Journal of Inorganic Materials ›› 2014, Vol. 29 ›› Issue (10): 1009-1017.DOI: 10.15541/jim20140010

• Orginal Article • Next Articles

LI Bo, XU Wen-Feng, LIAO Xiao-Ling

Received:2014-01-06

Revised:2014-02-27

Published:2014-10-20

Online:2014-09-22

About author:LI Bo. E-mail: leewave@126.com

Supported by:CLC Number:

LI Bo, XU Wen-Feng, LIAO Xiao-Ling. Research Progress in Calcium Phosphate Microspheres for Bone Defect Repair[J]. Journal of Inorganic Materials, 2014, 29(10): 1009-1017.

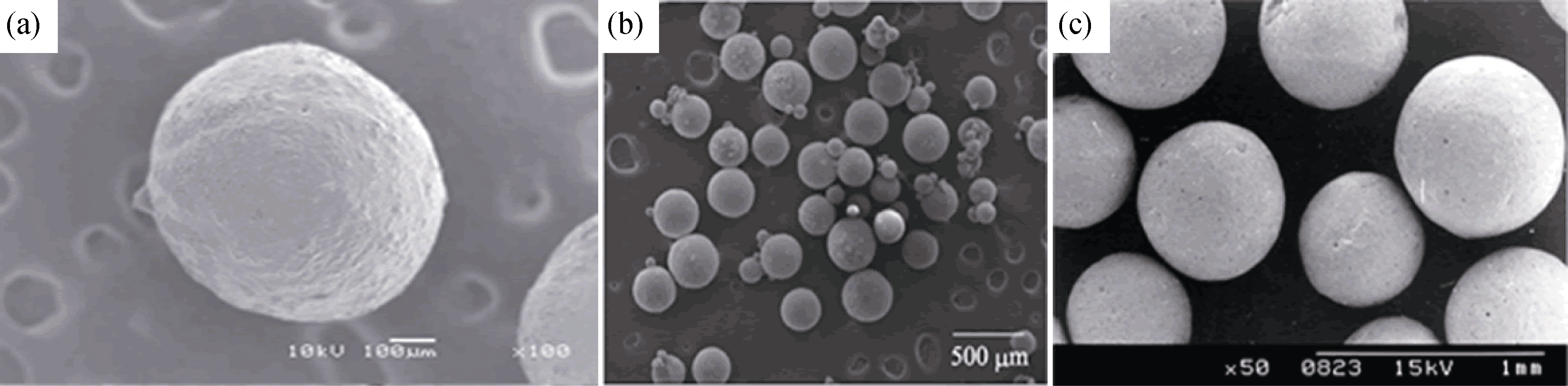

Fig. 1 Images of typical calcium phosphate solid microspheres (a) β-TCP microsphere prepared with nitrogen liquid freeze drying method[10]; (b) HA microsphere prepared with CMCS and gel as binder[12]; (c) HA microsphere prepared with emulsion method[13]

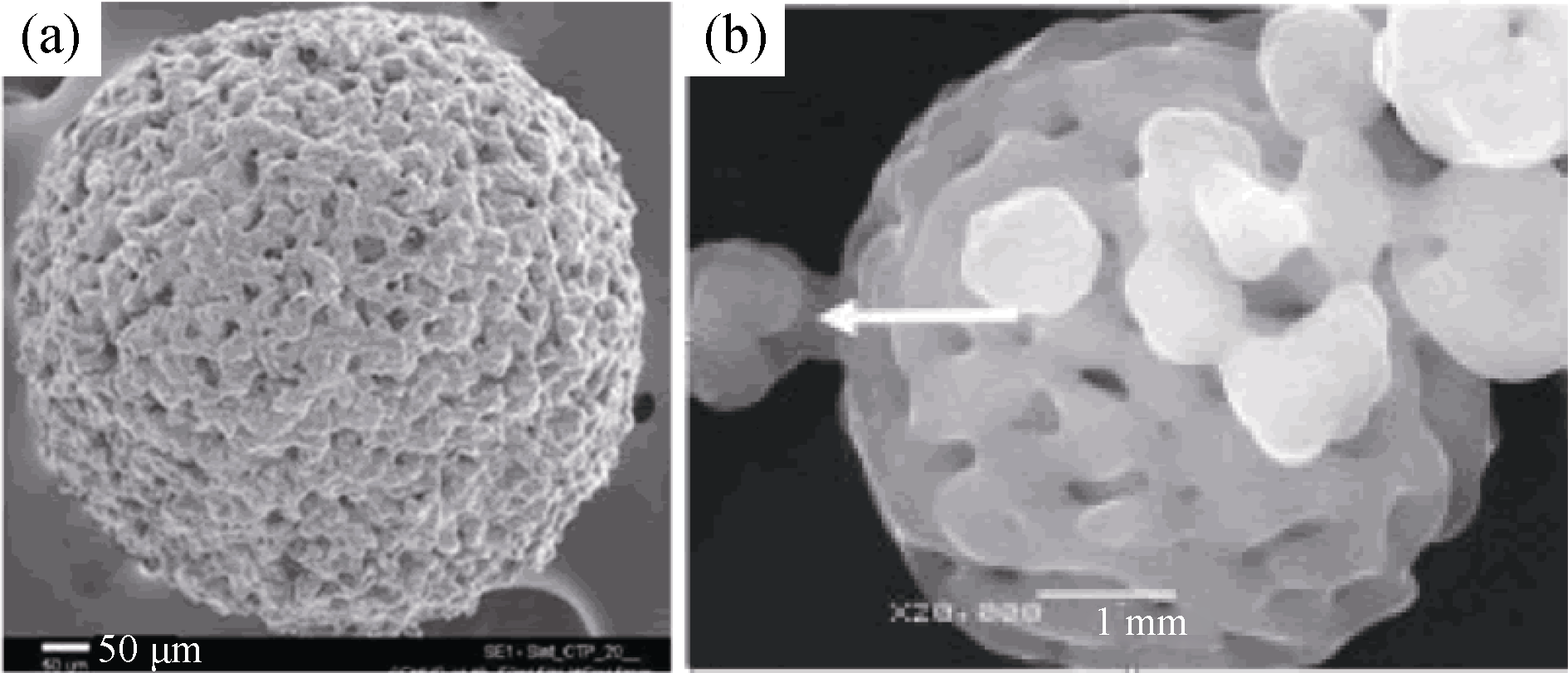

Fig. 2 Two typical porous CaP microspheres[18, 23] (a) HA microsphere prepared with alginate salt gel process[18], (b) HA microsphere prepared with spray drying method[23]

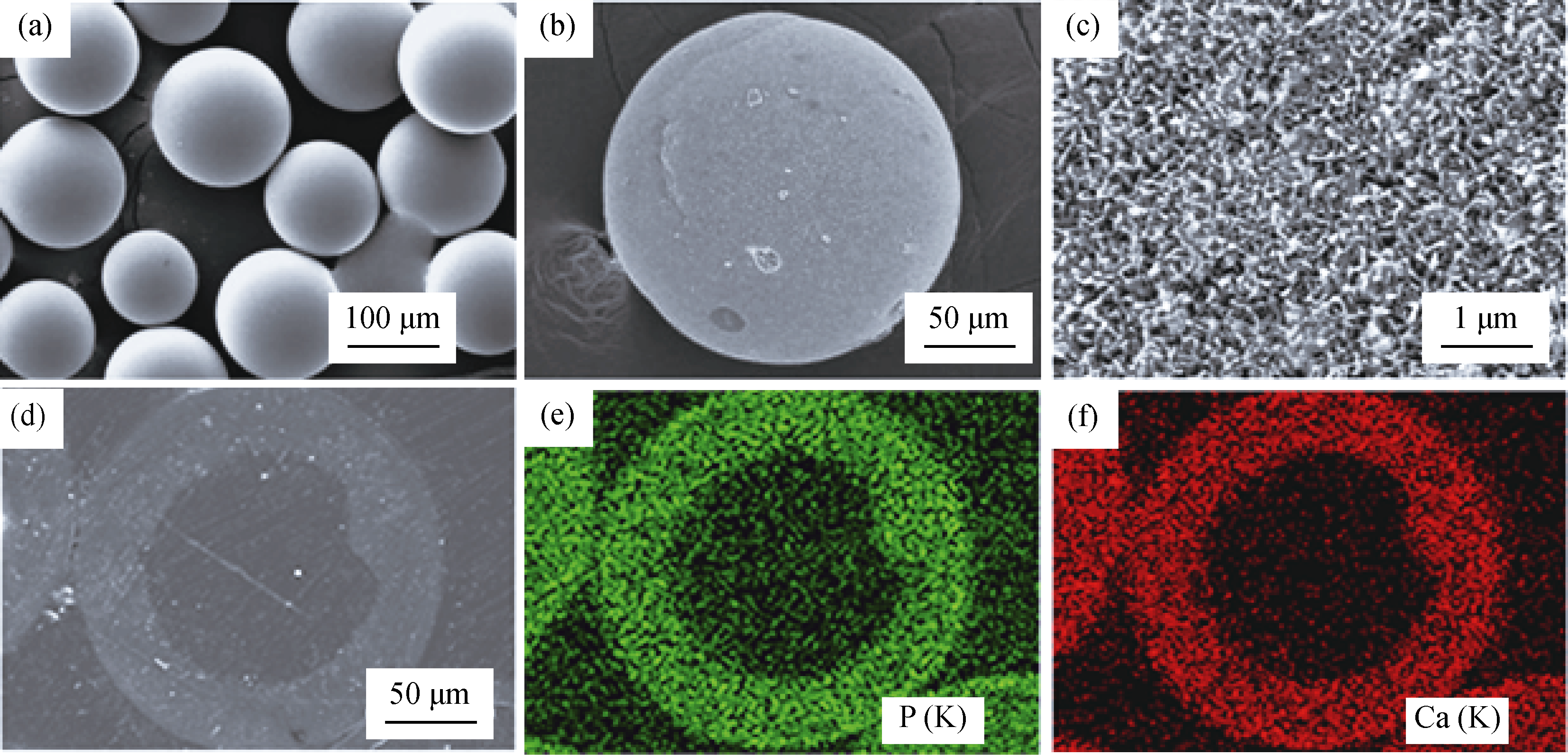

Fig. 4 SEM images of hollow HA microsphere with glass as hard template. (a) starting glass microspheres as hard template, (b) external surface of hollow HA microsphere, (c) external surface of hollow HA microsphere at high magnification. (d) SEM image in back-scattered mode of a polished cross section of a hollow hydroxyapatite microsphere, (e) and (f) X-ray maps of Ca(K) and P(K) across the planar section shown in (d)[27]

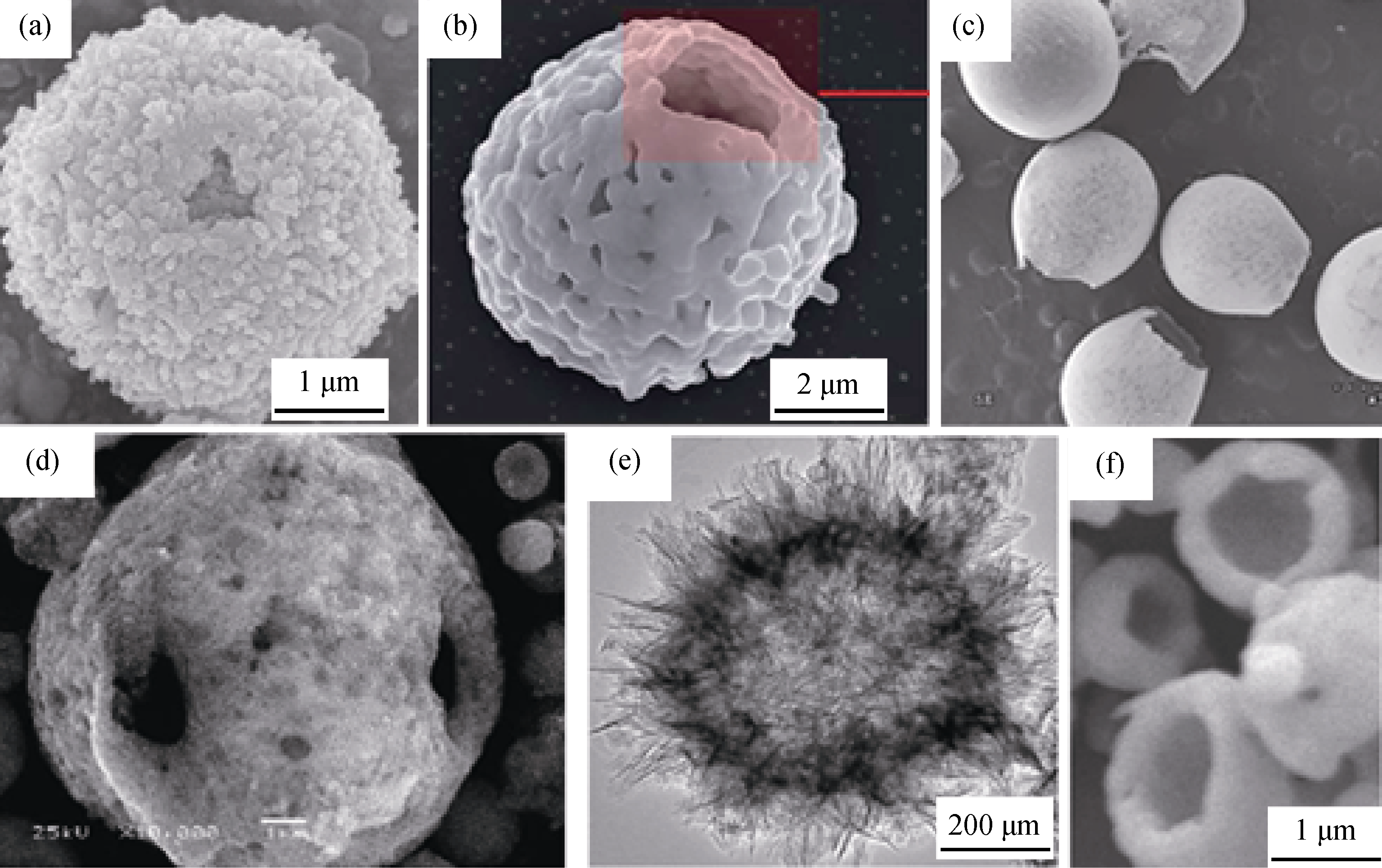

Fig. 5 Six typical hollow calcium phosphate microspheres prepared with (a) CaCO3/Fe3O4 as hard template[32], (b) yeast as bio- template[33], (c) DCM emulsion method[34], (d) spray drying method[35], (e) microwave-hydrothermal method[37], and (f) electrosprayed method[38], respectively

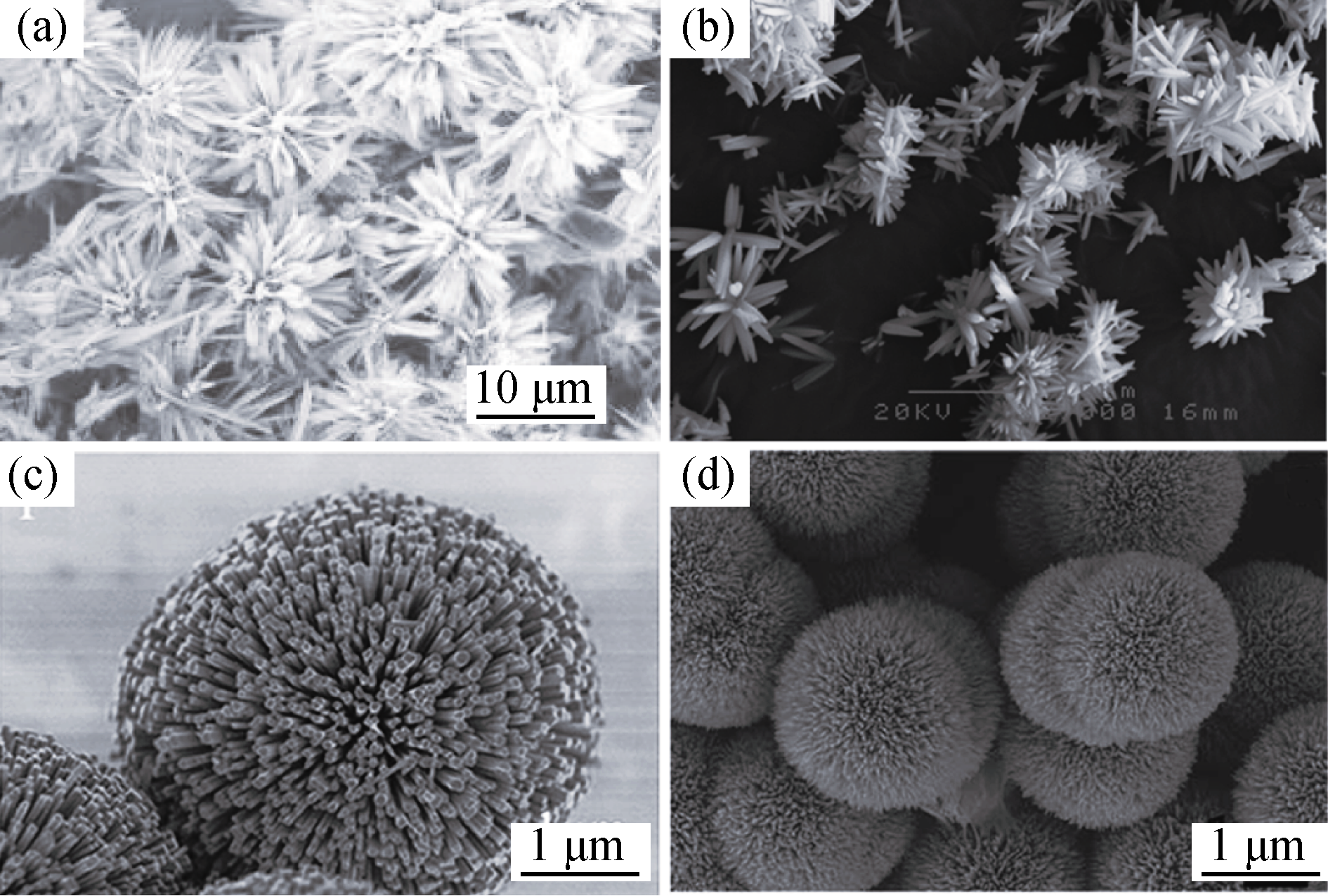

Fig. 6 Four typical flower-like microspheres prepared with potassium hydrogen tartrate (a)[39], EDTA[40] (b), F- substitution combined with EDTA (c) and citric acid[41] (d) as template, respectively[42]

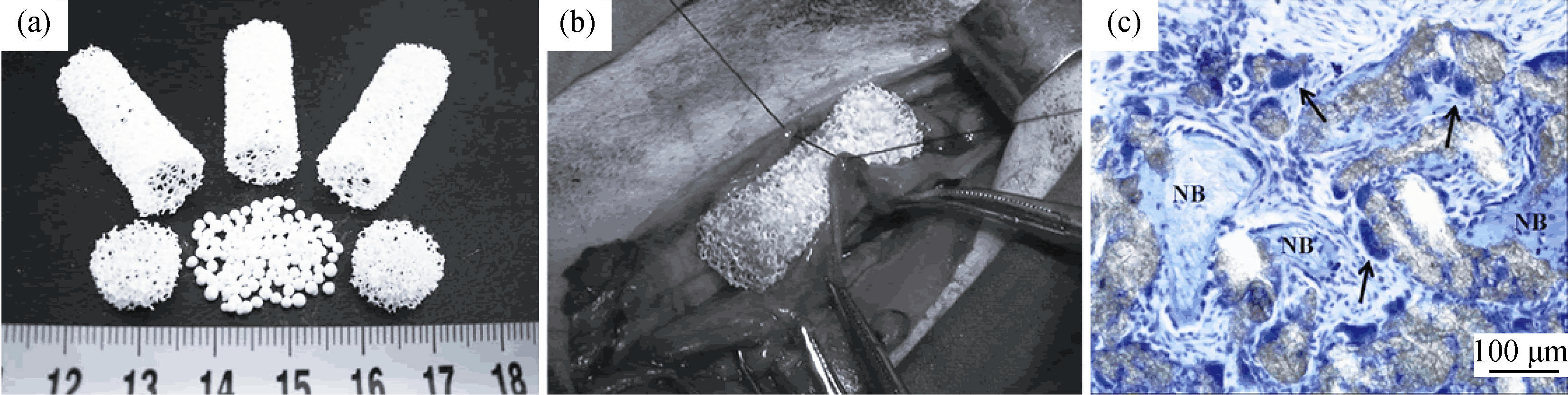

Fig. 8 Images of (a) the HA spherules, porous HA tubes, and HA disks fabricated to assemble the novel scaffolds, (b) digital photo shows the implantation of the porous scaffolds at peritoneum pocket[45], (c) photographs of toluidine blue stained spherulite HA-positive assemble scaffold after intramuscular implantation for 3 months[46]. NB represents new bone

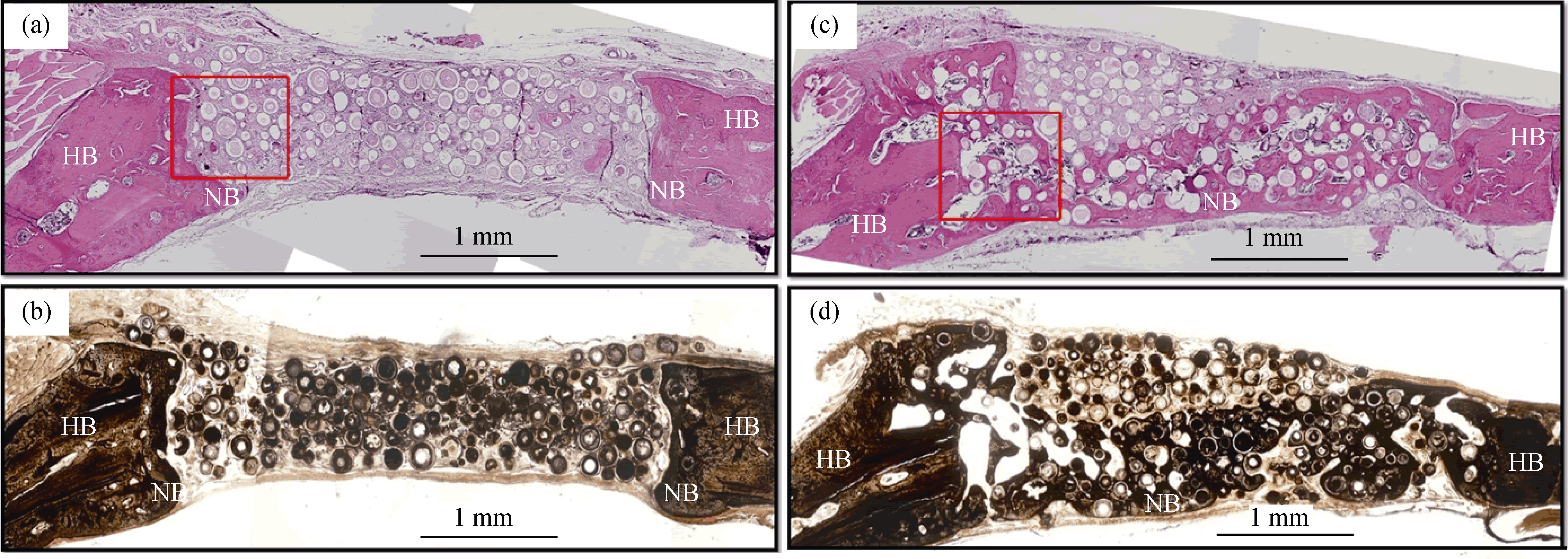

Fig. 9 (a, c) H&E and (b, d) von Kossa stained sections of rat calvarial defects implanted for 6 weeks with (a, b) as-prepared hollow HA microspheres (without BMP2) and (c, d) hollow HA microspheres loaded with BMP2 (1 μg per defect). HB represents host (old) bone; NB represents new bone[56]

| [1] | WANG H, LEEUWENBURGH S C G, LI Y, et al. The use of micro- and nano-spheres as functional components for bone tissue regeneration. Tissue. Eng. Part B Rev., 2012, 18(1): 24-39. |

| [2] | LIU X, JIN X, MA P X. Nanofibrous hollow microspheres self-assembled from star-shaped polymers as injectable cell carriers for knee repair. Nat. Mater., 2011, 10(5): 398-406. |

| [3] | FISHER M B, MAUCK R L. Tissue engineering and regenerative medicine: recent innovations and the transition to translation. Tissue Engineering Part B-Reviews, 2013, 19(1): 1-13. |

| [4] | HONG Y, FAN H, LI B, et al. Fabrication, biological effects, and medical applications of calcium phosphate nanoceramics. Mat. Sci. Eng. R., 2010, 70(3-6): 225-242. |

| [5] | SADAT-SHOJAI M, KHORASANI M T, DINPANAH- KHOSHDARGI E, et al. Synthesis methods for nanosized hydroxyapatite with diverse structures. Acta Biomater., 2013, 9(8): 7591-7621. |

| [6] | CHRISTENSON E M, ANSETH K S, VAN DEN BEUCKEN L, et al. Nanobiomaterial applications in orthopedics. J. Orthopaed. Res., 2007, 25(1): 11-22. |

| [7] | FAN J-B, HUANG C, JIANG L, et al. Nanoporous microspheres: from controllable synthesis to healthcare applications. J. Mater. Chem. B, 2013, 1(17): 2222-2235. |

| [8] | PARK J H, PEREZ R A, JIN G Z, et al. Microcarriers designed for cell culture and tissue engineering of bone. Tissue Engineering Part B-Reviews, 2013, 19(2): 172-190. |

| [9] | WANG A J, LU Y P, SUN R X. Recent progress on the fabrication of hollow microspheres. Mat. Sci. Eng. A, 2007, 460: 1-6. |

| [10] | MATSUNO T, HASHIMOTO Y, ADACHI S, et al. Preparation of injectable 3D-formed beta-tricalcium phosphate bead/alginate composite for bone tissue engineering. Dent. Mater. J., 2008, 27(6): 827-834. |

| [11] | HASHIMOTO Y, ADACHI S, MATSUNO T, et al. Effect of an injectable 3D scaffold for osteoblast differentiation depends on bead size. Bio-Med. Mater. Eng., 2009, 19(6): 391-400. |

| [12] | LUO H T, ZHI W, LU X, et al. Research on preparation and biological properties of dense hydroxyapatite spheresJ. Inorg. Mater., 2013, 28(1): 40-44. |

| [13] | SUNNY M C, RAMESH P, VARMA H K. Microstructured microspheres of hydroxyapatite bioceramic. J. Mater. Sci-Mater. Med., 2002, 13(7): 623-632. |

| [14] | KAMITAKAHARA M, IMAI R, IOKU K. Preparation and evaluation of spherical Ca-deficient hydroxyapatite granules with controlled surface microstructure as drug carriers. Mater. Sci. Eng. C, 2013, 33(4): 2446-2450. |

| [15] | PEREZ R A, ALTANKOV G, JORGE-HERRERO E, et al. Micro- and nanostructured hydroxyapatitecollagen microcarriers for bone tissue-engineering applications. J. Tissue. Eng. Regen. Med., 2013, 7(5): 353-361. |

| [16] | KOMLEV V S, BARINOV S M, KOPLIK E V. A method to fabricate porous spherical hydroxyapatite granules intended for time- controlled drug release. Biomaterials, 2002, 23(16): 3449-3454. |

| [17] | BERNHARDT A, DITTRICH R, LODE A, et al. Nanocrystalline spherical hydroxyapatite granules for bone repair: in vitro evaluation with osteoblast-like cells and osteoclasts. J. Mater. Sci-Mater. Med., 2013, 24(7): 1755-1766. |

| [18] | RIBEIRO C C, BARRIAS C C, BARBOSA M A. Preparation and characterisation of calcium-phosphate porous microspheres with a uniform size for biomedical applications. J. Mater. Sci-Mater. Med., 2006, 17(5): 455-463. |

| [19] | DO-VAN T, LEE B T. Formation and characterization of porous spherical biphasic calcium phosphate (BCP) granules using PCL. Ceram. Int., 2011, 37(6): 2043-2049. |

| [20] | YANG J H, KIM K H, YOU C K, et al. Synthesis of spherical hydroxyapatite granules with interconnected pore channels using camphene emulsion. J. Biomed. Mater. Res. B Appl. Biomater., 2011, 99B(1): 150-157. |

| [21] | HONG M H, SON J S, KIM K M, et al. Drug-loaded porous spherical hydroxyapatite granules for bone regeneration. J. Mater. Sci-Mater. Med., 2011, 22(2): 349-355. |

| [22] | WANG A, LU Y, ZHU R, et al. Effect of process parameters on the performance of spray dried hydroxyapatite microspheres. Powder Technol., 2009, 191(1/2): 1-6. |

| [23] | WANG A J, LU Y P, ZHU R F, et al. Effect of sintering on porosity, phase, and surface morphology of spray dried hydroxyapatite microspheres. J. Biomed. Mater. Res., 2008, 87A(2): 557-562. |

| [24] | LOU X W, ARCHER L A, YANG Z. Hollow micro-/nanostruc-tures: synthesis and applications. Adv. Mater., 2008, 20(21): 3987-4019. |

| [25] | WANG Y, YAO A, HUANG W, et al. In situ fabrication of hollow hydroxyapatite microspheres by phosphate solution immersion. J. Cryst. Growth, 2011, 327(1): 245-250. |

| [26] | WANG Y, MOO Y X, CHEN C, et al. Fast precipitation of uniform CaCO3 nanospheres and their transformation to hollow hydroxyapatite nanospheres. J. Colloid Interf. Sci., 2010, 352(2): 393-400. |

| [27] | FU H, RAHAMAN M N, DAY D E. Effect of process variables on the microstructure of hollow hydroxyapatite microspheres prepared by a glass conversion method. J. Am. Ceram. Soc., 2010, 93(10): 3116-3123. |

| [28] | YAO A, AI F, LIU X, et al. Preparation of hollow hydroxyapatite microspheres by the conversion of borate glass at near room temperature. Mater. Res. Bull., 2010, 45(1): 25-28. |

| [29] | GUO Y, ZHOU Y, JIA D, et al. Fabrication and characterization of hydroxycarbonate apatite with mesoporous structure. Micropor. Mesopor. Mater., 2009, 118(1/2/3): 480-488. |

| [30] | GUO Y-P, LIN T-S, ZHOU Y, et al. Fabrication of monodisperse mesoporous hydroxycarbonate apatite microspheres by emulsion method. Micropor. Mesopor. Mater., 2010, 127(3): 245-249. |

| [31] | GUO Y J, WANG Y Y, CHEN T, et al. Hollow carbonated hydroxyapatite microspheres with mesoporous structure: Hydrothermal fabrication and drug delivery property. Mater. Sci. Eng. C, 2013, 33(6): 3166-3172. |

| [32] | LIN K, CHEN L, LIU P, et al. Hollow magnetic hydroxyapatite microspheres with hierarchically mesoporous microstructure for pH- responsive drug delivery. CrystEngComm., 2013, 15(15): 2999-3008. |

| [33] | HUANG M, WANG Y. Synthesis of calcium phosphate microcapsules using yeast-based biotemplate. J. Mater. Chem., 2012, 22(2): 626-630. |

| [34] | LEE H H, HONG S J, KIM C H, et al. Preparation of hydroxyapatite spheres with an internal cavity as a scaffold for hard tissue regeneration. J. Mater. Sci-Mater. Med., 2008, 19(9): 3029-3034. |

| [35] | SUN R, LU Y, CHEN K. Preparation and characterization of hollow hydroxyapatite microspheres by spray drying method. Mater. Sci. Eng. C, 2009, 29(4): 1088-1092. |

| [36] | JIAO Y, LU Y P, XIAO G Y, et al. Preparation and characterization of hollow hydroxyapatite microspheres by the centrifugal spray drying method. Powder Technol., 2012, 217: 581-584. |

| [37] | WANG K W, ZHU Y J, CHEN F, et al. Microwave-assisted synthesis of hydroxyapatite hollow microspheres in aqueous solution. Mater. Lett., 2011, 65(15/16): 2361-2363. |

| [38] | ELTOHAMY M, SHIN U S, WON J E, et al. Electrosprayed tricalcium phosphate spherical microcups and antibiotic drug delivery. Mater. Lett., 2011, 65(13): 2043-2046. |

| [39] | MA M G. Hierarchically nanostructured hydroxyapatite: hydrothermal synthesis, morphology control, growth mechanism, and biological activity. Int. J. Nanomedicine, 2012, 7: 1781-1791. |

| [40] | KANG N H, KIM S J, SONG S H, et al. Hydroxyapatite synthesis using EDTA. J. Cran. Surg., 2013, 24(3): 1042-1045. |

| [41] | WANG Y, WU C, LIN K, et al. Facile fabrication of nanorod- assembled fluorine-substituted hydroxyapatite (FHA) microspheres. Chem. Asian. J., 2013, 8(5): 990-996. |

| [42] | YANG H, HAO L, DU C, et al. A systematic examination of the morphology of hydroxyapatite in the presence of citrate. RSC Adv., 2013, 3(45): 23184-23189. |

| [43] | YANG H, HAO L, ZHAO N, et al. Hierarchical porous hydroxyapatite microsphere as drug delivery carrier. CrystEngComm., 2013, 15(29): 5760-5763. |

| [44] | MA Y, HAO L, DU S, et al. Synthesis of hydroxyapatite microspheres by hydrothermal method under the control of sodium citrate. J. Inorg. Mater., 2014, 29(3): 284-288. |

| [45] | PENG Q, JIANG F, HUANG P, et al. A novel porous bioceramics scaffold by accumulating hydroxyapatite spherules for large bone tissue engineering in vivo. I. Preparation and characterization of scaffold. J. Biomed. Mater. Res., 2010, 93A(3): 920-929. |

| [46] | WANG H, ZHI W, LU X, et al. Comparative studies on ectopic bone formation in porous hydroxyapatite scaffolds with complementary pore structures. Acta Biomater., 2013, 9(9): 8413-8421. |

| [47] | LARANJEIRA M S, FERNANDES M H, MONTEIRO F J. Innovative macroporous granules of nanostructured-hydroxyapatite agglomerates: bioactivity and osteoblast-like cell behaviour. J. Biomed. Mater. Res., 2010, 95A(3): 891-900. |

| [48] | LEE J H, KO I H, JEON S H, et al. Micro-structured hydroxyapatite microspheres for local delivery of alendronate and BMP-2 carriers. Mater. Lett., 2013, 105: 136-139. |

| [49] | SUN R, CHEN K, LU Y. Fabrication and dissolution behavior of hollow hydroxyapatite microspheres intended for controlled drug release. Mater. Res. Bull., 2009, 44(10): 1939-1942. |

| [50] | YANG Y H, LIU C H, LIANG Y H, et al. Hollow mesoporous hydroxyapatite nanoparticles (hmHANPs) with enhanced drug loading and pH-responsive release properties for intracellular drug delivery. J. Mater. Chem. B, 2013, 1(19): 2447-2450. |

| [51] | JIANG F, WANG D P, WANG H, et al. Analysis of several factors for drug controlled release from apatite microspheres. J. Chin. Ceramic Soc., 2013, 41(10): 1347-1353. |

| [52] | XIA W, GRANDFIELD K, SCHWENKE A, et al. Synthesis and release of trace elements from hollow and porous hydroxyapatite spheres. Nanotechnology, 2011, 22(30): 305610-1-10. |

| [53] | PARK J S, HONG S J, KIM H Y, et al. Evacuated calcium phosphate spherical microcarriers for bone regeneration. Tissue Eng. Part A, 2010, 16(5): 1681-1691. |

| [54] | JIN G Z, KIM J H, PARK J H, et al. Performance of evacuated calcium phosphate microcarriers loaded with mesenchymal stem cells within a rat calvarium defect. J. Mater. Sci-Mater. Med., 2012, 23(7): 1739-1748. |

| [55] | FU H, RAHAMAN M N, BROWN R F, et al. Evaluation of bone regeneration in implants composed of hollow HA microspheres loaded with transforming growth factor beta 1 in a rat calvarial defect model. Acta Biomater., 2013, 9(3): 5718-5727. |

| [56] | XIAO W, FU H, RAHAMAN M N, et al. Hollow hydroxyapatite microspheres: A novel bioactive and osteoconductive carrier for controlled release of bone morphogenetic protein-2 in bone regeneration. Acta Biomater., 2013, 9(9): 8374-8383. |

| [57] | GREEN D W, BOLLAND B J R F, KANCZLER J M, et al. Augmentation of skeletal tissue formation in impaction bone grafting using vaterite microsphere biocomposites. Biomaterials, 2009, 30(10): 1918-1927. |

| [58] | WU K C W, YANG Y H, LIANG Y H, et al. Facile synthesis of hollow mesoporous hydroxyapatite nanoparticles for intracellular bio-imaging. Curr. Nanosci., 2011, 7(6): 926-931. |

| [59] | KIMURA I, KANATANI M, WATANABE K. Adhesion of hollow calcium- deficient hydroxyapatite microspheres onto titanium. Dent. Mater. J., 2009, 28(6): 700-707. |

| [60] | FU Q, HONG Y, LIU X, et al. A hierarchically graded bioactive scaffold bonded to titanium substrates for attachment to bone. Biomaterials, 2011, 32(30): 7333-7346. |

| [61] | FU H, RAHAMAN M N, BROWN R F, et al. Evaluation of BSA protein release from hollow hydroxyapatite microspheres into PEG hydrogel. Mater. Sci. Eng. C, 2013, 33(4): 2245-2250. |

| [62] | FU H, RAHAMAN M N, DAY D E, et al. Hollow hydroxyapatite microspheres as a device for controlled delivery of proteins. J. Mater. Sci-Mater. Med., 2011, 22(3): 579-591. |

| [1] | ZHU Wenjie, TANG Lu, LU Jichang, LIU Jiangping, LUO Yongming. Research Progress on Catalytic Oxidation of Volatile Organic Compounds by Perovskite Oxides [J]. Journal of Inorganic Materials, 2025, 40(7): 735-746. |

| [2] | TANG Xinli, DING Ziyou, CHEN Junrui, ZHAO Gang, HAN Yingchao. In vivo Distribution and Metabolism of Calcium Phosphate Nanomaterials Based on Fluorescent Labeling with Rare Earth Europium Ions [J]. Journal of Inorganic Materials, 2025, 40(7): 754-764. |

| [3] | HU Zhichao, YANG Hongyu, YANG Hongcheng, SUN Chengli, YANG Jun, LI Enzhu. Usage of the P-V-L Bond Theory in Regulating Properties of Microwave Dielectric Ceramics [J]. Journal of Inorganic Materials, 2025, 40(6): 609-626. |

| [4] | WU Qiong, SHEN Binglin, ZHANG Maohua, YAO Fangzhou, XING Zhipeng, WANG Ke. Research Progress on Lead-based Textured Piezoelectric Ceramics [J]. Journal of Inorganic Materials, 2025, 40(6): 563-574. |

| [5] | ZHANG Bihui, LIU Xiaoqiang, CHEN Xiangming. Recent Progress of Hybrid Improper Ferroelectrics with Ruddlesden-Popper Structure [J]. Journal of Inorganic Materials, 2025, 40(6): 587-608. |

| [6] | WU Jie, YANG Shuai, WANG Mingwen, LI Jinglei, LI Chunchun, LI Fei. Textured PT-based Piezoelectric Ceramics: Development, Status and Challenge [J]. Journal of Inorganic Materials, 2025, 40(6): 575-586. |

| [7] | JIANG Kun, LI Letian, ZHENG Mupeng, HU Yongming, PAN Qinxue, WU Chaofeng, WANG Ke. Research Progress on Low-temperature Sintering of PZT Ceramics [J]. Journal of Inorganic Materials, 2025, 40(6): 627-638. |

| [8] | CHEN Xi, YUAN Yuan, TAN Yeqiang, LIU Changsheng. Strategic Study on the Development of Inorganic Non-metallic Biomaterials [J]. Journal of Inorganic Materials, 2025, 40(5): 449-456. |

| [9] | TIAN Ruizhi, LAN Zhengyi, YIN Jie, HAO Nanjing, CHEN Hangrong, MA Ming. Microfluidic Technology Based Synthesis of Inorganic Nano-biomaterials: Principles and Progress [J]. Journal of Inorganic Materials, 2025, 40(4): 337-347. |

| [10] | ZHANG Jiguo, WU Tian, ZHAO Xu, YANG Fan, XIA Tian, SUN Shien. Improvement of Cycling Stability of Cathode Materials and Industrialization Process for Sodium-ion Batteries [J]. Journal of Inorganic Materials, 2025, 40(4): 348-362. |

| [11] | YIN Jie, GENG Jiayi, WANG Kanglong, CHEN Zhongming, LIU Xuejian, HUANG Zhengren. Recent Advances in 3D Printing and Densification of SiC Ceramics [J]. Journal of Inorganic Materials, 2025, 40(3): 245-255. |

| [12] | CHEN Guangchang, DUAN Xiaoming, ZHU Jinrong, GONG Qing, CAI Delong, LI Yuhang, YANG Donglei, CHEN Biao, LI Xinmin, DENG Xudong, YU Jin, LIU Boya, HE Peigang, JIA Dechang, ZHOU Yu. Advanced Ceramic Materials in Helicopter Special Structures: Research Progress and Application Prospect [J]. Journal of Inorganic Materials, 2025, 40(3): 225-244. |

| [13] | FAN Xiaobo, ZU Mei, YANG Xiangfei, SONG Ce, CHEN Chen, WANG Zi, LUO Wenhua, CHENG Haifeng. Research Progress on Proton-regulated Electrochemical Ionic Synapses [J]. Journal of Inorganic Materials, 2025, 40(3): 256-270. |

| [14] | HAIREGU Tuxun, GUO Le, DING Jiayi, ZHOU Jiaqi, ZHANG Xueliang, NUERNISHA Alifu. Research Progress of Optical Bioimaging Technology Assisted by Upconversion Fluorescence Probes in Tumor Imaging [J]. Journal of Inorganic Materials, 2025, 40(2): 145-158. |

| [15] | SUN Shujuan, ZHENG Nannan, PAN Haokun, MA Meng, CHEN Jun, HUANG Xiubing. Research Progress on Preparation Methods of Single-atom Catalysts [J]. Journal of Inorganic Materials, 2025, 40(2): 113-127. |

| Viewed | ||||||

|

Full text |

|

|||||

|

Abstract |

|

|||||