Journal of Inorganic Materials ›› 2018, Vol. 33 ›› Issue (6): 617-622.DOI: 10.15541/jim20170260

• Orginal Article • Previous Articles Next Articles

WANG Jing-Ping1, CHENG Fang-Yuan1, DU Xian-Feng2, XU You-Long2

Received:2017-05-25

Revised:2017-11-15

Published:2018-06-20

Online:2018-05-24

About author:WANG Jing-Ping. E-mail: wangjingping@sust.edu.cn

Supported by:CLC Number:

WANG Jing-Ping, CHENG Fang-Yuan, DU Xian-Feng, XU You-Long. Preparation of Al2O3/TiO2 Composite film with High Specific Capacitance by Surface Self-assembly Method[J]. Journal of Inorganic Materials, 2018, 33(6): 617-622.

| Specimen | S1 | S2 | S3 | S4 | S5 |

|---|---|---|---|---|---|

| Contact angle | 9.33° | 125.53° | 5.65° | 42.92° | 21.92° |

Table 1 Contact angle photos of different processing stages of aluminum foil

| Specimen | S1 | S2 | S3 | S4 | S5 |

|---|---|---|---|---|---|

| Contact angle | 9.33° | 125.53° | 5.65° | 42.92° | 21.92° |

| Specimen | S1 | S2 | S3 | S4 | S5 |

|---|---|---|---|---|---|

| Zeta potential/mV | +75.25 | +97.97 | -55.91 | +37.24 | +2.68 |

Table 2 Zeta potentials of aluminum foil surfaces on different processing stages

| Specimen | S1 | S2 | S3 | S4 | S5 |

|---|---|---|---|---|---|

| Zeta potential/mV | +75.25 | +97.97 | -55.91 | +37.24 | +2.68 |

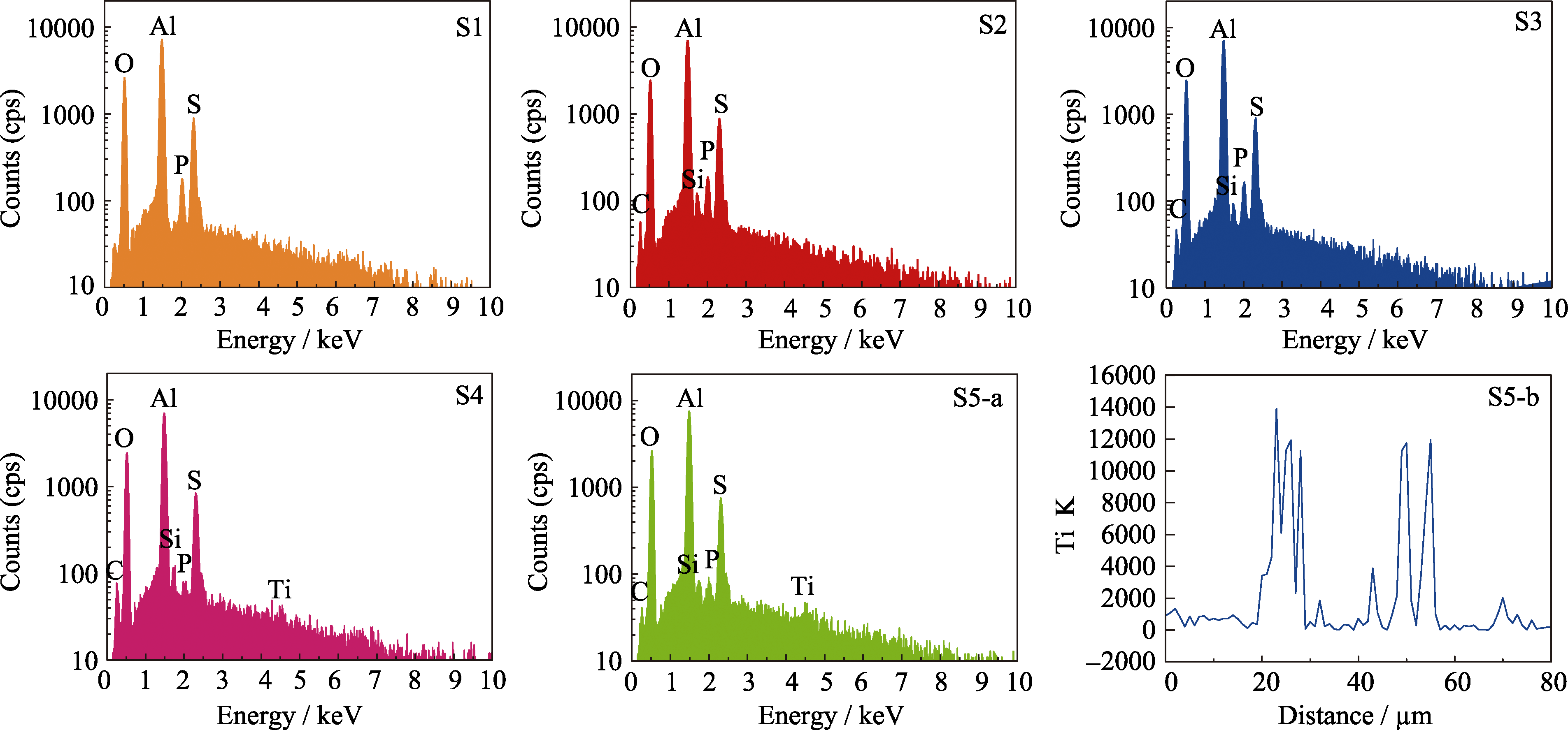

Fig. 3 EDAX patterns of different processing stages of aluminum foilS1, S2, S3, S4, S5, and S5-a are the surface EDAX results while S5-b is S5 cross section results

| Specimens | C/ (nF•cm-2) | V/V | CV/ (nF•V•cm-2) | ΔC/% | ΔCV/% |

|---|---|---|---|---|---|

| S0 | 29.46 | 408 | 12019.68 | - | - |

| S6 | 32.85 | 402 | 13205.70 | 11.51 | 9.87 |

| S5 | 42.50 | 405 | 17212.50 | 44.26 | 43.20 |

Table 3 Capacitor characteristic parameters of anodic aluminum foils coated with or without TiO2

| Specimens | C/ (nF•cm-2) | V/V | CV/ (nF•V•cm-2) | ΔC/% | ΔCV/% |

|---|---|---|---|---|---|

| S0 | 29.46 | 408 | 12019.68 | - | - |

| S6 | 32.85 | 402 | 13205.70 | 11.51 | 9.87 |

| S5 | 42.50 | 405 | 17212.50 | 44.26 | 43.20 |

| [1] | DU XIAN-FENG, LIN BAI-GE, LI BING, et al. Surface modification of Al foils for aluminum electrolytic capacitor. Advanced Functional Materials, 2017, 27(11): 1-5. |

| [2] | DU XIAN-FENG, XU YOU-LONG.Formation of Al2O3-BaTiO3 composite thin film to increase the specific capacitance of aluminum electrolytic capacitor.Thin Solid Films, 2008, 516(23): 8436-8440. |

| [3] | Du XIAN-FENG, Xu YOU-LONG.Preparation and electrical properties of an anodized Al2O3-BaTiO3 composite film. Journal of the American Ceramic Society, 2008, 91(7): 2360-2363. |

| [4] | DU XIAN-FENG, MEN KAI, XU YOU-LONG,et al. Enhanced capacitance performance of Al2O3-TiO2 composite thin film via Sol-Gel using double chelators. Journal of Colloid Interface Science, 2015, 443: 170-176. |

| [5] | 杨邦朝, 冯哲圣, 陈金菊.纳米复合高介电常数铝氧化膜生长技术. 中国.C23C 18/00. CN1502719. 2004.6.19. |

| [6] | GU DE-EN, CHEN JIN-JU, FENG ZHE-SHENG,et al. Aluminum foil composite surface anodic oxidation film studies. Functional materials, 2004, 35(5): 600-602. |

| [7] | CHEN JIN-JU, FENG ZHE-SHENG, JIANG MEI-LIAN,et al. The effect of anodizing voltage on the electrical properties of Al-Ti composite oxide film on aluminum. Journal of Electroanalytical Chemistry, 2006, 590(1): 26-31. |

| [8] | CHEN JIN-JU, FENG ZHE-SHENG, GUO HONG-LEI,et al. Preparation of high dielectric constant composite oxide films for aluminum electrolytic capacitors. Materials Engineering, 2006 (2): 56-60. |

| [9] | CHEN JIN-JU, JIANG MEI-LIAN, FENG ZHE-SHENG,et al. Effects of technologycal parameters on specific capacitance of Al-Ti composite oxide films. Electronic Components and Materials, 2005, (8): 8-10. |

| [10] | CHEN JIN-JU, YANG BANG-CHAO, JIANG MEI-LIAN,et al. The effect of anodizing temperature on the structure and electrical properties of Al-Ti composite oxide film. Science in China Series E-Engineering & Materials Science, 2005, 48(6): 612-621. |

| [11] | CHEN JIN-JU, GU DE-EN, FENG ZHE-SHENG,et al. Formation of Al-Ti composite oxide films on aluminum by hydrolysis precipitation and anodizing. Journal of Functional Materials, 2005, 36(3): 399-401. |

| [12] | CHEN JIN-JU, FENG ZHE-SHENG, JIANG MEI-LIAN,et al. The effect of anodizing voltage on the electrical properities of Al-Ti composite oxide films on aluminum. Journal of Electronalytical Chemistry, 2006, 590: 26-31. |

| [13] | XU YOU-LONG.Al2O3-(Ba0.5Sr0.5)TiO3 composite oxide films on etched aluminum foil by Sol-Gel coating and anodizing.Ceramics International, 2004, 30(7): 1741-1743. |

| [14] | DUXIAN-FENG, XU YOU-LONG.Formation of Al2O3-Bi4Ti3O12 nanocomposite oxide films on low-voltage etched aluminum foil by Sol-Gel processing.Surface and Coatings Technology, 2008, 202(10): 1923-1927. |

| [15] | DU XIAN-FENG, XU YOU-LONG.Formation of Al2O3-BaTiO3 nanocomposite oxide films on etched aluminum foil by Sol-Gel coating and anodizing. Journal of Sol-Gel Science and Technology, 2008, 45(1): 57-61. |

| [1] | WANG Xiaobo, ZHU Yuliang, XUE Wenchao, SHI Ruchuan, LUO Bofeng, LUO Chengtao. Effect of PbTiO3 Content Variation on High-power Performance of PMN-PT Single Crystal [J]. Journal of Inorganic Materials, 2025, 40(7): 840-846. |

| [2] | TANG Xinli, DING Ziyou, CHEN Junrui, ZHAO Gang, HAN Yingchao. In vivo Distribution and Metabolism of Calcium Phosphate Nanomaterials Based on Fluorescent Labeling with Rare Earth Europium Ions [J]. Journal of Inorganic Materials, 2025, 40(7): 754-764. |

| [3] | YU Leyangyang, ZHAO Fangxia, ZHANG Shuxin, XU Yixiang, NIU Yaran, ZHANG Zhenzhong, ZHENG Xuebin. Preparation of High-entropy Boride Powders for Plasma Spraying by Inductive Plasma Spheroidization [J]. Journal of Inorganic Materials, 2025, 40(7): 808-816. |

| [4] | YANG Guang, ZHANG Nan, CHEN Shujin, WANG Yi, XIE An, YAN Yujie. WO3 Films Based on Porous ITO Electrodes: Preparation and Electrochromic Property [J]. Journal of Inorganic Materials, 2025, 40(7): 781-789. |

| [5] | SUN Jing, LI Xiang, MAO Xiaojian, ZHANG Jian, WANG Shiwei. Effect of Lauric Acid Modifier on the Hydrolysis Resistance of Aluminum Nitride Powders [J]. Journal of Inorganic Materials, 2025, 40(7): 826-832. |

| [6] | CHAI Runyu, ZHANG Zhen, WANG Menglong, XIA Changrong. Preparation of Ceria Based Metal-supported Solid Oxide Fuel Cells by Direct Assembly Method [J]. Journal of Inorganic Materials, 2025, 40(7): 765-771. |

| [7] | WANG Lujie, ZHANG Yuxin, LI Tongyang, YU Yuan, REN Pengwei, WANG Jianzhang, TANG Huaguo, YAO Xiumin, HUANG Yihua, LIU Xuejian, QIAO Zhuhui. Corrosion and Wear Behavior of Silicon Carbide Ceramic in Deep-sea Service Environment [J]. Journal of Inorganic Materials, 2025, 40(7): 799-807. |

| [8] | LI Wenyuan, XU Jianan, DENG Han'ao, CHANG Aimin, ZHANG Bo. Effect of V5+ Substitution on Microstructure and Microwave Dielectric Properties of LaTaO4 Ceramics [J]. Journal of Inorganic Materials, 2025, 40(6): 697-703. |

| [9] | HU Zhichao, YANG Hongyu, YANG Hongcheng, SUN Chengli, YANG Jun, LI Enzhu. Usage of the P-V-L Bond Theory in Regulating Properties of Microwave Dielectric Ceramics [J]. Journal of Inorganic Materials, 2025, 40(6): 609-626. |

| [10] | DONG Chenyu, ZHENG Weijie, MA Yifan, ZHENG Chunyan, WEN Zheng. Characterizations by Piezoresponse Force Microscopy on Relaxor Properties of Pb(Mg,Nb)O3-PbTiO3 Ultra-thin Films [J]. Journal of Inorganic Materials, 2025, 40(6): 675-682. |

| [11] | HE Guoqiang, ZHANG Kaiheng, WANG Zhentao, BAO Jian, XI Zhaochen, FANG Zhen, WANG Changhao, WANG Wei, WANG Xin, JIANG Jiapei, LI Xiangkun, ZHOU Di. Ba(Nd1/2Nb1/2)O3: Au Underrated K40 Microwave Dielectric Ceramic [J]. Journal of Inorganic Materials, 2025, 40(6): 639-646. |

| [12] | ZHANG Jiawei, CHEN Ning, CHENG Yuan, WANG Bo, ZHU Jianguo, JIN Cheng. Electrical Properties of Bismuth Layered Piezoelectric Bi4Ti3O12 Ceramics with A/B-site Doping [J]. Journal of Inorganic Materials, 2025, 40(6): 690-696. |

| [13] | CUI Ning, ZHANG Yuxin, WANG Lujie, LI Tongyang, YU Yuan, TANG Huaguo, QIAO Zhuhui. Single-phase Formation Process and Carbon Vacancy Regulation of (TiVNbMoW)Cx High-entropy Ceramics [J]. Journal of Inorganic Materials, 2025, 40(5): 511-520. |

| [14] | XIONG Siyu, MO Chen, ZHU Xiaowei, ZHU Guobin, CHEN Deqin, LIU Laijun, SHI Xiaodong, LI Chunchun. Low-temperature Sintering of LiBxAl1-xSi2O6 Microwave Dielectric Ceramics with Ultra-low Permittivity [J]. Journal of Inorganic Materials, 2025, 40(5): 536-544. |

| [15] | AN Ran, LIN Si, GUO Shigang, ZHANG Chong, ZHU Shun, HAN Yingchao. Iron-doped Nano-hydroxyapatite: Preparation and Ultraviolet Absorption Performance [J]. Journal of Inorganic Materials, 2025, 40(5): 457-465. |

| Viewed | ||||||

|

Full text |

|

|||||

|

Abstract |

|

|||||