Journal of Inorganic Materials ›› 2019, Vol. 34 ›› Issue (11): 1133-1144.DOI: 10.15541/jim20180591

Received:2018-12-17

Revised:2019-03-25

Published:2019-11-20

Online:2019-05-29

Supported by:CLC Number:

TONG Wei, XIONG Dang-Sheng. Bioinspired Superhydrophobic Materials: Progress and Functional Application[J]. Journal of Inorganic Materials, 2019, 34(11): 1133-1144.

| Year | Bioinspired materials | Multiple functionalities for applications | Ref. |

|---|---|---|---|

| 1997 | Lotus leaf | Superhydrophobicity, self-cleaning | [8-9] |

| 2000 | Gecko foot-hair Spider silk | Superhydrophobicity, high adhesion Water collection | [10] [23] |

| 2001 | Desert beetle | Superhydrophobicity/superhydrophilicity | [11] |

| 2002 | Rice leaf Cactus stems | Superhydrophobicity, anisotropic wetting Fog collection, gradient wetting | [2] [24] |

| 2004 | Water strider leg Cicada wing | Superhydrophobicity, fluid friction reduction Superhydrophobicity, antireflection | [12] [13] |

| 2006 | Nepenthes pitcher plant | Slippery, underwater omniphobicity | [31-34] |

| 2007 | Butterfly wing Mosquito eye | Anisotropic wetting, structural coloration Antireflection, antifogging | [14] [15] |

| 2008 | Red rose petal | Superhydrophobicity, high or low adhesion | [16] |

| 2009 | Fish scale | Superhydrophilicity/underwater superoleophobicity | [17] |

| 2010 | Salvinia leaf Shark skin | Superhydrophobicity, high adhesion Fluid drag reduction | [18-19] [26-27] |

| 2011 | Poplar leaf hair Springtail cuticle | Superhydrophobicity, antireflection Superamphiphobicity | [20] [28] |

| 2012 | Clam shell | Superhydrophilicity/underwater superoleophobicity | [21] |

| 2016 | Penguin feather Skimmer beak | Icephobicity Drag reduction | [22] [29] |

| 2018 | Sarracenia trichome Earthworms | Water harvesting and transport Self-replenishing lubrication, friction reduction, antifouling | [25] [30] |

Table 1 Multiple functionalities of bioinspired materials

| Year | Bioinspired materials | Multiple functionalities for applications | Ref. |

|---|---|---|---|

| 1997 | Lotus leaf | Superhydrophobicity, self-cleaning | [8-9] |

| 2000 | Gecko foot-hair Spider silk | Superhydrophobicity, high adhesion Water collection | [10] [23] |

| 2001 | Desert beetle | Superhydrophobicity/superhydrophilicity | [11] |

| 2002 | Rice leaf Cactus stems | Superhydrophobicity, anisotropic wetting Fog collection, gradient wetting | [2] [24] |

| 2004 | Water strider leg Cicada wing | Superhydrophobicity, fluid friction reduction Superhydrophobicity, antireflection | [12] [13] |

| 2006 | Nepenthes pitcher plant | Slippery, underwater omniphobicity | [31-34] |

| 2007 | Butterfly wing Mosquito eye | Anisotropic wetting, structural coloration Antireflection, antifogging | [14] [15] |

| 2008 | Red rose petal | Superhydrophobicity, high or low adhesion | [16] |

| 2009 | Fish scale | Superhydrophilicity/underwater superoleophobicity | [17] |

| 2010 | Salvinia leaf Shark skin | Superhydrophobicity, high adhesion Fluid drag reduction | [18-19] [26-27] |

| 2011 | Poplar leaf hair Springtail cuticle | Superhydrophobicity, antireflection Superamphiphobicity | [20] [28] |

| 2012 | Clam shell | Superhydrophilicity/underwater superoleophobicity | [21] |

| 2016 | Penguin feather Skimmer beak | Icephobicity Drag reduction | [22] [29] |

| 2018 | Sarracenia trichome Earthworms | Water harvesting and transport Self-replenishing lubrication, friction reduction, antifouling | [25] [30] |

| Preparation | Advantages and Disadvantages | Mechanical durability | Wetting behaviors | Ref. | |||

|---|---|---|---|---|---|---|---|

| Sandpaper | Loading | Anti-wear situation | Before wear/(°) | After wear/(°) | |||

| Etching methods | Time-saving, low cost, but poor mechanical durability | 400# | 100 g | 200 cm | 161 | 156 | [42] |

| 240# | 200 g | 100 cm | 162 | 154 | [44] | ||

| Oscillating sand test Sand erosion test | 120 min | 170 | 155 | [41] | |||

| 9 kg | 161 | 158 | [43] | ||||

| Electrochemical methods | Fast, easily tuned, good mechanical durability, but high energy-consumption, needed complex operations | 1000# | 1.3 kPa | 500 cm | 160 | 148 | [49] |

| 1000# | 1.3 kPa | 500 cm | 167 | 137 | [51] | ||

| 400# | 2 kPa | 1200 cm | 155 | 143 | [52] | ||

| 800# | 3 kPa | 200 cm | 162 | 142 | [53] | ||

| 1000# | 3 kPa | 200 cm | 160 | 156 | [54] | ||

| 400# | 100 g | 500 cm | 165 | >150 | [58] | ||

| Chemical and physical deposition | Appplicable to different substrates, excellent mechanical durability, but time-consuming, limited to small areas | 1000# | 5 kPa | 1010 cm | 152 | 149 | [62] |

| 800# | 53 g | 400 cm | 157 | 152 | [63] | ||

| 320# | 300 g | 1460 cm | 178 | 140 | [64] | ||

| 1200# | 100 g | 320 cm | 152 | 150 | [65] | ||

| 240# | 100 g | 400 cm | 168 | 156 | [66] | ||

| 200# | 200 g | 965 cm | 166 | 153 | [67] | ||

| 2000# | 9.8 kPa | 6000 cm | 164 | 150 | [68] | ||

| 1000# | 100 g | 400 cm | 158 | 151 | [69] | ||

| 1500# | 200 g | 500 cm | 153 | 150 | [70] | ||

| Any other methods | - | 1000# | 50 g | 1200 cm | 172 | 150 | [74] |

| - | 400 g | 500 cm | 158 | 150 | [76] | ||

Table 2 Advantages and disadvantages with regard to superhydrophobic surface by different preparations

| Preparation | Advantages and Disadvantages | Mechanical durability | Wetting behaviors | Ref. | |||

|---|---|---|---|---|---|---|---|

| Sandpaper | Loading | Anti-wear situation | Before wear/(°) | After wear/(°) | |||

| Etching methods | Time-saving, low cost, but poor mechanical durability | 400# | 100 g | 200 cm | 161 | 156 | [42] |

| 240# | 200 g | 100 cm | 162 | 154 | [44] | ||

| Oscillating sand test Sand erosion test | 120 min | 170 | 155 | [41] | |||

| 9 kg | 161 | 158 | [43] | ||||

| Electrochemical methods | Fast, easily tuned, good mechanical durability, but high energy-consumption, needed complex operations | 1000# | 1.3 kPa | 500 cm | 160 | 148 | [49] |

| 1000# | 1.3 kPa | 500 cm | 167 | 137 | [51] | ||

| 400# | 2 kPa | 1200 cm | 155 | 143 | [52] | ||

| 800# | 3 kPa | 200 cm | 162 | 142 | [53] | ||

| 1000# | 3 kPa | 200 cm | 160 | 156 | [54] | ||

| 400# | 100 g | 500 cm | 165 | >150 | [58] | ||

| Chemical and physical deposition | Appplicable to different substrates, excellent mechanical durability, but time-consuming, limited to small areas | 1000# | 5 kPa | 1010 cm | 152 | 149 | [62] |

| 800# | 53 g | 400 cm | 157 | 152 | [63] | ||

| 320# | 300 g | 1460 cm | 178 | 140 | [64] | ||

| 1200# | 100 g | 320 cm | 152 | 150 | [65] | ||

| 240# | 100 g | 400 cm | 168 | 156 | [66] | ||

| 200# | 200 g | 965 cm | 166 | 153 | [67] | ||

| 2000# | 9.8 kPa | 6000 cm | 164 | 150 | [68] | ||

| 1000# | 100 g | 400 cm | 158 | 151 | [69] | ||

| 1500# | 200 g | 500 cm | 153 | 150 | [70] | ||

| Any other methods | - | 1000# | 50 g | 1200 cm | 172 | 150 | [74] |

| - | 400 g | 500 cm | 158 | 150 | [76] | ||

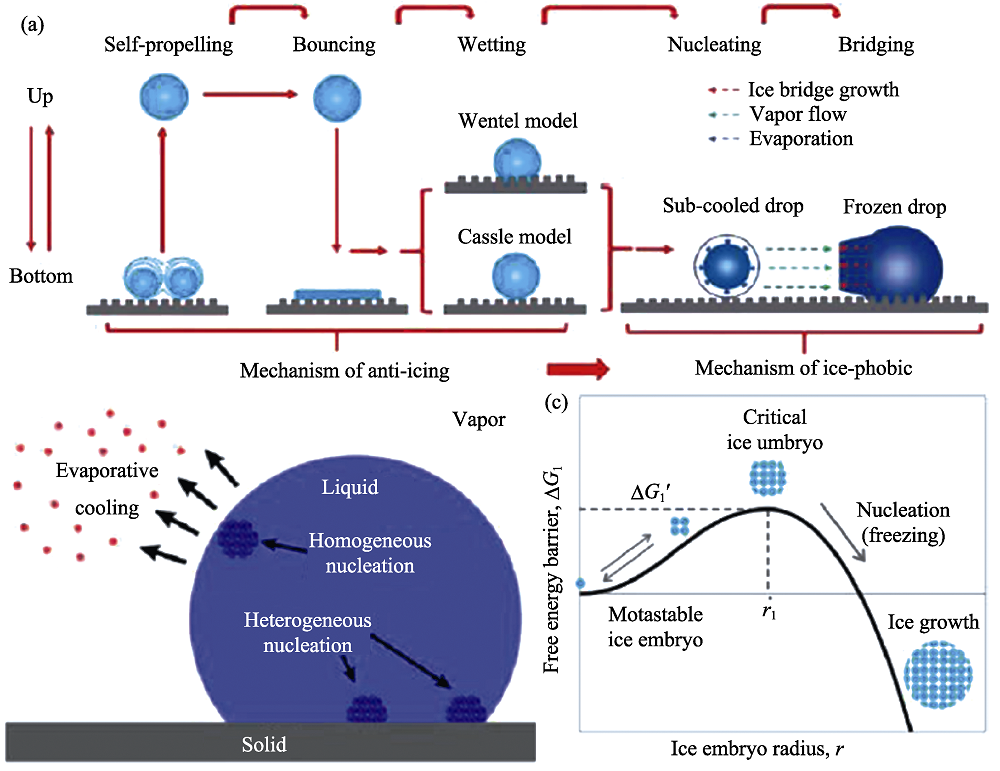

Fig. 3 (a) Mechanisms of anti-icing and ice-phobic surface[85]; (b) Schematic diagram showing the regions within a water droplet where homogeneous and heterogeneous ice nucleation occurs; (c) Gibbs free energy barrier during freezing process against the ice embryo radius (Below critical size the ice embryo is metastable and above critical size the ice embryo is stable to initiate the freezing process)[86]

| Superhydrophobic surfaces (Ref.) | [101] | [102] | [103] | [104] | [105] | [106] | [107] |

|---|---|---|---|---|---|---|---|

| Ice adhesion strength | 35.7 kPa | 201 kPa | 100 kPa | 64.7 kPa | 25 N | 113 kPa | 26.3 kPa |

| Contact angles/(°) | 164 | 154.3 | 164 | 157 | 161 | 153 | 155.3 |

| Sliding angles/(°) | 1.5 | 4.1 | 2 | - | 6.5 | 14.3 | 2 |

Table 3 Superhydrophobic surface against ice adhesion

| Superhydrophobic surfaces (Ref.) | [101] | [102] | [103] | [104] | [105] | [106] | [107] |

|---|---|---|---|---|---|---|---|

| Ice adhesion strength | 35.7 kPa | 201 kPa | 100 kPa | 64.7 kPa | 25 N | 113 kPa | 26.3 kPa |

| Contact angles/(°) | 164 | 154.3 | 164 | 157 | 161 | 153 | 155.3 |

| Sliding angles/(°) | 1.5 | 4.1 | 2 | - | 6.5 | 14.3 | 2 |

| [1] | 江雷, 冯琳 . 仿生智能纳米界面材料. 北京: 化学工业出版社, 2007: 1-48. |

| [2] | LIN F, LI S, LI Y , et al. Super-hydrophobic surfaces: from natural to artificial. Adv. Mater., 2002,14(24):1857-1860. |

| [3] | YOUNG T . An essay on the cohesion of fliuds. Philos. Trans. R. S. London, 1805,95:65-87. |

| [4] | WENZEL R N . Resistance of solid surfaces to wetting by water. Ind. Eng. Chem, 1936,28(8):988-994. |

| [5] | CASSIE A, BAXTER S . Wettability of porous surfaces. Trans. Faraday Soc., 1944,40:546-551. |

| [6] | SI Y, DONG Z, JIANG L . Bioinspired designs of superhydrophobic and superhydrophilic materials. ACS Cent. Sci., 2018,4(9):1102-1112. |

| [7] | SUN Y, GUO Z . Recent advances of bioinspired functional materials with special wettability: from nature and beyond nature. Nanoscale Horiz., 2019,4:52-76. |

| [8] | BARTHLOTT W, NEINHUIS C . Purity of the sacred lotus, or escape from contamination in biological surfaces. Planta, 1997,202(1):1-8. |

| [9] | NEINHUIS C, BARTHLOTT W . Characterization and distribution of water-repellent, self-cleaning plant surfaces. Ann. Bot., 1997,79(6):667-677. |

| [10] | AUTUMN K, LIANG Y A, HSIEH S T , et al. Adhesive force of a single gecko foot-hair. Nature, 2000,405(6787):681-685. |

| [11] | PARKER A R, LAWRENCE C R . Water capture by a desert beetle. Nature, 2001,414(6859):33-34. |

| [12] | GAO X, JIANG L . Biophysics: water-repellent legs of water striders. Nature, 2004,432(7013):36. |

| [13] | LEE W, JIN M K, YOO W C , et al. Nanostructuring of a polymeric substrate with well-defined nanometer-scale topography and tailored surface wettability. Langmuir, 2004,20(18):7665-7669. |

| [14] | ZHENG Y, GAO X, JIANG L . Directional adhesion of superhydrophobic butterfly wings. Soft Matter, 2007,3(2):178-182. |

| [15] | GAO X, YAN X, YAO X , et al. The dry-style antifogging properties of mosquito compound eyes and artificial analogues prepared by soft lithography. Adv. Mater., 2007,19(17):2213-2217. |

| [16] | FENG L, ZHANG Y, XI J , et al. Petal effect: a superhydrophobic state with high adhesive force. Langmuir, 2008,24(8):4114-4119. |

| [17] | LIU M, WANG S, WEI Z , et al. Bioinspired design of a superoleophobic and low adhesive water/solid interface. Adv. Mater., 2009,21(6):665-669. |

| [18] | KOCH K, BHUSHAN B, BARTHLOTT W . Multifunctional surface structures of plants: an inspiration for biomimetics. Prog. Mater. Sci., 2009,54(2):137-178. |

| [19] | BARTHLOTT W, SCHIMMEL T, WIERSCH S , et al. The salvinia paradox: superhydrophobic surfaces with hydrophilic pins for air retention under. Adv. Mater., 2010,22(21):2325-2328. |

| [20] | YE C, LI M, HU J , et al. Highly reflective superhydrophobic white coating inspired by poplar leaf hairs toward an effective “cool roof”. Energy Environ. Sci., 2011,4(9):3364-3367. |

| [21] | LIU X, ZHOU J, XUE Z , et al. Clam’s shell inspired high-energy inorganic coatings with underwater low adhesive superoleophobicity. Adv. Mater., 2012,24(25):3401-3405. |

| [22] | WANG S, YANG Z, GUO G , et al. Icephobicity of penguins spheniscus humboldti and an artificial replica of penguin feather with air-infused hierarchical rough structures. J. Phys. Chem. C, 2016,120(29):15923-15929. |

| [23] | ZHENG Y, BAI H, HUANG Z , et al. Directional water collection on wetted spider silk. Nature, 2010,463(7281):640-643. |

| [24] | JU J, BAI H, ZHENG Y , et al. A multi-structural and multi- functional integrated fog collection system in cactus. Nat. Commun., 2012,3(1):1247. |

| [25] | CHEN H, RAN T, GAN Y , et al. Ultrafast water harvesting and transport in hierarchical microchannels. Nat. Mater., 2018,17(10):935-942. |

| [26] | DEAN B, BHUSHAN B . Shark-skin surfaces for fluid-drag reduction in turbulent flow: a review. Phil. Trans. R. Soc. A, 2010,368(1929):4775-4806. |

| [27] | BIXLER G D, BHUSHAN B . Fluid drag reduction with shark- skin riblet inspired microstructured surfaces. Adv. Funct. Mater., 2013,23(26):4507-4528. |

| [28] | HELBIG R, NICKERL J, NEINHUIS C , et al. Smart skin patterns protect springtails. PLoS One, 2011,6(9):e25105. |

| [29] | MARTIN S, BHUSHAN B . Discovery of riblets in a bird beak (Rynchops) for low fluid drag. Phil. Trans. R. Soc. A, 2016,374(2073):20160134. |

| [30] | ZHAO H, SUN Q, DENG X , et al. Earthworm-inspired rough polymer coatings with self-replenishing lubrication for adaptive friction-reduction and antifouling surfaces. Adv. Mater., 2018,30(29):1802141. |

| [31] | GORB E V, GORB S N . Physicochernical properties of functional surfaces in pitchers of the carnivorous plant nepenthes alata blanco (Nepenthaceae). Plant Biol., 2006,8(6):841-848. |

| [32] | BOHN H F, FEDERLE W . Insect aquaplaning: nepenthes pitcher plants capture prey with the peristome, a fully wettable waterlubricated anisotropic surface. Proc. Natl. Acad. Sci. U. S. A., 2004,101(39):14138-14143. |

| [33] | GORB E, KASTNER V, PERESSADKO A , et al. Structure and properties of the glandular surface in the digestive zone of the pitcher in the carnivorous plant nepenthes ventrata and its role in insect trapping and retention. J. Exp. Biol., 2004,207(17):2947-2963. |

| [34] | WONG T S, KANG S H, TANG S K , et al. Bioinspired self- repairing slippery surfaces with pressure-stable omniphobicity. Nature, 2011,477(7365):443-447. |

| [35] | DOU W, WU J, GU T , et al. Preparation of super-hydrophobic micro-needle CuO surface as a barrier against marine atmospheric corrosion. Corros. Sci., 2018,131:156-163. |

| [36] | TONG W, XIONG D, WANG N , et al. Green and timesaving fabrication of a superhydrophobic surface and its application to anti-icing, self-cleaning and oil-water separation. Surf. Coat. Technol., 2018,352:609-618. |

| [37] | WAN Y, CHEN M, LIU W , et al. The research on preparation of superhydrophobic surfaces of pure copper by hydrothermal method and its corrosion resistance. Electrochim. Acta, 2018,270:310-318. |

| [38] | KIM J, MIRZAEI A, KIM H W , et al. Realization of superhydrophobic aluminum surfaces with novel micro-terrace nano- leaf hierarchical structure. Appl. Surf. Sci., 2018,451:207-217. |

| [39] | NANDA D, SAHOO A, KUMAR A , et al. Facile approach to develop durable and reusable superhydrophobic/superoleophilic coatings for steel mesh surfaces. J. Colloid Interface Sci., 2019,535:50-57. |

| [40] | LIU Y, LI X, JIN J , et al. Anti-icing property of bio-inspired micro- structure superhydrophobic surfaces and heat transfer model. Appl. Surf. Sci., 2017,400:498-505. |

| [41] | BOINOVICH L B, MODIN E B, SAYFUTDINOVA A R , et al. Combination of functional nanoengineering and nanosecond laser texturing for design of superhydrophobic aluminum alloy with exceptional mechanical and chemical properties. ACS Nano, 2017,11(10):10113-10123. |

| [42] | MA Q, TONG Z, WANG W , et al. Fabricating robust and repairable superhydrophobic surface on carbon steel by nanosecond laser texturing for corrosion protection. Appl. Surf. Sci., 2018,455:748-757. |

| [43] | LIN Y, HAN J, CAI M , et al. Durable and robust transparent superhydrophobic glass surfaces fabricated by a femtosecond laser with exceptional water repellency and thermostability. J. Mater. Chem. A, 2018,6(19):9049-9056. |

| [44] | SONG J, WANG D, HU L , et al. Superhydrophobic surface fabricated by nanosecond laser and perhydropolysilazane. Appl. Surf. Sci., 2018,455:771-779. |

| [45] | ZHU J, HU X . A novel route for fabrication of the corrosion- resistant superhydrophobic surface by turning operation. Surf. Coat. Technol., 2017,313:294-298. |

| [46] | ZHU J . A novel fabrication of superhydrophobic surfaces on aluminum substrate. Appl. Surf. Sci., 2018,447:363-367. |

| [47] | MOKHTARI S, KARIMZADEH F, ABBASI M H , et al. Development of super-hydrophobic surface on Al 6061 by anodizing and the evaluation of its corrosion behavior. Surf. Coat. Technol., 2017,324:99-105. |

| [48] | LI S, XIANG X, MA B , et al. Facile preparation of diverse alumina surface structures by anodization and superhydrophobic surfaces with tunable water droplet adhesion. J. Alloys Compd., 2019,779:219-228. |

| [49] | LIU Q, CHEN D, KANG Z . One-step electrodeposition process to fabricate corrosion-resistant superhydrophobic surface on magnesium alloy. ACS Appl. Mater. Interfaces, 2015,7(3):1859-1867. |

| [50] | TESLER A B, KIM P, KOLLE S , et al. Extremely durable biofouling-resistant metallic surfaces based on electrodeposited nanoporous tungstite films on steel. Nat. Commun., 2015,6(1):8649. |

| [51] | ZHANG B, ZHAO X, LI Y , et al. Fabrication of durable anticorrosion superhydrophobic surfaces on aluminum substrates via a facile one-step electrodeposition approach. RSC Advances, 2016,6(42):35455-35465. |

| [52] | TAM J, JIAO Z, LAU J C F , , et al. Wear stability of superhydrophobic nano Ni-PTFE electrodeposits. Wear, 2017, 374-375:1-4. |

| [53] | JAIN R, PITCHUMANI R . Facile fabrication of durable copper- based superhydrophobic surfaces via electrodeposition. Langmuir, 2018,34(10):3159-3169. |

| [54] | JAIN R, PITCHUMANI R . Fabrication and characterization of zinc-based superhydrophobic coatings. Surf. Coat. Technol., 2018,337:223-231. |

| [55] | YE Y, LIU Z, LIU W , et al. Superhydrophobic oligoaniline- containing electroactive silica coating as pre-process coating for corrosion protection of carbon steel. Chem. Eng. J., 2018,348:940-951. |

| [56] | ZOU Y, WANG Y, XU S , et al. Superhydrophobic double-layer coating for efficient heat dissipation and corrosion protection. Chem. Eng. J., 2019,362:638-649. |

| [57] | ZANG D, ZHU R, ZHANG W , et al. Corrosion-resistant superhydrophobic coatings on Mg alloy surfaces inspired by lotus seedpod. Adv. Funct. Mater., 2017,27(8):1605446. |

| [58] | QING Y, HU C, YANG C , et al. Rough structure of electrodeposition as a template for an ultrarobust self-cleaning surface. ACS Appl. Mater. Interfaces, 2017,9(19):16571-16580. |

| [59] | BÖKE F, GINER I, KELLER A , et al. Plasma-enhanced chemical vapor deposition (PE-CVD) yields better hydrolytical stability of biocompatible SiOx thin films on implant alumina ceramics compared to rapid thermal evaporation physical vapor deposition (PVD). ACS Appl. Mater. Interfaces, 2016,8(28):17805-17816. |

| [60] | VILARÓ I, YAGÜE J L, BORRÓS S . Superhydrophobic copper surfaces with anticorrosion properties fabricated by solventless CVD methods. ACS Appl. Mater. Interfaces, 2017,9(1):1057-1065. |

| [61] | ZHANG F, SHI Z, CHEN L , et al. Porous superhydrophobic and superoleophilic surfaces prepared by template assisted chemical vapor deposition. Surf. Coat. Technol., 2017,315:385-390. |

| [62] | WU Y, JIA S, WANG S , et al. A facile and novel emulsion for efficient and convenient fabrication of durable superhydrophobic materials. Chem. Eng. J., 2017,328:186-196. |

| [63] | REN G, SONG Y, LI X , et al. A simple way to an ultra-robust superhydrophobic fabric with mechanical stability, UV durability, and UV shielding property. J. Colloid Interface Sci., 2018,522:57-62. |

| [64] | ZHONG M, ZHANG Y, LI X , et al. Facile fabrication of durable superhydrophobic silica/epoxy resin coatings with compatible transparency and stability. Surf. Coat. Technol., 2018,347:191-198. |

| [65] | YU N, XIAO X, YE Z , et al. Facile preparation of durable superhydrophobic coating with self-cleaning property. Surf. Coat. Technol., 2018,347:199-208. |

| [66] | LU Y, SATHASIVAM S, SONG J , et al. Robust self-cleaning surfaces that function when exposed to either air or oil. Science, 2015,347(6226):1132-1135. |

| [67] | WANG N, LU Y, XIONG D , et al. Designing durable and flexible superhydrophobic coating and its application in oil purification. J. Mater. Chem. A, 2016,4(11):4107-4116. |

| [68] | LI Y, LI B, ZHAO X , et al. Totally waterborne, nonfluorinated, mechanically robust, and self-healing superhydrophobic coatings for actual anti-icing. ACS Appl. Mater. Interfaces, 2018,10(45):39391-39399. |

| [69] | CHEN Z, LI G, WANG L , et al. A strategy for constructing superhydrophobic multilayer coatings with self-cleaning properties and mechanical durability based on the anchoring effect of organopolysilazane. Mater. Des., 2018,141:37-47. |

| [70] | TU K, WANG X, KONG L , et al. Facile preparation of mechanically durable, self-healing and multifunctional superhydrophobic surfaces on solid wood. Mater. Des., 2018,140:30-36. |

| [71] | DENG X, MAMMEN L, BUTT H , et al. Candle soot as a template for a transparent robust superamphiphobic coating. Science, 2012,335(6064):67-69. |

| [72] | XIAO L, ZENG W, LIAO G , et al. Thermally and chemically stable candle soot superhydrophobic surface with excellent self- cleaning properties in air and oil. ACS Appl. Nano Mater., 2018,1(3):1204-1211. |

| [73] | TONG W, XIONG D, TIAN T , et al. Superhydrophobic surface on aeronautical materials via the deposition of nanoparticles and a PDMS seal. Appl. Phys. A, 2019,125(3):177. |

| [74] | DONG S, WANG Z, WANG Y , et al. Roll-to-roll manufacturing of robust superhydrophobic coating on metallic engineering materials. ACS Appl. Mater. Interfaces, 2018,10(2):2174-2184. |

| [75] | WU Y, ZHAO M, GUO Z . Multifunctional superamphiphobic SiO2 coating for crude oil transportation. Chem. Eng. J., 2018,334:1584-1593. |

| [76] | PENG W, GOU X, QIN H , et al. Creation of a multifunctional superhydrophobic coating for composite insulators. Chem. Eng. J., 2018,352:774-781. |

| [77] | SU X, LI H, LAI X , et al. Vacuum-assisted layer-by-layer superhydrophobic carbon nanotube films with electrothermal and photothermal effects for deicing and controllable manipulation. J. Mater. Chem. A, 2018,6(35):16910-16919. |

| [78] | PENG C, CHEN Z, TIWARI M K . All-organic superhydrophobic coatings with mechanochemical robustness and liquid impalement resistance. Nat. Mater., 2018,17(4):355-360. |

| [79] | KIM Y S, SHANG M, KANG S , et al. Strong hydrophobic coating by conducting a new hierarchical architecture. J. Phys. Chem. C, 2018,112(8):4628-4634. |

| [80] | ZHAO S, ZHAO J, WEN M , et al. Sequentially reinforced additive coating for transparent and durable superhydrophobic glass. Langmuir, 2018,34(38):11316-11324. |

| [81] | CHEN S, SONG Y, XU F . Highly transparent and hazy cellulose nanopaper simultaneously with a self-cleaning superhydrophobic surface. ACS Sustainable Chem. Eng., 2018,6(4):5173-5181. |

| [82] | TEISALA H, GEYER F, HAAPANEN J , et al. Ultrafast processing of hierarchical nanotexture for a transparent superamphiphobic coating with extremely low roll-off angle and high impalement pressure. Adv. Mater., 2018,30(14):1706529. |

| [83] | WU Y, ZENG J, SI Y , et al. Large-area preparation of robust and transparent superomniphobic polymer films. ACS Nano, 2018,12(10):10338-10346. |

| [84] | VARANASI K K, MING H, BHATE N , et al. Spatial control in the heterogeneous nucleation of water. Appl. Phys. Lett., 2009,95(9):144101. |

| [85] | LI Q, GUO Z . Fundamentals of icing and common strategies for designing biomimetic anti-icing surfaces. J. Mater. Chem. A, 2018,6(28):13549-13581. |

| [86] | JAMIL M I, ALI A, HAQ F , et al. Icephobic strategies and materials with superwettability: design principles and mechanism. Langmuir, 2018,34(50):15425-15444. |

| [87] | LI N, WU L, YU C , et al. Ballistic jumping drops on superhydrophobic surfaces via electrostatic manipulation. Adv. Mater., 2018,30(8):1703838. |

| [88] | SHEN Y, TAO J, WANG G , et al. Bioinspired fabrication of hierarchical-structured superhydrophobic surfaces to understand droplet bouncing dynamics for enhancing water repellency. J. Phys. Chem. C, 2018,122(13):7312-7320. |

| [89] | SHEN Y, LIU S, ZHU C , et al. Facile fabrication of hierarchical structured superhydrophobic surface and its ultra dynamic water repellency. Chem. Eng. J., 2017,313:47-55. |

| [90] | MISHCHENKO L, HATTON B, BAHADUR V , et al. Design of ice-free nanostructured surfaces based on repulsion of impacting water droplets. ACS Nano, 2010,4(12):7699-7707. |

| [91] | FAROKHIRAD S, LEE T . Computational study of microparticle effect on self-propelled jumping of droplets from superhydrophobic substrates. Int. J. Multiphas Flow, 2017,95:220-234. |

| [92] | RICHARD D, CLANET C, QUÉRÉ D . Surface phenomena: contact time of a bouncing drop. Nature, 2002,417(6891):811-811. |

| [93] | SCHUTZIUS T M, JUNG S, MAITRA T , et al. Spontaneous droplet trampolining on rigid superhydrophobic surfaces. Nature, 2015,527(7576):82-85. |

| [94] | WANG S, ZHANG W, YU X , et al. Sprayable superhydrophobic nano-chains coating with continuous self-jumping of dew and melting frost. Sci. Rep-UK, 2017,7(1):40300. |

| [95] | ZHANG W, WANG S, XIAO Z , et al. Frosting behavior of superhydrophobic nanoarrays under ultralow temperature. Langmuir, 2017,33(36):8891-8898. |

| [96] | ZHANG P, MAEDA Y, LÜ F , et al. Enhanced coalescence- induced droplet-jumping on nanostructured superhydrophobic surfaces in the absence of microstructures. ACS Appl. Mater. Interfaces, 2017,9(40):35391-35403. |

| [97] | JUNG S, DORRESTIJN M, RAPS D , et al. Are superhydrophobic surfaces best for icephobicity. Langmuir, 2011,27(6):3059-3066. |

| [98] | EMELYANENKO A M, BOINOVICH L B, BEZDOMNIKOV A A , et al. Reinforced superhydrophobic coating on silicone rubber for longstanding anti-icing performance in severe conditions. ACS Appl. Mater. Interfaces, 2017,9(28):24210-24219. |

| [99] | WU X, CHEN Z . A mechanically robust transparent coating for antiicing and self-cleaning applications. J. Mater. Chem. A, 2018,6:16043-16052. |

| [100] | RYZHKIN I A, PETRENKO V F . Proton ordering in ice at an ice-metal interface. J. Exp. Theor. Phys., 2005,101(2):317-321. |

| [101] | JIN M, SHEN Y, LUO X , et al. A combination structure of microblock and nanohair fabricated by chemical etching for excellent water repellency and icephobicity. Appl. Surf. Sci., 2018,455:883-890. |

| [102] | XI N, LIU Y, ZHANG X , et al. Steady anti-icing coatings on weathering steel fabricated by HVOF spraying. Appl. Surf. Sci., 2018,444:757-762. |

| [103] | WANG N, TANG L, TONG W , et al. Fabrication of robust and scalable superhydrophobic surfaces and investigation of their anti-icing properties. Mater. Des., 2018,156:320-328. |

| [104] | WU X, ZHAO X, HO J W C , et al. Design and durability study of environmental-friendly room-temperature processable icephobic coatings. Chem. Eng. J., 2019,355:901-909. |

| [105] | SONG J, LI Y, XU W , et al. Inexpensive and non-fluorinated superhydrophobic concrete coating for anti-icing and anti-corrosion. J. Colloid Interface Sci., 2019,541:86-92. |

| [106] | ZHENG S, BELLIDO-AGUILAR D A, WU X , et al. Durable waterborne hydrophobic bio-epoxy coating with improved anti-icing and self-cleaning performance. ACS Sustainable Chem. Eng., 2019,7(1):641-649. |

| [107] | SHEN Y, WU Y, TAO J , et al. Spraying fabrication of durable and transparent coatings for anti-icing application: dynamic water repellency, icing delay, and ice adhesion. ACS Appl. Mater. Interfaces, 2019,11(3):3590-3598. |

| [108] | WEI C, JIN B, ZHANG Q , et al. Anti-icing performance of super- wetting surfaces from icing-resistance to ice-phobic aspects: robust hydrophobic or slippery surfaces. J. Alloys Compd., 2018,765:721-730. |

| [109] | WANG F, DING W, HE J , et al. Phase transition enabled durable anti-icing surfaces and its DIY design. Chem. Eng. J., 2019,360:243-249. |

| [110] | VAZIRINASAB E, JAFARI R, MOMEN G . Application of superhydrophobic coatings as a corrosion barrier: a review. Surf. Coat. Technol., 2018,341:40-56. |

| [111] | DING C, TAI Y, WANG D , et al. Superhydrophobic composite coating with active corrosion resistance for AZ31B magnesium alloy protection. Chem. Eng. J., 2019,357:518-532. |

| [112] | WEN Q, DI J, JIANG L , et al. Zeolite-coated mesh film for efficient oil-water separation. Chem. Sci., 2013,4(2):591-595. |

| [113] | ZHANG W, SHI Z, ZHANG F , et al. Superhydrophobic and superoleophilic PVDF membranes for effective separation of water- in-oil emulsions with high flux. Adv. Mater., 2013,25(14):2071-2076. |

| [114] | ZULFIQAR U, HUSSAIN S Z, SUBHANI T , et al. Mechanically robust superhydrophobic coating from sawdust particles and carbon soot for oil/water separation. Colloids Surf. A, 2018,539:391-398. |

| [115] | LI J, XU C, GUO C , et al. Underoil superhydrophilic desert sand layer for efficient gravity-directed water-in-oil emulsions separation with high flux. J. Mater. Chem. A, 2018,6(1):223-230. |

| [116] | LI X, CAO M, SHAN H , et al. Facile and scalable fabrication of superhydrophobic and superoleophilic PDMS-co-PMHS coating on porous substrates for highly effective oil/water separation. Chem. Eng. J., 2019,358:1103-1113. |

| [117] | ZHAO X, LI Y, LI B , et al. Environmentally benign and durable superhydrophobic coatings based on SiO2 nanoparticles and silanes. J. Colloid Interface Sci., 2019,542:8-14. |

| [118] | ZHANG L, LI H, LAI X , et al. Thiolated graphene-based superhydrophobic sponges for oil-water separation. Chem. Eng. J., 2017,316:736-743. |

| [1] | ZHU Wenjie, TANG Lu, LU Jichang, LIU Jiangping, LUO Yongming. Research Progress on Catalytic Oxidation of Volatile Organic Compounds by Perovskite Oxides [J]. Journal of Inorganic Materials, 2025, 40(7): 735-746. |

| [2] | HU Zhichao, YANG Hongyu, YANG Hongcheng, SUN Chengli, YANG Jun, LI Enzhu. Usage of the P-V-L Bond Theory in Regulating Properties of Microwave Dielectric Ceramics [J]. Journal of Inorganic Materials, 2025, 40(6): 609-626. |

| [3] | WU Qiong, SHEN Binglin, ZHANG Maohua, YAO Fangzhou, XING Zhipeng, WANG Ke. Research Progress on Lead-based Textured Piezoelectric Ceramics [J]. Journal of Inorganic Materials, 2025, 40(6): 563-574. |

| [4] | ZHANG Bihui, LIU Xiaoqiang, CHEN Xiangming. Recent Progress of Hybrid Improper Ferroelectrics with Ruddlesden-Popper Structure [J]. Journal of Inorganic Materials, 2025, 40(6): 587-608. |

| [5] | WU Jie, YANG Shuai, WANG Mingwen, LI Jinglei, LI Chunchun, LI Fei. Textured PT-based Piezoelectric Ceramics: Development, Status and Challenge [J]. Journal of Inorganic Materials, 2025, 40(6): 575-586. |

| [6] | JIANG Kun, LI Letian, ZHENG Mupeng, HU Yongming, PAN Qinxue, WU Chaofeng, WANG Ke. Research Progress on Low-temperature Sintering of PZT Ceramics [J]. Journal of Inorganic Materials, 2025, 40(6): 627-638. |

| [7] | TIAN Ruizhi, LAN Zhengyi, YIN Jie, HAO Nanjing, CHEN Hangrong, MA Ming. Microfluidic Technology Based Synthesis of Inorganic Nano-biomaterials: Principles and Progress [J]. Journal of Inorganic Materials, 2025, 40(4): 337-347. |

| [8] | ZHANG Jiguo, WU Tian, ZHAO Xu, YANG Fan, XIA Tian, SUN Shien. Improvement of Cycling Stability of Cathode Materials and Industrialization Process for Sodium-ion Batteries [J]. Journal of Inorganic Materials, 2025, 40(4): 348-362. |

| [9] | YIN Jie, GENG Jiayi, WANG Kanglong, CHEN Zhongming, LIU Xuejian, HUANG Zhengren. Recent Advances in 3D Printing and Densification of SiC Ceramics [J]. Journal of Inorganic Materials, 2025, 40(3): 245-255. |

| [10] | CHEN Guangchang, DUAN Xiaoming, ZHU Jinrong, GONG Qing, CAI Delong, LI Yuhang, YANG Donglei, CHEN Biao, LI Xinmin, DENG Xudong, YU Jin, LIU Boya, HE Peigang, JIA Dechang, ZHOU Yu. Advanced Ceramic Materials in Helicopter Special Structures: Research Progress and Application Prospect [J]. Journal of Inorganic Materials, 2025, 40(3): 225-244. |

| [11] | FAN Xiaobo, ZU Mei, YANG Xiangfei, SONG Ce, CHEN Chen, WANG Zi, LUO Wenhua, CHENG Haifeng. Research Progress on Proton-regulated Electrochemical Ionic Synapses [J]. Journal of Inorganic Materials, 2025, 40(3): 256-270. |

| [12] | HAIREGU Tuxun, GUO Le, DING Jiayi, ZHOU Jiaqi, ZHANG Xueliang, NUERNISHA Alifu. Research Progress of Optical Bioimaging Technology Assisted by Upconversion Fluorescence Probes in Tumor Imaging [J]. Journal of Inorganic Materials, 2025, 40(2): 145-158. |

| [13] | SUN Shujuan, ZHENG Nannan, PAN Haokun, MA Meng, CHEN Jun, HUANG Xiubing. Research Progress on Preparation Methods of Single-atom Catalysts [J]. Journal of Inorganic Materials, 2025, 40(2): 113-127. |

| [14] | TAO Guilong, ZHI Guowei, LUO Tianyou, OUYANG Peidong, YI Xinyan, LI Guoqiang. Progress on Key Technologies of Cavity-structured Thin Film Bulk Acoustic Wave Filter [J]. Journal of Inorganic Materials, 2025, 40(2): 128-144. |

| [15] | ZHOU Fan, TIAN Zhilin, LI Bin. Research Progress on Carbide Ultra-high Temperature Ceramic Anti-ablation Coatings for Thermal Protection System [J]. Journal of Inorganic Materials, 2025, 40(1): 1-16. |

| Viewed | ||||||

|

Full text |

|

|||||

|

Abstract |

|

|||||