无机材料学报 ›› 2022, Vol. 37 ›› Issue (8): 911-917.DOI: 10.15541/jim20220025 CSTR: 32189.14.10.15541/jim20220025

刘强1( ), 王倩1,2, 陈鹏辉2,3, 李晓英2,3, 章立轩2,3, 谢腾飞2,3, 李江2,3(

), 王倩1,2, 陈鹏辉2,3, 李晓英2,3, 章立轩2,3, 谢腾飞2,3, 李江2,3( )

)

收稿日期:2022-01-17

修回日期:2022-03-17

出版日期:2022-08-20

网络出版日期:2022-04-07

通讯作者:

李 江, 研究员. E-mail: lijiang@mail.sic.ac.cn作者简介:刘 强(1964-), 男, 教授. E-mail: lq88611338@163.com

LIU Qiang1( ), WANG Qian1,2, CHEN Penghui2,3, LI Xiaoying2,3, ZHANG Lixuan2,3, XIE Tengfei2,3, LI Jiang2,3(

), WANG Qian1,2, CHEN Penghui2,3, LI Xiaoying2,3, ZHANG Lixuan2,3, XIE Tengfei2,3, LI Jiang2,3( )

)

Received:2022-01-17

Revised:2022-03-17

Published:2022-08-20

Online:2022-04-07

Contact:

LI Jiang, professor. E-mail: lijiang@mail.sic.ac.cnAbout author:LIU Qiang (1964-), male, professor. E-mail: lq88611338@163.com

Supported by:摘要:

彩色氧化锆陶瓷具有鲜艳色彩、高折射率、耐磨损、耐腐蚀及对人体无毒等优点, 被广泛应用于电子、装饰等领域。本研究采用共沉淀法合成了平均粒径为15.9 nm的立方相Ce:8YSZ纳米粉体。以经过800 ℃煅烧4 h的粉体为原料, 通过两步烧结技术制备了具有高光学透过率和高红色度的Ce:8YSZ透明陶瓷,并系统研究了空气预烧温度对红色Ce:8YSZ透明陶瓷微观结构、直线透过率和色度的影响。当预烧温度从1200 ℃升高到1300 ℃时, Ce:8YSZ陶瓷的平均晶粒尺寸从0.3 μm增大到2.2 μm, 同时相对密度从87.2%增加到97.1%。经过1275 ℃空气预烧2 h并结合1700 ℃热等静压烧结3 h所得的Ce:8YSZ透明陶瓷表现出最佳的光学质量和最大的红色度值, 在700 nm处的直线透过率为47.6%, 红色度为52.0。

中图分类号:

刘强, 王倩, 陈鹏辉, 李晓英, 章立轩, 谢腾飞, 李江. 两步烧结法制备红色Ce:8YSZ透明陶瓷及其性能研究[J]. 无机材料学报, 2022, 37(8): 911-917.

LIU Qiang, WANG Qian, CHEN Penghui, LI Xiaoying, ZHANG Lixuan, XIE Tengfei, LI Jiang. Fabrication and Characterizations of Red Ce-doped 8YSZ Transparent Ceramics by Two-step Sintering[J]. Journal of Inorganic Materials, 2022, 37(8): 911-917.

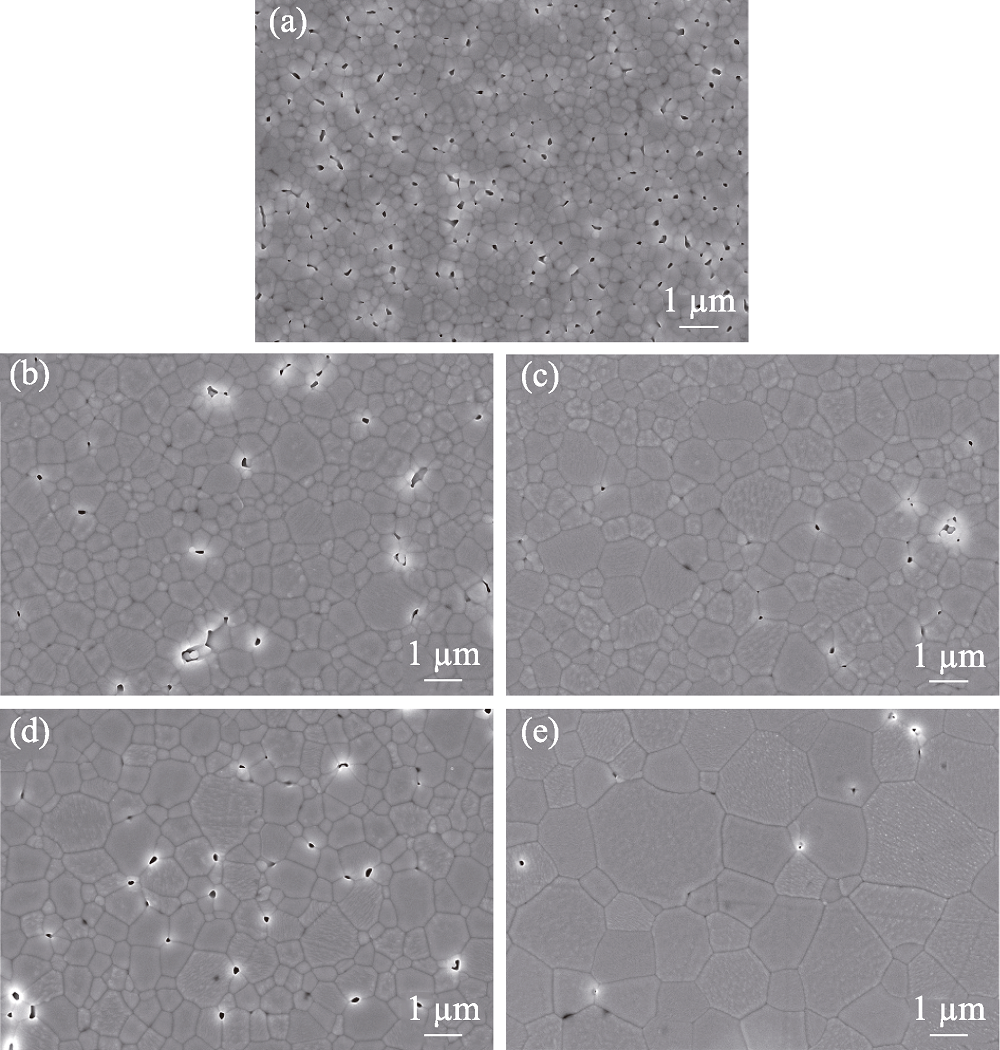

Fig. 4 FESEM micrographs of the thermally etched surfaces of Ce-doped 8YSZ ceramics pre-sintered at different temperatures in air for 2 h (a) 1200 ℃; (b) 1230 ℃; (c) 1250 ℃; (d) 1275 ℃; (e) 1300 ℃

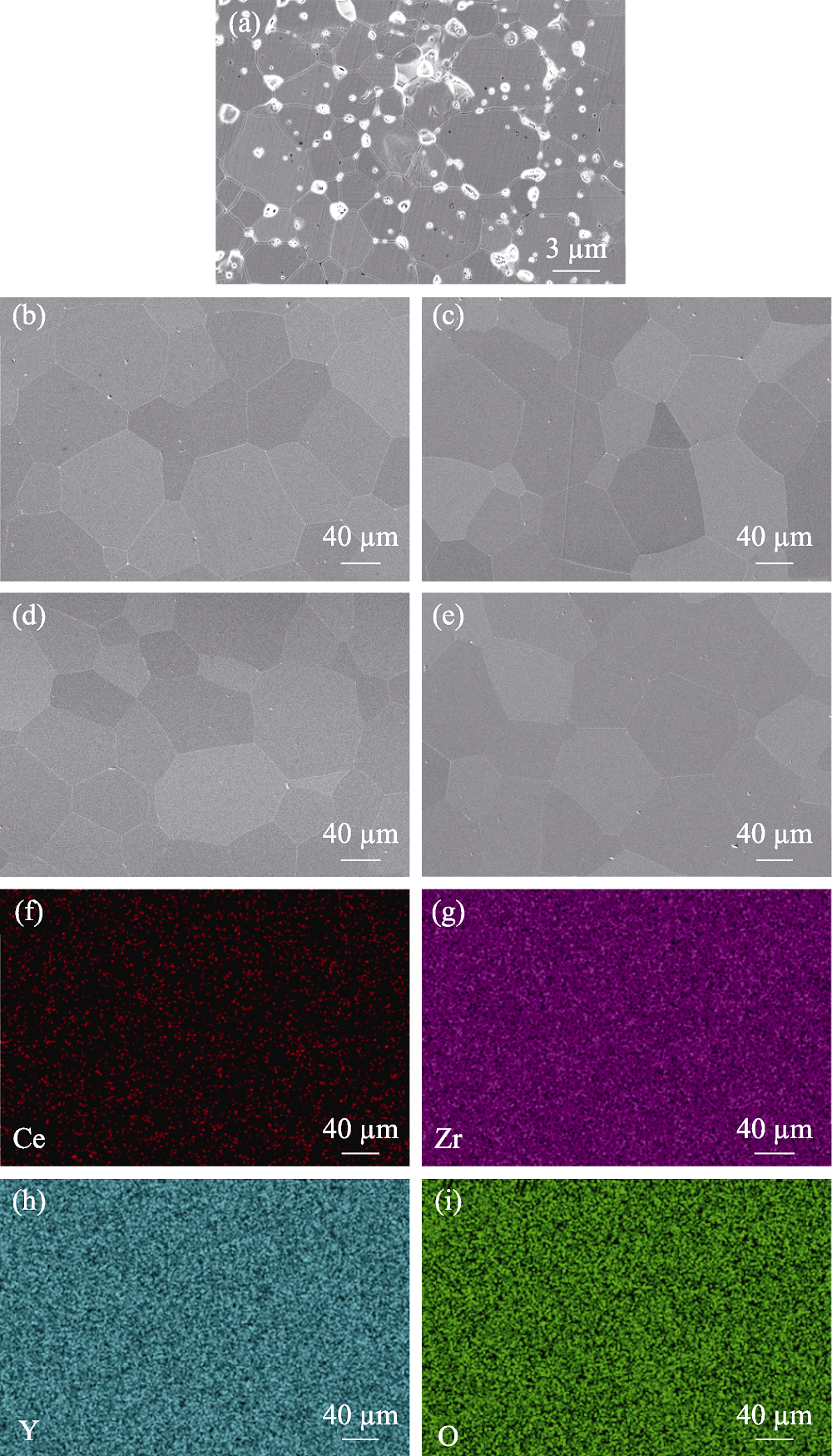

Fig. 6 (a-e) FESEM micrographs of the thermally etched surfaces of Ce-doped 8YSZ ceramics pre-sintered at 1200- 1300 ℃ for 2 h and HIP post-treatment at 1700 ℃ for 3 h; (f-i) EDS element mapping of the Ce-doped 8YSZ ceramics pre-sintered at 1275 ℃ (a) 1200 ℃; (b) 1230 ℃; (c) 1250 ℃; (d) 1275 ℃; (e) 1300 ℃

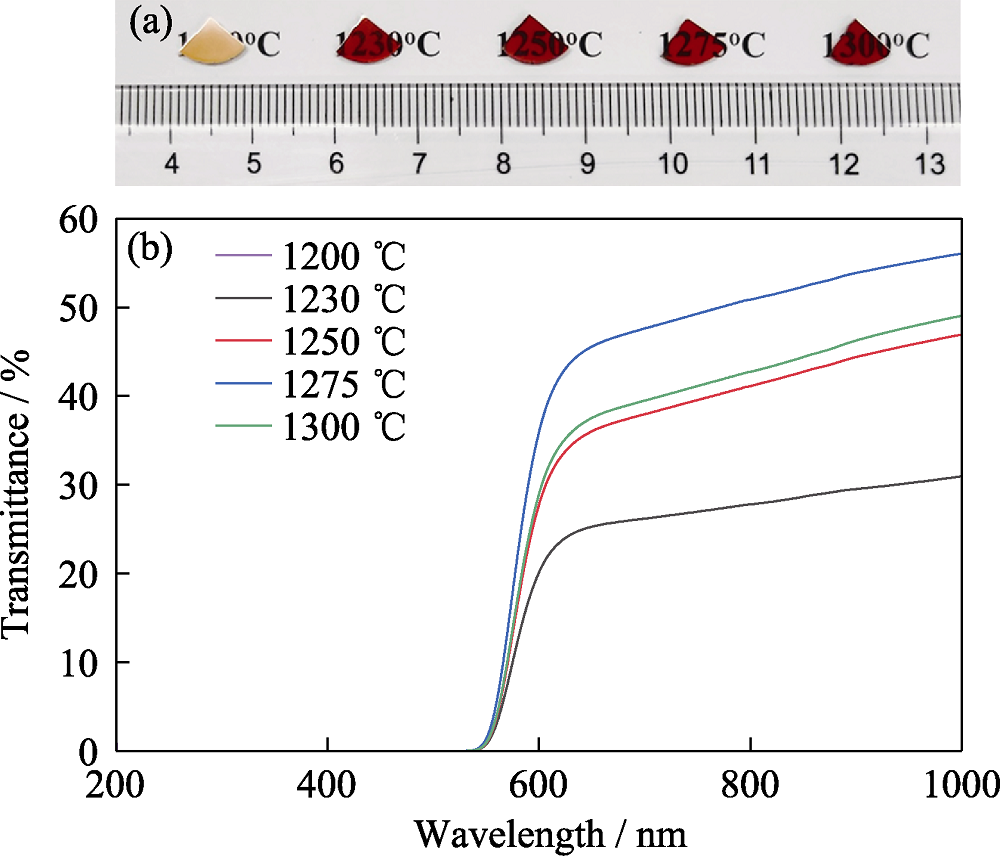

Fig. 8 (a) Photograph and (b) in-line transmittance of the Ce-doped 8YSZ ceramics (1 mm thick) pre-sintered at 1200-1300 ℃ in air for 2 h and HIP post-treatment at 1700 ℃ for 3 h under 176 MPa in Ar atmosphere

| Pre-sintering temperature/℃ | Value of CIE | ||

|---|---|---|---|

| L* | a* | b* | |

| 1230 | 31.8 | 42.5 | 54.7 |

| 1250 | 37.4 | 48.6 | 64.3 |

| 1275 | 42.4 | 52.0 | 72.9 |

| 1300 | 37.7 | 48.9 | 64.8 |

Table 1 CIE value of Ce-doped 8YSZ ceramics pre- sintered at 1230-1300 ℃ for 2 h and HIP post-treatment at 1700 ℃ for 3 h

| Pre-sintering temperature/℃ | Value of CIE | ||

|---|---|---|---|

| L* | a* | b* | |

| 1230 | 31.8 | 42.5 | 54.7 |

| 1250 | 37.4 | 48.6 | 64.3 |

| 1275 | 42.4 | 52.0 | 72.9 |

| 1300 | 37.7 | 48.9 | 64.8 |

| [1] | ZHANG X X, ZHU D B, LIANG J S. Progress on hydrothermal stability of dental zirconia ceramics. J. Inorg. Mater., 2020, 35(7): 759-768. |

| [2] |

LV H D, BAO J X, RUAN F, et al. Preparation and properties of black Ti-doped zirconia ceramics. J. Mater. Res. Technol., 2020, 9(3): 6201-6208.

DOI URL |

| [3] |

SANI E, SCITI D, CAPIANI C, et al. Colored zirconia with high absorbance and solar selectivity. Scr. Mater., 2020, 186: 147-151.

DOI URL |

| [4] |

LAGANOVSKA K, OLSTEINS D, SMITS K, et al. Formation of translucent nanostructured zirconia ceramics. J. Eur. Ceram. Soc., 2021, 41(13): 6641-6648.

DOI URL |

| [5] |

LEI L W, FU Z Y, WANG H, et al. Transparent yttria stabilized zirconia from glycine-nitrate process by spark plasma sintering. Ceram. Int., 2012, 38(1): 23-28.

DOI URL |

| [6] | IKESUE A. Processing of ceramics:breakthroughs in optical materials. Hoboken: John Wiley and Sons, 2021 : 275-348. |

| [7] |

BEJUGAMA S, CHAMEETTACHAL S, PATI F, et al. In vitro cellular response and hydrothermal aging of two-step sintered Nb2O5 doped ceria stabilized zirconia ceramics. Ceram. Int., 2021, 47(2): 1594-1601.

DOI URL |

| [8] |

WOOD D L, NASSAU K. Refractive index of cubic zirconia stabilized with yttria. Appl. Opt., 1982, 21(16): 2978-2981.

DOI URL |

| [9] | TIAN T, XU J Y, ZHAN Z G, et al. Study on the spectral characteristics of emerald-like cubic zirconia crystal. J. Synth. Cryst., 2015, 44(3): 581-586. |

| [10] |

DASHA A, KIMB B N, KLIMKEC J, et al. Transparent tetragonal-cubic zirconia composite ceramics densified by spark plasma sintering and hot isostatic pressing. J. Eur. Ceram. Soc., 2019, 39(4): 1428-1435.

DOI URL |

| [11] |

ZHANG H B, KIM B N, MORITA K, et al. Optimization of high-pressure sintering of transparent zirconia with nano-sized grains. J. Alloys Compd., 2010, 508(1): 196-199.

DOI URL |

| [12] |

ZHANG H B, KIM B N, MORITA K, et al. Optical properties and microstructure of nanocrystalline cubic zirconia prepared by high-pressure spark plasma sintering. J. Am. Ceram. Soc., 2011, 94(9): 2981-2986.

DOI URL |

| [13] | TIAN F, CHEN C, LIU Y, et al. Fabrication of Nd:YAG transparent ceramics from co-precipitated powders by vacuum pre- sintering and HIP post-treatment. Opt. Mater., 2020, 101: 109728. |

| [14] |

TSUKUMA K. Transparent titania-yttria-zirconia ceramics. J. Mater. Sci. Lett., 1986, 5: 1143-1144.

DOI URL |

| [15] |

TSUKUMA K, YAMASHITA I, KUSUNOSE T. Transparent 8mol% Y2O3-ZrO2 (8Y) ceramics. J. Am. Ceram. Soc., 2010, 91(3): 813-818.

DOI URL |

| [16] |

PEUCHERT U, OKANO Y, MENKE Y, et al. Transparent cubic-ZrO2 ceramics for application as optical lenses. J. Eur. Ceram. Soc., 2009, 29(2): 283-291.

DOI URL |

| [17] |

LIU Q, CHEN P H, JIANG N, et al. Fabrication and characterizations of 8.7mol% Y2O3-ZrO2 transparent ceramics using co-precipitated nanopowders. Scr. Mater., 2019, 171: 98-101.

DOI URL |

| [18] | LUO J M, CAO Z C, DENG L P, et al. Preparation and luminescence property of Ho3+/Yb3+:8YSZ nanopowders. J. Synth. Cryst., 2017, 46(10): 1902-1906. |

| [19] |

HUANG X Y, LIU Y M, LIU Y, et al. Fabrication and characterizations of Yb:YAG transparent ceramics using alcohol- water co-precipitation method. J. Inorg. Mater., 2021, 36(2): 217-224.

DOI URL |

| [20] |

LI X Y, SNETKOV I L, YAKOVLEV A, et al. Fabrication and performance evaluation of novel transparent ceramics RE:Tb3Ga5O12(RE=Pr, Tm, Dy) toward magneto-optical application. J. Adv. Ceram., 2021, 10(2): 271-278.

DOI URL |

| [21] |

LIU Z Y, TOCI G, PIRRI A, et al. Fabrication, microstructures, and optical properties of Yb:Lu2O3 laser ceramics from co-precipitated nano-powders. J. Adv. Ceram., 2020, 9(6): 674-682.

DOI URL |

| [22] | CHEN P H, LIU Q, LI X Y, et al. Influence of terminal pH value on co-precipitated nanopowders for yttria-stabilized ZrO2 transparent ceramics. Opt. Mater., 2019, 98: 109475. |

| [23] |

LV H D, BAO J X, QI S Y, et al. Optical and mechanical properties of purple zirconia ceramics. J. Asian Ceram. Soc., 2019, 7(3): 306-311.

DOI URL |

| [24] |

RӦMER H, LUTHER K D, ASSMUS W. Coloured zirconia. Cryst. Res. Technol., 1994, 29(6): 787-794.

DOI URL |

| [25] |

LV H D, BAO J X, CHAO L M, et al. Development mechanism of Ce-doped red zirconia ceramics prepared by a high-temperature reduction method. J. Alloys Compd., 2019, 797: 931-939.

DOI URL |

| [26] |

LEE D Y, KIM D J, SONG Y S. Chromaticity, hydrothermal stability, and mechanical properties of t-ZrO2/Al2O3 composites doped with yttrium, niobium, and ferric oxides. J. Mater. Sci. Eng. A, 2000, 289(1/2): 1-7.

DOI URL |

| [27] |

HOLZA L, MACIASB J, VITORINOB N, et al. Effect of Fe2O3 doping on colour and mechanical properties of Y-TZP ceramics. Ceram. Int., 2018, 44(15): 17962-17971.

DOI URL |

| [28] |

JOVANÍ M, FORTUÑO-MORTE M, BELTRÁN-MIR H, et al. Environmental-friendly red-orange ceramic pigment based on Pr and Fe co-doped Y2Zr2O7. J. Eur. Ceram. Soc., 2018, 38(4): 2210-2217.

DOI URL |

| [29] |

WILLEMS E, ZHANG F, VAN MEERBEEK B, et al. Iron oxide colouring of highly-translucent 3Y-TZP ceramics for dental restorations. J. Eur. Ceram. Soc., 2019, 39(2/3): 499-507.

DOI URL |

| [30] |

SALEHI S, FATHI M H. Fabrication and characterization of Sol-Gel derived hydroxyapatite/zirconia composite nanopowders with various yttria contents. Ceram. Int., 2010, 36(5): 1659-1667.

DOI URL |

| [31] |

SU S, LIU Q, HU Z W, et al. A simple way to prepare Co:MgAl2O4 transparent ceramics for saturable absorber. J. Alloys Compd., 2019, 797: 1288-1294.

DOI URL |

| [32] | CHEN P H, LIU Q, FENG Y G, et al. Transparent Y0.16Zr0.84O1.92 ceramics sintered from co-precipitated nanopowder. Opt. Mater., 2020, 100: 109645-1-6. |

| [33] |

NIKL M, LAGUTA V V, VEDDA A. Complex oxide scintillators: material defects and scintillation performance. Phys. Stat. Sol., 2008, 245(9): 1701-1722.

DOI URL |

| [1] | 叶君豪, 周真真, 胡辰, 王雁斌, 荆延秋, 李廷松, 程梓秋, 吴俊林, IVANOV Maxim, HRENIAK Dariusz, 李江. 共沉淀纳米粉体制备Yb:Sc2O3透明陶瓷的微结构与光学性能[J]. 无机材料学报, 2025, 40(2): 215-224. |

| [2] | 吕朝阳, 徐勇, 杨久延, 涂广升, 涂兵田, 王皓. MgF2助剂对MgAl1.9Ga0.1O4透明陶瓷的制备与光学性能的影响[J]. 无机材料学报, 2024, 39(5): 531-538. |

| [3] | 顾军毅, 范武刚, 张兆泉, 姚琴, 展红全. 还原制备Pr2O3粉体及其结构和光学性能研究[J]. 无机材料学报, 2023, 38(7): 771-777. |

| [4] | 李悦, 张旭良, 景芳丽, 胡章贵, 吴以成. 铈掺杂硼酸钙镧晶体的生长与性能研究[J]. 无机材料学报, 2023, 38(5): 583-588. |

| [5] | 王海东, 王燕, 朱昭捷, 李坚富, LAKSHMINARAYANA Gandham, 涂朝阳. Dy3+掺杂SrGdGa3O7晶体的晶体生长, 结构、光学和可见光荧光特性[J]. 无机材料学报, 2023, 38(12): 1475-1482. |

| [6] | 李文俊, 王皓, 涂兵田, 谌强国, 郑凯平, 王为民, 傅正义. 宽光谱透过Mg0.9Al2.08O3.97N0.03透明陶瓷的制备与性能研究[J]. 无机材料学报, 2022, 37(9): 969-975. |

| [7] | 荆延秋, 刘强, 苏莎, 李晓英, 刘子玉, 王静雅, 李江. 1.5 μm被动调Q可饱和吸收体用Co:MgAl 2O4透明陶瓷的制备[J]. 无机材料学报, 2021, 36(8): 877-882. |

| [8] | 刘子玉, TOCI Guido, PIRRI Angela, PATRIZI Barbara, 冯亚刚, 陈肖朴, 胡殿君, 田丰, 吴乐翔, VANNINIMatteo, 李江. 固体激光用Nd:Lu2O3透明陶瓷的制备和光学性能研究[J]. 无机材料学报, 2021, 36(2): 210-216. |

| [9] | 黄新友, 刘玉敏, 刘洋, 李晓英, 冯亚刚, 陈肖朴, 陈鹏辉, 刘欣, 谢腾飞, 李江. 醇水共沉淀法制备Yb:YAG透明陶瓷及其性能研究[J]. 无机材料学报, 2021, 36(2): 217-224. |

| [10] | 朱丹阳, 钱康, 陈肖朴, 胡泽望, 刘欣, 李晓英, 潘裕柏, MIHÓKOVÁ Eva, NIKL Martin, 李江. 热等静压烧结制备细晶粒Ce,Y:SrHfO3闪烁陶瓷[J]. 无机材料学报, 2021, 36(10): 1118-1124. |

| [11] | 韦家蓓, TOCIGuido, PIRRIAngela, PATRIZIBarbara, 冯亚刚, VANNINIMatteo, 李江. 共沉淀纳米粉体制备Yb:CaF2激光陶瓷及其性能研究[J]. 无机材料学报, 2019, 34(12): 1341-1348. |

| [12] | 张金诚, 王皓, 徐鹏宇, 涂兵田, 王为民, 傅正义. ZnO·2.56Al2O3透明陶瓷凝胶注模成型与烧结制备[J]. 无机材料学报, 2019, 34(10): 1072-1076. |

| [13] | 刘小元, 刘宝丹, 姜亚南, 王柯, 周洋, 杨兵, 张兴来, 姜辛. 形貌可控及光学吸收性能可调的钙钛矿型SrTiO3纳米结构的原位生长[J]. 无机材料学报, 2019, 34(1): 65-71. |

| [14] | 杨锁龙, 王晓方, 蒋春丽, 赵雅文, 曾荣光, 王怀胜, 赖新春. InP量子点的掺杂及其光学性能[J]. 无机材料学报, 2016, 31(10): 1051-1057. |

| [15] | 周 鼎, 施 鹰, 范灵聪, 林德宝, 孙泽清, 徐家跃. Ce, Pr离子双掺LuAG透明陶瓷制备及光学性能[J]. 无机材料学报, 2016, 31(10): 1099-1102. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||