Journal of Inorganic Materials ›› 2022, Vol. 37 ›› Issue (3): 325-332.DOI: 10.15541/jim20210654

• RESEARCH ARTICLE • Previous Articles Next Articles

LI Qiaolei1,2, GU Yue3, YU Xuehua4, ZHANG Chaowei1, ZOU Mingke1, LIANG Jingjing1,3( ), LI Jinguo1,3(

), LI Jinguo1,3( )

)

Received:2021-10-23

Revised:2021-11-28

Published:2022-03-20

Online:2022-01-06

Contact:

LIANG Jingjing, professor. E-mail: jjliang@imr.ac.cn; LI Jinguo, professor. E-mail: jgli@imr.ac.cn

About author:LI Qiaolei (1993-), male, PhD candidate. E-mail: lql_614@163.com

Supported by:CLC Number:

LI Qiaolei, GU Yue, YU Xuehua, ZHANG Chaowei, ZOU Mingke, LIANG Jingjing, LI Jinguo. Effect of Sintering Temperature on Surface Morphology and Roughness of 3D-printed Silicon Ceramic Cores[J]. Journal of Inorganic Materials, 2022, 37(3): 325-332.

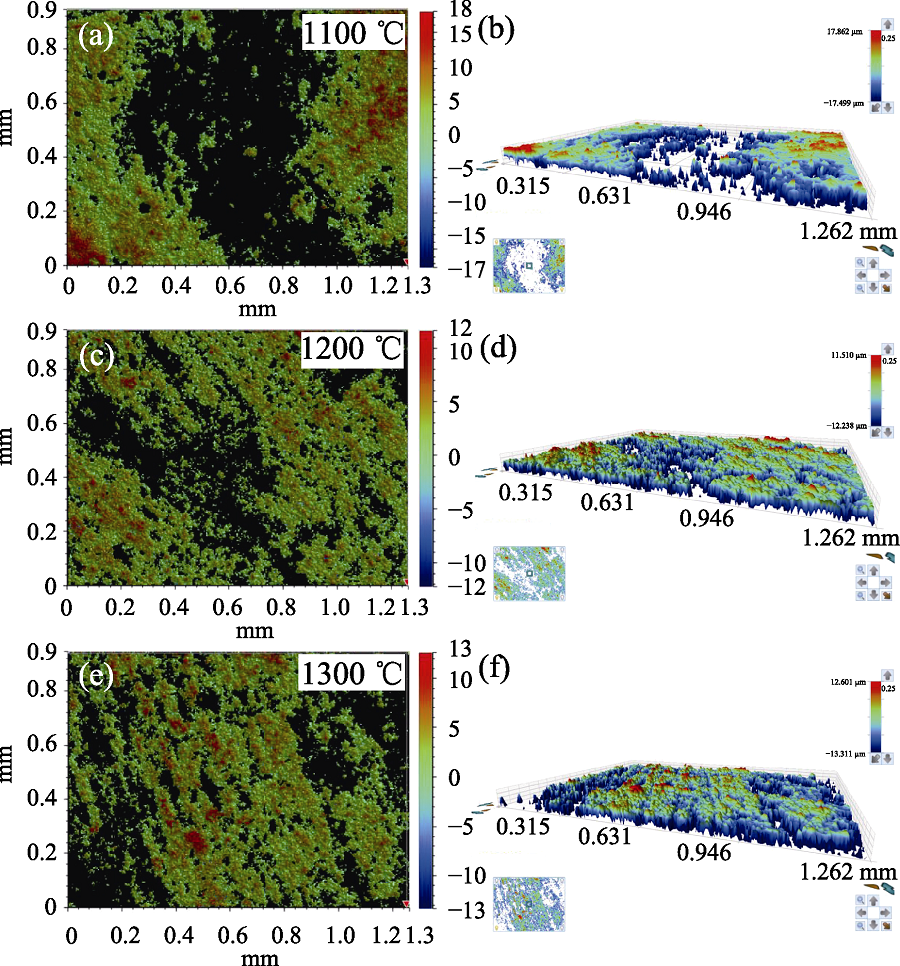

Fig. 8 2D and 3D surface morphologies of the printed surfaces of ceramic cores sintered at different temperatures The reference surface was established by commercial morphology analysis software Vision64

Fig. 10 2D and 3D surface morphologies of ceramic cores sintered at different temperatures in printing stacking direction The reference surface was established by commercial morphology analysis software Vision64

| [1] |

POLLOCK T M. Alloy design for aircraft engines. Nature Materials, 2016, 15(8): 809-815.

DOI URL |

| [2] |

PADTURE N P, GELL M, JORDAN E H. Thermal barrier coatings for gas-turbine engine applications. Science, 2002, 296(5566): 280-284.

DOI URL |

| [3] |

LIANG X, ZHAO Y T, MA D, et al. Study on the preparation and microstructure of a single-crystal hollow turbine blade. Materials and Manufacturing Processes, 2017, 32(16): 1887-1892.

DOI URL |

| [4] |

GUO Z, SONG Z, FAN J, et al. Experimental and analytical investigation on service life of film cooling structure for single crystal turbine blade. International Journal of Fatigue, 2021, 150: 106318.

DOI URL |

| [5] | LIANG J, LIN Q, ZHANG X, et al. Effects of alumina on cristobalite crystallization and properties of silica-based ceramic cores. Journal of Materials Science & Technology, 2017, 33(2): 204-209. |

| [6] |

XU W, LU Z, TIAN G, et al. Fabrication of single-crystal superalloy hollow blade based on integral ceramic mold. Journal of Materials Processing Technology, 2019, 271: 615-622.

DOI URL |

| [7] | WALALE A, CHAUHAN A S, SATYANARAYANA A, et al. Analysis of shrinkage & warpage in ceramic injection molding of HPT vane leading edge core of a gas turbine casting. Materials Today: Proceedings, 2018, 5(9): 19471-19479. |

| [8] | CHAUHAN A S, ANIRUDH B, SATYANARAYANA A, et al. FEA optimization of injection parameters in ceramic core development for investment casting of a gas turbine blade. Materials Today: Proceedings, 2020, 26: 2190-2199. |

| [9] | LI Q, MA D W, JIANG Y H, et al. Effcet of cristoablite content on the properties of ceramic core in making directionally solidified hollow blade. Journal of Materials Engineering, 1994(5): 18-19. |

| [10] |

DONG Y, LI X, ZHAN Q, et al. Modeling of shrinkage during investment casting of thin-walled hollow turbine blades. Journal of Materials Processing Technology, 2017, 244: 190-203.

DOI URL |

| [11] |

MUKHTARKHANOV M, PERVEEN A, TALAMONA D. Application of stereolithography based 3D printing technology in investment casting. Micromachines, 2020, 11(10): 946.

DOI URL |

| [12] |

PARK H Y, KIM E H, CHO G H, et al. Process development of fabricating ceramic core using 3D printing technique. Materials Chemistry and Physics, 2019, 231: 382-387.

DOI URL |

| [13] |

HALLORAN J W, TOMECKOVA V, GENTRY S, et al. Photopolymerization of powder suspensions for shaping ceramics. Journal of the European Ceramic Society, 2011, 31(14): 2613-2619.

DOI URL |

| [14] |

GENTRY S P, HALLORAN J W. Absorption effects in photopolymerized ceramic suspensions. Journal of the European Ceramic Society, 2013, 33(10): 1989-1994.

DOI URL |

| [15] |

GENTRY S P, HALLORAN J W. Depth and width of cured lines in photopolymerizable ceramic suspensions. Journal of the European Ceramic Society, 2013, 33(10): 1981-1988.

DOI URL |

| [16] |

TOMECKOVA V, HALLORAN J W. Cure depth for photopolymerization of ceramic suspensions. Journal of the European Ceramic Society, 2010, 30(15): 3023-3033.

DOI URL |

| [17] |

TOMECKOVA V, HALLORAN J W. Predictive models for the photopolymerization of ceramic suspensions. Journal of the European Ceramic Society, 2010, 30(14): 2833-2840.

DOI URL |

| [18] |

BAE C J, HALLORAN J W. Integrally cored ceramic mold fabricated by ceramic stereolithography. International Journal of Applied Ceramic Technology, 2011, 8(6): 1255-1262.

DOI URL |

| [19] |

BAE C J, KIM D, HALLORAN J W. Mechanical and kinetic studies on the refractory fused silica of integrally cored ceramic mold fabricated by additive manufacturing. Journal of the European Ceramic Society, 2019, 39(2/3): 618-623.

DOI URL |

| [20] |

LI H, LIU Y, COLOMBO P, et al. The influence of sintering procedure and porosity on the properties of 3D printed alumina ceramic cores. Ceramics International, 2021, 47(19): 27668-27676.

DOI URL |

| [21] |

LI H, HU K, LIU Y, et al. Improved mechanical properties of silica ceramic cores prepared by 3D printing and sintering processes. Scripta Materialia, 2021, 194: 113665.

DOI URL |

| [22] |

LI H, LIU Y, LIU Y, et al. Silica strengthened alumina ceramic cores prepared by 3D printing. Journal of the European Ceramic Society, 2021, 41(4): 2938-2947.

DOI URL |

| [23] |

LI H, LIU Y, LIU Y, et al. Evolution of the microstructure and mechanical properties of stereolithography formed alumina cores sintered in vacuum. Journal of the European Ceramic Society, 2020, 40(14): 4825-4836.

DOI URL |

| [24] |

QIAN C, HU K, LU Z, et al. Volume shrinkage and conversion rate of Al2O3 ceramic stereolithography suspension polymerised by ultraviolet light. Materials Chemistry and Physics, 2021, 267: 124661.

DOI URL |

| [25] |

LI X, HU K, LU Z. Effect of light attenuation on polymerization of ceramic suspensions for stereolithography. Journal of the European Ceramic Society, 2019, 39(7): 2503-2509.

DOI URL |

| [26] |

QIAN C, HU K, LI J, et al. The effect of light scattering in stereolithography ceramic manufacturing. Journal of the European Ceramic Society, 2021, 41(14): 7141-7154.

DOI URL |

| [27] | LI Q, AN X, LIANG J, et al. Balancing flexural strength and porosity in DLP-3D printing Al2O3 cores for hollow turbine blades. Journal of Materials Science & Technology, 2022, 104: 19-32. |

| [28] |

LI Q, LIANG J, ZHANG Y, et al. Fused silica ceramic core based on network-structured zircon design via 3D printing. Scripta Materialia, 2022, 208: 114342.

DOI URL |

| [29] |

OLEVSKY E A. Theory of sintering: from discrete to continuum. Materials Science and Engineering: R: Reports, 1998, 23(2): 41-100.

DOI URL |

| [30] |

SUNDARESAN S, AKSAY I A. Mullitization of diphasic aluminosilicate gels. Journal of the American Ceramic Society, 1991, 74(10): 2388-2392.

DOI URL |

| [31] |

CAHOON H P, CHRISTENSEN C J. Sintering and grain growth of alpha-alumina. Journal of the American Ceramic Society, 1956, 39(10): 337-344.

DOI URL |

| [32] |

SMOTHERS W J, REYNOLDS H J. Sintering and grain growth of alumina. Journal of the American Ceramic Society, 1954, 37(12): 588-595.

DOI URL |

| [33] | PAN J Y, LIU X F, HE L M, et al. Research progress of silica-base ceramic core. Foundry, 2012, 61(2): 174-178. |

| [1] | GENG Rui-Wen, YANG Xiao-Jing, XIE Qi-Ming, LI Rui, LUO Liang. Material Removal Mechanism of Monocrystalline Germanium Based on Nano-scratch Experiment [J]. Journal of Inorganic Materials, 2019, 34(8): 867-872. |

| [2] | LI Xin, NIU Shu-Xin, YAO Jian-Sheng, TANG Ding-Zhong, CAO Chun-Xiao, YAN Jun-Hao. Effect of Al Powder on Property and Microstructure of Silica-based Ceramic Core [J]. Journal of Inorganic Materials, 2019, 34(2): 207-212. |

| [3] | YANG Zhi-Gang, YU Jian-Bo, LI Chuan-Jun, XUAN Wei-Dong, ZHANG Zhen-Qiang, DENG Kang, REN Zhong-Ming. Preparing Porous Si-based Ceramic Core Using Thermosetting Silicon Resin Injection Method [J]. Journal of Inorganic Materials, 2015, 30(2): 147-152. |

| [4] | ZHANG Xiao-Feng, ZHOU Ke-Song, ZHANG Ji-Fu, HAN Tao, Song Jin-Bing, LIU-Min. Erosion Failure Mechanism and Model Establishment of Thermal Barrier Coatings Based on Roughness [J]. Journal of Inorganic Materials, 2014, 29(3): 294-300. |

| [5] | HOU Wei-Min, YU Yun, HU Xue-Bing, YU Yang, MI Le, SONG Li-Xin. Study on Superhydrophobic Modification of Al2O3 Microfiltration Membrane [J]. Journal of Inorganic Materials, 2013, 28(8): 864-868. |

| [6] | WANG Bao-Quan, YU Jian-Bo, REN Zhong-Ming, ZENG Yu-Ping. Fabrication and Properties of Porous Alumina-based Ceramic Core [J]. Journal of Inorganic Materials, 2012, 27(3): 239-244. |

| [7] | YUAN Zi-Jian,ZHU Xia-Ming,WANG Xiong,ZHANG Ying-Ying,WAN Zheng-Fen,QIU Dong-Jiang,WU Hui-Zhen,DU Bin-Yang. Preparation and Characteristics of Indium Oxide Thin Films [J]. Journal of Inorganic Materials, 2010, 15(2): 141-144. |

| [8] | CAO Feng,LI Dong-Xu,GUAN Zi-Sheng. Preparation of Silica Hollow Microspheres with Special Surface Morphology by Biotemplate Method [J]. Journal of Inorganic Materials, 2009, 24(3): 501-506. |

| [9] | LIU Cui-Xia,YANG Yan-Qing,HUANG Bin,ZHANG Rong-Jun,LUO Xian,REN Xiao-Xia. Atomic Scale Simulation of {111}-Oriented SiC Film Growth by Chemical Vapor Deposition Method [J]. Journal of Inorganic Materials, 2008, 23(5): 933-937. |

| [10] | ZHANG Lei-Lei,LI He-Jun,LI Ke-Zhi,LI Xin-Tao,ZHAI Yan-Qiang,ZHANG Yu-Lei. Effect of Surface Roughness of Carbon/Carbon Composites on Osteoblasts [J]. Journal of Inorganic Materials, 2008, 23(2): 341-345. |

| [11] |

YUAN Ming,HUANG Zheng-Ren,DONG Shao-Ming,JIANG Dong-Liang.

Carbon/Silicon Carbide Composites with Interphases Processed by Temperature-pulsing Chemical Vapor Infiltration Technique [J]. Journal of Inorganic Materials, 2007, 22(2): 305-310. |

| [12] | WANG Jian-Bo,WU Han-Hua,JIN Zeng-Sun,TANG Yuan-Guang,CHANG Hong. Microcrystal Growing Characters of Titania Film by MAO [J]. Journal of Inorganic Materials, 2006, 21(3): 731-735. |

| [13] | SU Qing-Feng,XIA Yi-Ben,WANG Lin-Jun,SHI Wei-Min. Improvement Smoothness of CVD Diamond by Composite Polishing [J]. Journal of Inorganic Materials, 2006, 21(2): 499-502. |

| [14] | LI Quan-Jun,WU Han-Hua,WANG Jian-Bo,GU Guang-Rui,JIN Zeng-Sun. Effects of Pulse Frequencies on Properties of MAO Coatings on Pure Titanium [J]. Journal of Inorganic Materials, 2006, 21(2): 488-492. |

| [15] | FENG Li-Ping,LIU Zheng-Tang. Improving on Surface and High-temperature Strength of Sapphire by SiO2 Films [J]. Journal of Inorganic Materials, 2006, 21(1): 217-222. |

| Viewed | ||||||

|

Full text |

|

|||||

|

Abstract |

|

|||||