Journal of Inorganic Materials ›› 2019, Vol. 34 ›› Issue (12): 1245-1256.DOI: 10.15541/jim20190086

Special Issue: 二维材料

ZHANG Xing-Wang1,2,GAO Meng-Lei1,2,MENG Jun-Hua1,2

Received:2019-02-27

Revised:2019-04-19

Published:2019-12-20

Online:2019-06-17

Supported by:CLC Number:

ZHANG Xing-Wang, GAO Meng-Lei, MENG Jun-Hua. Research Progress of Direct Growth of Two-dimensional Hexagonal Boron Nitride on Dielectric Substrates[J]. Journal of Inorganic Materials, 2019, 34(12): 1245-1256.

| Preparation method | Advantages | Disadvantages |

|---|---|---|

| CVD | Low equipment cost, suitable for preparing large area sample | The complicated process, the interrelated growth parameters, many by-products |

| MOVPE | The cold wall reaction chamber which can prevent precursors from reacting on the inner wall | Highly toxic precursors, high growth temperature (>1000 ℃) |

| PLD, ALD and Magnetron sputtering | Easy to control the process, the low growth temperature (250-700 ℃) | The poor material quality, mostly amorphous |

| MBE | High material quality | Expensive equipment and high growth temperature (>1300 ℃) |

| Two-step method | The lower growth temperature (500-1000 ℃), simple process, suitable for preparing large area and patterned sample | Impurities are introduced during spin coating |

Table 1 Comparison of different methods for preparing 2D h-BN on dielectric substrates

| Preparation method | Advantages | Disadvantages |

|---|---|---|

| CVD | Low equipment cost, suitable for preparing large area sample | The complicated process, the interrelated growth parameters, many by-products |

| MOVPE | The cold wall reaction chamber which can prevent precursors from reacting on the inner wall | Highly toxic precursors, high growth temperature (>1000 ℃) |

| PLD, ALD and Magnetron sputtering | Easy to control the process, the low growth temperature (250-700 ℃) | The poor material quality, mostly amorphous |

| MBE | High material quality | Expensive equipment and high growth temperature (>1300 ℃) |

| Two-step method | The lower growth temperature (500-1000 ℃), simple process, suitable for preparing large area and patterned sample | Impurities are introduced during spin coating |

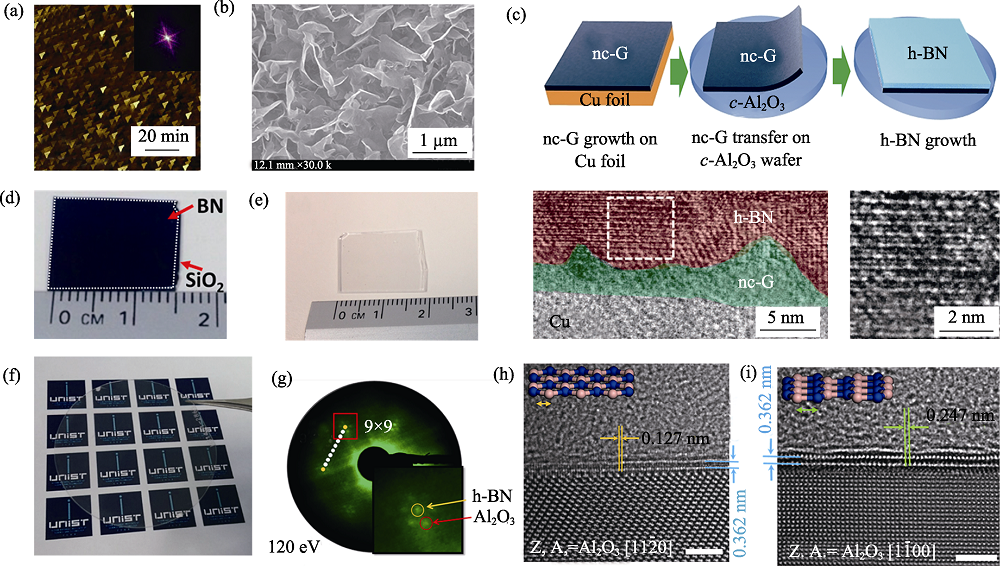

Fig. 1 (a) AFM image of h-BN on SiO2 for 20 min with inset image showing the FFT data[26]; (b) SEM image of the BN sheets grown on Si[27]; (c) Synthesis of h-BN film on sapphire substrate using nc-G and corresponding cross-sectional TEM and HRTEM images[28]; Camera view of h-BN on (d) SiO2 and (e) quartz surface[29,30]; (f) Photograph of EM-h-BN on sapphire substrate; (g) LEED pattern of h-BN grown on sapphire substrate; HR-TEM images of multilayer h-BN grown (h) perpendicular to Al2O3 (11ˉ20) and (i) parallel to Al2O3 (11ˉ20)[31]

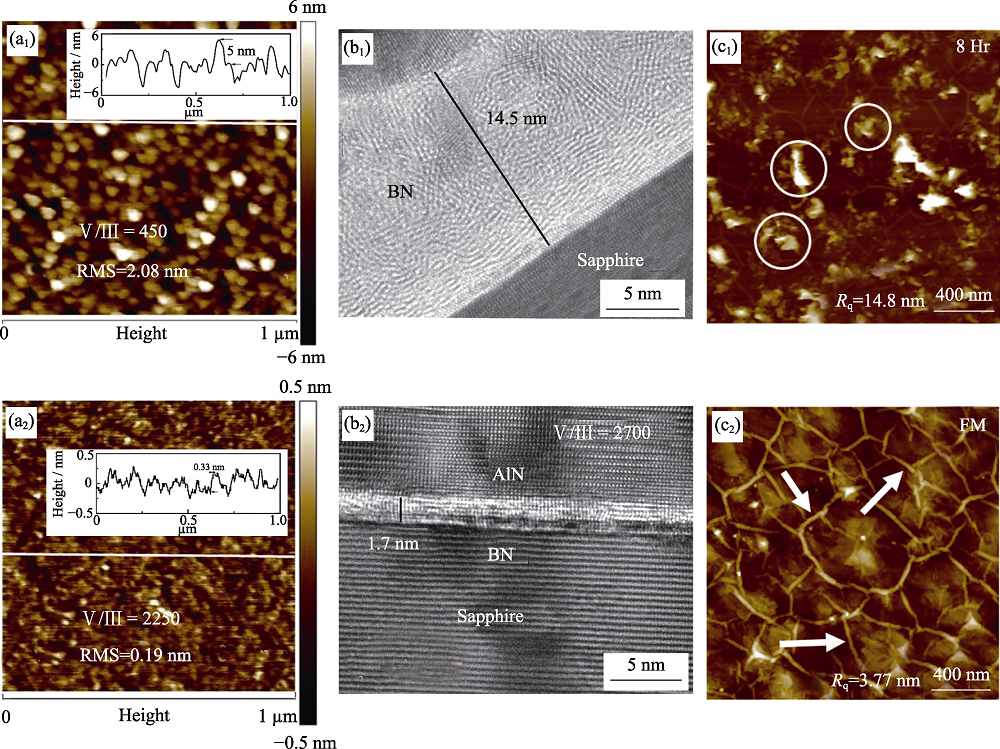

Fig. 2 (a) AFM micrographs with line scans and surface roughness measured on BN films grown at 1000 ℃ for 30 min[35]: (a1) V/III = 450, (a2) V/III = 2250; (b) Cross sectional TEM images of BN layer deposited using (b1) V/III ratio of 450 and (b2) 2700[35]; (c) Surface topography of h-BN films deposited for 8 h (c1) under continuous flow conditions and (c2) using FM scheme[36,37]

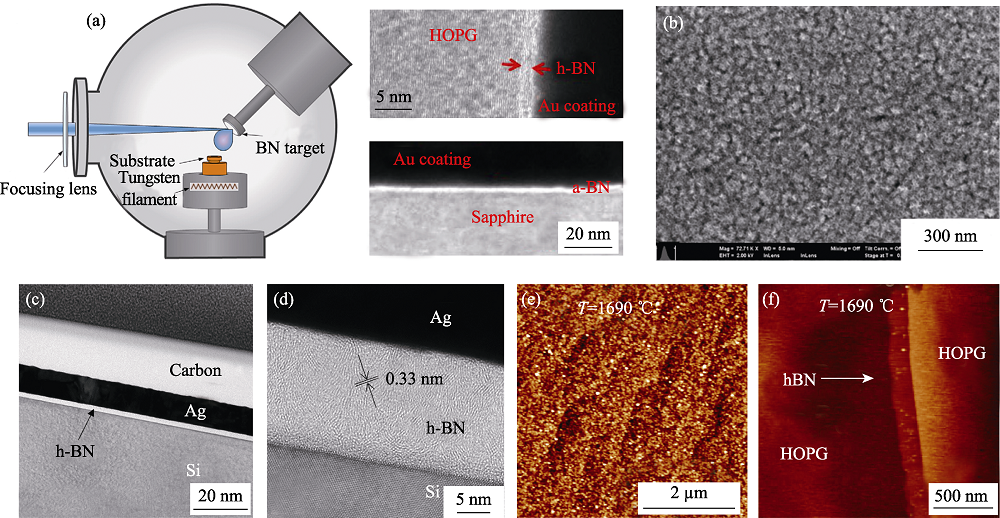

Fig. 3 (a) Schematic of PLD setup and the cross-sectional TEM image of h-BN on HOPG and a-BN on sapphire[42]; (b) High magnification SEM image of an amorphous BN film deposited on sapphire substrate[43]; (c) Cross-sectional TEM image of h-BN film on Si[44]; (d) High-magnification TEM image of the h-BN layered structure on Si[44]; (e-f) AFM images of h-BN grown on (e) sapphire and (f) HOPG for 3 h, 1690 ℃[45]

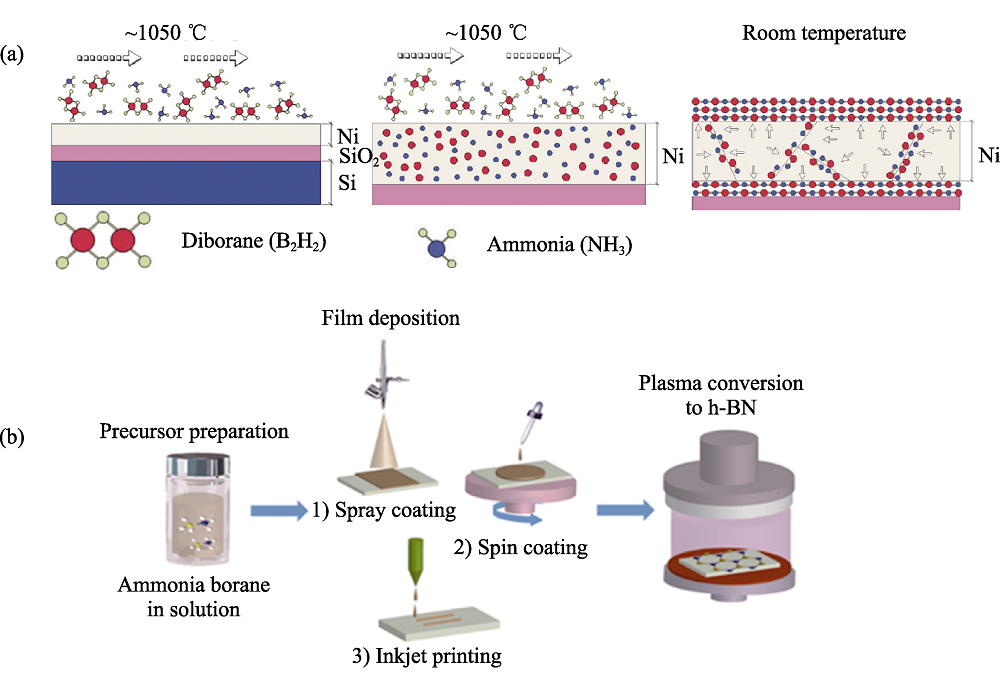

Fig. 4 (a) Growth mechanism of h-BN by diffusion and segregation[47] and (b) schematic illustration of process flow for synthesis of h-BN films by a two-step method[48]

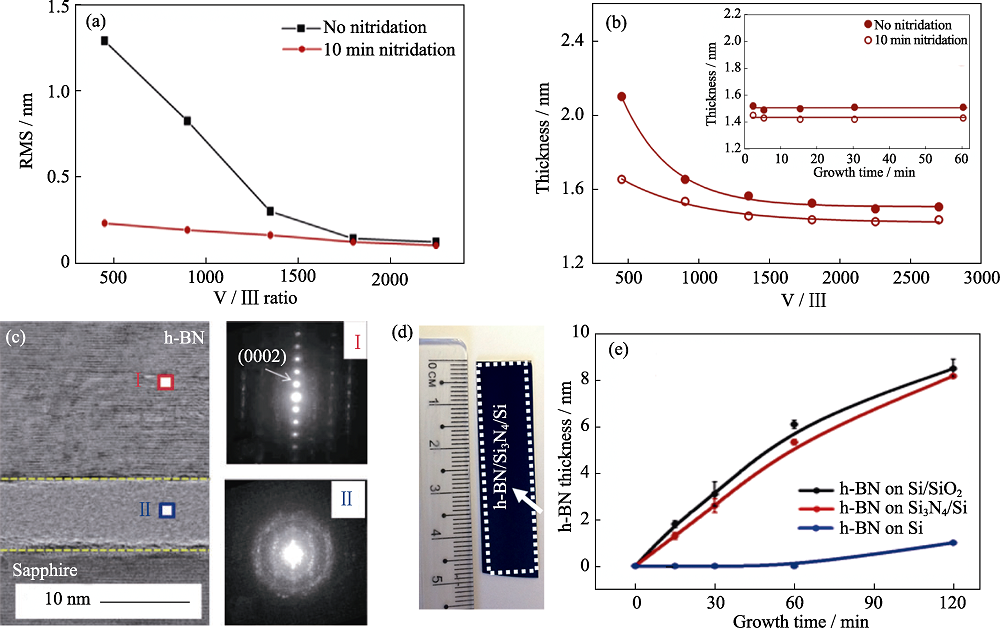

Fig. 5 (a) Plot of RMS determined by AFM vs. V/III; (b) Thickness vs. V/III for BN films grown on sapphire with and without the pre-growth nitridation process with insetshowing thickness vs. growth time for films grown using a V/III ratio of 2250; (c) Cross-sectional STEM image of h-BN grown on sapphire and diffraction patterns for selected areas I and II; (d) Camera view of h-BN on Si3N4/Si; (e) Variations of h-BN film thickness at different CVD growth times for Si3N4/Si, SiO2/Si, and Si substrates[30, 49-53]

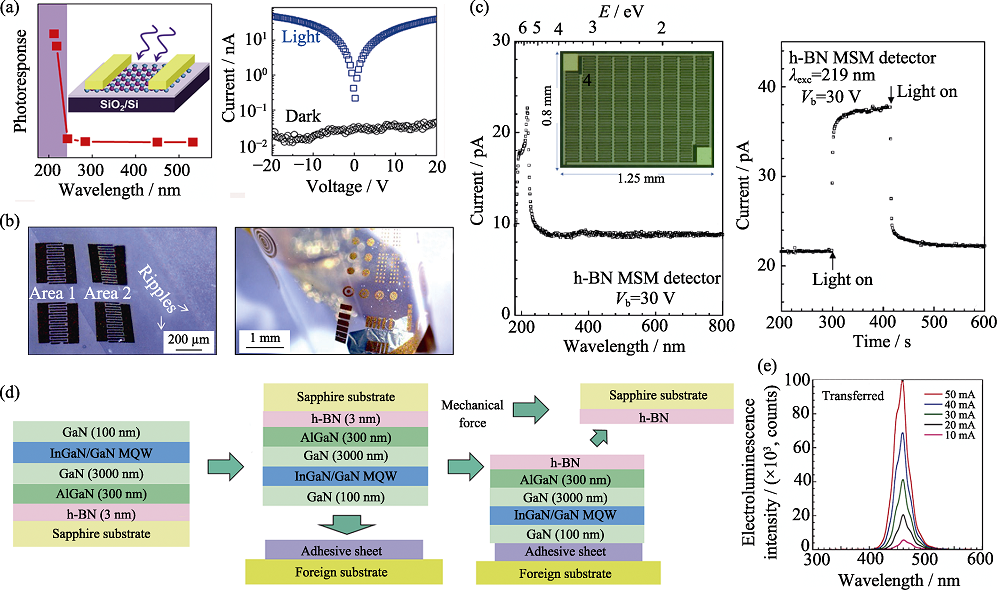

Fig. 6 (a) Response spectrum of the h-BN detector and I-V curves under 212 nm laser irradiation and dark condition[60]; (b) Microscope image of the transferred film and the photograph of the flexible metal-semiconductormetal device[61]; (c) The relative spectral response and photocurrent decay kinetics of h-BN MSM detector measured at Vb = 30 V (Inset showing a microscope image of the h-BN MSM photodetector)[62]; (d) Schematic illustrations of the MQW materials design, release and transfer processes[67]; (e) Electroluminescence spectra from the transferred LED[68]

| [1] | FERRARI A C, BONACCORSO F, FAL´KO V , et al. Science and technology roadmap for graphene, related two-dimensional crystals, and hybrid systems. Nanoscale, 2015,7(11):4598-4810. |

| [2] | TAN C, CAO X, WU X J ,et al. Recent advances in ultrathin two-dimensional nanomaterials. Chem. Rev., 2017,117(9):6225-6331. |

| [3] | GENG D, YANG H Y . Recent advances in growth of novel 2D materials: beyond graphene and transition metal dichalcogenides. Adv. Mater., 2018, 30 (45): 1800865-1-23. |

| [4] | LI L H, CHEN Y . Atomically thin boron nitride unique properties and applications. Adv. Funct. Mater., 2016,26(16):2594-2608. |

| [5] | IZYUMSKAYA N, DEMCHENKO D O, DAS S , et al. Recent development of boron nitride towards electronic applications. Adv. Electron. Mater., 2017,3(5):1600485. |

| [6] | DEAN C R, YOUNG A F, MERIC I , et al. Boron nitride substrates for high-quality graphene electronics. Nat. Nanotech., 2010,5:722-726. |

| [7] | WANG L, MERIC I, HUANG P Y , et al. One-dimensional electrical contact to a two-dimensional material. Science, 2013,324(6158):614-617. |

| [8] | LEE K H, SHIN H J, LEE J , et al. Large-scale synthesis of high-quality hexagonal boron nitride nanosheets for large-area graphene electronics. Nano Lett., 2012,12(2):714-718. |

| [9] | LEE J S, CHOI S H, YUN S J , et al. Wafer-scale single-crystal hexagonal boron nitride film via self-collimated grain formation. Science, 2018,362(6416):817-821. |

| [10] | BRITNELL L, GORBACHEV R V, JALIL R , et al. Field-effect tunneling transistor based on vertical graphene heterostructures. Science, 2012,335(6071):947-950. |

| [11] | WANG H, ZHAO Y. XIE Y , et al. Recent progress in synthesis of two-dimensional hexagonal boron nitride. J. Semicond., 2017,38(3):031003. |

| [12] | KHAN M H, LIU H K, SUN X , et al. Few-atomic-layered hexagonal boron nitride: CVD growth, characterization, and applications. Materials Today, 2017,20(10):611-628. |

| [13] | SUN J, LU C, SONG Y , et al. Recent progress in the tailored growth of two-dimensional hexagonal boron nitride via chemical vapour deposition. Chem. Soc. Rev., 2018,47:4242-4257 . |

| [14] | SONG L, CI L, LU H , et al. Large scale growth and characterization of atomic hexagonal boron nitride layers. Nano Lett., 2010,10(8):3209-3215. |

| [15] | LU G, WU T, YUAN Q , et al. Synthesis of large single-crystal hexagonal boron nitride grains on Cu-Ni alloy. Nat. Commun., 2015, 6: 6160-1-7. |

| [16] | CANEVA S, WEATHERUP R S, BAYER B C , et al. Nucleation control for large, single crystalline domains of monolayer hexagonal boron nitride via Si-doped Fe catalysts. Nano Lett., 2015,15(3):1867-1875. |

| [17] | JI Y, CALDERON B, HAN Y , et al. Chemical vapor deposition growth of large single-crystal mono-, bi-, tri-layer hexagonal boron nitride and their interlayer stacking. ACS Nano, 2017,11(12):12057-12066. |

| [18] | LIU L, SIEGEL D A, CHEN W , et al. Unusual role of epilayer- substrate interactions in determining orientational relations in van der Waals epitaxy. Proc. Natl. Acad. Sci. USA, 2014,111(47):16670-16675. |

| [19] | YIN J, LIU X F, LU W L , et al. Aligned growth of hexagonal boron nitride monolayer on germanium. Small, 2015,11(40):5375-5380. |

| [20] | WANG H L, ZHANG X W, LIU H , et al. Synthesis of large-sized single-crystal hexagonal boron nitride domains on nickel foils by ion beam sputtering deposition. Adv. Mater., 2015,27(48):8109-8115. |

| [21] | MENG J H, ZHANG X W, WANG Y , et al. Aligned growth of millimeter-size hexagonal boron nitride single-crystal domains on epitaxial nickel thin film. Small, 2017, 13(18): 1604179-1-8. |

| [22] | MENG J H, MING B M, ZHANG X W , et al. Controlled growth of unidirectionally aligned hexagonal boron nitride domains on single crystal Ni (111)/MgO thin films. Cryst. Growth Des., 2019,19(1):453-459. |

| [23] | OH H, JO J, TCHOE Y , et al. Centimeter-sized epitaxial h-BN films. NPG Asia Materials, 2016,8:e330. |

| [24] | KIM K, CHOI J Y, KIM T , et al. A role for graphene in silicon- based semiconductor devices. Nature, 2011,479:338-344. |

| [25] | TAY R Y, TSANG S H, LOEBLEIN M , et al. Direct growth of nanocrystalline hexagonal boron nitride films on dielectric substrates. Appl. Phys. Lett., 2015, 106(10): 101901-1-5. |

| [26] | WU Q, LEE J, SUN J , et al. In situ direct growth of graphene/ hexagonal boron nitride heterostructure on SiO2 substrate without metal catalyst. Carbon, 2018,138:76-80. |

| [27] | QIN L, YU J, LI M , et al. Catalyst-free growth of mono- Catalyst-free growth of mono- and few-atomic-layer boron nitride sheets by chemical vapor deposition. Nanotechnology, 2011, 22(21): 215602-1-7. |

| [28] | LEE K H, SHIN H J, KUMAR B , et al. Nanocrystalline graphene tailored hexagonal boron nitride thin films. Angew. Chem. Int. Ed., 2014,53(43):11493-11497. |

| [29] | CHEN Y, LIANG H, XIA X , et al. Growth temperature impact on film quality of hBN grown on Al2O3 using non-catalyzed borazane CVD. J. Mater. Sci.: Mater. Electron., 2017,28(19):14341-14347. |

| [30] | BEHURA S, NGUYEN P, CHE S , et al. Large-area, transfer-free, oxide-assisted synthesis of hexagonal boron nitride films and their heterostructures with MoS2 and WS2. J. Am. Chem. Soc, 2015,137(40):13060-13065. |

| [31] | JANG A R, HONG S, HYUN C , et al. Wafer-scale and wrinkle- free epitaxial growth of single-orientated multilayer hexagonal boron nitride on sapphire. Nano Lett., 2016,16(5):3360-3366. |

| [32] | CHUBAROV M, PEDERSEN H, HÖGBERG H , et al. Growth of high quality epitaxial rhombohedral boron nitride. Cryst. Growth Des., 2012,12(6):3215-3220. |

| [33] | PADUANO Q S, SNURE M, BONDY J , et al. Self-terminating growth in hexagonal boron nitride by metal organic chemical vapor deposition. Appl. Phys. Express, 2014, 7(7): 071004-1-4. |

| [34] | PADUANO Q, SNURE M, WEYBURNE D , et al. Metalorganic chemical vapor deposition of few-layer sp2 bonded boron nitride films. J. Cryst. Growth, 2016,449:148-155. |

| [35] | VANGALA S, SIEGEL G, PRUSNICK T , et al. Wafer scale BN on sapphire substrates for improved grapheme transport. Sci. Rep., 2018, 8(1): 8842-1-9. |

| [36] | YANG X, NITTA S, NAGAMATSU K , et al. Growth of hexagonal boron nitride on sapphire substrate by pulsed-mode metalorganic vapor phase epitaxy. J. Cryst. Growth, 2018,482:1-8. |

| [37] | CHUGH D, LEUNG J W, LI L , et al. Flow modulation epitaxy of hexagonal boron nitride. 2D Mater., 2018, 5(4): 045018-1-10. |

| [38] | RICE A, ALLERMAN A, CRAWFORD M , et al. Effects of deposition temperature and ammonia flow on metal-organic chemical vapor deposition of hexagonal boron nitride. J. Cryst. Growth, 2018,485:90-95. |

| [39] | LI X, SUNDARAM S, GMILI Y E , et al. Large-area two-dimensional layered hexagonal boron nitride grown on sapphire by metalorganic vapor phase epitaxy. Cryst. Growth Des., 2016,16(6):3409-3415. |

| [40] | SUTTER P, LAHIRI J, ZAHL P , et al. Scalable synthesis of uniform few-layer hexagonal boron nitride dielectric Films. Nano Lett., 2013,13(1):276-281. |

| [41] | WANG H L, ZHANG X W, MENG J H , et al. Controlled growth of few-layer hexagonal boron nitride on copper foils using ion beam sputtering deposition. Small, 2015,11(13):1542-1547. |

| [42] | GLAVIN N R, JESPERSEN M L, CHECK M H , et al. Synthesis of few-layer, large area hexagonal-boron nitride by pulsed laser deposition. Thin Solid Films, 2014,572:245-250. |

| [43] | STEWART D M, LAD R J . Enhanced crystallinity of h-BN films induced by substrate bias during magnetron sputtering. Phys. Status Solidi B, 2017, 255(3): 1700458-1-5. |

| [44] | PARK H, KIM T K, CHO S W , et al. Large-scale synthesis of uniform hexagonal boron nitride films by plasma-enhanced atomic layer deposition. Sci. Rep., 2017, 7: 40091-1-8. |

| [45] | VUONG T Q P, CASSABOISs G, VALVIN P , et al. Deep ultraviolet emission in hexagonal boron nitride grown by high-temperature molecular beam epitaxy. 2D Mater., 2017, 4(2): 021023-1-7. |

| [46] | BRESNEHAN M S, HOLLANDER M J, WETHERINGTON M , et al. Prospects of direct growth boron nitride films as substrates for graphene electronics. J. Mater. Res., 2014,29(3):459-471. |

| [47] | SONDE S, DOLOCAN A, LU N , et al. Ultrathin, wafer-scale hexagonal boron nitride on dielectric surfaces by diffusion and segregation mechanism. 2D Mater., 2017, 4(2): 025052-1-10. |

| [48] | LIU T, PREMASIRI K, SUI Y , et al. Direct, transfer-free growth of large-area hexagonal boron nitride films by plasma-enhanced chemical film conversion (PECFC) of printable, solution-processed ammonia borane. ACS Appl. Mater. Interfaces, 2018,10(50):43936-43945. |

| [49] | SNURE M, PADUANO Q, KIEFER A . Effect of surface nitridation on the epitaxial growth of few-layer sp2 BN. J. Cryst. Growth, 2014,436:16-22. |

| [50] | AHMED K, DAHAL R, WELTZ A , et al. Effects of sapphire nitridation and growth temperature on the epitaxial growth of hexagonal boron nitride on sapphire. Mater. Res. Express, 2017, 4(1): 015007-1-6. |

| [51] | YANG X, NITTA S, PRISTOVSEK M , et al. Interface amorphization in hexagonal boron nitride films on sapphire substrate grown by metalorganic vapor phase epitaxy. Appl. Phys. Express, 2018, 11(5): 051002-1-4. |

| [52] | SUNDARAM S, LI X, ALAM S , et al. Wafer-scale MOVPE growth and characterization of highly ordered h-BN on patterned sapphire substrates. J. Cryst. Growth, 2019,509:40-43. |

| [53] | BEHURA S, NGUYEN P, DEBBARMA R , et al. Chemical interaction- guided, metal-free growth of large-area hexagonal boron nitride on silicon-based substrates. ACS Nano, 2017,11(5):4985-4994. |

| [54] | LI Q, WU Q, GAO J , et al. Direct growth of 5 in. uniform hexagonal boron nitride on glass for high-performance deep-ultraviolet light-emitting diodes. Adv. Mater. Interfaces, 2018, 5(18): 1800662-1-8. |

| [55] | MAJETY S, LI J, ZHAO W P , et al. Hexagonal boron nitride and 6H- SiC heterostructures. Appl. Phys. Lett., 2013, 102(21): 213505-1-4. |

| [56] | SHIN H C, JANG Y, KIM T H , et al. Epitaxial growth of a single- crystal hybridized boron nitride and graphene layer on a wide-band gap semiconductor. J. Am. Chem. Soc., 2015,137(21):6897-6905. |

| [57] | WANG X B, WENG Q H, WANG X , et al. Biomass-directed synthesis of 20 g high-quality boron nitride nanosheets for thermoconductive polymeric composites. ACS Nano, 2014,8(9):9081-9088. |

| [58] | OROFEO C M, SUZUKI S, HIBINO H . Ultrathin chemical vapor deposition (CVD)-grown hexagonal boron nitride as a high-quality dielectric for tunneling devices on rigid and flexible substrates. J. Phys. Chem. C, 2014,118(6):3340-3346. |

| [59] | CHUANG H J, CHAMLAGAIN B, KOEHLER M , et al. Low-resistance 2D/2D ohmic contacts: a universal approach to high-performance WSe2, MoS2, and MoSe2 transistors. Nano Lett., 2016,16(3):1896-1902. |

| [60] | LIU H, MENG J, ZHANG X , et al. High-performance deep ultraviolet photodetectors based on few-layer hexagonal boron nitride. Nanoscale, 2018,10(12):5559-5565. |

| [61] | LI X, JORDAN M B, AYARI T , et al. Flexible metal- semiconductor-metal device prototype on waferscale thick boron nitride layers grown by MOVPE. Sci. Rep., 2017, 7(1): 786-1-8. |

| [62] | LI J, MAJETY S, DAHAL R , et al. Dielectric strength, optical absorption, and deep ultraviolet detectors of hexagonal boron nitride epilayers. Appl. Phys. Lett., 2012, 101(17): 171112-1-4. |

| [63] | AHMED K, DAHAL R, WELTZ A , et al. Growth of hexagonal boron nitride on (111) Si for deep UV photonics and thermal neutron detection. Appl. Phys. Lett., 2016, 109(11): 113501-1-4. |

| [64] | THANH D T, JIN J, KO K B , et al. Hexagonal boron nitride pattern embedded in AIN template layer for visible-blind ultraviolet photodetectors. Opt. Mater. Express, 2017,7(5):1463-1472. |

| [65] | WU Q, YAN J, ZHANG L , et al. Growth mechanism of AlN on hexagonal BN/sapphire substrate by metal-organic chemical vapor deposition. Cryst. Eng. Comm., 2017,19(39):5849-5856. |

| [66] | WU Q, GUO Y, SUNDARAM S , et al. Exfoliation of AlN film using two-dimensional multilayer hexagonal BN for deep-ultraviolet light-emitting diodes. Appl. Phys. Express, 2019, 12(1): 015505-1-5. |

| [67] | KOBAYASHI Y, KUMAKURA K, AKASAKA T , et al. Layered boron nitride as a release layer for mechanical transfer of GaN-based devices. Nature, 2012,484:223-227. |

| [68] | SUNDARAM S, LI X, ALAM S , et al. MOVPE van der Waals epitaxial growth of AlGaN/AlGaN multiple quantum well structures with deep UV emission on large scale 2D h-BN buffered sapphire substrates. J. Cryst. Growth, 2019,507:352-356. |

| [1] | ZHU Wenjie, TANG Lu, LU Jichang, LIU Jiangping, LUO Yongming. Research Progress on Catalytic Oxidation of Volatile Organic Compounds by Perovskite Oxides [J]. Journal of Inorganic Materials, 2025, 40(7): 735-746. |

| [2] | HU Zhichao, YANG Hongyu, YANG Hongcheng, SUN Chengli, YANG Jun, LI Enzhu. Usage of the P-V-L Bond Theory in Regulating Properties of Microwave Dielectric Ceramics [J]. Journal of Inorganic Materials, 2025, 40(6): 609-626. |

| [3] | WU Qiong, SHEN Binglin, ZHANG Maohua, YAO Fangzhou, XING Zhipeng, WANG Ke. Research Progress on Lead-based Textured Piezoelectric Ceramics [J]. Journal of Inorganic Materials, 2025, 40(6): 563-574. |

| [4] | ZHANG Bihui, LIU Xiaoqiang, CHEN Xiangming. Recent Progress of Hybrid Improper Ferroelectrics with Ruddlesden-Popper Structure [J]. Journal of Inorganic Materials, 2025, 40(6): 587-608. |

| [5] | WU Jie, YANG Shuai, WANG Mingwen, LI Jinglei, LI Chunchun, LI Fei. Textured PT-based Piezoelectric Ceramics: Development, Status and Challenge [J]. Journal of Inorganic Materials, 2025, 40(6): 575-586. |

| [6] | JIANG Kun, LI Letian, ZHENG Mupeng, HU Yongming, PAN Qinxue, WU Chaofeng, WANG Ke. Research Progress on Low-temperature Sintering of PZT Ceramics [J]. Journal of Inorganic Materials, 2025, 40(6): 627-638. |

| [7] | TIAN Ruizhi, LAN Zhengyi, YIN Jie, HAO Nanjing, CHEN Hangrong, MA Ming. Microfluidic Technology Based Synthesis of Inorganic Nano-biomaterials: Principles and Progress [J]. Journal of Inorganic Materials, 2025, 40(4): 337-347. |

| [8] | ZHANG Jiguo, WU Tian, ZHAO Xu, YANG Fan, XIA Tian, SUN Shien. Improvement of Cycling Stability of Cathode Materials and Industrialization Process for Sodium-ion Batteries [J]. Journal of Inorganic Materials, 2025, 40(4): 348-362. |

| [9] | YIN Jie, GENG Jiayi, WANG Kanglong, CHEN Zhongming, LIU Xuejian, HUANG Zhengren. Recent Advances in 3D Printing and Densification of SiC Ceramics [J]. Journal of Inorganic Materials, 2025, 40(3): 245-255. |

| [10] | CHEN Guangchang, DUAN Xiaoming, ZHU Jinrong, GONG Qing, CAI Delong, LI Yuhang, YANG Donglei, CHEN Biao, LI Xinmin, DENG Xudong, YU Jin, LIU Boya, HE Peigang, JIA Dechang, ZHOU Yu. Advanced Ceramic Materials in Helicopter Special Structures: Research Progress and Application Prospect [J]. Journal of Inorganic Materials, 2025, 40(3): 225-244. |

| [11] | FAN Xiaobo, ZU Mei, YANG Xiangfei, SONG Ce, CHEN Chen, WANG Zi, LUO Wenhua, CHENG Haifeng. Research Progress on Proton-regulated Electrochemical Ionic Synapses [J]. Journal of Inorganic Materials, 2025, 40(3): 256-270. |

| [12] | HAIREGU Tuxun, GUO Le, DING Jiayi, ZHOU Jiaqi, ZHANG Xueliang, NUERNISHA Alifu. Research Progress of Optical Bioimaging Technology Assisted by Upconversion Fluorescence Probes in Tumor Imaging [J]. Journal of Inorganic Materials, 2025, 40(2): 145-158. |

| [13] | SUN Shujuan, ZHENG Nannan, PAN Haokun, MA Meng, CHEN Jun, HUANG Xiubing. Research Progress on Preparation Methods of Single-atom Catalysts [J]. Journal of Inorganic Materials, 2025, 40(2): 113-127. |

| [14] | TAO Guilong, ZHI Guowei, LUO Tianyou, OUYANG Peidong, YI Xinyan, LI Guoqiang. Progress on Key Technologies of Cavity-structured Thin Film Bulk Acoustic Wave Filter [J]. Journal of Inorganic Materials, 2025, 40(2): 128-144. |

| [15] | ZHOU Fan, TIAN Zhilin, LI Bin. Research Progress on Carbide Ultra-high Temperature Ceramic Anti-ablation Coatings for Thermal Protection System [J]. Journal of Inorganic Materials, 2025, 40(1): 1-16. |

| Viewed | ||||||

|

Full text |

|

|||||

|

Abstract |

|

|||||