Journal of Inorganic Materials ›› 2026, Vol. 41 ›› Issue (1): 55-62.DOI: 10.15541/jim20250137

• RESEARCH ARTICLE • Previous Articles Next Articles

GE Yeming1( ), TANG Zhe1, LIU Miao1, LOU Size1, LIU Zhenguo2, ZHOU Yan3, WAN Shun4(

), TANG Zhe1, LIU Miao1, LOU Size1, LIU Zhenguo2, ZHOU Yan3, WAN Shun4( ), ZONG Peng'an1(

), ZONG Peng'an1( )

)

Received:2025-04-01

Revised:2025-06-05

Published:2026-01-20

Online:2025-06-27

Contact:

ZONG Peng'an, associate professor. E-mail: pazong@njtech.edu.cn;About author:GE Yeming (2000-), male, Master candidate. E-mail: 202261103011@njtech.edu.cn

Supported by:CLC Number:

GE Yeming, TANG Zhe, LIU Miao, LOU Size, LIU Zhenguo, ZHOU Yan, WAN Shun, ZONG Peng'an. Fabrication and Thermoelectric Performance of Ce0.9Fe3CoSb12 Thin Films via Magnetron Sputtering for Flexible Thermoelectric and Sensing Applications[J]. Journal of Inorganic Materials, 2026, 41(1): 55-62.

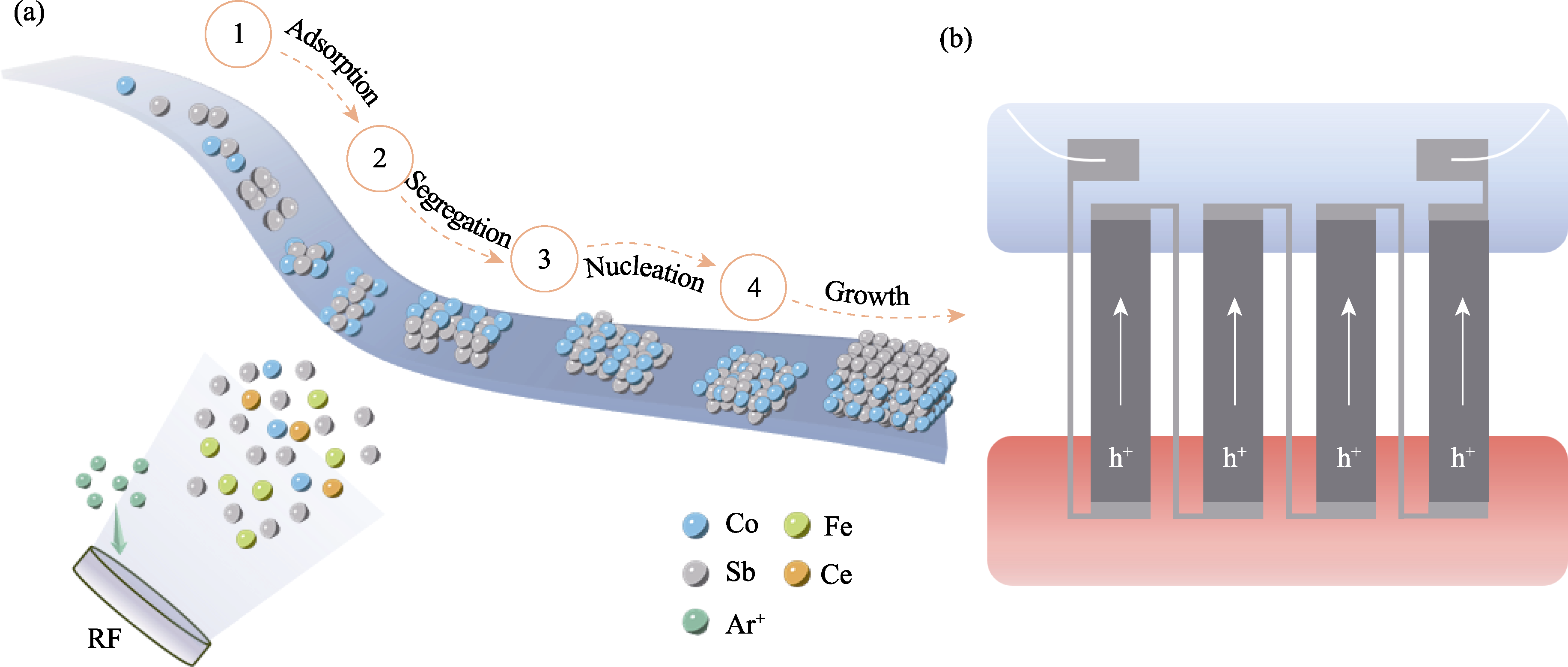

Fig. 1 Diagrams of thin film and thermoelectric device fabrication (a) Schematic diagram of fabrication of Ce0.9Fe3CoSb12 thin film by magnetron sputtering; (b) Schematic diagram of thermoelectric device

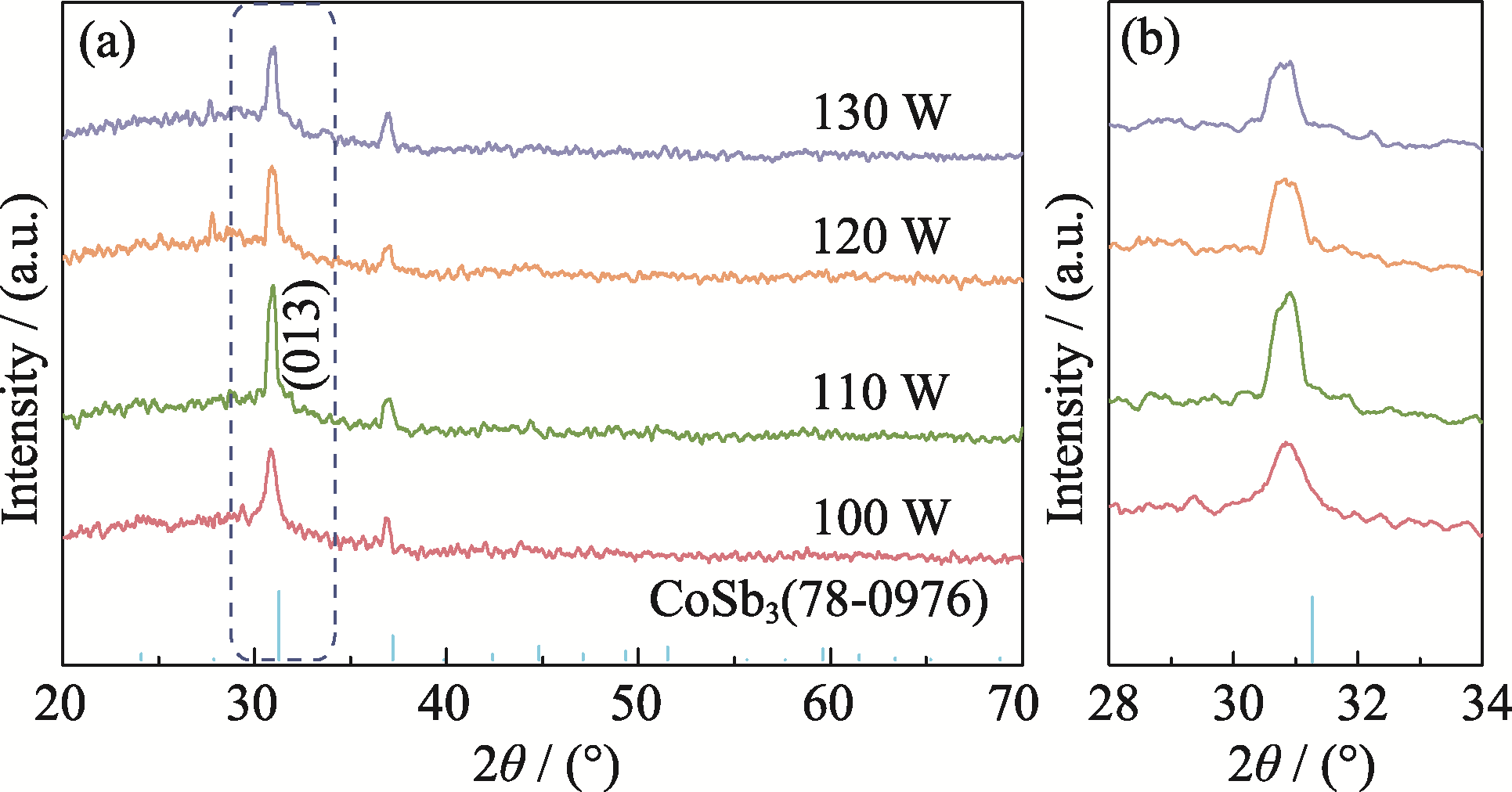

Fig. 2 XRD patterns of Ce0.9Fe3CoSb12 thin films deposited at different sputtering powers (a) XRD patterns; (b) Localized enlargements of (013) crystal plane diffraction peak

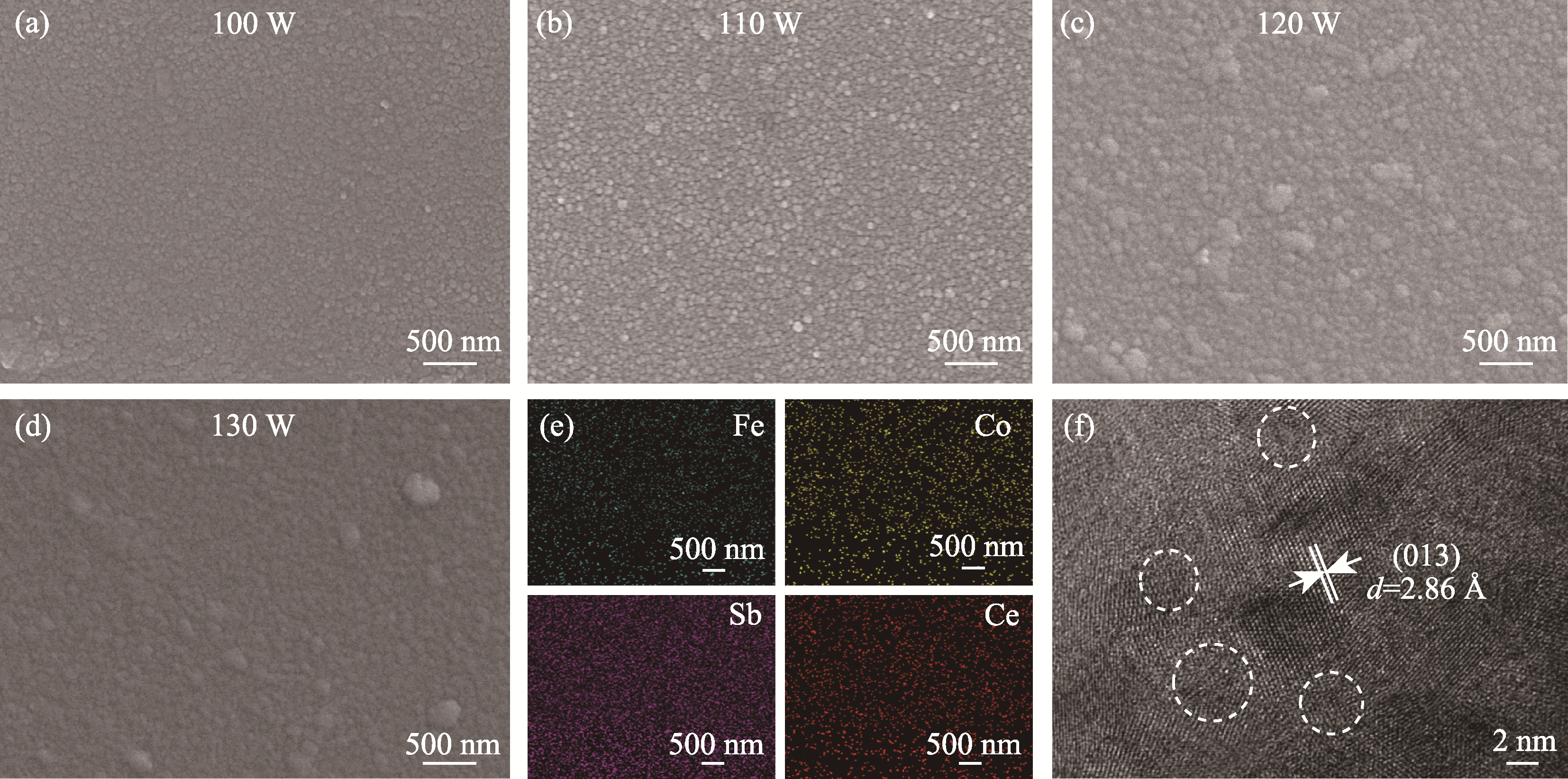

Fig. 3 Microstructure analyses of Ce0.9Fe3CoSb12 thin films (a-d) SEM images of Ce0.9Fe3CoSb12 thin films deposited at different sputtering powers; (e) EDS elemental mappings and (f) HRTEM image of Ce0.9Fe3CoSb12 thin film deposited at 110 W

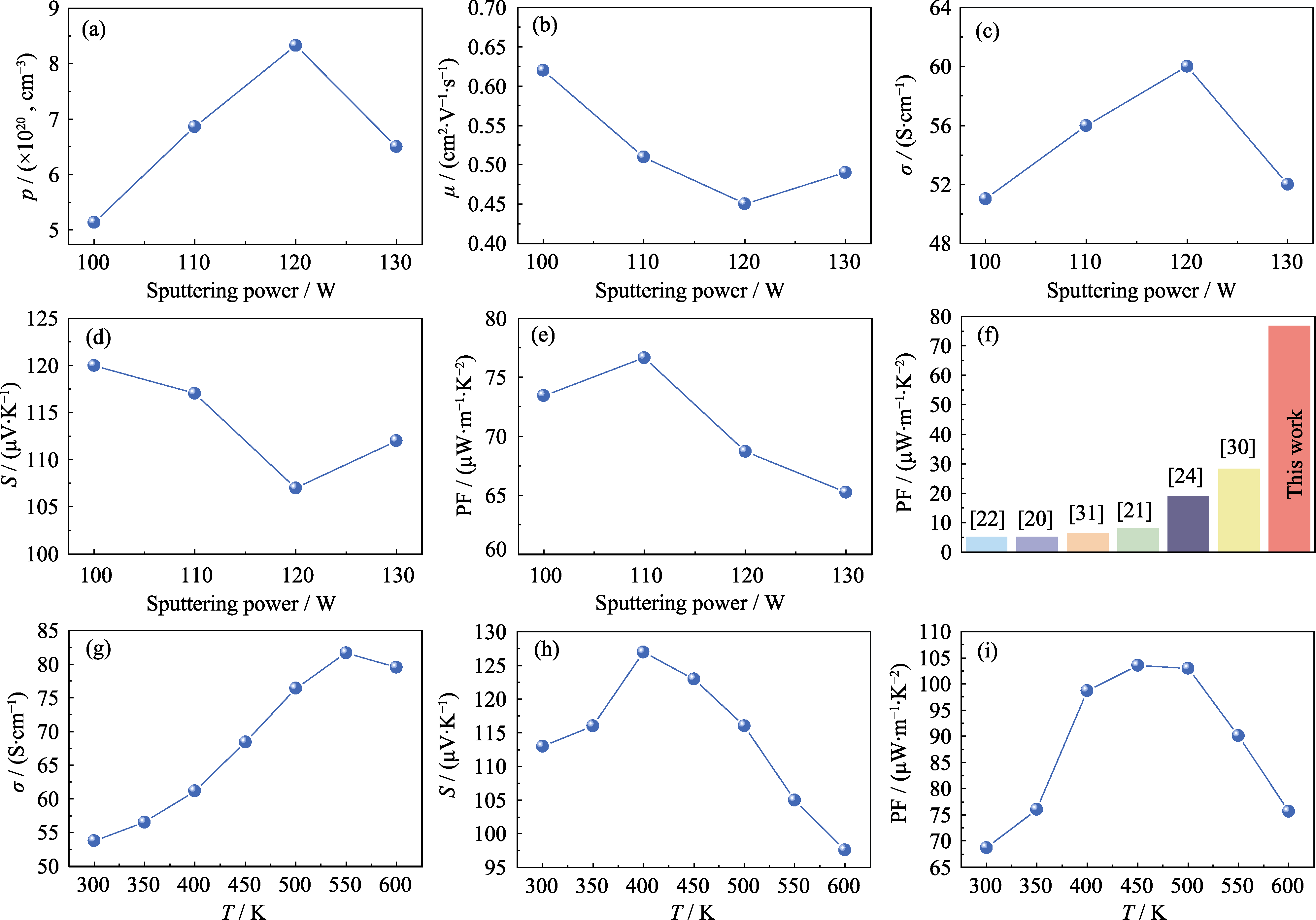

Fig. 4 Thermoelectric performance of Ce0.9Fe3CoSb12 thin films prepared at various sputtering powers (a-e) p, μ, σ, S, and PF of Ce0.9Fe3CoSb12 thin films prepared under different sputtering powers; (f) Comparison of PF of CoSb3-based films at room temperature[20-22,24,30 -31]; (g-i) Relationship between σ, S, and PF of the 110 W Ce0.9Fe3CoSb12 sample as a function of temperature

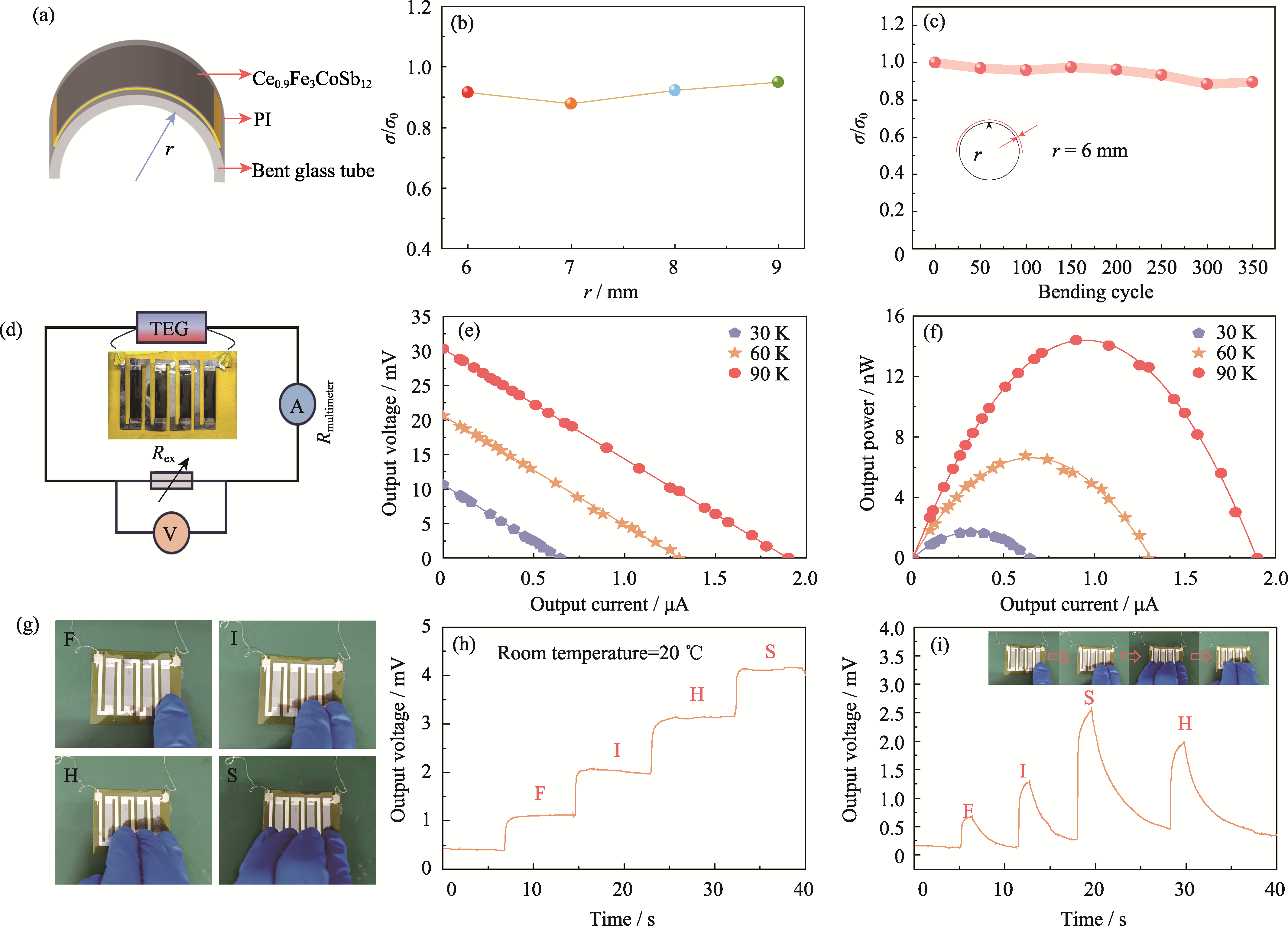

Fig. 5 Characterization of mechanical flexibility, thermoelectric output and touch sensing capability of the Ce0.9Fe3CoSb12 flexible thermoelectric device (a) Schematic diagram of Ce0.9Fe3CoSb12 flexible thin film placed on a bent tube during the bending test; (b) σ/σ0 varied with different curvature radii after 200 bending cycles on tubes; (c) σ/σ0 varied with bending cycles on a tube with a curvature radius of 6 mm; (d) Schematic diagram of the voltage-current circuit for device output performance testing; (e) Relationship between output voltage and output current under different ΔT; (f) Relationship between output power and output current under different ΔT; (g, h) Output voltage corresponding to different numbers of legs touched on the touch sensor; (i) Voltage signals converted into words by touch sensor, using "FISH" as an example

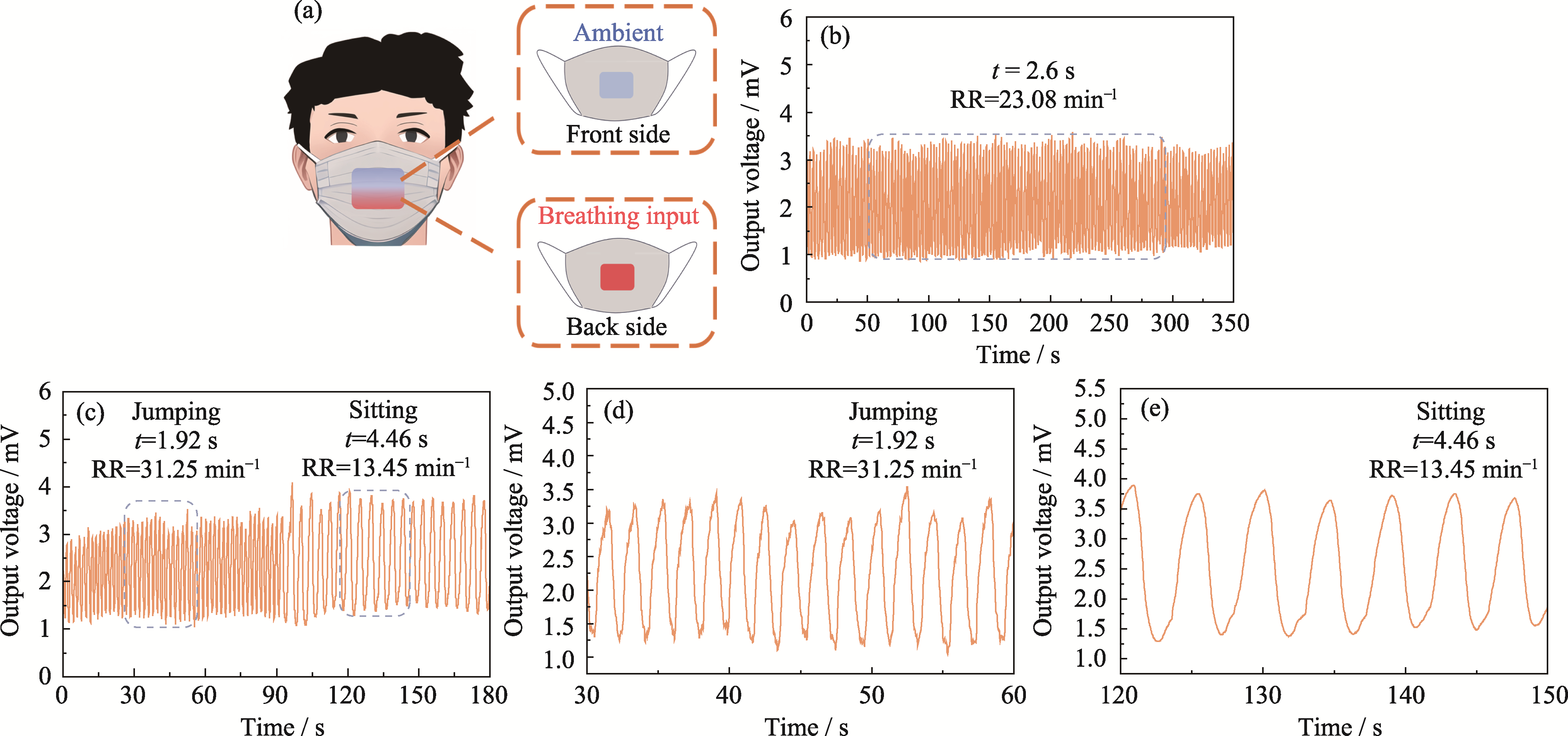

Fig. 6 Respiratory sensing output test (a) Integration of the respiratory sensor into a mask, with the backside positioned near the breathing inlet and the front side exposed to the ambient air; (b) Voltage signals detected by the sensor while worn in a resting state; (c-e) Voltage signals recorded during the transition from jumping to sitting while wearing the sensor

| Sputtering power/W | Ce/% | Fe/% | Co/% | Sb/% | Formula |

|---|---|---|---|---|---|

| 100 | 7.23 | 8.91 | 3.24 | 80.62 | Ce0.938Fe2.9CoSb12.04 |

| 110 | 6.88 | 9.21 | 3.14 | 80.77 | Ce0.92Fe3.09CoSb12.43 |

| 120 | 6.82 | 9.98 | 3.38 | 79.81 | Ce0.85Fe3.14CoSb11.43 |

| 130 | 6.83 | 9.03 | 3.04 | 81.09 | Ce0.942Fe3.13CoSb12.9 |

Table S1 Mass fractions of various elements in thin films deposited at different sputtering powers and chemical formulas of films calculated with Co molar ratio as the base

| Sputtering power/W | Ce/% | Fe/% | Co/% | Sb/% | Formula |

|---|---|---|---|---|---|

| 100 | 7.23 | 8.91 | 3.24 | 80.62 | Ce0.938Fe2.9CoSb12.04 |

| 110 | 6.88 | 9.21 | 3.14 | 80.77 | Ce0.92Fe3.09CoSb12.43 |

| 120 | 6.82 | 9.98 | 3.38 | 79.81 | Ce0.85Fe3.14CoSb11.43 |

| 130 | 6.83 | 9.03 | 3.04 | 81.09 | Ce0.942Fe3.13CoSb12.9 |

| [1] |

TAN G J, ZHAO L D, KANATZIDIS M G. Rationally designing high-performance bulk thermoelectric materials. Chemical Reviews, 2016, 116(19): 12123.

PMID |

| [2] |

SHI X, CHEN L, UHER C. Recent advances in high-performance bulk thermoelectric materials. International Materials Reviews, 2016, 61(6): 379.

DOI URL |

| [3] |

IBÁÑEZ M, LUO Z S, GENÇ A, et al. High-performance thermoelectric nanocomposites from nanocrystal building blocks. Nature Communications, 2016, 7: 10766.

DOI PMID |

| [4] |

LIU B, HU J Z, ZHOU J, et al. Thermoelectric transport in nanocomposites. Materials, 2017, 10(4): 418.

DOI URL |

| [5] |

XIAO Y, ZHAO L D. Seeking new, highly effective thermoelectrics. Science, 2020, 367(6483): 1196.

DOI PMID |

| [6] |

JIANG B B, WANG W, LIU S X, et al. High figure-of-merit and power generation in high-entropy GeTe-based thermoelectrics. Science, 2022, 377(6602): 208.

DOI PMID |

| [7] |

CAO T Y, SHI X L, CHEN Z G. Advances in the design and assembly of flexible thermoelectric device. Progress in Materials Science, 2023, 131: 101003.

DOI URL |

| [8] | GAO M Y, WANG P, JIANG L L, et al. Power generation for wearable systems. Energy & Environmental Science, 2021, 14(4): 2114. |

| [9] | LIANG J S, WANG T, QIU P F, et al. Flexible thermoelectrics: from silver chalcogenides to full-inorganic devices. Energy & Environmental Science, 2019, 12(10): 2983. |

| [10] |

YANG Q Y, YANG S Q, QIU P F, et al. Flexible thermoelectrics based on ductile semiconductors. Science, 2022, 377(6608): 854.

DOI PMID |

| [11] |

WEI T R, JIN M, WANG Y C, et al. Exceptional plasticity in the bulk single-crystalline van der Waals semiconductor InSe. Science, 2020, 369(6503): 542.

DOI URL |

| [12] | NOLAS G S, MORELLI D T, TRITT T M. Skutterudites: a phonon-glass-electron crystal approach to advanced thermoelectric energy conversion applications. Annual Review of Materials Research, 1999, 29: 89. |

| [13] |

LIU Z Y, WANG Y G, YANG T, et al. Alloying engineering for thermoelectric performance enhancement in p-type skutterudites with synergistic carrier concentration optimization and thermal conductivity reduction. Journal of Advanced Ceramics, 2023, 12(3): 539.

DOI URL |

| [14] |

ROGL G, GRYTSIV A, ROGL P, et al. Nanostructuring of p- and n-type skutterudites reaching figures of merit of approximately 1.3 and 1.6, respectively. Acta Materialia, 2014, 76: 434.

DOI URL |

| [15] |

TANG Y L, GIBBS Z M, AGAPITO L A, et al. Convergence of multi-valley bands as the electronic origin of high thermoelectric performance in CoSb3 skutterudites. Nature Materials, 2015, 14(12): 1223.

DOI |

| [16] |

MENG X F, LIU Z H, CUI B, et al. Grain boundary engineering for achieving high thermoelectric performance in n-type skutterudites. Advanced Energy Materials, 2017, 7(13): 1602582.

DOI URL |

| [17] |

LIU Z Y, ZHU J L, TONG X, et al. A review of CoSb3-based skutterudite thermoelectric materials. Journal of Advanced Ceramics, 2020, 9(6): 647.

DOI |

| [18] |

ORTIZ B R, CRAWFORD C M, MCKINNEY R W, et al. Thermoelectric properties of bromine filled CoSb3 skutterudite. Journal of Materials Chemistry A, 2016, 4(21): 8444.

DOI URL |

| [19] |

HERMANN R P, JIN R Y, SCHWEIKA W, et al. Einstein oscillators in thallium filled antimony skutterudites. Physical Review Letters, 2003, 90(13): 135505.

DOI URL |

| [20] |

WEI M, MA H L, NIE M Y, et al. Enhanced thermoelectric performance of CoSb3 thin films by Ag and Ti co-doping. Materials, 2023, 16(3): 1271.

DOI URL |

| [21] |

LI D, SHI X L, ZHU J X, et al. Ce-filled Ni1.5Co2.5Sb12 skutterudite thin films with record-high figure of merit and device performance. Advanced Energy Materials, 2023, 13(37): 2301525.

DOI URL |

| [22] |

ZHENG Z H, SHI X L, AO D W, et al. Rational band engineering and structural manipulations inducing high thermoelectric performance in n-type CoSb3 thin films. Nano Energy, 2021, 81: 105683.

DOI URL |

| [23] |

AMIRGHASEMI F, KASSEGNE S. Effects of RF magnetron sputtering deposition power on crystallinity and thermoelectric properties of antimony telluride and bismuth telluride thin films on flexible substrates. Journal of Electronic Materials, 2021, 50(4): 2190.

DOI |

| [24] |

LI D, SHI X L, ZHU J X, et al. High-performance flexible p-type Ce-filled Fe3CoSb12 skutterudite thin film for medium-to-high- temperature applications. Nature Communications, 2024, 15: 4242.

DOI |

| [25] |

CAO X F, HE M K, MA B P, et al. Enhanced thermoelectric properties of Mm-filled p-type (Fe, Co)Sb3 skutterudites via Co/Fe ratio regulation and extra Sb compensation. Journal of Alloys and Compounds, 2024, 972: 172815.

DOI URL |

| [26] |

YADAV S, CHAUDHARY S, PANDYA D K. Enhancing thermoelectric properties of p-type CoSb3 skutterudite by Fe doping. Materials Science in Semiconductor Processing, 2021, 127: 105721.

DOI URL |

| [27] | RAUSCHENBACH B. Low-energy ion irradiation of materials. Cham: Springer International Publishing, 2022: 123-174. |

| [28] |

JUNLABHUT P, NUTHONGKUM P, HARNWUNGGMOUNG A, et al. Thickness dependence of thermoelectric properties and maximum output power of single planar Sb2Te3 films. Materials, 2022, 15(24): 8850.

DOI URL |

| [29] |

SHI T F, CHEN M R, ZHANG C R, et al. Modifying carbon fiber fabric for flexible thermoelectric energy conversion. Applied Surface Science, 2023, 610: 155479.

DOI URL |

| [30] |

ZHENG Z H, WEI M, LUO J T, et al. An enhanced power factor via multilayer growth of Ag-doped skutterudite CoSb3 thin films. Inorganic Chemistry Frontiers, 2018, 5(6): 1409.

DOI URL |

| [31] | ZHENG Z H, NIU J Y, AO D W, et al. In-situ growth of high-performance (Ag, Sn) Co-doped CoSb3 thermoelectric thin films. Journal of Materials Science & Technology, 2021, 92: 178. |

| [32] |

LI X G, LIU W D, LI S M, et al. Ce filling limit and its influence on thermoelectric performance of Fe3CoSb12-based skutterudite grown by a temperature gradient zone melting method. Materials, 2021, 14(22): 6810.

DOI URL |

| [33] |

WANG Z W, ZHANG C R, ZHANG J, et al. Construction of an MXene/organic superlattice for flexible thermoelectric energy conversion. ACS Applied Energy Materials, 2022, 5(9): 11351.

DOI URL |

| [34] |

ZHU J J, SUN C, FENG W L, et al. Permeable carbon fiber based thermoelectric film with exceptional EMI shielding performance and sensor capabilities. Journal of Advanced Ceramics, 2024, 13(8): 1119.

DOI URL |

| [35] |

ZHANG C R, ZONG P A, GE Z S, et al. MXene-based wearable thermoelectric respiration sensor. Nano Energy, 2023, 118: 109037.

DOI URL |

| [1] | HU Yuchen, XU Zishuo, HU Yuejuan, CHEN Lidong, YAO Qin. Enhanced Thermoelectric Properties of Two-dimensional Planar Copper Polyphthalocyanine by Dispersing Single-walled Carbon Nanotubes [J]. Journal of Inorganic Materials, 2026, 41(1): 63-69. |

| [2] | WU Huaxin, ZHANG Qihao, YAN Haixue, WANG Lianjun, JIANG Wan. Optimization of Thermoelectric Transport Properties in Nanocomposite MgAgSb-based Alloys [J]. Journal of Inorganic Materials, 2025, 40(9): 997-1004. |

| [3] | YANG Guang, ZHANG Nan, CHEN Shujin, WANG Yi, XIE An, YAN Yujie. WO3 Films Based on Porous ITO Electrodes: Preparation and Electrochromic Property [J]. Journal of Inorganic Materials, 2025, 40(7): 781-789. |

| [4] | DONG Chenyu, ZHENG Weijie, MA Yifan, ZHENG Chunyan, WEN Zheng. Characterizations by Piezoresponse Force Microscopy on Relaxor Properties of Pb(Mg,Nb)O3-PbTiO3 Ultra-thin Films [J]. Journal of Inorganic Materials, 2025, 40(6): 675-682. |

| [5] | MIAO Pengcheng, WANG Lijun, SHEN Ziyi, HUANG Li, YUAN Ningyi, DING Jianning. Micro-spherical Ag2Se: Solvothermal Synthesis and Thermoelectric Properties [J]. Journal of Inorganic Materials, 2025, 40(12): 1373-1378. |

| [6] | ZHENG Yuanshun, YU Jian, YE Xianfeng, LIANG Dong, ZHU Wanting, NIE Xiaolei, WEI Ping, ZHAO Wenyu, ZHANG Qingjie. Boosting the Thermoelectric Performance of Full-Heusler Fe2VAl Alloy via Substituting Al Site with V [J]. Journal of Inorganic Materials, 2025, 40(12): 1425-1432. |

| [7] | WU Mingxuan, LI Junjie, CHEN Shuo, YAN Yonggao, SU Xianli, ZHANG Qingjie, TANG Xinfeng. Homogeneity of Zone-melted n-type Bi1.96Sb0.04Te2.70Se0.30 Thermoelectric Material [J]. Journal of Inorganic Materials, 2025, 40(11): 1252-1260. |

| [8] | GE Zesheng, LIU Miao, TANG Zhe, ZHOU Yan, WAN Shun, ZONG Peng’an. Flexible Cu0.005Bi0.5Sb1.495Te3 Thin Films: Magnetron Sputtering Preparation and Thermoelectric Properties [J]. Journal of Inorganic Materials, 2025, 40(11): 1237-1244. |

| [9] | CHENG Jun, ZHANG Jiawei, QIU Pengfei, CHEN Lidong, SHI Xun. Preparation and Thermoelectric Transport Properties of P-doped β-FeSi2 [J]. Journal of Inorganic Materials, 2024, 39(8): 895-902. |

| [10] | MIAO Xin, YAN Shiqiang, WEI Jindou, WU Chao, FAN Wenhao, CHEN Shaoping. Interface Layer of Te-based Thermoelectric Device: Abnormal Growth and Interface Stability [J]. Journal of Inorganic Materials, 2024, 39(8): 903-910. |

| [11] | CHEN Hao, FAN Wenhao, AN Decheng, CHEN Shaoping. Improvement of Thermoelectric Performance of SnTe by Energy Band Optimization and Carrier Regulation [J]. Journal of Inorganic Materials, 2024, 39(3): 306-312. |

| [12] | BAO Ke, LI Xijun. Chemical Vapor Deposition of Vanadium Dioxide for Thermochromic Smart Window Applications [J]. Journal of Inorganic Materials, 2024, 39(3): 233-258. |

| [13] | LIU Song, ZHANG Faqiang, LUO Jin, LIU Zhifu. 0.9BaTiO3-0.1Bi(Mg1/2Ti1/2)O3 Ferroelectric Thin Films: Preparation and Energy Storage [J]. Journal of Inorganic Materials, 2024, 39(3): 291-298. |

| [14] | XU Xiangming, Husam N ALSHAREEF. Perspective of MXetronics [J]. Journal of Inorganic Materials, 2024, 39(2): 171-178. |

| [15] | ZHANG Botao, SUN Tingting, WANG Lianjun, JIANG Wan. Inkjet Printing Preparation of AgCuTe Thermoelectric Thin Films [J]. Journal of Inorganic Materials, 2024, 39(12): 1325-1330. |

| Viewed | ||||||

|

Full text |

|

|||||

|

Abstract |

|

|||||