Journal of Inorganic Materials ›› 2017, Vol. 32 ›› Issue (10): 1109-1114.DOI: 10.15541/jim20170036

• Orginal Article • Previous Articles Next Articles

WANG Wei-Lei1,2,3, LIU Wei-Li1,3, BAI Lin-Sen3, SONG Zhi-Tang1,3, HUO Jun-Chao1,3

Received:2017-01-17

Published:2017-10-20

Online:2017-09-21

About author:WANG Wei-Lei(1990–), male, candidate of Master degree. E-mail: awelly@mail.sim.ac.cn

Supported by:CLC Number:

WANG Wei-Lei, LIU Wei-Li, BAI Lin-Sen, SONG Zhi-Tang, HUO Jun-Chao. Surface Modified Alumina Particles and Their Chemical Mechanical Polishing (CMP) Behavior on C-plane (0001) Sapphire Substrate[J]. Journal of Inorganic Materials, 2017, 32(10): 1109-1114.

| Elements in sample | Al2p | O1s |

|---|---|---|

| Binding energy/eV | 74.03 73.08 | 531.06 530.87 |

Table 1 Binding energy of abrasives containing before and after modified alumina particles

| Elements in sample | Al2p | O1s |

|---|---|---|

| Binding energy/eV | 74.03 73.08 | 531.06 530.87 |

| Atomic% | Al | O | C | N | Si |

|---|---|---|---|---|---|

| Unmodified alumina | 30.67 | 52.44 | 16.89 | 0 | 0 |

| Modified alumina | 27.35 | 46.41 | 21.19 | 2.77 | 2.28 |

Table 2 Cmposition of elements on the surface of alumina particles before and after modification

| Atomic% | Al | O | C | N | Si |

|---|---|---|---|---|---|

| Unmodified alumina | 30.67 | 52.44 | 16.89 | 0 | 0 |

| Modified alumina | 27.35 | 46.41 | 21.19 | 2.77 | 2.28 |

| Chemical state | Band energy/eV |

|---|---|

| (-Si(OCH3)2O-)xAly | 73.8 |

| AlN | 73.1 |

Table 3 Binding energy of Al2p

| Chemical state | Band energy/eV |

|---|---|

| (-Si(OCH3)2O-)xAly | 73.8 |

| AlN | 73.1 |

| Chemical state | Band energy/eV |

|---|---|

| (-Si(OCH3)2O-)xAly | 531.10 |

| Al2O3 | 530.30 |

Table 4 Binding energy of O1s

| Chemical state | Band energy/eV |

|---|---|

| (-Si(OCH3)2O-)xAly | 531.10 |

| Al2O3 | 530.30 |

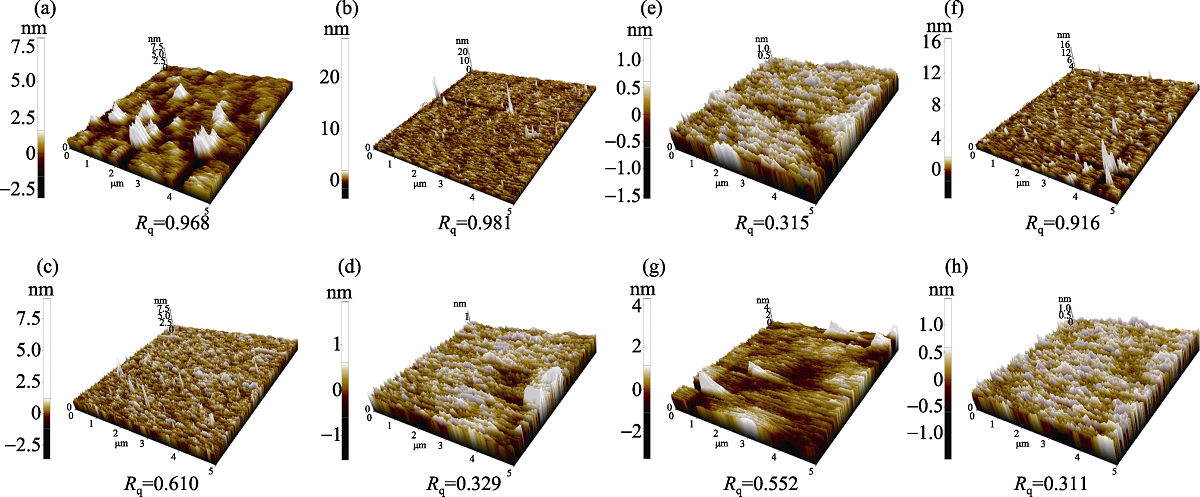

| pH | Type of particles | MRR (0.0001 g/30 min) | Before polishing Rq Roughness/nm | After polishing Rq Roughness/nm |

|---|---|---|---|---|

| 10.00 | Pure alumina | 46 | 0.968 | 0.610 |

| 10.00 | Modified alumina | 127 | 0.610 | 0.329 |

| 10.00 | Modified alumina | 139 | 0.981 | 0.315 |

| 13.00 | Pure alumina | 93 | 0.916 | 0.552 |

| 13.00 | Modified alumina | 122 | 0.552 | 0.311 |

Table 5 Surface roughness (Rq) and material removal rate(MRR)by applying before and after modified alumina particles in different pH

| pH | Type of particles | MRR (0.0001 g/30 min) | Before polishing Rq Roughness/nm | After polishing Rq Roughness/nm |

|---|---|---|---|---|

| 10.00 | Pure alumina | 46 | 0.968 | 0.610 |

| 10.00 | Modified alumina | 127 | 0.610 | 0.329 |

| 10.00 | Modified alumina | 139 | 0.981 | 0.315 |

| 13.00 | Pure alumina | 93 | 0.916 | 0.552 |

| 13.00 | Modified alumina | 122 | 0.552 | 0.311 |

Fig. 6 (a, b, f) AFM morphologies of sapphire substrate before polishing; (c) polished by pure alumina particles at pH 10.00; (d) polished by modified alumina particle (using sapphire substrate polished by pure alumina particles (c)) at pH 10.00; (e) polished by modified alumina particle at pH 10.00; (g) polished by modified alumina particle at pH 13.00; (h) polished by pure alumina particles (using sapphire substrate polished by pure alumina particles (g)) at pH 13.00

| [1] | SAITO T, HIRAYAMA T, YAMAMOTO T, et al.Lattice strain and dislocations in polished surfaces on sapphire.J. Am. Ceram. Soc., 2005, 88: 2277-2285. |

| [2] | NIU X H, LIU Y L, TAN B M, et al.Method of surface treatment on sapphire substrate.Transactions of Nonferrous Metals Society of China, 2006, 16: 732-734. |

| [3] | TAKEUCHI T, TAKEUCHI H, SOTA S, et al.Optical properties of strained AlGaN and GaInN on GaN.Jpn. J. Appl. Phys., 1997, 36: L177-L179. |

| [4] | LIMA R S, MARPLE B R.Thermal spray coatings engineered from nanostructured ceramic agglomerated powders for structural, thermal barrier and biomedical applications: a review.J. Therm. Spray Technol., 2007, 16: 40-63. |

| [5] | KIM K T, KOO H Y, LEE G G, et al.Synthesis of alumina nanoparticle-embedded-bismuth telluride matrix thermoelectric composite powders.Mater. Lett. , 2012, 82: 141-144. |

| [6] | ZOIS D, LEKATOU A, VARDAVOULIAS M, et al.Nanostructured alumina coatings manufactured by air plasma spraying: correlation of properties with the raw powder microstructure.J. Alloys Compd., 2010, 495: 611-616. |

| [7] | TANG E J, CHENG G X, MA X L, et al.Surface modification of zinc oxide nanoparticle by PMAA and its dispersion in aqueous system.Appl. Surf. Sci., 2006, 252: 5227-5232. |

| [8] | LEI H, LU H S, LUO J B, et al.Preparation of α-alumina- g-polyacrylamide composite abrasive and chemical mechanical polishing behavior.Thin Solid Films, 2008, 516: 3005-3008. |

| [9] | LEI H, ZHANG P Z.Preparation of alumina/silica core-shell abrasives and their CMP behavior.Appl. Surf. Sci., 2007, 253: 8754-8761. |

| [10] | ZHANG Z F, LEI H.Preparation of α-alumina/polymethacrylic acid composite abrasive and its CMP performance on glass substrate.Microelectron. Eng., 2008, 85: 714-720. |

| [11] | SHEN X C, FANG X Z, ZHOU Y H, et al.Synthesis and characterization of 3-aminopropyltriethoxysilane-modified superpar- amagnetic magnetite nanoparticles.Chem. Lett., 2004, 33: 1468-1469. |

| [12] | ZHANG Z F, YU L, LIU W L, et al.Surface modification of ceria nanoparticles and their chemical mechanical polishing behavior on glass substrate.Appl. Surf. Sci., 2010, 256: 3856-3861. |

| [13] | HOMMA Y.Dynamical mechanism of chemical mechanical polishing analyzed to correct Preston's empirical model.J. Electroanal. Chem., 2006, 153: G587-G590. |

| [14] | MATSUDA T, TAKAHASHI H, TSURUGAYA M, et al.Characteristics of abrasive-free micelle slurry for copper CMP.J. Electrochem. Soc., 2003, 150: G532-G536. |

| [15] | ABIADE J T, CHOI W, SINGH R K.Effect of pH on ceria-silica interactions during chemical mechanical.J. Mater. Res., 2005, 20: 1139-1145. |

| [16] | LIANG H, CRAVEN D R.Tribology in Chemical-Mechanical Planarization. Taylor & Francis, Boca Raton, Fla., 2005. |

| [1] | WANG Xiaobo, ZHU Yuliang, XUE Wenchao, SHI Ruchuan, LUO Bofeng, LUO Chengtao. Effect of PbTiO3 Content Variation on High-power Performance of PMN-PT Single Crystal [J]. Journal of Inorganic Materials, 2025, 40(7): 840-846. |

| [2] | TANG Xinli, DING Ziyou, CHEN Junrui, ZHAO Gang, HAN Yingchao. In vivo Distribution and Metabolism of Calcium Phosphate Nanomaterials Based on Fluorescent Labeling with Rare Earth Europium Ions [J]. Journal of Inorganic Materials, 2025, 40(7): 754-764. |

| [3] | YU Leyangyang, ZHAO Fangxia, ZHANG Shuxin, XU Yixiang, NIU Yaran, ZHANG Zhenzhong, ZHENG Xuebin. Preparation of High-entropy Boride Powders for Plasma Spraying by Inductive Plasma Spheroidization [J]. Journal of Inorganic Materials, 2025, 40(7): 808-816. |

| [4] | YANG Guang, ZHANG Nan, CHEN Shujin, WANG Yi, XIE An, YAN Yujie. WO3 Films Based on Porous ITO Electrodes: Preparation and Electrochromic Property [J]. Journal of Inorganic Materials, 2025, 40(7): 781-789. |

| [5] | SUN Jing, LI Xiang, MAO Xiaojian, ZHANG Jian, WANG Shiwei. Effect of Lauric Acid Modifier on the Hydrolysis Resistance of Aluminum Nitride Powders [J]. Journal of Inorganic Materials, 2025, 40(7): 826-832. |

| [6] | CHAI Runyu, ZHANG Zhen, WANG Menglong, XIA Changrong. Preparation of Ceria Based Metal-supported Solid Oxide Fuel Cells by Direct Assembly Method [J]. Journal of Inorganic Materials, 2025, 40(7): 765-771. |

| [7] | WANG Lujie, ZHANG Yuxin, LI Tongyang, YU Yuan, REN Pengwei, WANG Jianzhang, TANG Huaguo, YAO Xiumin, HUANG Yihua, LIU Xuejian, QIAO Zhuhui. Corrosion and Wear Behavior of Silicon Carbide Ceramic in Deep-sea Service Environment [J]. Journal of Inorganic Materials, 2025, 40(7): 799-807. |

| [8] | LI Wenyuan, XU Jianan, DENG Han'ao, CHANG Aimin, ZHANG Bo. Effect of V5+ Substitution on Microstructure and Microwave Dielectric Properties of LaTaO4 Ceramics [J]. Journal of Inorganic Materials, 2025, 40(6): 697-703. |

| [9] | HU Zhichao, YANG Hongyu, YANG Hongcheng, SUN Chengli, YANG Jun, LI Enzhu. Usage of the P-V-L Bond Theory in Regulating Properties of Microwave Dielectric Ceramics [J]. Journal of Inorganic Materials, 2025, 40(6): 609-626. |

| [10] | DONG Chenyu, ZHENG Weijie, MA Yifan, ZHENG Chunyan, WEN Zheng. Characterizations by Piezoresponse Force Microscopy on Relaxor Properties of Pb(Mg,Nb)O3-PbTiO3 Ultra-thin Films [J]. Journal of Inorganic Materials, 2025, 40(6): 675-682. |

| [11] | HE Guoqiang, ZHANG Kaiheng, WANG Zhentao, BAO Jian, XI Zhaochen, FANG Zhen, WANG Changhao, WANG Wei, WANG Xin, JIANG Jiapei, LI Xiangkun, ZHOU Di. Ba(Nd1/2Nb1/2)O3: Au Underrated K40 Microwave Dielectric Ceramic [J]. Journal of Inorganic Materials, 2025, 40(6): 639-646. |

| [12] | ZHANG Jiawei, CHEN Ning, CHENG Yuan, WANG Bo, ZHU Jianguo, JIN Cheng. Electrical Properties of Bismuth Layered Piezoelectric Bi4Ti3O12 Ceramics with A/B-site Doping [J]. Journal of Inorganic Materials, 2025, 40(6): 690-696. |

| [13] | CUI Ning, ZHANG Yuxin, WANG Lujie, LI Tongyang, YU Yuan, TANG Huaguo, QIAO Zhuhui. Single-phase Formation Process and Carbon Vacancy Regulation of (TiVNbMoW)Cx High-entropy Ceramics [J]. Journal of Inorganic Materials, 2025, 40(5): 511-520. |

| [14] | XIONG Siyu, MO Chen, ZHU Xiaowei, ZHU Guobin, CHEN Deqin, LIU Laijun, SHI Xiaodong, LI Chunchun. Low-temperature Sintering of LiBxAl1-xSi2O6 Microwave Dielectric Ceramics with Ultra-low Permittivity [J]. Journal of Inorganic Materials, 2025, 40(5): 536-544. |

| [15] | AN Ran, LIN Si, GUO Shigang, ZHANG Chong, ZHU Shun, HAN Yingchao. Iron-doped Nano-hydroxyapatite: Preparation and Ultraviolet Absorption Performance [J]. Journal of Inorganic Materials, 2025, 40(5): 457-465. |

| Viewed | ||||||

|

Full text |

|

|||||

|

Abstract |

|

|||||