSHMINARAYAN U, OGRYDIZIAK S, MARCUS H. Selective Laser Sintering of Ceramic Materials. 1990 International Solid Freeform Fabrication Symposium, Austin, 1990: 16-26. |

| [7] | LAKSHMINARAYAN U, MARCUS H. Microstructural and Mechanical Properties of Al2O3/P2O5 and Al2O3/B2O3 Composties Fabricated by Selective Laser Sintering. 1991 International Solid Freeform Fabrication Symposium, Austin, 1991: 205-212. |

| [8] |

CLARE A, CHALKER P, DAVIES S, et al. Selective laser sintering of barium titanate-polymer composite films. Journal of Materials Science, 2008, 43(9): 3197-3202.

DOI URL |

| [9] |

TAN K, CHUA C, LEONG K, et al. Scaffold development using selective laser sintering of polyetheretherketone-hydroxyapatite biocomposite blends. Biomaterials, 2003, 24(18): 3115-3123.

DOI URL |

| [10] |

GAO C, YANG B, HU H, et al. Enhanced sintering ability of biphasic calcium phosphate by polymers used for bone scaffold fabrication. Materials Science and Engineering: C, 2013, 33(7): 3802-3810.

DOI URL |

| [11] |

LEE I. Densification of porous Al2O3-Al4B2O9 ceramic composites fabricated by SLS process. Journal of Materials Science Letters, 1999, 18(19): 1557-1561.

DOI URL |

| [12] | HARLAN N, PARK S M, BOURELL D L, et al. Selective Laser Sintering of Zirconia with Micro-scale Features. 1999 International Solid Freeform Fabrication Symposium, Austin, 1999: 297-302. |

| [13] |

TANG H H. Direct laser fusing to form ceramic parts. Rapid Prototyping Journal, 2002, 8(5): 284-289.

DOI URL |

| [14] |

XIAO K, DALGARNO K, WOOD D, et al. Indirect selective laser sintering of apatite-wollostonite glass-ceramic. Proceedings of the Institution of Mechanical Engineers, Part H: Journal of Engineering in Medicine, 2008, 222(7): 1107-1114.

DOI URL |

| [15] |

LIU J, ZHANG B, YAN C, et al. The effect of processing parameters on characteristics of selective laser sintering dental glass-ceramic powder. Rapid Prototyping Journal, 2010, 16(2): 138-145.

DOI URL |

| [16] | SHI Y S, CHENG D, LIU J H, et al. Al2O3/SiO2 composite ceramic parts by selective laser sintering. Journal of Huazhong University of Science and Technology (Nature Science Edition), 2007, 35(11): 20-23. |

| [17] |

YVES-CHRISTIAN H, JAN W, WILHELM M, et al. Net shaped high performance oxide ceramic parts by selective laser melting. Physics Procedia, 2010, 5: 587-594.

DOI URL |

| [18] | VAIL N K, BALASUBRAMANIAN B, BARLOW J W, et al. A thermal model of polymer degradation during selective laser sintering of polymer coated ceramic powders. Rapid Prototyping Journal, 1996, 2(3): 24-40. |

| [19] |

CHEN A N, WU J M, LIU K, et al. High-performance ceramic parts with complex shape prepared by selective laser sintering: a review. Advances in Applied Ceramics, 2017, 117(2): 100-117.

DOI URL |

| [20] | WU J M, CHEN A N, LIU M Y, et al. Preparation of ceramic materials used for selective laser sintering and related forming methods. Materials China, 2017, 36(Z1): 575-582. |

| [21] |

TANG H H, CHIU M L, YEN H C. Slurry-based selective laser sintering of polymer-coated ceramic powders to fabricate high strength alumina parts. Journal of the European Ceramic Society, 2011, 31(8): 1383-1388.

DOI URL |

| [22] |

FRIEDEL T, TRAVITZKY N, NIEBLING F, et al. Fabrication of polymer derived ceramic parts by selective laser curing. Journal of the European Ceramic Society, 2005, 25(2/3): 193-197.

DOI URL |

| [23] | WOHLERT M, BOURELL D. Rapid Prototyping of Mg/SiC Composites by a Combined SLS and Pressureless Infiltration Process. 1996 Solid Freeform Fabrication Symposium, Austin, 1996: 79-88. |

| [24] |

DECKERS J, KRUTH J P, SHAHZAD K, et al. Density improvement of alumina parts produced through selective laser sintering of alumina-polyamide composite powder. CIRP Annals- Manufacturing Technology, 2012, 61(1): 211-214.

DOI URL |

| [25] |

DECKERS J, SHAHZAD K, VLEUGELS J, et al. Isostatic pressing assisted indirect selective laser sintering of alumina components. Rapid Prototyping Journal, 2012, 18(5): 409-419.

DOI URL |

| [26] |

SHAHZAD K, DECKERS J, KRUTH J P, et al. Additive manufacturing of alumina parts by indirect selective laser sintering and post processing. Journal of Materials Processing Technology, 2013, 213(9): 1484-1494.

DOI URL |

| [27] |

DECKERS J P, SHAHZAD K, CARDON L, et al. Shaping ceramics through indirect selective laser sintering. Rapid Prototyping Journal, 2016, 22(3): 544-558.

DOI URL |

| [28] |

SHAHZAD K, DECKERS J, ZHANG Z, et al. Additive manufacturing of zirconia parts by indirect selective laser sintering. Journal of the European Ceramic Society, 2014, 34(1): 81-89.

DOI URL |

| [29] |

WANG K, BAO C, ZHANG C, et al. Preparation of high-strength Si3N4 antenna window using selective laser sintering. Ceramics International, 2021, 47(22): 31277-31285.

DOI URL |

| [30] | SHI Y S, LIU K, HE W T, et al. Densification of alumina components via indirect selective laser sintering combined with isostatic pressing. Applied Laser, 2013(1): 7-12. |

| [31] | DU Y Y, SHI Y S, WEI Q S. Technology and simulation of cold isostatic pressing of selective laser sintered parts. Laser Technology, 2014, 38(1): 96-100. |

| [32] | HE W T, WEI Q S, LIU K, et al. The application of numerical simulation in the SLS/CIP process of alumina ceramics. Materials Science & Technology, 2014, 22(4): 56-60. |

| [33] |

ZHU W, FU H, XU Z, et al. Fabrication and characterization of carbon fiber reinforced SiC ceramic matrix composites based on 3D printing technology. Journal of the European Ceramic Society, 2018, 38(14): 4604-4613.

DOI URL |

| [34] |

FU H, ZHU W, XU Z, et al. Effect of silicon addition on the microstructure, mechanical and thermal properties of Cf/SiC composite prepared via selective laser sintering. Journal of Alloys and Compounds, 2019, 792: 1045-1053.

DOI URL |

| [35] |

YU S, ZENG T, PAN X, et al. Fabrication of Si3N4-SiC/SiO2 composites using 3D printing and infiltration processing. Ceramics International, 2021, 47(20): 28218-28225.

DOI URL |

| [36] |

JIN L, ZHANG K, XU T, et al. The fabrication and mechanical properties of SiC/SiC composites prepared by SLS combined with PIP. Ceramics International, 2018, 44(17): 20992-20999.

DOI URL |

| [37] | ZHANG K, ZENG T, XU G, et al. Mechanical properties of SiCp/SiC composite lattice core sandwich panels fabricated by 3D printing combined with precursor impregnation and pyrolysis. Composite Structures, 2020, 240: 12060. |

| [38] |

WEI Z H, CHENG L J, MA Y X, et al. Direct fabrication mechanism of pre-sintered Si3N4 ceramic with ultra-high porosity by laser additive manufacturing. Scripta Materialia, 2019, 173: 91-95.

DOI URL |

| [39] |

CHEN A N, LI M, WU J M, et al. Enhancement mechanism of mechanical performance of highly porous mullite ceramics with bimodal pore structures prepared by selective laser sintering. Journal of Alloys and Compounds, 2019, 776: 486-494.

DOI URL |

| [40] |

WU J M, LI M, LIU S S, et al. Preparation of porous Al2O3 ceramics with enhanced properties by SLS using Al2O3 poly-hollow microspheres (PHMs) coated with CaSiO3 sintering additive. Ceramics International, 2020, 46(17): 26888-26894.

DOI URL |

| [41] |

CHEN A N, GAO F, LI M, et al. Mullite ceramic foams with controlled pore structures and low thermal conductivity prepared by SLS using core-shell structured polyamide12/FAHSs composites. Ceramics International, 2019, 45(12): 15538-15546.

DOI URL |

| [42] |

SONG X, LI W, SONG P, et al. Selective laser sintering of aliphatic-polycarbonate/hydroxyapatite composite scaffolds for medical applications. The International Journal of Advanced Manufacturing Technology, 2015, 81(1-4): 15-25.

DOI URL |

| [43] |

GAYER C, RITTER J, BULLEMER M, et al. Development of a solvent-free polylactide/calcium carbonate composite for selective laser sintering of bone tissue engineering scaffolds. Materials Science and Engineering: C, 2019, 101: 660-673.

DOI URL |

| [44] |

CHUNG H, DAS S. Functionally graded Nylon-11/silica nanocomposites produced by selective laser sintering. Materials Science and Engineering: A, 2008, 487(1/2): 251-257.

DOI URL |

| [45] |

LORRISON J, DALGARNO K, WOOD D. Processing of an apatite-mullite glass-ceramic and an hydroxyapatite/phosphate glass composite by selective laser sintering. Journal of Materials Science: Materials in Medicine, 2005, 16(8): 775-781.

DOI URL |

| [46] |

GOODRIDGE R, DALGARNO K, WOOD D. Indirect selective laser sintering of an apatite-mullite glass-ceramic for potential use in bone replacement applications. Proceedings of the Institution of Mechanical Engineers, Part H: Journal of Engineering in Medicine, 2006, 220(1): 57-68.

DOI URL |

| [47] |

GOODRIDGE R D, WOOD D J, OHTSUKI C, et al. Biological evaluation of an apatite-mullite glass-ceramic produced via selective laser sintering. Acta Biomaterialia, 2007, 3(2): 221-231.

DOI URL |

| [48] |

DUAN B, WANG M, ZHOU W Y, et al. Three-dimensional nanocomposite scaffolds fabricated via selective laser sintering for bone tissue engineering. Acta Biomater, 2010, 6(12): 4495-4505.

DOI URL |

| [49] |

SCHLEIFENBAUM H, MEINERS W, WISSENBACH K, et al. Individualized production by means of high power selective laser melting. CIRP Journal of Manufacturing Science and Technology, 2010, 2(3): 161-169.

DOI URL |

| [50] |

MERCELIS P, KRUTH J P. Residual stresses in selective laser sintering and selective laser melting. Rapid Prototyping Journal, 2006, 12(5): 254-265.

DOI URL |

| [51] |

SHISHKOVSKY I, YADROITSEV I, BERTRAND P, et al. Alumina-zirconium ceramics synthesis by selective laser sintering/ melting. Applied Surface Science, 2007, 254(4): 966-970.

DOI URL |

| [52] |

DECKERS J, MEYERS S, KRUTH J P, et al. Direct selective laser sintering/melting of high density alumina powder layers at elevated temperatures. Physics Procedia, 2014, 56 117-124.

DOI URL |

| [53] |

BERTRAND P, BAYLE F, COMBE C, et al. Ceramic components manufacturing by selective laser sintering. Applied Surface Science, 2007, 254(4): 989-992.

DOI URL |

| [54] |

LIU H, SU H, SHEN Z, et al. Effect of scanning speed on the solidification process of Al2O3/GdAlO3/ZrO2 eutectic ceramics in a single track by selective laser melting. Ceramics International, 2019, 45(14): 17252-17257.

DOI URL |

| [55] |

MÜHLER T, GOMES C M, HEINRICH J, et al. Slurry-based additive manufacturing of ceramics. International Journal of Applied Ceramic Technology, 2015, 12(1): 18-25.

DOI URL |

| [56] |

GAHLER A, HEINRICH J G, GUENSTER J. Direct laser sintering of Al2O3-SiO2 dental ceramic components by layer-wise slurry deposition. Journal of the American Ceramic Society, 2006, 89(10): 3076-3080.

DOI URL |

| [57] | MÜHLER T, GOMES C, ASCHERI M, et al. Slurry-based powder beds for the selective laser sintering of silicate ceramics. J. Ceram. Sci. Technol., 2015, 6(2): 113-118. |

| [58] |

TIAN X, GÜNSTER J, MELCHER J, et al. Process parameters analysis of direct laser sintering and post treatment of porcelain components using Taguchi's method. Journal of the European Ceramic Society, 2009, 29(10): 1903-1915.

DOI URL |

| [59] |

LI Y, HU Y, CONG W, et al. Additive manufacturing of alumina using laser engineered net shaping: effects of deposition variables. Ceramics International, 2017, 43(10): 7768-7775.

DOI URL |

| [60] |

BALLA V K, BOSE S, BANDYOPADHYAY A. Processing of bulk alumina ceramics using laser engineered net shaping. International Journal of Applied Ceramic Technology, 2008, 5(3): 234-242.

DOI URL |

| [61] | GRIFFITH M, KEICHER D, ATWOOD C, et al. Free Form Fabrication of Metallic Components Using Laser Engineered Net Shaping (LENS). 1996 Solid Freeform Fabrication Symposium, Austin, 1996. |

| [62] |

NIU F, WU D, LU F, et al. Microstructure and macro properties of Al2O3 ceramics prepared by laser engineered net shaping. Ceramics International, 2018, 44(12): 14303-14310.

DOI URL |

| [63] |

HU Y, NING F, CONG W, et al. Ultrasonic vibration-assisted laser engineering net shaping of ZrO2-Al2O3 bulk parts: effects on crack suppression, microstructure, and mechanical properties. Ceramics International, 2018, 44(3): 2752-2760.

DOI URL |

| [64] |

NIU F, WU D, MA G, et al. Nanosized microstructure of Al2O3-ZrO2(Y2O3) eutectics fabricated by laser engineered net shaping. Scripta Materialia, 2015, 95: 39-41.

DOI URL |

| [65] |

NIU F, WU D, MA G, et al. Rapid fabrication of eutectic ceramic structures by laser engineered net shaping. Procedia CIRP, 2016, 42: 91-95.

DOI URL |

| [66] |

YAN S, WU D, MA G, et al. Nano-sized Al2O3-ZrO2 eutectic ceramic structures prepared by ultrasonic-assisted laser engineered net shaping. Materials Letters, 2018, 212: 8-11.

DOI URL |

| [67] |

NIU F, WU D, ZHOU S, et al. Power prediction for laser engineered net shaping of Al2O3 ceramic parts. Journal of the European Ceramic Society, 2014, 34(15): 3811-3817.

DOI URL |

| [68] |

YAN S, WU D, NIU F, et al. Effect of ultrasonic power on forming quality of nano-sized Al2O3-ZrO2 eutectic ceramic via laser engineered net shaping (LENS). Ceramics International, 2018, 44(1): 1120-1126.

DOI URL |

| [69] |

SU H J, ZHANG J, LIU L, et al. Rapid growth and formation mechanism of ultrafine structural oxide eutectic ceramics by laser direct forming. Applied Physics Letters, 2011, 99(22): 221913.

DOI URL |

| [70] | LIU H, SU H, SHEN Z, et al. Preparation of large-size Al2O3/GdAlO3/ZrO2 ternary eutectic ceramic rod by laser directed energy deposition and its microstructure homogenization mechanism. Journal of Materials Science & Technology, 2021, 85: 218-223. |

| [71] |

LIU H, SU H, SHEN Z, et al. One-step additive manufacturing and microstructure evolution of melt-grown Al2O3/GdAlO3/ZrO2 eutectic ceramics by laser directed energy deposition. Journal of the European Ceramic Society, 2021, 41(6): 3547-3558.

DOI URL |

| [72] |

WILKES J, HAGEDORN Y C, MEINERS W, et al. Additive manufacturing of ZrO2-Al2O3 ceramic components by selective laser melting. Rapid Prototyping Journal, 2013, 19(1): 51-57.

DOI URL |

| [73] | AGGARANGSI P, BEUTH J L. Localized Preheating Approaches for Reducing Residual Stress in Additive Manufacturing. International Solid Freeform Fabrication Symposium, Austin, 2006. |

| [74] | HAGEDORN Y, BALACHANDRAN N, MEINERS W, et al. SLM of Net-shaped High Strength Ceramics: New Opportunities for Producing Dental Restorations. Proceedings of the Solid Freeform Fabrication Symposium, Austin, 2011: 536-546. |

| [75] | LIU Z, SONG K, GAO B, et al. Microstructure and mechanical properties of Al2O3/ZrO2 directionally solidified eutectic ceramic prepared by laser 3D printing. Journal of Materials Science & Technology, 2016, 32(4): 320-325. |

| [76] | WILKES J, HAGEDORN Y C, OCYLOK S, et al. Rapid Manufacturing of Ceramic Parts by Selective Laser Melting. Ceramic Engineering and Science Proceedings, Wiley-Blackwell, United States, 2010. |

| [77] |

WILKES J, HAGEDORN Y C, MEINERS W, et al. Additive manufacturing of ZrO2-Al2O3 ceramic components by selective laser melting. Rapid Prototyping Journal, 2013, 19(1): 51-57.

DOI URL |

| [78] |

MISHRA G K, PAUL C P, RAI A K, et al. Experimental investigation on laser directed energy deposition based additive manufacturing of Al2O3 bulk structures. Ceramics International, 2021, 47(4): 5708-5720.

DOI URL |

| [79] |

MEYERS S, DE LEERSNIJDER L, VLEUGELS J, et al. Direct laser sintering of reaction bonded silicon carbide with low residual silicon content. Journal of the European Ceramic Society, 2018, 38(11): 3709-3717.

DOI URL |

| [80] | DUBINENKO G E, ZINOVIEV A L, BOLBASOV E N, et al. Preparation of poly(l-lactic acid)/hydroxyapatite composite scaffolds by fused deposit modeling 3D printing. Materials Today: Proceedings, 2020, 22: 228-234. |

| [81] |

MINASYAN T, LIU L, HOLOVENKO Y, et al. Additively manufactured mesostructured MoSi2-Si3N4 ceramic lattice. Ceramics International, 2019, 45(8): 9926-9933.

DOI URL |

| [82] |

HONG M H, MIN B K, LEE D H, et al. Marginal fit of metal-ceramic crowns fabricated by using a casting and two selective laser melting processes before and after ceramic firing. Journal of Prosthetic Dentistry, 2019, 122(5): 475-481.

DOI URL |

| [83] |

KING D, MIDDENDORF J, CISSEL K, et al. Selective laser melting for the preparation of an ultra-high temperature ceramic coating. Ceramics International, 2019, 45(2): 2466-2473.

DOI URL |

| [1] | ZHU Wenjie, TANG Lu, LU Jichang, LIU Jiangping, LUO Yongming. Research Progress on Catalytic Oxidation of Volatile Organic Compounds by Perovskite Oxides [J]. Journal of Inorganic Materials, 2025, 40(7): 735-746. |

| [2] | YU Leyangyang, ZHAO Fangxia, ZHANG Shuxin, XU Yixiang, NIU Yaran, ZHANG Zhenzhong, ZHENG Xuebin. Preparation of High-entropy Boride Powders for Plasma Spraying by Inductive Plasma Spheroidization [J]. Journal of Inorganic Materials, 2025, 40(7): 808-816. |

| [3] | WEI Zhifan, CHEN Guoqing, ZU Yufei, LIU Yuan, LI Minghao, FU Xuesong, ZHOU Wenlong. ZrB2-HfSi2 Ceramics: Microstructure and Formation Mechanism of Core-rim Structure [J]. Journal of Inorganic Materials, 2025, 40(7): 817-825. |

| [4] | HU Zhichao, YANG Hongyu, YANG Hongcheng, SUN Chengli, YANG Jun, LI Enzhu. Usage of the P-V-L Bond Theory in Regulating Properties of Microwave Dielectric Ceramics [J]. Journal of Inorganic Materials, 2025, 40(6): 609-626. |

| [5] | HE Guoqiang, ZHANG Kaiheng, WANG Zhentao, BAO Jian, XI Zhaochen, FANG Zhen, WANG Changhao, WANG Wei, WANG Xin, JIANG Jiapei, LI Xiangkun, ZHOU Di. Ba(Nd1/2Nb1/2)O3: Au Underrated K40 Microwave Dielectric Ceramic [J]. Journal of Inorganic Materials, 2025, 40(6): 639-646. |

| [6] | ZHANG Jiawei, CHEN Ning, CHENG Yuan, WANG Bo, ZHU Jianguo, JIN Cheng. Electrical Properties of Bismuth Layered Piezoelectric Bi4Ti3O12 Ceramics with A/B-site Doping [J]. Journal of Inorganic Materials, 2025, 40(6): 690-696. |

| [7] | TANG Ying, LI Jie, XIANG Huaicheng, FANG Weishuang, LIN Huixing, YANG Junfeng, FANG Liang. Rattling Effect: A New Mechanism Affecting the Resonant Frequency Temperature Coefficient of Microwave Dielectric Ceramics [J]. Journal of Inorganic Materials, 2025, 40(6): 656-666. |

| [8] | WU Qiong, SHEN Binglin, ZHANG Maohua, YAO Fangzhou, XING Zhipeng, WANG Ke. Research Progress on Lead-based Textured Piezoelectric Ceramics [J]. Journal of Inorganic Materials, 2025, 40(6): 563-574. |

| [9] | ZHANG Bihui, LIU Xiaoqiang, CHEN Xiangming. Recent Progress of Hybrid Improper Ferroelectrics with Ruddlesden-Popper Structure [J]. Journal of Inorganic Materials, 2025, 40(6): 587-608. |

| [10] | WU Jie, YANG Shuai, WANG Mingwen, LI Jinglei, LI Chunchun, LI Fei. Textured PT-based Piezoelectric Ceramics: Development, Status and Challenge [J]. Journal of Inorganic Materials, 2025, 40(6): 575-586. |

| [11] | ZHOU Yangyang, ZHANG Yanyan, YU Ziyi, FU Zhengqian, XU Fangfang, LIANG Ruihong, ZHOU Zhiyong. Enhancement of Piezoelectric Properties in CaBi4Ti4O15-based Ceramics through Bi3+ Self-doping Strategy [J]. Journal of Inorganic Materials, 2025, 40(6): 719-728. |

| [12] | YANG Yan, ZHANG Faqiang, MA Mingsheng, WANG Yongzhe, OUYANG Qi, LIU Zhifu. Low Temperature Sintering of ZnAl2O4 Ceramics with CuO-TiO2-Nb2O5 Composite Oxide Sintering Aid [J]. Journal of Inorganic Materials, 2025, 40(6): 711-718. |

| [13] | HUANG Zipeng, JIA Wenxiao, LI Lingxia. Crystal Structure and Terahertz Dielectric Properties of (Ti0.5W0.5)5+ Doped MgNb2O6 Ceramics [J]. Journal of Inorganic Materials, 2025, 40(6): 647-655. |

| [14] | JIANG Kun, LI Letian, ZHENG Mupeng, HU Yongming, PAN Qinxue, WU Chaofeng, WANG Ke. Research Progress on Low-temperature Sintering of PZT Ceramics [J]. Journal of Inorganic Materials, 2025, 40(6): 627-638. |

| [15] | YIN Changzhi, CHENG Mingfei, LEI Weicheng, CAI Yiyang, SONG Xiaoqiang, FU Ming, LÜ Wenzhong, LEI Wen. Effect of Ga3+ Doping on Crystal Structure Evolution and Microwave Dielectric Properties of SrAl2Si2O8 Ceramic [J]. Journal of Inorganic Materials, 2025, 40(6): 704-710. |

| Viewed | ||||||

|

Full text |

|

|||||

|

Abstract |

|

|||||