无机材料学报 ›› 2025, Vol. 40 ›› Issue (6): 563-574.DOI: 10.15541/jim20240520 CSTR: 32189.14.jim20240520

吴琼1( ), 沈炳林2, 张茂华2, 姚方周2, 邢志鹏1, 王轲1(

), 沈炳林2, 张茂华2, 姚方周2, 邢志鹏1, 王轲1( )

)

收稿日期:2024-12-16

修回日期:2025-02-14

出版日期:2025-06-20

网络出版日期:2025-02-19

通讯作者:

王 轲, 研究员. E-mail: wang-ke@tsinghua.edu.cn作者简介:吴 琼(1993-), 男, 博士. E-mail: wu-qiong@mail.tsinghua.edu.cn

基金资助:

WU Qiong1( ), SHEN Binglin2, ZHANG Maohua2, YAO Fangzhou2, XING Zhipeng1, WANG Ke1(

), SHEN Binglin2, ZHANG Maohua2, YAO Fangzhou2, XING Zhipeng1, WANG Ke1( )

)

Received:2024-12-16

Revised:2025-02-14

Published:2025-06-20

Online:2025-02-19

Contact:

WANG Ke, professor. E-mail: wang-ke@tsinghua.edu.cnAbout author:WU Qiong (1993-), male, PhD. E-mail: wu-qiong@mail.tsinghua.edu.cn

Supported by:摘要:

铅基织构压电陶瓷因其制备成本远低于单晶且性能显著高于非织构压电陶瓷, 被视为最有潜力的锆钛酸铅多晶陶瓷替代者, 成为近年来材料领域的重点研究课题。基于过去数十年的研究进展, 本文详细介绍了铅基织构压电陶瓷的生长原理与表征方法、模板的制备工艺与铅基织构压电陶瓷制备过程中的关键工艺, 进而全面汇总了具有代表性的铅基织构压电陶瓷研究成果, 讨论了不同改进策略的特点。从材料配方的角度来看, 三元体系与二元体系织构压电陶瓷的各组分比例通常选择在相界处, 使各极性态在外电场下较易翻转, 进而获得高压电系数(d33)。虽然两种体系的d33接近, 但三元体系的居里温度普遍高于二元体系, 体现出更高的应用价值。从烧结等制备工艺的角度看, 添加助烧剂可以显著促进晶粒定向生长, 后退火处理可以消除晶界和孔洞缺陷内的杂相, 淬火处理可以使电偶极子从无序状态中固定。这些改善工艺都显著增强了铅基织构压电陶瓷的性能。最后, 本文分析了目前存在的问题与发展的挑战, 认为模板与基体材料的晶格参数和B位离子价态的差异是限制铅基织构压电陶瓷性能提升的主要原因, 针对不同基体材料定制匹配性好的模板将有助于进一步改善其性能。

中图分类号:

吴琼, 沈炳林, 张茂华, 姚方周, 邢志鹏, 王轲. 铅基织构压电陶瓷研究进展[J]. 无机材料学报, 2025, 40(6): 563-574.

WU Qiong, SHEN Binglin, ZHANG Maohua, YAO Fangzhou, XING Zhipeng, WANG Ke. Research Progress on Lead-based Textured Piezoelectric Ceramics[J]. Journal of Inorganic Materials, 2025, 40(6): 563-574.

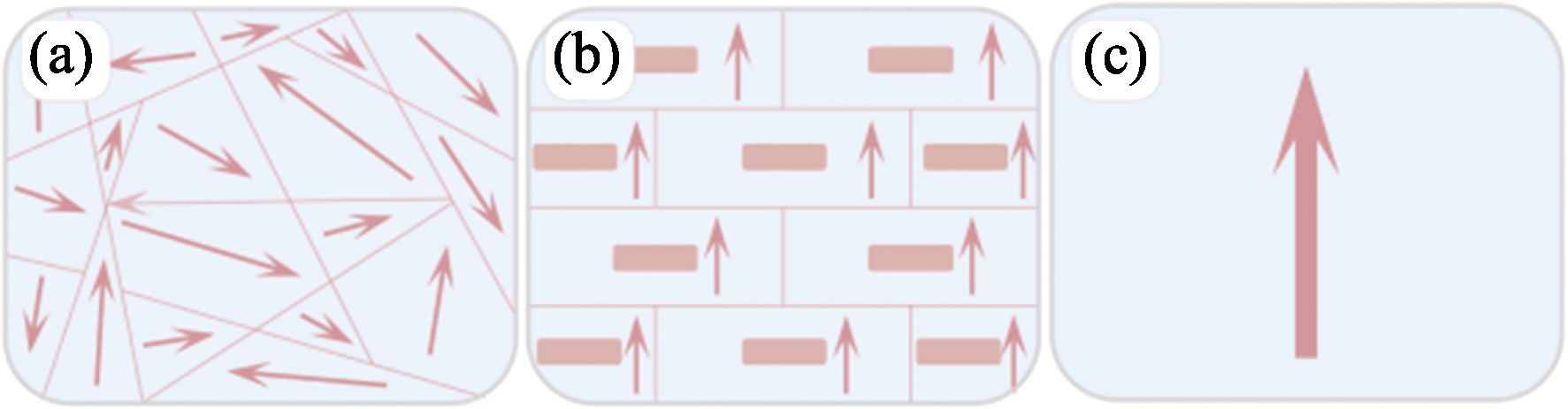

图1 (a)普通陶瓷、(b)织构陶瓷与(c)单晶的微观结构示意图

Fig. 1 Schematic diagrams of microstructures of (a) conventional ceramics, (b) textured ceramics and (c) single crystals

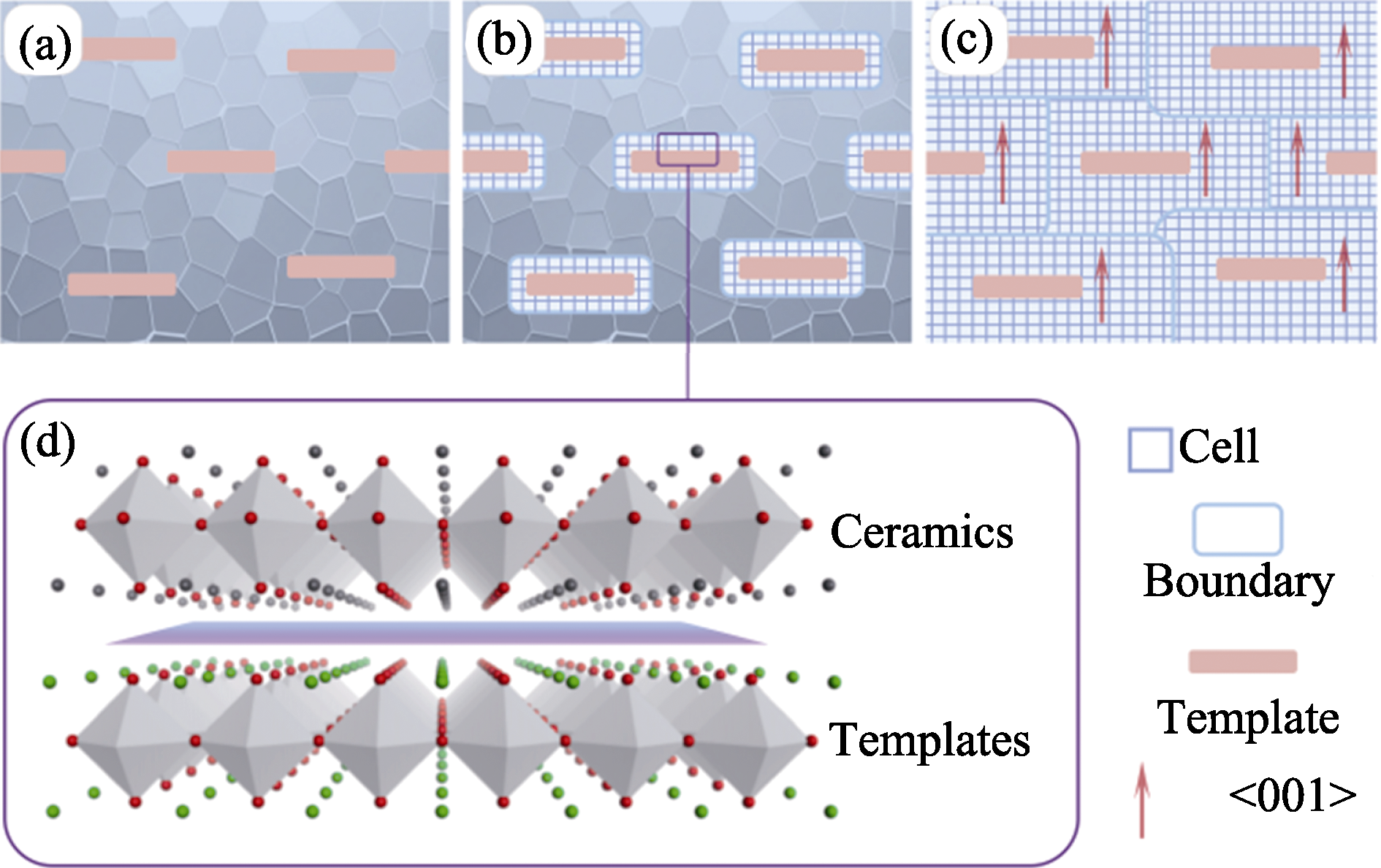

图2 TGG法制备织构陶瓷在(a)烧结前、(b)烧结中、(c)烧结后以及(d)模板与陶瓷接触界面的内部状态示意图

Fig. 2 Schematic diagrams of the internal state of textured ceramics prepared by TGG method (a) before, (b) during, (c) after sintering and (d) at the interface between template and ceramic

| System | Template | F001/% | ɛ33 | Random d33/(pC•N-1) | Textured d33/(pC•N-1) | Tm/℃ | tanδ | Year | Ref. |

|---|---|---|---|---|---|---|---|---|---|

| PMN-0.285PT | NBT-0.6PT | 87 | 3490 | — | 855 | 129 | 0.01 | 2011 | [ |

| PMN-0.325PT | 1% BT | 98 | 2591 | — | 1000 | ~160 | 0.006 | 2012 | [ |

| Mn-doped PMN-0.325PT | 1% BT | 96 | 2233 | 455 | 450 | ~165 | 0.0044 | 2018 | [ |

| Sm-doped PMN-0.3PT | 5% BT | 90 | ~4500 | — | 1040 | 90 | 0.05 | 2021 | [ |

| CuO/B2O3 sintered PMN-0.28PT | 1% BT | 99.5 | 3450 | 340 | 1180 | ~150 | 0.008 | 2021 | [ |

| Sm-doped PMN-0.29PT | 5% BT | 82 | 5130 | 500 | 810 | 102 | 0.056 | 2021 | [ |

| PMN-0.31PT | 3% BT | 93 | 3560 | 660 | 1020 | 134 | 0.019 | 2022 | [ |

| Eu-doped PMN-0.28PT | 2% BT | 98 | ~6000 | 1300 | 1950 | ~80 | 0.015 | 2022 | [ |

| Sm-doped PMN-0.26PT | 1% BT | 99 | 10115 | 1245 | 1882 | 76 | 0.042 | 2023 | [ |

| Er-doped PMN-0.33PT | 5% BT | 36.4 | ~5000 | — | 634 | ~100 | ~0.02 | 2023 | [ |

表1 二元体系PMN-PT织构压电陶瓷的性能[63-72]

Table 1 Electric properties of PMN-PT textured piezoelectric ceramics[63-72]

| System | Template | F001/% | ɛ33 | Random d33/(pC•N-1) | Textured d33/(pC•N-1) | Tm/℃ | tanδ | Year | Ref. |

|---|---|---|---|---|---|---|---|---|---|

| PMN-0.285PT | NBT-0.6PT | 87 | 3490 | — | 855 | 129 | 0.01 | 2011 | [ |

| PMN-0.325PT | 1% BT | 98 | 2591 | — | 1000 | ~160 | 0.006 | 2012 | [ |

| Mn-doped PMN-0.325PT | 1% BT | 96 | 2233 | 455 | 450 | ~165 | 0.0044 | 2018 | [ |

| Sm-doped PMN-0.3PT | 5% BT | 90 | ~4500 | — | 1040 | 90 | 0.05 | 2021 | [ |

| CuO/B2O3 sintered PMN-0.28PT | 1% BT | 99.5 | 3450 | 340 | 1180 | ~150 | 0.008 | 2021 | [ |

| Sm-doped PMN-0.29PT | 5% BT | 82 | 5130 | 500 | 810 | 102 | 0.056 | 2021 | [ |

| PMN-0.31PT | 3% BT | 93 | 3560 | 660 | 1020 | 134 | 0.019 | 2022 | [ |

| Eu-doped PMN-0.28PT | 2% BT | 98 | ~6000 | 1300 | 1950 | ~80 | 0.015 | 2022 | [ |

| Sm-doped PMN-0.26PT | 1% BT | 99 | 10115 | 1245 | 1882 | 76 | 0.042 | 2023 | [ |

| Er-doped PMN-0.33PT | 5% BT | 36.4 | ~5000 | — | 634 | ~100 | ~0.02 | 2023 | [ |

| System | Template | F001/% | ɛ33 | Random d33/(pC•N-1) | Textured d33/(pC•N-1) | Tm/℃ | tanδ | Year | Ref. |

|---|---|---|---|---|---|---|---|---|---|

| Mn-doped PMN-0.25PZ-0.35PT | 3% BT | 93 | — | 230 | 720 | 210 | 0.003 | 2012 | [ |

| PMN-0.25PZ-0.35PT | 5% BT | 90 | 2310 | 230 | 1100 | 204 | — | 2013 | [ |

| Quenched PMN-0.25PZ-0.35PT | 5% BT | 92 | 1815 | 275 | 750 | 265 | 0.01 | 2019 | [ |

| PMN-0.22PZ-0.38PT | 5% BT | 98 | 1100 | ~250 | 950 | 235 | — | 2022 | [ |

| PMN-0.25PZ-0.35PT | 2% BT | 98 | 1000 | 230 | 1470 | ~225 | 0.011 | 2022 | [ |

| CuO sintered PMN-0.25PZ-0.33PT | 5% BT | 98 | 1720 | 235 | 860 | 222 | 0.008 | 2022 | [ |

| PMN-0.25PZ-0.33PT | 5% BT | 98 | 1500 | — | 1080 | ~225 | — | 2023 | [ |

| Mn-doped PMN-0.25PZ-0.35PT | 2% BT | 99 | 2100 | 223 | 862 | — | ~0.003 | 2023 | [ |

| CuO sintered PMN-0.47PZ-0.39PT | 1% BT | 92 | 1000 | 143 | 278 | 304 | ~0.007 | 2023 | [ |

| PMN-PZ-PT | 3% BT | 98 | 2410 | — | 1220 | 229 | 0.012 | 2024 | [ |

表2 三元体系PMN-PZ-PT织构压电陶瓷的性能[76-85]

Table 2 Electric properties of PMN-PZ-PT textured piezoelectric ceramics[76-85]

| System | Template | F001/% | ɛ33 | Random d33/(pC•N-1) | Textured d33/(pC•N-1) | Tm/℃ | tanδ | Year | Ref. |

|---|---|---|---|---|---|---|---|---|---|

| Mn-doped PMN-0.25PZ-0.35PT | 3% BT | 93 | — | 230 | 720 | 210 | 0.003 | 2012 | [ |

| PMN-0.25PZ-0.35PT | 5% BT | 90 | 2310 | 230 | 1100 | 204 | — | 2013 | [ |

| Quenched PMN-0.25PZ-0.35PT | 5% BT | 92 | 1815 | 275 | 750 | 265 | 0.01 | 2019 | [ |

| PMN-0.22PZ-0.38PT | 5% BT | 98 | 1100 | ~250 | 950 | 235 | — | 2022 | [ |

| PMN-0.25PZ-0.35PT | 2% BT | 98 | 1000 | 230 | 1470 | ~225 | 0.011 | 2022 | [ |

| CuO sintered PMN-0.25PZ-0.33PT | 5% BT | 98 | 1720 | 235 | 860 | 222 | 0.008 | 2022 | [ |

| PMN-0.25PZ-0.33PT | 5% BT | 98 | 1500 | — | 1080 | ~225 | — | 2023 | [ |

| Mn-doped PMN-0.25PZ-0.35PT | 2% BT | 99 | 2100 | 223 | 862 | — | ~0.003 | 2023 | [ |

| CuO sintered PMN-0.47PZ-0.39PT | 1% BT | 92 | 1000 | 143 | 278 | 304 | ~0.007 | 2023 | [ |

| PMN-PZ-PT | 3% BT | 98 | 2410 | — | 1220 | 229 | 0.012 | 2024 | [ |

| System | Template | F001/% | ɛ33 | Random d33/(pC•N-1) | Textured d33/(pC•N-1) | Tm/℃ | tanδ | Year | Ref. |

|---|---|---|---|---|---|---|---|---|---|

| PIN-0.40PMN-0.32PT | 5% BT | 93 | ~2500 | 416 | 824 | 203 | ~0.025 | 2015 | [ |

| PMN-16PYN-0.38PT | 5% BT | 91 | ~2000 | — | — | 214 | 0.019 | 2016 | [ |

| PIN-0.30PMN-0.34PT | 5% BT | 62 | 2668 | 450 | 560 | 220 | ~0.04 | 2016 | [ |

| PIN-0.40PMN-0.32PT | 5% BT | 94 | ~2500 | 429 | 841 | ~200 | — | 2016 | [ |

| CuO-doped PIN-0.4PMN-0.32PT | 5% BT | 97 | ~2430 | 416 | 927 | 200 | 0.013 | 2017 | [ |

| PMN-16PYN-0.38PT | 5% BT | 91 | 2110 | — | — | 213 | 0.022 | 2017 | [ |

| PNN-0.15PZ-0.3PT | 2% BT | 82 | ~7500 | ~1020 | 1210 | ~103 | ~0.031 | 2020 | [ |

| PYN-0.52PMN-0.32PT | 3% BT | ~99 | ~2000 | — | — | 205 | ~0.01 | 2020 | [ |

| PYN-0.41MN-0.38PT | 5% BT | 83 | ~2000 | 413 | 409 | 224 | ~0.050 | 2020 | [ |

| CuO-doped PYN-46PMN-34PT | — | 94 | 1960 | 380 | 460 | — | 0.019 | 2020 | [ |

| Mn-doped PIN-0.42PMN-0.34PT | 2% BT | 84 | 1514 | 370 | 517 | 205 | 0.0049 | 2021 | [ |

| PIN-0.445PSN-0.365PT | 5% BT | 99.2 | 2310 | 240 | 1090 | 247 | 0.012 | 2021 | [ |

| BZZ-0.375BS-0.60PT | 5% BT | 91 | 980 | 216 | 353 | 403 | 0.024 | 2021 | [ |

| BMT-0.6PMN-0.3PT | — | 90 | 4500 | — | — | — | — | 2022 | [ |

| PSN-0.20PZ-0.41PT | 3% BT | ~95 | 1300 | 265 | 580 | 299 | 0.007 | 2022 | [ |

| PNN-0.21PZ-0.37PT | 3% BT | 96 | ~3000 | 730 | 830 | ~170 | ~0.017 | 2022 | [ |

| PIN-0.445PSN-0.365PT | 2.5% BT | 99 | 2155 | — | 770 | ~270 | 0.0072 | 2022 | [ |

| Mn&Cu-doped PIN-0.42PMN-0.34PT | 2% BT | 97 | 1498 | 304 | 725 | 205 | 0.0045 | 2022 | [ |

| MnO2-doped PIN-0.46PSN-0.37PT | 3% BT | 99 | 1739 | 181 | 735 | 244 | 0.0039 | 2023 | [ |

| MnO2-doped PIN-0.42PMN-0.34PT | 2% BT | 98 | 1498 | 304 | 725 | ~205 | 0.0042 | 2023 | [ |

| PIN-0.445PSN-0.365PT | 3% BT | — | 2100 | — | 840 | 261 | 0.006 | 2023 | [ |

| PIN-0.46PMN-0.3PT | 5% BT | ~99 | 1960 | 270 | 860 | 195 | 0.007 | 2023 | [ |

| CuO-doped PMN-0.29PIN-0.34PT | 3% BT | 97 | ~2000 | ~450 | 578 | 231 | — | 2023 | [ |

| PNN-0.25PZ-0.39PT | 3% BT | 98 | 2790 | 443 | 1165 | 197 | 0.021 | 2023 | [ |

| PZT-0.11PZN-0.06PNN | 10% BZT | 63 | 1123 | — | 318 | 230 | ~0.021 | 2024 | [ |

| PNT-0.34PZ-0.42PT | 5% BT | 98 | 2499 | ~250 | 820 | 180 | — | 2024 | [ |

| Li2CO3-doped PNN-0.16PZ-0.34PT | 2% BT | 85 | 3942 | 943 | 1180 | 146 | ~0.04 | 2024 | [ |

表3 其它三元体系织构压电陶瓷的性能[40,48,57,59,86 -108]

Table 3 Electric properties of ternary systems except the PMN-PZ-PT textured piezoelectric ceramics[40,48,57,59,86 -108]

| System | Template | F001/% | ɛ33 | Random d33/(pC•N-1) | Textured d33/(pC•N-1) | Tm/℃ | tanδ | Year | Ref. |

|---|---|---|---|---|---|---|---|---|---|

| PIN-0.40PMN-0.32PT | 5% BT | 93 | ~2500 | 416 | 824 | 203 | ~0.025 | 2015 | [ |

| PMN-16PYN-0.38PT | 5% BT | 91 | ~2000 | — | — | 214 | 0.019 | 2016 | [ |

| PIN-0.30PMN-0.34PT | 5% BT | 62 | 2668 | 450 | 560 | 220 | ~0.04 | 2016 | [ |

| PIN-0.40PMN-0.32PT | 5% BT | 94 | ~2500 | 429 | 841 | ~200 | — | 2016 | [ |

| CuO-doped PIN-0.4PMN-0.32PT | 5% BT | 97 | ~2430 | 416 | 927 | 200 | 0.013 | 2017 | [ |

| PMN-16PYN-0.38PT | 5% BT | 91 | 2110 | — | — | 213 | 0.022 | 2017 | [ |

| PNN-0.15PZ-0.3PT | 2% BT | 82 | ~7500 | ~1020 | 1210 | ~103 | ~0.031 | 2020 | [ |

| PYN-0.52PMN-0.32PT | 3% BT | ~99 | ~2000 | — | — | 205 | ~0.01 | 2020 | [ |

| PYN-0.41MN-0.38PT | 5% BT | 83 | ~2000 | 413 | 409 | 224 | ~0.050 | 2020 | [ |

| CuO-doped PYN-46PMN-34PT | — | 94 | 1960 | 380 | 460 | — | 0.019 | 2020 | [ |

| Mn-doped PIN-0.42PMN-0.34PT | 2% BT | 84 | 1514 | 370 | 517 | 205 | 0.0049 | 2021 | [ |

| PIN-0.445PSN-0.365PT | 5% BT | 99.2 | 2310 | 240 | 1090 | 247 | 0.012 | 2021 | [ |

| BZZ-0.375BS-0.60PT | 5% BT | 91 | 980 | 216 | 353 | 403 | 0.024 | 2021 | [ |

| BMT-0.6PMN-0.3PT | — | 90 | 4500 | — | — | — | — | 2022 | [ |

| PSN-0.20PZ-0.41PT | 3% BT | ~95 | 1300 | 265 | 580 | 299 | 0.007 | 2022 | [ |

| PNN-0.21PZ-0.37PT | 3% BT | 96 | ~3000 | 730 | 830 | ~170 | ~0.017 | 2022 | [ |

| PIN-0.445PSN-0.365PT | 2.5% BT | 99 | 2155 | — | 770 | ~270 | 0.0072 | 2022 | [ |

| Mn&Cu-doped PIN-0.42PMN-0.34PT | 2% BT | 97 | 1498 | 304 | 725 | 205 | 0.0045 | 2022 | [ |

| MnO2-doped PIN-0.46PSN-0.37PT | 3% BT | 99 | 1739 | 181 | 735 | 244 | 0.0039 | 2023 | [ |

| MnO2-doped PIN-0.42PMN-0.34PT | 2% BT | 98 | 1498 | 304 | 725 | ~205 | 0.0042 | 2023 | [ |

| PIN-0.445PSN-0.365PT | 3% BT | — | 2100 | — | 840 | 261 | 0.006 | 2023 | [ |

| PIN-0.46PMN-0.3PT | 5% BT | ~99 | 1960 | 270 | 860 | 195 | 0.007 | 2023 | [ |

| CuO-doped PMN-0.29PIN-0.34PT | 3% BT | 97 | ~2000 | ~450 | 578 | 231 | — | 2023 | [ |

| PNN-0.25PZ-0.39PT | 3% BT | 98 | 2790 | 443 | 1165 | 197 | 0.021 | 2023 | [ |

| PZT-0.11PZN-0.06PNN | 10% BZT | 63 | 1123 | — | 318 | 230 | ~0.021 | 2024 | [ |

| PNT-0.34PZ-0.42PT | 5% BT | 98 | 2499 | ~250 | 820 | 180 | — | 2024 | [ |

| Li2CO3-doped PNN-0.16PZ-0.34PT | 2% BT | 85 | 3942 | 943 | 1180 | 146 | ~0.04 | 2024 | [ |

| [1] | COLLINS E, PANTOYA M, NEUBER A A, et al. Piezoelectric ignition of nanocomposite energetic materials. Journal of Propulsion and Power, 2014, 30(1): 15. |

| [2] | ZHOU T, WANG S, BAO D, et al. Correlation and comprehensive selection of the piezoelectric ignition material parameters. Ferroelectrics, 1997, 195(1): 97. |

| [3] | WAN X, CONG H, JIANG G, et al. A review on PVDF nanofibers in textiles for flexible piezoelectric sensors. ACS Applied Nano Materials, 2023, 6(3): 1522. |

| [4] | LU B, XIE L, LEI H, et al. Research progress in self-powered pressure sensors for Internet of healthcare. Advanced Materials Technologies, 2024, 9(21): 2301480. |

| [5] | ZHI C, SHI S, SI Y, et al. Recent progress of wearable piezoelectric pressure sensors based on nanofibers, yarns, and their fabrics via electrospinning. Advanced Materials Technologies, 2022, 8(5): 2201161. |

| [6] | MESHKINZAR A, AL-JUMAILY A M. Cylindrical piezoelectric PZT transducers for sensing and actuation. Sensors, 2023, 23(6): 3042. |

| [7] | PYUN J Y, KIM Y H, PARK K K. Design of piezoelectric acoustic transducers for underwater applications. Sensors, 2023, 23(4): 1821. |

| [8] | JIN H, GAO X, REN K, et al. Review on piezoelectric actuators based on high-performance piezoelectric materials. IEEE Transactions on Ultrasonics, Ferroelectrics, and Frequency Control, 2022, 69(11): 3057. |

| [9] | LIU J, GAO X, JIN H, et al. Miniaturized electromechanical devices with multi-vibration modes achieved by orderly stacked structure with piezoelectric strain units. Nature Communications, 2022, 13: 6567. |

| [10] | GAO X, YANG J, WU J, et al. Piezoelectric actuators and motors: materials, designs, and applications. Advanced Materials Technologies, 2019, 5: 1900716. |

| [11] |

ZHOU X, WU S, WANG X, et al. Review on piezoelectric actuators: materials, classifications, applications, and recent trends. Frontiers of Mechanical Engineering, 2024, 19(1): 6.

DOI |

| [12] | YU Y, CHENG Z, CHANG J, et al. Enhanced in-plane omnidirectional energy harvesting from extremely weak magnetic fields via fourfold symmetric magneto-mechano-electric coupling. Advanced Energy Materials, 2024, 14(43): 2402487. |

| [13] | YU Z, YANG J, XU L, et al. Giant tridimensional power responses in a T-shaped magneto-mechano-electric energy harvester. Energy & Environmental Science, 2024, 17(4): 1426. |

| [14] | YU Z, YANG J, CAO J, et al. A PMNN-PZT piezoceramic based magneto-mechano-electric coupled energy harvester. Advanced Functional Materials, 2022, 32(25): 2111140. |

| [15] | YU Z, LI Z, YUAN X, et al. Enhanced extremely weak-field energy harvesting via magnetic flux and stress concentration effects in ferromagnetic/ferroelectric composite. Applied Physics Letters, 2022, 121(7): 072902. |

| [16] | YUAN X, GAO X, YANG J, et al. The large piezoelectricity and high power density of a 3D-printed multilayer copolymer in a rugby ball-structured mechanical energy harvester. Energy & Environmental Science, 2020, 13(1): 152. |

| [17] | ZHU R, CHENG Z, LV X, et al. Piezo-turned magnet rotation for ELF/SLF cross-medium communication in omni-direction. Advanced Optical Materials, 2024, 12(20): 2400461. |

| [18] | CHENG Z, ZHOU J, WANG B, et al. A bionic flapping magnetic-dipole resonator for ELF cross-medium communication. Advanced Science, 2024, 11(30): 2403746. |

| [19] | 智研瞻产业研究院. 中国压电材料行业报告: 概述、行业企业布局、产业链、应用机遇及发展前景分析. (2024-07-04) [2024-12-16]. https://roll.sohu.com/a/790593871_120815556. |

| [20] | WANG J, QIN X, LIU Z, et al. Development and performance analysis of hemispherical piezoelectric transducer for road applications. Ferroelectrics, 2021, 584(1): 70. |

| [21] | ZHENG X, HE L, WANG S, et al. A review of piezoelectric energy harvesters for harvesting wind energy. Sensors and Actuators A: Physical, 2023, 352: 114190. |

| [22] | HE L, HAN Y, SUN L, et al. A rotating piezoelectric- electromagnetic hybrid harvester for water flow energy. Energy Conversion and Management, 2023, 290: 117221. |

| [23] | ZHANG L, SUN D, CHAI M, et al. Ultrafast photoinduced strain in super-tetragonal PbTiO3 ferroelectric films. Science China Materials, 2021, 64(7): 1679. |

| [24] |

SHI X, HE J. Thermopower and harvesting heat. Science, 2021, 371(6527): 343.

DOI PMID |

| [25] |

YANG Q Y, YANG S Q, QIU P F, et al. Flexible thermoelectrics based on ductile semiconductors. Science, 2022, 377(6608): 854.

DOI PMID |

| [26] | PARK S E, SHROUT T R. Ultrahigh strain and piezoelectric behavior in relaxor based ferroelectric single crystals. Journal of Applied Physics, 1997, 82(4): 1804. |

| [27] | SERVICE R F. Shape-changing crystals get shiftier. Science, 1997, 275(5308): 1878. |

| [28] | SUN Y, CHANG Y, WU J, et al. Ultrahigh energy harvesting properties in textured lead-free piezoelectric composites. Journal of Materials Chemistry A, 2019, 7(8): 3603. |

| [29] | YANG Z, ZHOU S, ZU J, et al. High-performance piezoelectric energy harvesters and their applications. Joule, 2018, 2(4): 642. |

| [30] | WU J, ZHANG S, LI F. Prospect of texture engineered ferroelectric ceramics. Applied Physics Letters, 2022, 121(12): 120501. |

| [31] | LE FERRAND H. Magnetic slip casting for dense and textured ceramics: a review of current achievements and issues. Journal of the European Ceramic Society, 2021, 41(1): 24. |

| [32] | WANG M, FAN L, WANG S, et al. Fabrication of textured cerium-doped lutetium oxyorthosilicate ceramics by slip casting in a strong magnetic field. Journal of the American Ceramic Society, 2022, 105(8): 5102. |

| [33] | LI R Z, WANG X G, YUAN J H, et al. Enhanced high-temperature strength in textured (Ti1/3Zr1/3Hf1/3)B2 medium-entropy ceramics via strong magnetic field. Journal of the American Ceramic Society, 2023, 106(9): 5440. |

| [34] | SONG Y, LIU P, WU W, et al. High-performance colossal permittivity for textured (Al+Nb) co-doped TiO2 ceramics sintered in nitrogen atmosphere. Journal of the European Ceramic Society, 2021, 41(7): 4146. |

| [35] | SHI Y, HE Q, WANG A, et al. Effect of additive content on texture evolution and mechanical properties of Si3N4 ceramics prepared by hot pressing. Materials Science and Engineering: A, 2024, 898: 146348. |

| [36] | LI J, JIANG Q, PAN Z, et al. Fabrication of silicon nitride with high thermal conductivity and flexural strength by hot-pressing flowing sintering. International Journal of Applied Ceramic Technology, 2024, 21(4): 2841. |

| [37] | FU Z, WEI Y, LIU Y, et al. Polycrystalline thermosensitive ceramic oxides in CaCeNbWO8: density, texture, and thermal aging stability. Journal of the American Ceramic Society, 2021, 105(4): 2442. |

| [38] | ZHANG Z, DUAN X, TIAN Z, et al. Texture and anisotropy of hot-pressed h-BN matrix composite ceramics with in situ formed YAG. Journal of Advanced Ceramics, 2022, 11(4): 532. |

| [39] | WALTON R L, KUPP E R, MESSING G L. Additive manufacturing of textured ceramics: a review. Journal of Materials Research, 2021, 36(18): 3591. |

| [40] | AKÇA E, DURAN C, KOWALSKI B, et al. Templated grain growth of Bi(Zn0.5Zr0.5)O3 modified BiScO3-PbTiO3piezoelectric ceramics for high temperature applications. Journal of Asian Ceramic Societies, 2021, 9(3): 874. |

| [41] | ZHANG L, LIN J, LI G, et al. Dual-template textured BNT-based ceramics with ultra-low electrostrain hysteresis. Journal of the European Ceramic Society, 2024, 44(13): 7597. |

| [42] | LI X, YAO M, LIN W, et al. Morphological evolution of plate-like B-site complex perovskite Pb(ZrxTi1-x)O3 microcrystals. Journal of Solid State Chemistry, 2023, 326: 124236. |

| [43] | PENG J, LIU W, ZENG J, et al. Large electromechanical strain at high temperatures of novel <001> textured BiFeGaO3-BaTiO3 based ceramics. Journal of Materials Science & Technology, 2020, 48: 92. |

| [44] | LIU Y, ZHANG H, MA C, et al. Fine grained textured BaTiO3- based piezoelectric ceramics with outstanding strain properties for the lead-free multilayer actuator. Ceramics International, 2024, 50(14): 26018. |

| [45] | LAI L X, ZHAO Z H, TIAN S, et al. Ultrahigh electrostrain with excellent fatigue resistance in textured Nb5+-doped (Bi0.5Na0.5)TiO3- based piezoceramics. Journal of Advanced Ceramics, 2023, 12(3): 487. |

| [46] | TATO M, SHIRNONISHI R, HAGIWARA M, et al. Reactive templated grain growth and thermoelectric power factor enhancement of textured CuFeO2 ceramics. ACS Applied Energy Materials, 2020, 3(2): 1979. |

| [47] | WU Q, ZHANG F Q, WANG B, et al. A lead-free KNN-based, co-fired multilayered piezoceramic energy harvester with a high output current and power. Journal of Materiomics, 2025, 11(2): 100876. |

| [48] | CHANG Y, SUN Y, WU J, et al. Formation mechanism of highly [001]c textured Pb(In1/2Nb1/2)O3-Pb(Mg1/3Nb2/3)O3-PbTiO3 relaxor ferroelectric ceramics with giant piezoelectricity. Journal of the European Ceramic Society, 2016, 36(8): 1973. |

| [49] | LOTGERING F K. Topotactical reactions with ferrimagnetic oxides having hexagonal crystal structures—II. Journal of Inorganic & Nuclear Chemistry, 1960, 16(1/2): 100. |

| [50] |

LI L, DENG J, CHEN J, et al. Topochemical molten salt synthesis for functional perovskite compounds. Chemical Science, 2016, 7(2): 855.

DOI PMID |

| [51] | WU Q, ZHAO L, CHEN X, et al. Efficiently enhanced energy storage performance of Ba2Bi4Ti5O18 film by co-doping Fe3+ and Ta5+ ion with larger radius. Chinese Physics B, 2022, 31(9): 097701. |

| [52] | WU Q, WU X, ZHAO Y S, et al. Design of lead-free films with high energy storage performance via inserting a single perovskite into Bi4Ti3O12. Chinese Physics Letters, 2020, 37(11): 118401. |

| [53] | WU Q, CHEN X, ZHAO L, et al. The relaxor properties and energy storage performance of Aurivillius compounds with different number of perovskite-like layers. Journal of Alloys and Compounds, 2022, 911: 165081. |

| [54] | WU Q, ZHAO Y, ZHOU Y, et al. Energy storage properties of composite films with relaxor antiferroelectric behaviors. Journal of Alloys and Compounds, 2021, 881: 160576. |

| [55] |

LI J L, QU W B, DANIELS J, et al. Lead zirconate titanate ceramics with aligned crystallite grains. Science, 2023, 380(6640): 87.

DOI PMID |

| [56] | PAN M J, RANDALL C A. A brief introduction to ceramic capacitors. IEEE Electrical Insulation Magazine, 2010, 26(3): 44. |

| [57] | YANG S, LI J, LIU Y, et al. Textured ferroelectric ceramics with high electromechanical coupling factors over a broad temperature range. Nature Communications, 2021, 12: 1414. |

| [58] | TOK A I Y, BOEY F Y C, LAM Y C. Non-newtonian fluid flow model for ceramic tape casting. Materials Science and Engineering: A, 2000, 280(2): 282. |

| [59] | BIAN L, QI X, LI K, et al. High-performance [001]c-textured PNN-PZT relaxor ferroelectric ceramics for electromechanical coupling devices. Advanced Functional Materials, 2020, 30(25): 2001846. |

| [60] | WU Y, SOON P S, LU J T, et al. Life cycle assessment of lead-free potassium sodium niobate versus lead zirconate titanate: energy and environmental impacts. EcoMat, 2024, 6(5): e12450. |

| [61] | KUWATA J, UCHINO K, NOMURA S. Dielectric and piezoelectric properties of 0.91Pb(Zn1/3Nb2/3)O3-0.09PbTiO3 single crystals. Japanese Journal of Applied Physics, 1982, 21(9): 1298. |

| [62] | ZHANG Y, XUE D, WU H, et al. Adaptive ferroelectric state at morphotropic phase boundary: coexisting tetragonal and rhombohedral phases. Acta Materialia, 2014, 71: 176. |

| [63] | POTERALA S F, TROLIER-MCKINSTRY S, MEYER R J, et al. Processing, texture quality, and piezoelectric properties of <001>c textured (1-x)Pb(Mg1/3Nb2/3)TiO3-xPbTiO3 ceramics. Journal of Applied Physics, 2011, 110: 014105. |

| [64] | YAN Y, WANG Y U, PRIYA S. Electromechanical behavior of [001]-textured Pb(Mg1/3Nb2/3)O3-PbTiO3 ceramics. Applied Physics Letters, 2012, 100(19): 192905. |

| [65] | BERKSOY-YAVUZ A, MENSUR-ALKOY E. Enhanced soft character of crystallographically textured Mn-doped binary 0.675[Pb(Mg1/3Nb2/3)O3]-0.325[PbTiO3] ceramics. Journal of Electronic Materials, 2018, 47(11): 6557. |

| [66] | JIA H, YANG S, ZHU W, et al. Improved piezoelectric properties of Pb(Mg1/3Nb2/3)O3-PbTiO3 textured ferroelectric ceramics via Sm-doping method. Journal of Alloys and Compounds, 2021, 881: 160666. |

| [67] | YANG S, WANG M, WANG L, et al. Achieving both high electromechanical properties and temperature stability in textured PMN-PT ceramics. Journal of the American Ceramic Society, 2021, 105(5): 3322. |

| [68] | ZHENG K, QUAN Y, ZHUANG J, et al. Achieving high piezoelectric performances with enhanced domain-wall contributions in <001>-textured Sm-modified PMN-29PT ceramics. Journal of the European Ceramic Society, 2021, 41(4): 24584. |

| [69] | MORIANA A D, ZHANG S J. Determining the effects of BaTiO3 template alignment on template grain growth of Pb(Mg1/3Nb2/3)O3- PbTiO3 and effects on piezoelectric properties. Journal of the European Ceramic Society, 2022, 42(6): 2752. |

| [70] | YAN Y, GENG L D, ZHU L F, et al. Ultrahigh piezoelectric performance through synergistic compositional and microstructural engineering. Advanced Science, 2022, 9(14): 2105715. |

| [71] | TANG M, LIU X, WANG Y, et al. High piezoelectric response in [001] textured Sm3+ doped Pb(Mg1/3Nb2/3)O3-PbTiO3 ceramics. Journal of Applied Physics, 2023, 133(18): 184102. |

| [72] | WANG Q, YAO M, LIN W, et al. Microstructure and electrical properties of Er-doped 0.67Pb(Mg1/3Nb2/3)O3-0.33PbTiO3 ceramics with BaTiO3 templates. Ceramics International, 2023, 49(1): 437. |

| [73] | LI F, CABRAL M J, XU B, et al. Giant piezoelectricity of Sm-doped Pb(Mg1/3Nb2/3)O3-PbTiO3 single crystals. Science, 2019, 364(6437): 264. |

| [74] |

PAN H, LAN S, XU S Q, et al. Ultrahigh energy storage in superparaelectric relaxor ferroelectrics. Science, 2021, 374(6563): 100.

DOI PMID |

| [75] | ZHANG S, LI F. High performance ferroelectric relaxor-PbTiO3 single crystals: status and perspective. Journal of Applied Physics, 2012, 111(3): 031301. |

| [76] | YAN Y, CHO K H, PRIYA S. Piezoelectric properties and temperature stability of Mn-doped Pb(Mg1/3Nb2/3)-PbZrO3-PbTiO3 textured ceramics. Applied Physics Letters, 2012, 100(13): 132908. |

| [77] | YAN Y, CHO K H, MAURYA D, et al. Giant energy density in [001]-textured Pb(Mg1/3Nb2/3)O3-PbZrO3-PbTiO3 piezoelectric ceramics. Applied Physics Letters, 2013, 102(4): 042903. |

| [78] | ZATE T T, KIM M, JEON J H. Outstanding unipolar strain of textured Pb(Mg1/3Nb2/3)O3-PbZrO3-PbTiO3 piezoelectric ceramics manufactured by particle size distribution control of the plate-like BaTiO3 template. Sensors and Actuators A: Physical, 2022, 335: 113373. |

| [79] | LIU L, YANG B, YANG S, et al. Cu-modified Pb(Mg1/3Nb2/3)O3- PbZrO3-PbTiO3 textured ceramics with enhanced electromechanical properties and improved thermal stability. Journal of the European Ceramic Society, 2022, 42(6): 2743. |

| [80] | KIM E J, KIM S W, KIM D S, et al. Piezoelectric properties of [001]-textured high-power PMnN-PZT piezoceramics sintered at a low temperature. Journal of the European Ceramic Society, 2023, 43(5): 1912. |

| [81] | YAN Y, GENG L D, LIU H, et al. Near-ideal electromechanical coupling in textured piezoelectric ceramics. Nature Communications, 2022, 13: 3565. |

| [82] | DURSUN S, MENSUR-ALKOY E, UNVER M U, et al. Enhancement of electrical properties in the ternary PMN-PT-PZ through compositional variation, crystallographic texture, and quenching. Journal of the American Ceramic Society, 2019, 103(4): 24998. |

| [83] | LIU L, YANG B, LV R, et al. Enhanced unipolar electrical fatigue resistance and related mechanism in grain-oriented Pb(Mg1/3Nb2/3)O3-Pb(Zr,Ti)O3 piezoceramics. Journal of Materials Science & Technology, 2023, 145: 40. |

| [84] | TANG M, HU L, WU Y, et al. Electromechanical properties of [001]-textured Mn-PMN-PZT ceramics under hydrostatic pressure. Journal of the American Ceramic Society, 2023, 107(2): 1042. |

| [85] | ZHANG Y, TANG M, WANG Y, et al. Effect of post-annealing on the electrical properties of textured Pb(Mg1/3Nb2/3)O3-PbZrO3- PbTiO3 piezoelectric ceramics. Ceramics International, 2024, 50(11): 18814. |

| [86] | CHANG Y, WU J, SUN Y, et al. Enhanced electromechanical properties and phase transition temperatures in [001] textured Pb(In1/2Nb1/2)O3-Pb(Mg1/3Nb2/3)O3-PbTiO3 ternary ceramics. Applied Physics Letters, 2015, 107(8): 082902. |

| [87] | DURAN C, DURSUN S, AKÇA E. High strain, <001>-textured Pb(Mg1/3Nb2/3)O3-Pb(Yb1/2Nb1/2)O3-PbTiO3 piezoelectric ceramics. Scripta Materialia, 2016, 113: 14. |

| [88] | WEI D, WANG H. Low-temperature sintering and enhanced piezoelectric properties of random and textured PIN-PMN-PT ceramics with Li2CO3. Journal of the American Ceramic Society, 2016, 100(3): 1073. |

| [89] | CHANG Y, WATSON B, FANTON M, et al. Enhanced texture evolution and piezoelectric properties in CuO-doped Pb(In1/2Nb1/2)O3-Pb(Mg1/3Nb2/3)O3-PbTiO3 grain-oriented ceramics. Applied Physics Letters, 2017, 111(23): 232901. |

| [90] | DURAN C, CENGIZ S, ECEBAŞ N, et al. Processing and characterization of <001>-textured Pb(Mg1/3Nb2/3)O3- Pb(Yb1/2Nb1/2)O3-PbTiO3 ceramics. Journal of Materials Research, 2017, 32(13): 2471. |

| [91] | CHANG Y, WU J, LIU Z, et al. Grain-oriented ferroelectric ceramics with single-crystal-like piezoelectric properties and low texture temperature. ACS Applied Materials & Interfaces, 2020, 12(34): 38415. |

| [92] | BROVA M J, WATSON B H, WALTON R L, et al. Templated grain growth of high coercive field CuO-doped textured PYN- PMN-PT ceramics. Journal of the American Ceramic Society, 2020, 103(11): 6149. |

| [93] | BROVA M J, WATSON B H, WALTON R L, et al. Relationship between composition and electromechanical properties of CuO-doped textured PYN-PMN-PT ceramics. Journal of the European Ceramic Society, 2021, 41(2): 1230. |

| [94] | LENG H, YAN Y, LIU H, et al. Design and development of high- power piezoelectric ceramics through integration of crystallographic texturing and acceptor-doping. Acta Materialia, 2021, 206: 116610. |

| [95] | JIA H, LIANG Z, LI Z, et al. Texture technique to simultaneously achieve large electric field induced strain response and ultralow hysteresis in BMT-PMN-PT relaxor ferroelectric ceramics. Scripta Materialia, 2022, 209: 114409. |

| [96] | MORIANA A D, ZHANG S. Enhancing electromechanical properties of Pb(Sc1/2Nb1/2)O3-PbZrO3-PbTiO3 piezoelectric ceramics via templated grain growth. Advanced Electronic Materials, 2021, 8(6): 2100919. |

| [97] | BIAN L, KOU Q, LIU L, et al. Enhancing the temperature stability of 0.42PNN-0.21PZ-0.37PT ceramics through texture engineering. ACS Applied Materials & Interfaces, 2022, 14(2): 3076. |

| [98] | YANG S, QIAO L, WANG J, et al. Full matrix electromechanical properties of textured Pb(In1/2Nb1/2)O3-Pb(Sc1/2Nb1/2)O3-PbTiO3 ceramic. Journal of Applied Physics, 2022, 131(12): 124104. |

| [99] | LENG H, YAN Y, WANG B, et al. High performance high-power textured Mn/Cu-doped PIN-PMN-PT ceramics. Acta Materialia, 2022, 234: 118015. |

| [100] | LENG H, WANG Y U, YAN Y, et al. Water quenched and acceptor-doped textured piezoelectric ceramics for off-resonance and on-resonance devices. Small, 2022, 19(1): 2204454. |

| [101] | LENG H, YAN Y, LI X, et al. High-power piezoelectric behavior of acceptor-doped <001> and <111> textured piezoelectric ceramics. Journal of Materials Chemistry C, 2023, 11(6): 2229. |

| [102] | YANG S, TIAN F, LI C, et al. Electromechanical properties of textured PIN-PSN-PT ceramics under uniaxial stress, hydrostatic pressure, and bias electric field. Journal of Applied Physics, 2023, 133(9): 094104. |

| [103] | YANG S, ZHANG J, QIU C, et al. Investigation on the planar Poisson’s ratio of <001>-oriented Pb(In1/2Nb1/2)O3-Pb(Mg1/3Nb2/3)O3- PbTiO3 ceramics. Journal of the European Ceramic Society, 2024, 44(5): 3058. |

| [104] | ZATE T T, KO N R, YU H L, et al. Textured Pb(Mg1/3Nb2/3)O3- Pb(In1/2Nb1/2)O3-PbTiO3 ceramics with enhanced piezoelectric properties and high Curie temperature prepared by low-temperature sintering. Sensors and Actuators A: Physical, 2024, 366: 114929. |

| [105] | WANG Q, BIAN L, LI K, et al. Achieving ultrahigh electromechanical properties with high TC in PNN-PZT textured ceramics. Journal of Materials Science & Technology, 2024, 175: 258. |

| [106] | FENG X, LI L, XU X, et al. Microstructure evolution and properties of textured, Pb(Zr1/2Ti1/2)O3-Pb(Zn1/3Nb2/3)O3-Pb(Ni1/3Nb2/3)O3 ceramics with plate-like BaZr0.1Ti0.9O3 template. Journal of Alloys and Compounds, 2024, 1002: 175439. |

| [107] | BIAN L, WANG Q, HE S, et al. Excellent strain and temperature stability in PNT-PZT multilayer textured ceramics. Journal of the European Ceramic Society, 2024, 44(8): 5048. |

| [108] | CHO S W, NA Y H, BAIK J M, et al. Low-temperature sintered 0.5Pb(Ni1/3Nb2/3)O3-0.16PbZrO3-0.34PbTiO3 piezoelectric textured ceramics by Li2CO3 addition. Journal of the American Ceramic Society, 2024, 107(6): 4178. |

| [109] | KIM E J, LEE T G, KIM D S, et al. Textured Pb(Zr,Ti)O3- Pb[(Zn,Ni)1/3Nb2/3]O3 multilayer ceramics and their application to piezoelectric actuators. Applied Materials Today, 2020, 20: 100695. |

| [110] | ZHANG Z, WANG Z, YANG S, et al. Textured ferroelectric ceramics based 1-3 piezoelectric composite for photoacoustic imaging. Sensors and Actuators A: Physical, 2024, 380: 116030. |

| [111] | HAO M, FAN G, CAI W, et al. Texture tolerance to B-site valence mismatch for [001] textured Pb97.5%Ba2.5%[(Zn1/3Nb2/3)(1-x)Tix]O3 transparent ceramics. Ceramics International, 2021, 47(1): 1253. |

| [1] | 余升阳, 苏海军, 姜浩, 余明辉, 姚佳彤, 杨培鑫. 激光增材制造超高温氧化物陶瓷孔隙缺陷形成及抑制研究进展[J]. 无机材料学报, 2025, 40(9): 944-956. |

| [2] | 刘江平, 管鑫, 唐振杰, 朱文杰, 罗永明. 含氮挥发性有机化合物催化氧化的研究进展[J]. 无机材料学报, 2025, 40(9): 933-943. |

| [3] | 肖晓琳, 王玉祥, 谷佩洋, 朱圳荣, 孙勇. 二维无机材料调控病损皮肤组织再生的研究进展[J]. 无机材料学报, 2025, 40(8): 860-870. |

| [4] | 马景阁, 吴成铁. 无机生物材料用于毛囊和毛发再生的研究[J]. 无机材料学报, 2025, 40(8): 901-910. |

| [5] | 张洪健, 赵梓壹, 吴成铁. 无机生物材料调控神经细胞功能及神经化组织再生的研究进展[J]. 无机材料学报, 2025, 40(8): 849-859. |

| [6] | 艾敏慧, 雷波. 微纳米生物活性玻璃: 功能化设计与血管化皮肤再生[J]. 无机材料学报, 2025, 40(8): 921-932. |

| [7] | 王宇彤, 常江, 徐合, 吴成铁. 硅酸盐生物陶瓷/玻璃促创面修复的研究进展:作用、机制和应用方式[J]. 无机材料学报, 2025, 40(8): 911-920. |

| [8] | 马文平, 韩雅卉, 吴成铁, 吕宏旭. 无机活性材料在类器官研究领域的应用[J]. 无机材料学报, 2025, 40(8): 888-900. |

| [9] | 罗晓民, 乔志龙, 刘颍, 杨晨, 常江. 无机生物活性材料调控心肌再生的研究进展[J]. 无机材料学报, 2025, 40(8): 871-887. |

| [10] | 朱文杰, 唐璐, 陆继长, 刘江平, 罗永明. 钙钛矿型氧化物催化氧化挥发性有机化合物的研究进展[J]. 无机材料学报, 2025, 40(7): 735-746. |

| [11] | 陈相杰, 李玲, 雷添福, 王佳佳, 汪尧进. 相界工程和畴工程调控(1-x)(0.8PZT-0.2PZN)-xBZT陶瓷的压电性能[J]. 无机材料学报, 2025, 40(6): 729-734. |

| [12] | 胡智超, 杨鸿宇, 杨鸿程, 孙成礼, 杨俊, 李恩竹. P-V-L键理论在微波介质陶瓷性能调控中的应用[J]. 无机材料学报, 2025, 40(6): 609-626. |

| [13] | 张碧辉, 刘小强, 陈湘明. Ruddlesden-Popper结构杂化非常规铁电体的研究进展[J]. 无机材料学报, 2025, 40(6): 587-608. |

| [14] | 吴杰, 杨帅, 王明文, 李景雷, 李纯纯, 李飞. 铅基织构压电陶瓷的发展历程、现状与挑战[J]. 无机材料学报, 2025, 40(6): 575-586. |

| [15] | 姜昆, 李乐天, 郑木鹏, 胡永明, 潘勤学, 吴超峰, 王轲. PZT陶瓷的低温烧结研究进展[J]. 无机材料学报, 2025, 40(6): 627-638. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||