Journal of Inorganic Materials ›› 2021, Vol. 36 ›› Issue (4): 436-442.DOI: 10.15541/jim20200560

• RESEARCH PAPER • Previous Articles Next Articles

ZHANG Li1( ), YANG Xianfeng1(

), YANG Xianfeng1( ), XU Xiewen1, GUO Jinyu1, ZHOU Zhe1, LIU Peng1, XIE Zhipeng2

), XU Xiewen1, GUO Jinyu1, ZHOU Zhe1, LIU Peng1, XIE Zhipeng2

Received:2020-09-22

Revised:2020-10-28

Published:2021-04-20

Online:2020-12-01

Contact:

YANG Xianfeng, professor. E-mail: yangxfcsust@csust.edu.cn

About author:ZHANG Li(1994-), male, Master candidate. E-mail: 1297511664@qq.com

Supported by:CLC Number:

ZHANG Li, YANG Xianfeng, XU Xiewen, GUO Jinyu, ZHOU Zhe, LIU Peng, XIE Zhipeng. 3D Printed Zirconia Ceramics via Fused Deposit Modeling and Its Mechanical Properties[J]. Journal of Inorganic Materials, 2021, 36(4): 436-442.

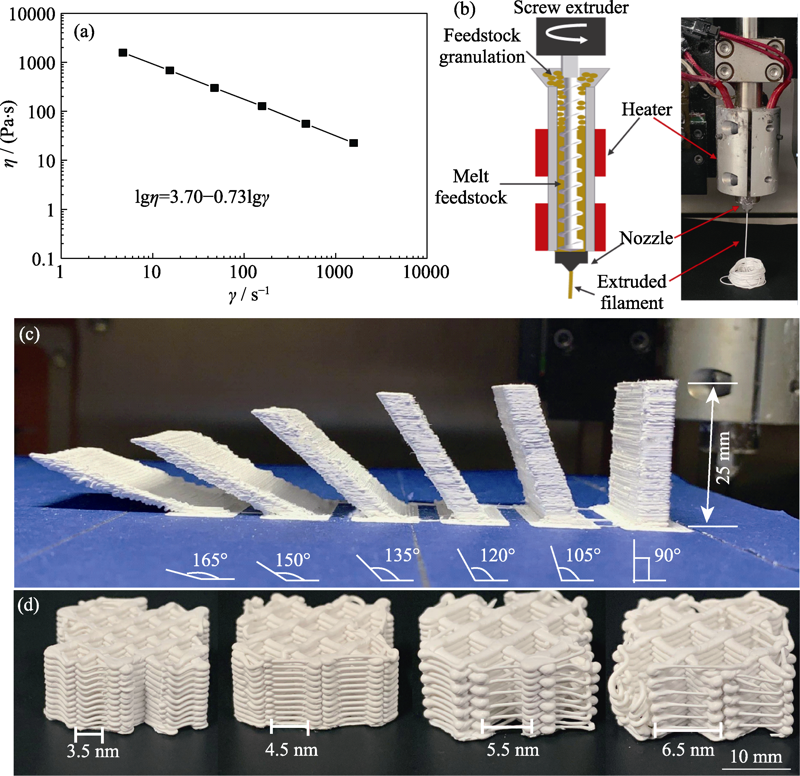

Fig. 2 Rheology and printability of the feedstock (a) Viscosity at various shear rate at 170 ℃; (b) Schematic diagram of the extrusion mechanism; (c) Unsupported structures with different inclinations; (d) Unsupported structures with different spans

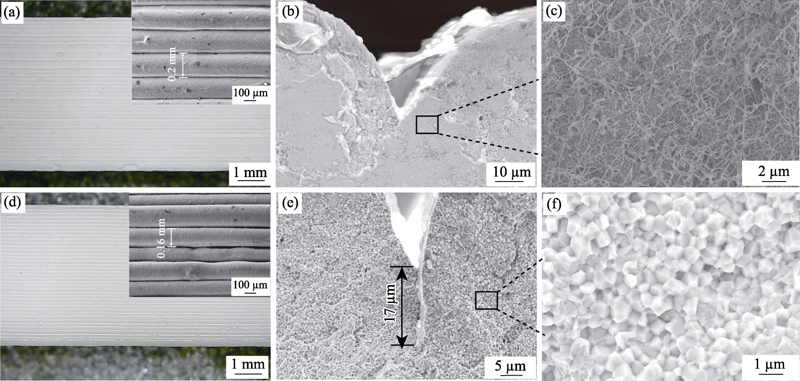

Fig. 3 SEM images of the printed green body and sintered ceramics (a) Surface of the green body and partial enlarged SEM image; (b) SEM image of fracture surface of green body; (c) Partial enlarged SEM image of Fig. 3(b); (d) Surface of the sintered part and partial enlarged SEM image; (e) SEM image of fracture surface of sintered part; (f) Partial enlarged SEM image of Fig. 3(e)

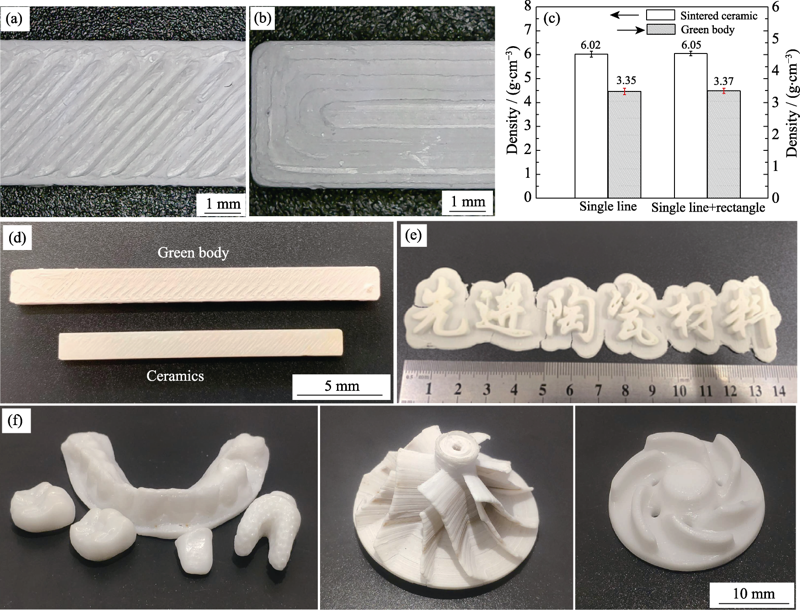

Fig. 4 3D printed dense zirconia ceramics (a) Surface of single line filling mode; (b) Surface of “single line+rectangle” filling mode; (c) Densities of the printed green bodies and sintered ceramics; (d) Printed and sintered rectangular bar; (e) Sintered 3D Chinese letters; (f) Sintered dental ceramics, turbine rotor and impeller

Fig. 6 3D printing porous zirconia ceramics (a) Picture of zirconia porous ceramics; (b) Enlarged view of pore structure; (c) Microstructure of the intersection area of the printing path; (d) Microstructure of the fracture surface of the pore walls

Fig. 7 Mechanical properties of porous ceramics (a) Compressive strength vs porosity; (b) Stress-strain curves of the porous ceramics with different porosities

| [1] | CHEN Z W, LI Z Y, LI J J, et al. 3D printing of ceramics: a review. Journal of the European Ceramic Society, 2019,39(4):661-687. |

| [2] |

ZHENG Y, ZHANG K, LIU T T, et al. Cracks of alumina ceramics by selective laser melting. Ceramics International, 2019,45(1):175-184.

DOI URL |

| [3] | NIU F Y, WU D J, LU F, et al. Microstructure and macro properties of Al2O3 ceramics prepared by laser engineered net shaping. Ceramics International, 2018,44(12):14303-14310. |

| [4] | HALLORAN J W. Ceramic stereolithography: additive manufacturing for ceramics by photopolymerization. Annual Review of Materials Research, 2016,46:19-40 |

| [5] | LI X B, ZHONG H, ZHANG J X, et al. Powder characteristics on the rheological performance of resin-based zirconia suspension for stereolithography. Journal of Inorganic Materials, 2020,35(2):231-235. |

| [6] | FEILDEN E, BLANCA E G T, GIULIANI F, et al. Robocasting of structural ceramic parts with hydrogel inks. Journal of the European Ceramic Society, 2016,36(10):2525-2533. |

| [7] | BENARFA B A E, NETO A S, MIRANDA I M, et al. Robocasting: prediction of ink printability in solgel bioactive glass. Journal of the American Ceramic Society, 2019,102(4):1608-1618. |

| [8] | HE Q L, JIE J, YANG X F, et al. Additive manufacturing of dense zirconia ceramics by fused deposition modeling via screw extrusion. Journal of the European Ceramic Society, 2021,41(1):1033-1040. |

| [9] | CANO S, GONZALEZ-GUTIERREZ J, SAPKOTA J, et al. Additive manufacturing of zirconia parts by fused filament fabrication and solvent debinding: selection of binder formulation. Additive Manufacturing, 2019,26(3):117-128. |

| [10] | GORJAN L, TONELLO R, SEBASTIAN T, et al. Fused deposition modeling of mullite structures from a preceramic polymer and gamma-alumina. Journal of the European Ceramic Society, 2019,39(7):2463-2471. |

| [11] | ARNESANO A, PADMANABHAN S K, NOTARANGELO A, et al. Fused deposition modeling shaping of glass infiltrated alumina for dental restoration. Ceramics International, 2020,46(2):2206-2212. |

| [12] | KIM N P, CHO D, ZIELEWSKI M. Optimization of 3D printing parameters of screw type extrusion (STE) for ceramics using the taguchi method. Ceramics International, 2019,45(2):2351-2360. |

| [13] | SCHEITHAUER U, SCHWARZER E, RICHTER H J, et al. Thermoplastic 3D printing-An additive manufacturing method for producing dense ceramics. International Journal of Applied Ceramic Technology, 2015,12(1):26-31. |

| [14] | LI J B, XIE Z G, ZHANG X H, et al. Study of metal powder extrusion and accumulating rapid prototyping. Key Engineering Materials, 2010,443:81-86. |

| [15] | RYSHKEWITCH E. Compression strength of porous sintered alumina and zirconia. Journal of the American Ceramic Society, 1953,36(2):65-68. |

| [1] | YIN Jie, GENG Jiayi, WANG Kanglong, CHEN Zhongming, LIU Xuejian, HUANG Zhengren. Recent Advances in 3D Printing and Densification of SiC Ceramics [J]. Journal of Inorganic Materials, 2025, 40(3): 245-255. |

| [2] | SHI Zhe, LIU Weiye, ZHAI Dong, XIE Jianjun, ZHU Yufang. Akermanite Scaffolds for Bone Tissue Engineering: 3D Printing Using Polymer Precursor and Scaffold Properties [J]. Journal of Inorganic Materials, 2023, 38(7): 763-770. |

| [3] | YUAN Jingkun, XIONG Shufeng, CHEN Zhangwei. Research Trends and Challenges of Additive Manufacturing of Polymer-derived Ceramics [J]. Journal of Inorganic Materials, 2023, 38(5): 477-488. |

| [4] | WANG Lukai, FENG Junzong, JIANG Yonggang, LI Liangjun, FENG Jian. Direct-ink-writing 3D Printing of Ceramic-based Porous Structures: a Review [J]. Journal of Inorganic Materials, 2023, 38(10): 1133-1148. |

| [5] | WU Songze, ZHOU Yang, LI Runfeng, LIU Xiaoqian, LI Cuiwei, HUANG Zhenying. Reaction Sintered Porous Ceramics Using Iron Tailings: Preparation and Properties [J]. Journal of Inorganic Materials, 2023, 38(10): 1193-1199. |

| [6] | WANG Shiwei. Progress of Spontaneous Coagulation Casting of Ceramic Slurries Based on Hydrophobic Interaction [J]. Journal of Inorganic Materials, 2022, 37(8): 809-820. |

| [7] | SHI Jixiang, ZHAI Dong, ZHU Min, ZHU Yufang. Preparation and Characterization of Bioactive Glass-Manganese Dioxide Composite Scaffolds [J]. Journal of Inorganic Materials, 2022, 37(4): 427-435. |

| [8] | YANG Yong, GUO Xiaotian, TANG Jie, CHANG Haotian, HUANG Zhengren, HU Xiulan. Research Progress and Prospects of Non-oxide Ceramic in Stereolithography Additive Manufacturing [J]. Journal of Inorganic Materials, 2022, 37(3): 267-277. |

| [9] | LI Qi, HUANG Yi, QIAN Bin, XU Beibei, CHEN Liying, XIAO Wenge, QIU Jianrong. Photo Curing and Pressureless Sintering of Orange-emitting Glass-ceramics [J]. Journal of Inorganic Materials, 2022, 37(3): 289-296. |

| [10] | WANG Yaning, ZHANG Yuqi, SONG Suocheng, CHEN Ruomeng, LIU Yaxiong, DUAN Yugang. Laser Stereolithography for Zirconia Ceramic Fabrication and Its Debinding and Sintering Process [J]. Journal of Inorganic Materials, 2022, 37(3): 303-309. |

| [11] | ZHU Junyi, ZHANG Cheng, LUO Zhongqiang, CAO Jiwei, LIU Zhiyuan, WANG Pei, LIU Changyong, CHEN Zhangwei. Influence of Debinding Process on the Properties of Photopolymerization 3D Printed Cordierite Ceramics [J]. Journal of Inorganic Materials, 2022, 37(3): 317-324. |

| [12] | LI Qiaolei, GU Yue, YU Xuehua, ZHANG Chaowei, ZOU Mingke, LIANG Jingjing, LI Jinguo. Effect of Sintering Temperature on Surface Morphology and Roughness of 3D-printed Silicon Ceramic Cores [J]. Journal of Inorganic Materials, 2022, 37(3): 325-332. |

| [13] | WU Zhongcao, HUAN Zhiguang, ZHU Yufang, WU Chengtie. 3D Printing and Characterization of Microsphere Hydroxyapatite Scaffolds [J]. Journal of Inorganic Materials, 2021, 36(6): 601-607. |

| [14] | ZHU Quan, HU Jianbao, YANG Jinshan, ZHOU Haijun, DONG Shaoming. Strong SiC Porous Ceramic Obtained by Sintering of Reticulated Aligned SiC Nanowires [J]. Journal of Inorganic Materials, 2021, 36(5): 547-551. |

| [15] | DONG Longhao,ZHANG Haijun,ZHANG Jun,WU Wenhao,JIA Quanli. Carbon Nanotube Modified Sepiolite Porous Ceramics for High-efficient Oil/Water Separation [J]. Journal of Inorganic Materials, 2020, 35(6): 689-696. |

| Viewed | ||||||

|

Full text |

|

|||||

|

Abstract |

|

|||||