无机材料学报 ›› 2022, Vol. 37 ›› Issue (9): 969-975.DOI: 10.15541/jim20210771 CSTR: 32189.14.10.15541/jim20210771

李文俊( ), 王皓(

), 王皓( ), 涂兵田, 谌强国, 郑凯平, 王为民, 傅正义

), 涂兵田, 谌强国, 郑凯平, 王为民, 傅正义

收稿日期:2021-12-17

修回日期:2022-02-22

出版日期:2022-09-20

网络出版日期:2022-06-16

通讯作者:

王 皓, 教授. E-mail: shswangh@whut.edu.cn作者简介:李文俊(1996-), 男, 硕士研究生. E-mail: 15826911464@163.com

基金资助:

LI Wenjun( ), WANG Hao(

), WANG Hao( ), TU Bingtian, CHEN Qiangguo, ZHENG Kaiping, WANG Weiming, FU Zhengyi

), TU Bingtian, CHEN Qiangguo, ZHENG Kaiping, WANG Weiming, FU Zhengyi

Received:2021-12-17

Revised:2022-02-22

Published:2022-09-20

Online:2022-06-16

Contact:

WANG Hao, professor. E-mail: shswangh@whut.edu.cnAbout author:LI Wenjun (1996-), male, Master candidate. E-mail: 15826911464@163.com

Supported by:摘要:

MgAl2O4透明陶瓷具有优异的光学性能, 但其较差的机械性能和成型过程中的水解问题限制了实际应用, 通过组成设计MgAlON四元尖晶石可以有效调节其综合性能。本研究采用凝胶注模成型、无压烧结和热等静压处理制备了一种具有宽光谱透过范围的新型Mg0.9Al2.08O3.97N0.03透明陶瓷, 系统比较其与MgAl2O4透明陶瓷的光学性能和机械性能, 分析了低应力下裂纹的缓慢扩展并预测使用寿命。研究表明:固相体积分数为50%的陶瓷浆料粘度最低, 为124 mPa·s, 满足凝胶注模成型的需求; 2 mm厚的Mg0.9Al2.08O3.97N0.03透明陶瓷样品在3.7 μm处的直线透过率达86.2%, 光学透过范围与MgAl2O4相比拟, 折射率和阿贝数略高于MgAl2O4; 同时, 该陶瓷具有和MgAl2O4相近的Weibull模数, 尽管裂纹缓慢扩展系数比MgAl2O4小, 但特征强度(210.6 MPa)和惰性强度(227.5 MPa)均高于MgAl2O4。包含少量N的MgAlON尖晶石较好地克服了陶瓷粉体的水解问题, 并在保持优越光学性能的前提下显著提高了透明陶瓷的机械性能。本研究为尖晶石型透明陶瓷的制备与性能的改善提供了新的途径。

中图分类号:

李文俊, 王皓, 涂兵田, 谌强国, 郑凯平, 王为民, 傅正义. 宽光谱透过Mg0.9Al2.08O3.97N0.03透明陶瓷的制备与性能研究[J]. 无机材料学报, 2022, 37(9): 969-975.

LI Wenjun, WANG Hao, TU Bingtian, CHEN Qiangguo, ZHENG Kaiping, WANG Weiming, FU Zhengyi. Preparation and Property of Mg0.9Al2.08O3.97N0.03 Transparent Ceramic with Broad Optical Transmission Range[J]. Journal of Inorganic Materials, 2022, 37(9): 969-975.

图1 Mg0.9Al2.08O3.97N0.03陶瓷粉体、浆料、坯体以及透明陶瓷的表征

Fig. 1 Characterization of Mg0.9Al2.08O3.97N0.03 powder, slurry, green body, and transparent ceramic (a) XRD patterns of powder and ceramic; (b) Relationship between viscosity of slurry and contents of TAC; (c) Morphology of green body; (d) SEM image of etched surface of transparent ceramic

图2 透明陶瓷光学性能比较

Fig. 2 Comparison of optical property of transparent ceramics (a) In-line transmittance of Mg0.9Al2.08O3.97N0.03, MgAl2O4, c-plane sapphire[1], Mg0.27Al2.58O3.73N0.27 transparent ceramics[14]; (b) Refractive index of Mg0.9Al2.08O3.97N0.03, MgAl2O4 transparent ceramics[19]

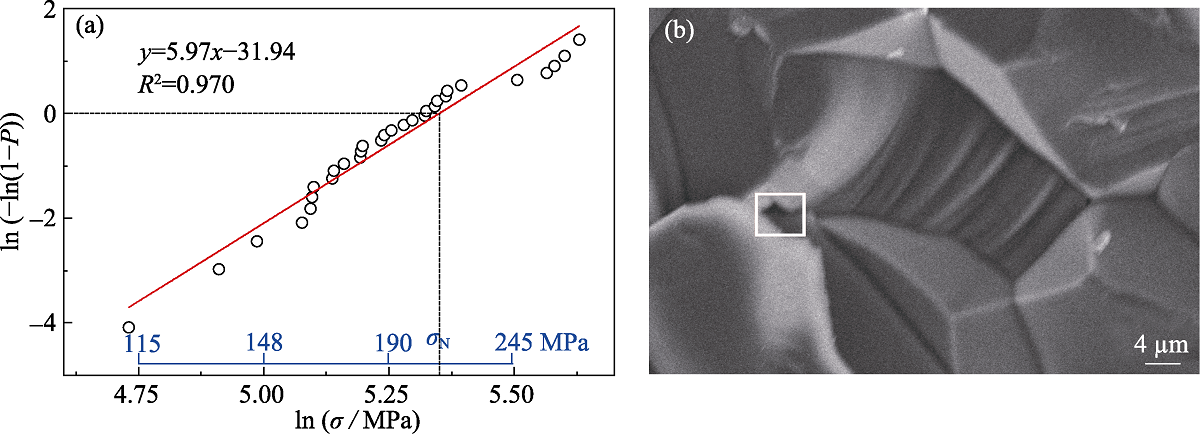

图3 Mg0.9Al2.08O3.97N0.03透明陶瓷的抗弯强度Weibull统计图(a)和断面SEM照片(b)

Fig. 3 Weibull plot of fracture strength (a) and SEM image of fractured surface (b) of Mg0.9Al2.08O3.97N0.03 transparent ceramic

图4 Mg0.9Al2.08O3.97N0.03和MgAl2O4透明陶瓷[27]在不同载荷速率下的抗弯强度(a)与强度-概率-时间关系图(b)

Fig. 4 Fractured strength under different load rates (a) and strength-probability-time diagram (b) of Mg0.9Al2.08O3.97N0.03 and MgAl2O4[27] transparent ceramics Colorful figures are available on website

| Sample | Vickers hardness/GPa | Fracture toughness/(MPa·m1/2) | Young’s modulus/GPa | Thermal expansion coefficient/(×10-6, K-1) |

|---|---|---|---|---|

| MgAl2O4[ | 12.9±0.49 | 1.6±0.1 | 273 | 6.97 |

| Mg0.9Al2.08O3.97N0.03 | 13.7±0.12 | 2.12±0.1 | 280 | 6.57 |

表1 Mg0.9Al2.08O3.97N0.03和MgAl2O4透明陶瓷的性能

Table 1 Property of Mg0.9Al2.08O3.97N0.03 and MgAl2O4 transparent ceramic

| Sample | Vickers hardness/GPa | Fracture toughness/(MPa·m1/2) | Young’s modulus/GPa | Thermal expansion coefficient/(×10-6, K-1) |

|---|---|---|---|---|

| MgAl2O4[ | 12.9±0.49 | 1.6±0.1 | 273 | 6.97 |

| Mg0.9Al2.08O3.97N0.03 | 13.7±0.12 | 2.12±0.1 | 280 | 6.57 |

| [1] |

RUBAT D M, KLEEBE H J, MÜLLER M M, et al. Fifty years of research and development coming to fruition; unraveling the complex interactions during processing of transparent magnesium aluminate (MgAl2O4) spinel. Journal of the American Ceramic Society, 2013, 96(11): 3341-3365.

DOI URL |

| [2] |

WAETZIG K, KRELL A, TRICE R. The effect of composition on the optical properties and hardness of transparent Al-rich MgO·nAl2O3 spinel ceramics. Journal of the American Ceramic Society, 2015, 99(3): 946-953.

DOI URL |

| [3] |

SANGHERA J, BAYYA S, VILLALOBOS G, et al. Transparent ceramics for high-energy laser systems. Optical Materials, 2011, 33(3): 511-518.

DOI URL |

| [4] |

PAPPAS J M, DONG X Y. Porosity characterization of additively manufactured transparent MgAl2O4 spinel by laser direct deposition. Ceramics International, 2020, 46(5): 6745-6755.

DOI URL |

| [5] |

SALEM J A, SGLAVO V. Transparent armor ceramics as spacecraft windows. Journal of the American Ceramic Society, 2013, 96(1): 281-289.

DOI URL |

| [6] |

ROTHMAN A, KALABUKHOV S, SVERDLOV N, et al. The effect of grain size on the mechanical and optical properties of spark plasma sintering-processed magnesium aluminate spinel MgAl2O4. International Journal of Applied Ceramic Technology, 2014, 11(1): 146-153.

DOI URL |

| [7] |

SOKOL M, KALABUKHOV S, SHNECK R, et al. Effect of grain size on the static and dynamic mechanical properties of magnesium aluminate spinel (MgAl2O4). Journal of the European Ceramic Society, 2017, 37(10): 3417-3424.

DOI URL |

| [8] |

NECINA V, PABST W. Grain growth of MgAl2O4 ceramics with LiF and NaF addition. Open Ceramics, 2021, 5(2): 100078.

DOI URL |

| [9] |

ZHANG H, WANG H, GU H, et al. Preparation of transparent MgO·1.8Al2O3 spinel ceramics by aqueous gelcasting, presintering and hot isostatic pressing. Journal of the European Ceramic Society, 2018, 38(11): 4057-4063.

DOI URL |

| [10] | YAN J, YAN W, CHEN Z, et al. A strategy for controlling microstructure and mechanical properties of microporous spinel (MgAl2O4) aggregates from magnesite and Al(OH)3. Journal of Alloys and Compounds, 2022, 896: 163088. |

| [11] | ZHANG P, LIU P, SUN Y, et al. Microstructure and properties of transparent MgAl2O4 ceramic fabricated by aqueous gelcasting. Journal of Alloys and Compounds, 2016, 657: 246-249. |

| [12] |

WILLEMS H X, WITH G D, METSELAAR R. Thermodynamics of AlON III: stabilization of AlON with MgO. Journal of the European Ceramic Society, 1993, 12(1): 43-49.

DOI URL |

| [13] |

ZONG X, WANG H, GU H, et al. A novel spinel-type Mg0.55Al2.36O3.81N0.19 transparent ceramic with infrared transmittance range comparable to c-plane sapphire. Scripta Materialia, 2020, 178(15): 428-432.

DOI URL |

| [14] |

LIU X, WANG H, TU B T, et al. Highly transparent Mg0.27Al2.58O3.73N0.27ceramic prepared by pressureless sintering. Journal of the American Ceramic Society, 2014, 97(1): 63-66.

DOI URL |

| [15] |

ZHANG Z, WANG H, TU B T, et al. Characterization and evaluation on mechanical property of Mg0.27Al2.58O3.73N0.27transparent ceramic. Journal of Inorganic Materials, 2018, 33(9): 1006-1010.

DOI |

| [16] |

ZONG X, WANG H, GU H, et al. Highly transparent Mg0.27Al2.58O3.73N0.27ceramic fabricated by aqueous gelcasting, pressureless sintering, and post-HIP. Journal of the American Ceramic Society, 2019, 102(11): 6507-6516.

DOI URL |

| [17] | GB/T 6569-2006, 精细陶瓷弯曲强度试验方法. |

| [18] |

GRANON A, GOEURIOT P, THEVENOT F, et al. Reactivity in the Al2O3-AlN-MgO system. The MgAlON spinel phase. Journal of the European Ceramic Society, 1994, 13(4): 365-370.

DOI URL |

| [19] |

KRELL A, HUTZLER T, KLIMKE J. Transmission physics and consequences for materials selection, manufacturing, and applications. Journal of the European Ceramic Society, 2009, 29(2): 207-221.

DOI URL |

| [20] |

WEMPLE S H, DIDOMENICO M J. Behavior of the electronic dielectric constant in covalent and ionic materials. Physical Review B, 1971, 3(4): 1338-1351.

DOI URL |

| [21] |

CAI B, KAINO T, SUGIHARA O. Sulfonyl-containing polymer and its alumina nanocomposite with high Abbe number and high refractive index. Optical Materials Express, 2015, 5(5): 1210-1216.

DOI URL |

| [22] | KLEIN C A. Flexural strength of infrared-transmitting window materials: bimodal Weibull statistical analysis. Optical Engineering, 2011, 50(2): 1-10. |

| [23] |

DENG B, JIANG D, GONG J. Is a three-parameter Weibull function really necessary for the characterization of the statistical variation of the strength of brittle ceramics? Journal of the European Ceramic Society, 2018, 38(4): 2234-2242.

DOI URL |

| [24] | KHALILI A. Statistical properties of Weibull estimators. Journal of Materials Science, 1991, 26: 6741-6752. |

| [25] |

TOKARIEV O, SCHNETTER L, BECK T, et al. Grain size effect on the mechanical properties of transparent spinel ceramics. Journal of the European Ceramic Society, 2013, 33(4): 749-757.

DOI URL |

| [26] |

MALZBENDER J, STEINBRECH R W. Threshold fracture stress of thin ceramic components. Journal of the European Ceramic Society, 2008, 28(1): 247-252.

DOI URL |

| [27] | TOKARIEV O, STEINBRECH R W, SCHNETTER L, et al. Micro- and macro-mechanical testing of transparent MgAl2O4 spinel. Journal of Materials Science, 2012, 47: 4821-4826. |

| [28] | CHOI S R. Slow crack growth analysis of brittle materials with finite thickness subjected to constant stress-rate flexural loading. Journal of Materials Science, 1999, 34: 3875-3882. |

| [29] |

RAMOS N D, CAMPOS T M, PAZ I S, et al. Microstructure characterization and SCG of newly engineered dental ceramics. Dental Materials, 2016, 32(7): 870-878.

DOI URL |

| [30] | EKATERINA N, KEYUR K, KIRA C, et al. Hall-Petch effect in binary and ternary alumina/zirconia/spinel composites. Journal of Materials Research and Technology, 2021, 11: 823-832. |

| [31] | SENTHIL K, BISWAS P, JOHNSON R, et al. Transparent ceramics for ballistic armor applications. Handbook of Advanced Ceramics and Composites, 2020, 11: 435-457. |

| [32] |

KRELL A, STRASSBURGER E, HUTZLER T, et al. Single and polycrystalline transparent ceramic armor with different crystal structure. Journal of the American Ceramic Society, 2013, 96(9): 2718-2721.

DOI URL |

| [33] |

IQBAL M J, ISMAIL B, RENTENBERGER C, et al. Modification of the physical properties of semiconducting MgAl2O4 by doping with a binary mixture of Co and Zn ions. Materials Research Bulletin, 2011, 46(12): 2271-2277.

DOI URL |

| [34] |

REN L, WANG H, TU B T, et al. Investigation on composition- dependent properties of Mg5xAl23-5xO27+5xN5-5x (0≤x≤1): Part II. Mechanical properties via first-principles calculations combined with bond valence models. Journal of the European Ceramic Society, 2021, 41(3): 4942-4950.

DOI URL |

| [1] | 叶君豪, 周真真, 胡辰, 王雁斌, 荆延秋, 李廷松, 程梓秋, 吴俊林, IVANOV Maxim, HRENIAK Dariusz, 李江. 共沉淀纳米粉体制备Yb:Sc2O3透明陶瓷的微结构与光学性能[J]. 无机材料学报, 2025, 40(2): 215-224. |

| [2] | 王月月, 黄佳慧, 孔红星, 李怀珠, 姚晓红. 载银放射状介孔二氧化硅的制备及其在牙科树脂中的应用[J]. 无机材料学报, 2025, 40(1): 77-83. |

| [3] | 吕朝阳, 徐勇, 杨久延, 涂广升, 涂兵田, 王皓. MgF2助剂对MgAl1.9Ga0.1O4透明陶瓷的制备与光学性能的影响[J]. 无机材料学报, 2024, 39(5): 531-538. |

| [4] | 杨平军, 李铁虎, 李昊, 党阿磊. 石墨烯对环氧树脂泡沫炭石墨化、电导率和力学性能的影响[J]. 无机材料学报, 2024, 39(1): 107-112. |

| [5] | 顾军毅, 范武刚, 张兆泉, 姚琴, 展红全. 还原制备Pr2O3粉体及其结构和光学性能研究[J]. 无机材料学报, 2023, 38(7): 771-777. |

| [6] | 李悦, 张旭良, 景芳丽, 胡章贵, 吴以成. 铈掺杂硼酸钙镧晶体的生长与性能研究[J]. 无机材料学报, 2023, 38(5): 583-588. |

| [7] | 靳喜海, 董满江, 阚艳梅, 梁波, 董绍明. 透明AlON陶瓷凝胶浇注成型及其无压烧结制备[J]. 无机材料学报, 2023, 38(2): 193-198. |

| [8] | 王海东, 王燕, 朱昭捷, 李坚富, LAKSHMINARAYANA Gandham, 涂朝阳. Dy3+掺杂SrGdGa3O7晶体的晶体生长, 结构、光学和可见光荧光特性[J]. 无机材料学报, 2023, 38(12): 1475-1482. |

| [9] | 汪德文, 王俊平, 袁厚呈, 刘章, 周进, 邓佳杰, 王鑫, 吴贲华, 章健, 王士维. 真空反应烧结制备米级尺寸钇铝石榴石(YAG)透明陶瓷[J]. 无机材料学报, 2023, 38(12): 1483-1484. |

| [10] | 孙小凡, 陈小武, 靳喜海, 阚艳梅, 胡建宝, 董绍明. 低温反应熔渗工艺制备AlN-SiC复相陶瓷及其性能研究[J]. 无机材料学报, 2023, 38(10): 1223-1229. |

| [11] | 母利成, 杨金萍, 王俊平, 赵瑾, 刘梦玮, 汪德文, 章健. 环氧树脂改性自发凝固成型制备YAG透明陶瓷[J]. 无机材料学报, 2022, 37(9): 941-946. |

| [12] | 刘强, 王倩, 陈鹏辉, 李晓英, 章立轩, 谢腾飞, 李江. 两步烧结法制备红色Ce:8YSZ透明陶瓷及其性能研究[J]. 无机材料学报, 2022, 37(8): 911-917. |

| [13] | 肖舒琳, 戴中华, 李定妍, 张凡博, 杨利红, 任晓兵. 氧化镧掺杂铌酸钾钠陶瓷的电、光性能研究[J]. 无机材料学报, 2022, 37(5): 520-526. |

| [14] | 魏婷婷, 高希光, 宋迎东. 2D SiC/SiC复合材料电阻率对服役环境的响应特性[J]. 无机材料学报, 2022, 37(4): 420-426. |

| [15] | 荆延秋, 刘强, 苏莎, 李晓英, 刘子玉, 王静雅, 李江. 1.5 μm被动调Q可饱和吸收体用Co:MgAl 2O4透明陶瓷的制备[J]. 无机材料学报, 2021, 36(8): 877-882. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||