无机材料学报 ›› 2024, Vol. 39 ›› Issue (5): 531-538.DOI: 10.15541/jim20230587 CSTR: 32189.14.10.15541/jim20230587

所属专题: 【信息功能】透明与闪烁陶瓷(202506)

吕朝阳1,2( ), 徐勇1,2, 杨久延1,2, 涂广升1,2, 涂兵田1,2, 王皓1,2(

), 徐勇1,2, 杨久延1,2, 涂广升1,2, 涂兵田1,2, 王皓1,2( )

)

收稿日期:2023-12-21

修回日期:2024-01-20

出版日期:2024-05-20

网络出版日期:2024-02-22

通讯作者:

王 皓, 教授. E-mail: shswangh@whut.edu.cn作者简介:吕朝阳(1999-), 男, 硕士研究生. E-mail: lvzhaoyang2021@163.com

基金资助:

LÜ Zhaoyang1,2( ), XU Yong1,2, YANG Jiuyan1,2, TU Guangsheng1,2, TU Bingtian1,2, WANG Hao1,2(

), XU Yong1,2, YANG Jiuyan1,2, TU Guangsheng1,2, TU Bingtian1,2, WANG Hao1,2( )

)

Received:2023-12-21

Revised:2024-01-20

Published:2024-05-20

Online:2024-02-22

Contact:

WANG Hao, professor. E-mail: shswangh@whut.edu.cnAbout author:LÜ Zhaoyang (1999-), male, Master candidate. E-mail: lvzhaoyang2021@163.com

Supported by:摘要:

MgAl1.9Ga0.1O4透明陶瓷具有优异的光学性能, 其制备依赖于高质量坯体的凝胶注模成型和长时间的无压预烧。本研究选择MgF2为烧结助剂, 并通过瞬时液相调节无压预烧的致密化过程。采用干压成型、无压预烧和热等静压烧结制备了不同尺寸的MgAl1.9Ga0.1O4透明陶瓷样品, 并系统分析了MgF2对材料显微结构、光学和机械性能的影响。研究表明:MgF2在~1230 ℃熔化形成的液相促使陶瓷的致密度与晶粒尺寸增大, 后续烧结过程中残留的MgF2氧化为MgO并固溶进入MgAl1.9Ga0.1O4晶格。添加质量分数0.2% MgF2的2.04 mm厚透明陶瓷样品在紫外和可见光区域具有76.5%~83.4%的直线透过率和较高的光学质量。此外, 该陶瓷的特征抗弯强度为167.1 MPa, 与细晶MgAl2O4透明陶瓷相近, 但是前者的Weibull模数(8.81±0.29)更高。本研究为制备光学性能良好的大尺寸MgAl1.9Ga0.1O4透明陶瓷提供了新的选择。

中图分类号:

吕朝阳, 徐勇, 杨久延, 涂广升, 涂兵田, 王皓. MgF2助剂对MgAl1.9Ga0.1O4透明陶瓷的制备与光学性能的影响[J]. 无机材料学报, 2024, 39(5): 531-538.

LÜ Zhaoyang, XU Yong, YANG Jiuyan, TU Guangsheng, TU Bingtian, WANG Hao. Effect of MgF2 Additive on Preparation and Optical Properties of MgAl1.9Ga0.1O4 Transparent Ceramics[J]. Journal of Inorganic Materials, 2024, 39(5): 531-538.

图1 含0.1%、0.2%、0.5% MgF2的MAGS-0.1陶瓷与无助剂MAGS-0.1陶瓷的烧结轨迹曲线

Fig. 1 Sintering trajectories of MAGS-0.1 ceramics with 0.1%, 0.2% and 0.5% MgF2 and the unaided MAGS-0.1 ceramics Colorful figure is available on website

图2 含0、0.2% MgF2的MAGS-0.1陶瓷坯体收缩率和收缩速率随温度的变化曲线

Fig. 2 Variations of the shrinkage and shrinkage rate of MAGS-0.1 ceramic green bodies containing 0 and 0.2% MgF2 as a function of temperature (a) Shrinkage curves; (b) Shrinkage rate curves

图3 含10% MgF2 MAGS-0.1粉体的TG-DSC曲线与不同温度保温后含10% MgF2 MAGS-0.1粉体的XRD图谱

Fig. 3 TG-DSC curves of MAGS-0.1 powder containing 10% MgF2 and XRD patterns of MAGS-0.1 powder containing 10% MgF2 after heating and holding at different temperatures (a) TG-DSC curves of MAGS-0.1 powder containing 10% MgF2 heated at 10 ℃/min; (b) XRD patterns of MAGS-0.1 powder containing 10% MgF2 after heating and holding at 1150, 1250, 1350 and 1450 ℃ for 5 min followed by quenching; (c) Enlarged XRD patterns of the (220) crystal face in (b)

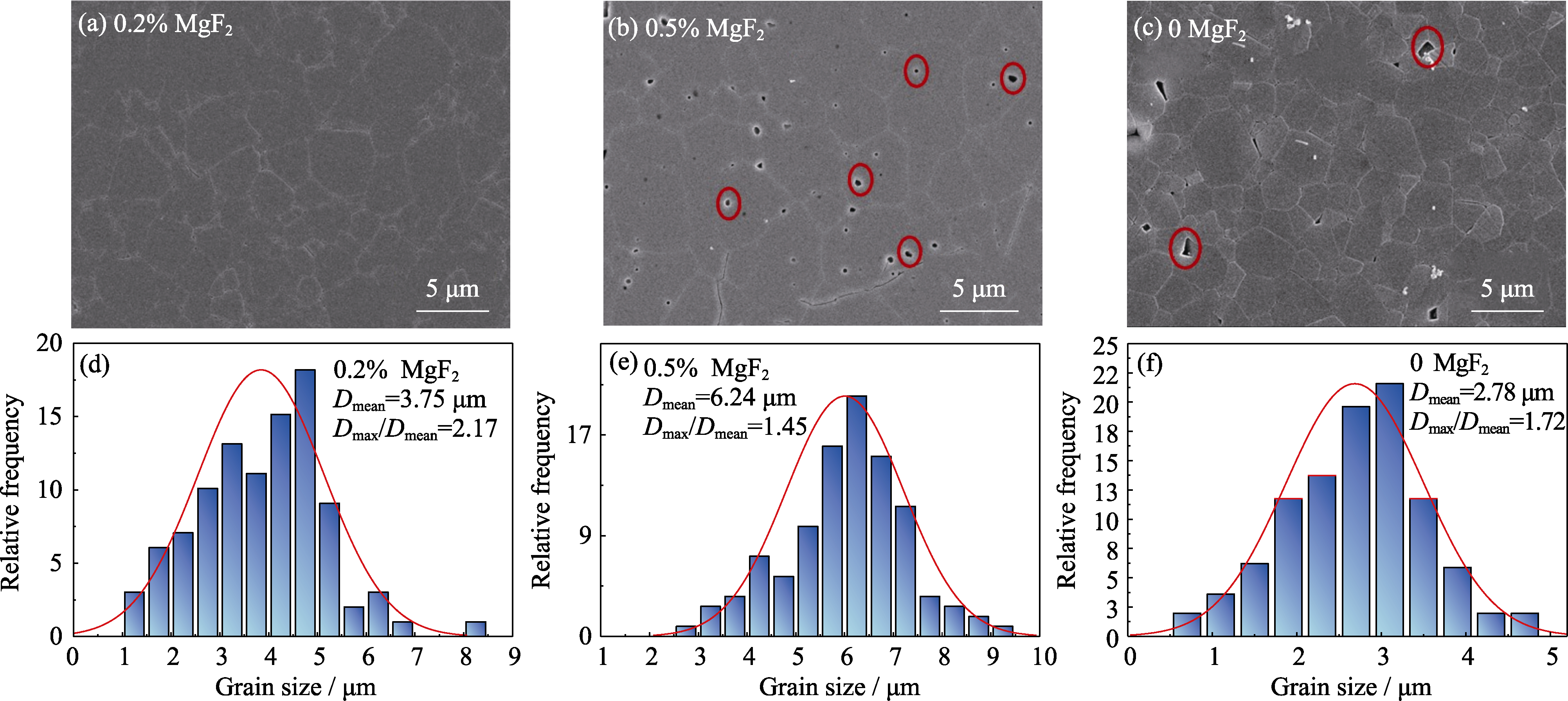

图6 无压预烧后经化学刻蚀的不同助剂含量的MAGS-0.1陶瓷的表面SEM照片及粒度分布图

Fig. 6 Surface SEM images and grain size distributions of MAGS-0.1 ceramics with different additive contents after pressureless presintering and chemical etching (a, d) Sample with 0.2% MgF2; (b, e) Sample with 0.5% MgF2; (c, f) Sample without additive

图7 HIP烧结后经化学刻蚀的MAGS-0.1陶瓷的表面SEM照片与粒度分布图

Fig. 7 Surface SEM images and grain size distributions of MAGS-0.1 ceramics after HIP sintering and chemical etching (a, c) Sample with 0.2% MgF2; (b, d) Sample without additive

图8 无助剂与含0.2% MgF2的MAGS-0.1透明陶瓷的表观照片

Fig. 8 Appearance images of MAGS-0.1 transparent ceramics without additive and with 0.2% MgF2 (a) Sample with 0.2% MgF2; (b) Sample without additive

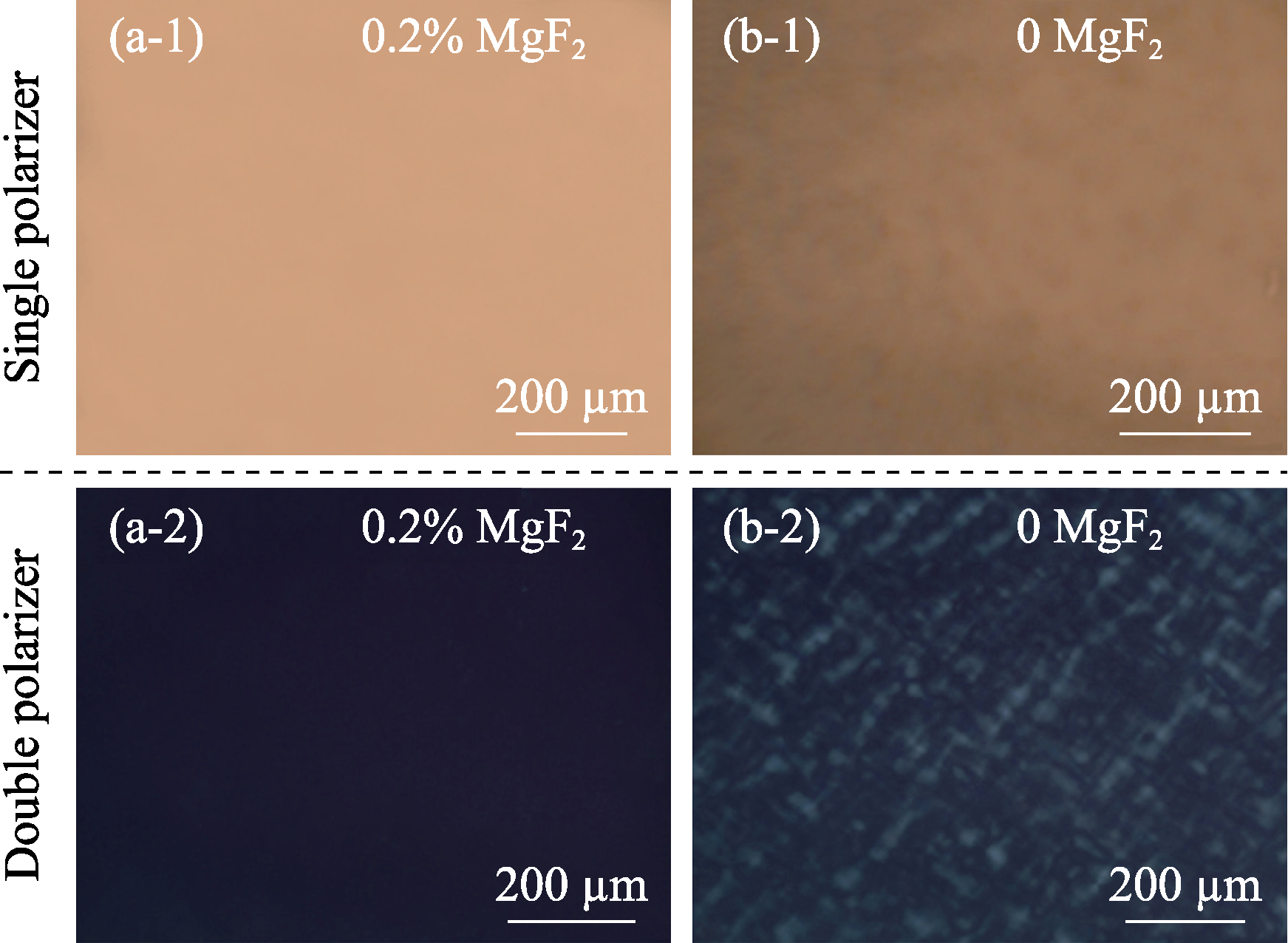

图9 无助剂与含0.2% MgF2的MAGS-0.1透明陶瓷的光学偏振透射显微镜照片

Fig. 9 Optical polarized transmission micrographs of transparent ceramics without additive and with 0.2% MgF2 (a) Sample with 0.2% MgF2; (b) Sample without additive

图10 不同助剂含量与不同尺寸样品的光学性能

Fig. 10 Optical properties of samples with different additive contents and sizes Inset: Appearance image of a sample containing 0.2% MgF2 with ϕ108.8 mm×9.36 mm

图11 MAGS-0.1透明陶瓷抗弯强度的Weibull统计图

Fig. 11 Weibull plots of fracture strength for MAGS-0.1 transparent ceramics (a) Sample without additive[6]; (b) Sample with 0.2% MgF2

| [1] | RUBAT D M, KLEEBE H J, MÜLLER M M, et al. Fifty years of research and development coming to fruition; unraveling the complex interactions during processing of transparent magnesium aluminate (MgAl2O4) spinel. Journal of the American Ceramic Society, 2013, 96(11): 3341. |

| [2] | WAETZIG K, KRELL A. The effect of composition on the optical properties and hardness of transparent Al-rich MgO·nAl2O3 spinel ceramics. Journal of the American Ceramic Society, 2016, 99(3): 946. |

| [3] | SANGHERA J, BAYYA S, VILLALOBOS G, et al. Transparent ceramics for high-energy laser systems. Optical Materials, 2011, 33(3): 511. |

| [4] | PAPPAS J M, DONG X. Porosity characterization of additively manufactured transparent MgAl2O4 spinel by laser direct deposition. Ceramics International, 2020, 46(5): 6745. |

| [5] | TU B T, TU G S, WANG H, et al. Highly transparent MgAl0.5Ga1.5O4 ceramic for overcoming the trade-off between infrared transmittance and mechanical properties. Scripta Materialia, 2022, 216: 114756. |

| [6] | YANG J Y, WANG H, TU B T, et al. Preparation and optical properties of highly transparent MgAl1.9Ga0.1O4 ceramics via aqueous gel-casting method. Journal of the European Ceramic Society, 2023, 43(10): 4506. |

| [7] | MEIR S, KALABUKHOV S, FROUMIN N, et al. Synthesis and densification of transparent magnesium aluminate spinel by SPS processing. Journal of the American Ceramic Society, 2009, 92(2): 358. |

| [8] | ROZENBURG K, REIMANIS I E, KLEEBE H J, et al. Chemical interaction between LiF and MgAl2O4 spinel during sintering. Journal of the American Ceramic Society, 2007, 90(7): 2038. |

| [9] | GOLDSTEIN A, RAETHEL J, KATZ M, et al. Transparent MgAl2O4/LiF ceramics by hot-pressing: host-additive interaction mechanisms issue revisited. Journal of the European Ceramic Society, 2016, 36(7): 1731. |

| [10] | IKESUE A, AUNG Y L. Advanced spinel ceramics with highest VUV-vis transparency. Journal of the European Ceramic Society, 2020, 40(6): 2432. |

| [11] | NEČINA V, HOSTAŠA J, PABST W, et al. Magnesium fluoride (MgF2)-a novel sintering additive for the preparation of transparent YAG ceramics via SPS. Journal of the European Ceramic Society, 2022, 42(7): 3290. |

| [12] | XU Z Y, SUN D M, LI A X, et al. X-ray diffraction analysis of the oxidation of MgF2. Journal of the Chinese Ceramic Society, 2002, 30(4): 505. |

| [13] | LIU Y M, ZHAO Z Y, LI A X, et al. A Rietveld full-spectrum fitting study on the oxidation of MgF2. Journal of Anhui University Natural Science Edition, 2002, 26(4): 46. |

| [14] | ZHOU T Y, ZHANG L, WEI S, et al. MgO assisted densification of highly transparent YAG ceramics and their microstructural evolution. Journal of the European Ceramic Society, 2018, 38(2): 687. |

| [15] | MOHAMED N R. Sintering of Ceramics. Florida: CRC Press, 2007: 79-81. |

| [16] | TALIMIAN A, EL-MAGHRABY H F, MICHÁLKOVÁ M, et al. Sintering and grain growth behaviour of magnesium aluminate spinel: effect of lithium hydroxide addition. Journal of the European Ceramic Society, 2021, 41(11): 5634. |

| [17] | 宗潇. MgAlON透明陶瓷的设计、制备及组成—结构—性能关系研究. 武汉: 武汉理工大学博士学位论文, 2021. |

| [18] | BOULESTEIX R, MAITRE A, BAUMARD J F, et al. Mechanism of the liquid-phase sintering for Nd: YAG ceramics. Optical Materials, 2009, 31(5): 711. |

| [19] | LI W J, WANG H, TU B T, et al. Preparation and property of Mg0.9Al2.08O3.97N0.03 transparent ceramic with broad optical transmission range. Journal of Inorganic Materials, 2022, 37(9): 969. |

| [20] | IKESUE A, AUNG Y L. Anisotropic alumina ceramics with isotropic optical properties. Journal of Advanced Ceramics, 2023, 12(1): 72. |

| [21] | KLEIN C A. Flexural strength of infrared-transmitting window materials: bimodal Weibull statistical analysis. Optical En-gineering, 2011, 50(2): 1. |

| [22] | DENG B, JIANG D, GONG J. Is a three-parameter Weibull function really necessary for the characterization of the statistical variation of the strength of brittle ceramics. Journal of the European Ceramic Society, 2018, 38(4): 2234. |

| [23] | KHALILI A. Statistical properties of Weibull estimators. Journal of Materials Science 1991, 26: 6741. |

| [24] | TOKARIEV O, SCHNETTER L, BECK T, et al. Grain size effect on the mechanical properties of transparent spinel ceramics. Journal of the European Ceramic Society, 2013, 33(4): 749. |

| [1] | 叶君豪, 周真真, 胡辰, 王雁斌, 荆延秋, 李廷松, 程梓秋, 吴俊林, IVANOV Maxim, HRENIAK Dariusz, 李江. 共沉淀纳米粉体制备Yb:Sc2O3透明陶瓷的微结构与光学性能[J]. 无机材料学报, 2025, 40(2): 215-224. |

| [2] | 顾军毅, 范武刚, 张兆泉, 姚琴, 展红全. 还原制备Pr2O3粉体及其结构和光学性能研究[J]. 无机材料学报, 2023, 38(7): 771-777. |

| [3] | 李悦, 张旭良, 景芳丽, 胡章贵, 吴以成. 铈掺杂硼酸钙镧晶体的生长与性能研究[J]. 无机材料学报, 2023, 38(5): 583-588. |

| [4] | 靳喜海, 董满江, 阚艳梅, 梁波, 董绍明. 透明AlON陶瓷凝胶浇注成型及其无压烧结制备[J]. 无机材料学报, 2023, 38(2): 193-198. |

| [5] | 王海东, 王燕, 朱昭捷, 李坚富, LAKSHMINARAYANA Gandham, 涂朝阳. Dy3+掺杂SrGdGa3O7晶体的晶体生长, 结构、光学和可见光荧光特性[J]. 无机材料学报, 2023, 38(12): 1475-1482. |

| [6] | 汪德文, 王俊平, 袁厚呈, 刘章, 周进, 邓佳杰, 王鑫, 吴贲华, 章健, 王士维. 真空反应烧结制备米级尺寸钇铝石榴石(YAG)透明陶瓷[J]. 无机材料学报, 2023, 38(12): 1483-1484. |

| [7] | 李文俊, 王皓, 涂兵田, 谌强国, 郑凯平, 王为民, 傅正义. 宽光谱透过Mg0.9Al2.08O3.97N0.03透明陶瓷的制备与性能研究[J]. 无机材料学报, 2022, 37(9): 969-975. |

| [8] | 母利成, 杨金萍, 王俊平, 赵瑾, 刘梦玮, 汪德文, 章健. 环氧树脂改性自发凝固成型制备YAG透明陶瓷[J]. 无机材料学报, 2022, 37(9): 941-946. |

| [9] | 刘强, 王倩, 陈鹏辉, 李晓英, 章立轩, 谢腾飞, 李江. 两步烧结法制备红色Ce:8YSZ透明陶瓷及其性能研究[J]. 无机材料学报, 2022, 37(8): 911-917. |

| [10] | 肖舒琳, 戴中华, 李定妍, 张凡博, 杨利红, 任晓兵. 氧化镧掺杂铌酸钾钠陶瓷的电、光性能研究[J]. 无机材料学报, 2022, 37(5): 520-526. |

| [11] | 荆延秋, 刘强, 苏莎, 李晓英, 刘子玉, 王静雅, 李江. 1.5 μm被动调Q可饱和吸收体用Co:MgAl 2O4透明陶瓷的制备[J]. 无机材料学报, 2021, 36(8): 877-882. |

| [12] | 曾建军, 张魁宝, 陈代梦, 郭海燕, 邓婷, 刘奎. 真空烧结制备(La0.2Nd0.2Sm0.2Gd0.2Er0.2)2Zr2O7高熵透明陶瓷[J]. 无机材料学报, 2021, 36(4): 418-424. |

| [13] | 刘子玉, TOCI Guido, PIRRI Angela, PATRIZI Barbara, 冯亚刚, 陈肖朴, 胡殿君, 田丰, 吴乐翔, VANNINIMatteo, 李江. 固体激光用Nd:Lu2O3透明陶瓷的制备和光学性能研究[J]. 无机材料学报, 2021, 36(2): 210-216. |

| [14] | 黄新友, 刘玉敏, 刘洋, 李晓英, 冯亚刚, 陈肖朴, 陈鹏辉, 刘欣, 谢腾飞, 李江. 醇水共沉淀法制备Yb:YAG透明陶瓷及其性能研究[J]. 无机材料学报, 2021, 36(2): 217-224. |

| [15] | 冯明星, 王斌, 徐鹏宇, 涂兵田, 王皓. 基于键价模型的MgAl2O4透明陶瓷热机械性能预测[J]. 无机材料学报, 2021, 36(10): 1067-1073. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||