Journal of Inorganic Materials ›› 2025, Vol. 40 ›› Issue (7): 781-789.DOI: 10.15541/jim20240531

• RESEARCH ARTICLE • Previous Articles Next Articles

YANG Guang( ), ZHANG Nan, CHEN Shujin, WANG Yi(

), ZHANG Nan, CHEN Shujin, WANG Yi( ), XIE An, YAN Yujie(

), XIE An, YAN Yujie( )

)

Received:2024-12-23

Revised:2025-01-23

Published:2025-07-20

Online:2025-03-19

Contact:

YAN Yujie, associate professor. E-mail: yujieyan@xmut.edu.cn;About author:YANG Guang (2000-), male, Master candidate. E-mail: yangguang@stu.xmut.edu.cn

Supported by:CLC Number:

YANG Guang, ZHANG Nan, CHEN Shujin, WANG Yi, XIE An, YAN Yujie. WO3 Films Based on Porous ITO Electrodes: Preparation and Electrochromic Property[J]. Journal of Inorganic Materials, 2025, 40(7): 781-789.

Fig. 2 SEM images of the porous ITO film and porous and dense WO3 film (a) SEM image of porous ITO film; (b, c) SEM-EDS images of In and Sn elements in ITO film; (d) SEM image of porous WO3 film; (e, f) SEM-EDS images of W and O elements in WO3 film; (g) SEM image of porous WO3 film; (h) Cross-sectional SEM image of FTO/ITO/WO3; (i) SEM image of dense WO3 film

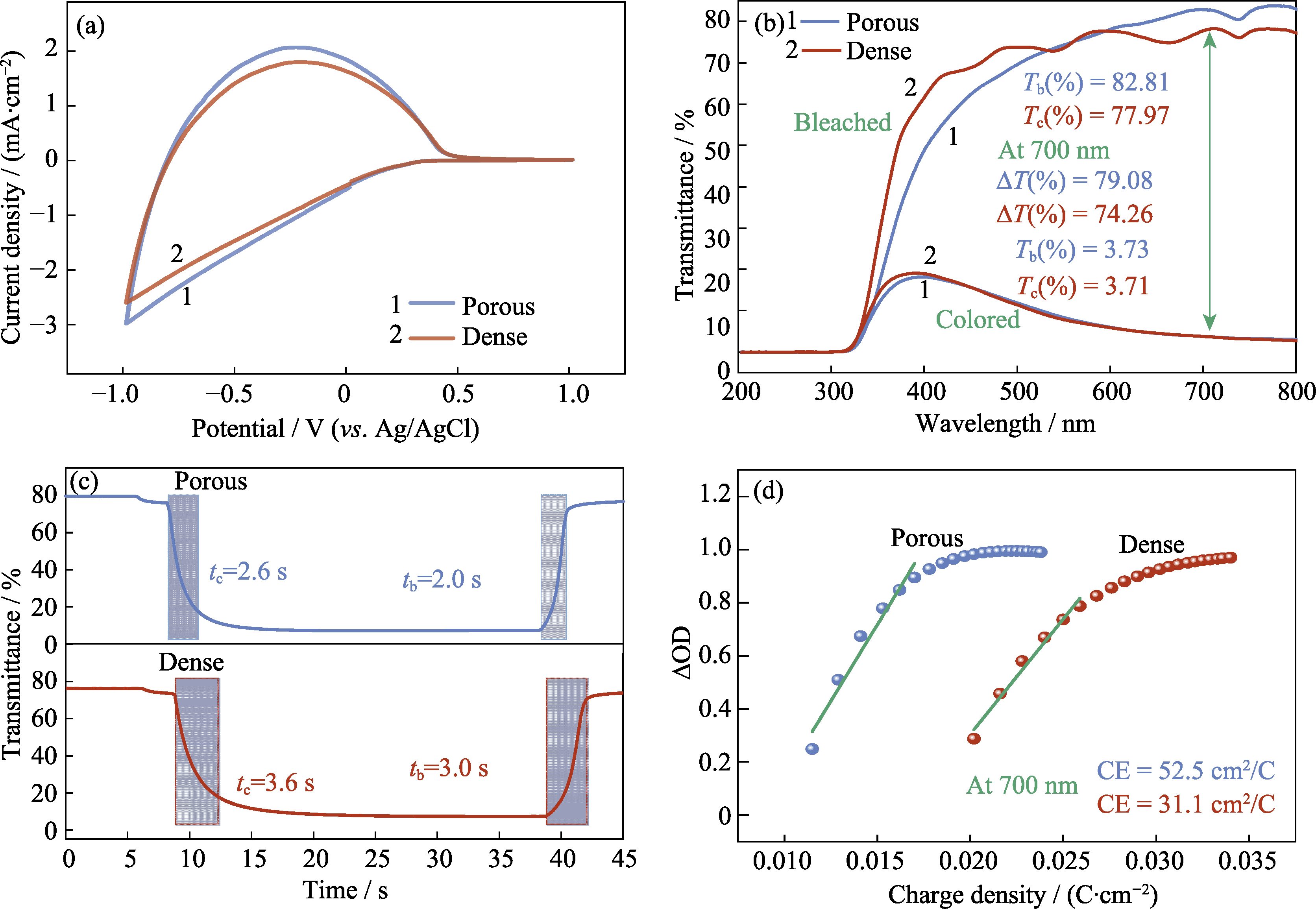

Fig. 3 Electrochemical and electrochromic properties of the porous and dense WO3 films (a) CV curves at 50 mV/s; (b) Transmittance spectra at the colored and bleached states; (c) In-situ transmittance spectra at 700 nm; (d) Optical density (ΔOD) variations with respect to the charge density at 700 nm

Fig. 4 Electrochemical and electrochromic properties of the porous WO3 films with different thicknesses (a) CV curves at 50 mV/s; (b) Transmittance spectra at the colored and bleached states; (c) In-situ transmittance spectra at 700 nm; (d) ΔOD variations with respect to the charge density at 700 nm; (e) Digital photos of the coloring and bleaching states. Colorful figures are available on website

Fig. 5 Electrochemical and electrochromic properties of the porous WO3 films prepared from PS microspheres with different diameters (a) CV curves at 50 mV/s; (b) Transmittance spectra at the colored and bleached states; (c) In-situ transmittance spectra at 700 nm; (d) ΔOD variations with respect to the charge density at 700 nm. Colorful figures are available on website

Fig. 6 Schematic diagrams of ion and charge transport in dense bulk and porous WO3 films and related EIS curves (a) Dense bulk WO3 film; (b) Porous WO3 film; (c) EIS curves of dense bulk and porous WO3 films. Colorful figures are available on website

| [1] | LI Y, SUN P Y, CHEN J, et al. Colorful electrochromic displays with high visual quality based on porous metamaterials. Advanced Materials, 2023, 35(23): 2300116. |

| [2] | BERA M K, MOHANTY S, KASHYAP S S, et al. Electrochromic coordination nanosheets: achievements and future perspective. Coordination Chemistry Reviews, 2022, 454: 214353. |

| [3] | AMATE R U, MORANKAR P J, TELI A M, et al. Versatile electrochromic energy storage smart window utilizing surfactant- assisted niobium oxide thin films. Chemical Engineering Journal, 2024, 484: 149556. |

| [4] | LIU H H, ZHANG Y M, LEI P Y, et al. Selective electrochromic regulation for near-infrared and visible light via porous tungsten oxide films with core/shell architecture. ACS Applied Materials & Interfaces, 2023, 15(19): 23412. |

| [5] |

MENG Q C, CAO S, GUO J Q, et al. Sol-Gel-based porous Ti-doped tungsten oxide films for high-performance dual-band electrochromic smart windows. Journal of Energy Chemistry, 2023, 77: 137.

DOI |

| [6] | ZHANG S L, PENG Y T, ZHAO J, et al. Amorphous and porous tungsten oxide films for fast-switching dual-band electrochromic smart windows. Advanced Optical Materials, 2023, 11(1): 2202115. |

| [7] | ZHOU Z, CHEN Z, MA D, et al. Porous WO3·2H2O film with large optical modulation and high coloration efficiency for electrochromic smart window. Solar Energy Materials and Solar Cells, 2023, 253: 112226. |

| [8] |

MIAO H Y, CHEN L, XING F F, et al. Viologen-based solution-processable ionic porous polymers for electrochromic applications. Chemical Science, 2024, 15(20): 7576.

DOI PMID |

| [9] | ZHAO Y M, ZHANG X, CHEN X, et al. Preparation of WO3 films with controllable crystallinity for improved near-infrared electrochromic performances. ACS Sustainable Chemistry & Engineering, 2020, 8(31): 11658. |

| [10] | WANG Y X, ZENG J M, ZHOU Z H, et al. Growth of a high-performance WO3 nanofilm directly on a polydopamine- modified ITO electrode for electrochromism and power storage applications. Applied Surface Science, 2022, 573: 151603. |

| [11] | LOULOUDAKIS D, MOURATIS K, KOUDOUMAS E, et al. Electrochromic response and porous structure of WO3 cathode layers. Electrochimica Acta, 2021, 376: 138049. |

| [12] | ZHOU K L, WANG H, ZHANG Q Q, et al. Dynamic process of ions transport and cyclic stability of WO3 electrochromic film. Journal of Inorganic Materials, 2021, 36(2): 152. |

| [13] | HAN Z, TONG M, ZHANG C, et al. Unlocking dual-band electrochromism with stacked structure of amorphous tungsten oxide and Prussian blue. Solar Energy Materials and Solar Cells, 2024, 273: 112939. |

| [14] | NIU H B, HUANG J H, LI Q W, et al. Directly hydrothermal growth and electrochromic properties of porous NiMoO4 nanosheet films. Journal of Inorganic Materials, 2023, 38(12): 1427. |

| [15] | LIU H Y, WANG M Y, DIAO X G, et al. In situ synthesis and structural morphology analysis of 3D porous hierarchical V2O5 films for transmissive-to-black all-solid-state electrochromic devices. Chemical Engineering Journal, 2024, 500: 156657. |

| [16] | SUN X H, WU W, LIU N N, et al. Controlled assembly and synthesis of oxygen-deficient W18O49 films based on solvent molecular strategy for electrochromic energy storage smart windows. Chemical Engineering Journal, 2024, 499: 156109. |

| [17] | SAHU D R, HUANG C Y, WANG S C, et al. Effects of a polystyrene intermediate layer for improved electrochromic properties of nano porous WO3 electrochromic films. Advanced Materials, 2022, 3(14): 6000. |

| [18] | JEONG S J, KIM K H, BAI S, et al. Porous fluorine-doped tin oxide-anchored vanadium oxide films for multi-functional highly capacitive electrochromic layers. Journal of Alloys and Compounds, 2022, 923: 166329. |

| [19] | TONG X R, WANG J H, ZHANG P, et al. Insight into the structure-activity relationship in electrochromism of WO3 with rational internal cavities for broadband tunable smart windows. Chemical Engineering Journal, 2023, 470: 144130. |

| [20] | KHAN A, FACEIRA B, BARDET L, et al. Silver nanowire-based transparent electrodes for V2O5 thin films with electrochromic properties. ACS Applied Mater & Interfaces, 2024, 16(8): 10439. |

| [21] | LI J, LIU W, WEI Y, et al. SiO2 : a novel electrolyte for high-performance all-solid-state electrochromic devices. ACS Sustainable Chemistry & Engineering, 2023, 11(2): 824. |

| [22] | XIE H L, WANG Y X, LIU H T, et al. Electrochromic electrode with high optical contrast and long cyclic life using nest-like porous doped-Sm WO3 films. Ceramics International, 2023, 49(5): 8223. |

| [23] | WANG L K, LIU Y, HAN G R, et al. Dual-band electrochromic film based on mesoporous h-WO3/o-WO3·H2O/r-TiO2 for high performance smart windows. Solar Energy Materials and Solar Cells, 2023, 250: 112053. |

| [24] | DAI B H, WU C Z, XIE Y, et al. Boosting the electrochromic performance of TiO2 nanowire film via successively evolving surface structure. Science China Chemical, 2021, 64(5): 745. |

| [25] | SONG Y L, ZHANG Q Y, YAO A H. Template-free electrodeposition and electrochromic performance of porous WO3·2H2O thin film. Chinese Journal of Inorganic Chemistry, 2023, 39(1): 127. |

| [26] | SHI Y D, SUN M J, ZHANG Y, et al. Rational design of oxygen deficiency-controlled tungsten oxide electrochromic films with an exceptional memory effect. ACS Applied Materials & Interfaces, 2020, 12(29): 32658. |

| [27] | BIAN C C, WANG J H, LIU H H, et al. Complementary multicolor electrochromic devices with excellent stability based on porous tin oxide nanosheet scaffold. Nano Research, 2024, 17(4): 3035. |

| [28] | CHANG C M, CHIANG Y C, CHENG M H, et al. Fabrication of WO3 electrochromic devices using electro-exploding wire techniques and spray coating. Solar Energy Materials and Solar Cells, 2021, 223: 110960. |

| [29] | DADKHAH M, NINE M J, PURASINHALA K, et al. Nanostructure-dependent colouration efficiency of electrochromic coatings using 0D, 1D, and 2D WO3 for smart windows. (2024-10-05). https://doi.org/10.1016/j.nanoms.2024.09.003. |

| [30] | LI Z J, WANG M H, WEI L Y, et al. Preparation of porous WO3 film and its electrochromic properties. Journal of Functional Materials, 2023, 54(9): 9172. |

| [31] | SHI Y D, MA K, FAN M X, et al. Designed growth of hollow WO3/PEDOT bilayer hybrid nanosphere arrays film with superior electrochromic and capacitive performance. Acta Materiae Compositae Sinica, 2024, 41(6): 3060. |

| [32] | WANG X R, ZHENG Y, CHEN L R, et al. Multicolor V2O5/TiO2 electrochromic films with fast switching and long lifespan for camouflage and information display. Science China Mater, 2024, 67(9): 2807. |

| [33] | GANESHA M K, MONDAL I, SINGH A K, et al. Fabrication of large-area, affordable dual-function electrochromic smart windows by using a hybrid electrode coated with an oxygen-deficient tungsten oxide ultrathin porous film. ACS Applied Materials & Interfaces, 2023, 15(15): 19111. |

| [1] | GE Zesheng, LIU Miao, TANG Zhe, ZHOU Yan, WAN Shun, ZONG Peng’an. Flexible Cu0.005Bi0.5Sb1.495Te3 Thin Films: Magnetron Sputtering Preparation and Thermoelectric Properties [J]. Journal of Inorganic Materials, 2025, 40(11): 1237-1244. |

| [2] | ZHANG Jiaqiang, ZOU Xinlei, WANG Nengze, JIA Chunyang. Zn-Fe PBA Films by Two-step Electrodeposition Method: Preparation and Performance in Electrochromic Devices [J]. Journal of Inorganic Materials, 2022, 37(9): 961-968. |

| [3] | ZHANG Xiaoyu, LIU Yongsheng, LI Ran, LI Yaogang, ZHANG Qinghong, HOU Chengyi, LI Kerui, WANG Hongzhi. Cu3(HHTP)2 Film-based Ionic-liquid Electrochromic Electrode [J]. Journal of Inorganic Materials, 2022, 37(8): 883-890. |

| [4] | WANG Ying, ZHANG Wenlong, XING Yanfeng, CAO suqun, DAI Xinyi, LI Jingze. Performance of Amorphous Lithium Phosphate Coated Lithium Titanate Electrodes in Extended Working Range of 0.01-3.00 V [J]. Journal of Inorganic Materials, 2021, 36(9): 999-1005. |

| [5] | WANG Jinmin, HOU Lijun, MA Dongyun. Molybdenum Oxide Electrochromic Materials and Devices [J]. Journal of Inorganic Materials, 2021, 36(5): 461-470. |

| [6] | WU Qi, CONG Shan, ZHAO Zhigang. Infrared Electrochromic Property of the Colorful Tungsten Oxide Films [J]. Journal of Inorganic Materials, 2021, 36(5): 485-491. |

| [7] | FAN Hongwei, LI Kerui, HOU Chengyi, ZHANG Qinghong, LI Yaogang, WANG Hongzhi. Multi-functional Electrochromic Devices: Integration Strategies Based on Multiple and Single Devices [J]. Journal of Inorganic Materials, 2021, 36(2): 115-127. |

| [8] | ZHAO Changjiang,MA Chao,LIU Juncheng,LIU Zhigang,CHEN Yan. Sputtering Power on the Microstructure and Properties of MgF2 Thin Films Prepared with Magnetron Sputtering [J]. Journal of Inorganic Materials, 2020, 35(9): 1064-1070. |

| [9] | WANG Jinmin, YU Hongyu, MA Dongyun. Progress in the Preparation and Application of Nanostructured Manganese Dioxide [J]. Journal of Inorganic Materials, 2020, 35(12): 1307-1314. |

| [10] | WANG Mei-Han, WEN Jia-Xing, CHEN Yun, LEI Hao. Nano-structured WO3 Thin Films Deposited by Glancing Angle Magnetron Sputtering [J]. Journal of Inorganic Materials, 2018, 33(12): 1303-1308. |

| [11] | CHENG Dan, HUANG Bin, CHEN Tao, JING Feng-Juan, XIE Dong, LENG Yong-Xiang, HUANG Nan. Microstructure of TiCuO Films on Copper Ion Release and Endothelial Cell Behavior [J]. Journal of Inorganic Materials, 2018, 33(10): 1089-1096. |

| [12] | WANG Hong-Yan, ZHANG Hao, JIANG Hong, WANG Guo-Qing, XIONG Chun-Rong. Preparation of Coating Glass with High Visible Transmittance and High UV Cut-off [J]. Journal of Inorganic Materials, 2017, 32(7): 758-764. |

| [13] | WANG Fo-Gen, CHEN Yun-Lu, REN Sheng-Qiang, ZHANG Jia-Yuan, WU Li-Li, FENG Liang-Huan. Properties of CdS:Al Films Deposited by Magnetron Sputtering [J]. Journal of Inorganic Materials, 2017, 32(4): 413-417. |

| [14] | LU Shu-Juan, WANG Chang, ZHAO Bo-Wen, WANG Hao, LIU Jing-Bing, YAN Hui. Electrochromic Properties of PEG-modified Tungsten Oxide Thin Films [J]. Journal of Inorganic Materials, 2017, 32(2): 185-190. |

| [15] | LI Miao-Lei, WANG En-Qing, YUE Jian-Ling, HUANG Xiao-Zhong. Microstructure, Mechanical and Tribological Property of TiAlN/VN Nano-multilayer Films [J]. Journal of Inorganic Materials, 2017, 32(12): 1280-1284. |

| Viewed | ||||||

|

Full text |

|

|||||

|

Abstract |

|

|||||