无机材料学报 ›› 2023, Vol. 38 ›› Issue (7): 763-770.DOI: 10.15541/jim20220635 CSTR: 32189.14.10.15541/jim20220635

所属专题: 【生物材料】骨骼与齿类组织修复(202506); 【制备方法】3D打印(202506)

施哲1,2( ), 刘伟业2,3, 翟东2, 谢建军1(

), 刘伟业2,3, 翟东2, 谢建军1( ), 朱钰方2(

), 朱钰方2( )

)

收稿日期:2022-10-27

修回日期:2022-11-23

出版日期:2023-12-30

网络出版日期:2022-12-28

通讯作者:

谢建军, 副教授. E-mail: xiejianjun@shu.edu.cn;作者简介:施 哲(1998-), 男, 硕士研究生. E-mail: zheshi1998@163.com

基金资助:

SHI Zhe1,2( ), LIU Weiye2,3, ZHAI Dong2, XIE Jianjun1(

), LIU Weiye2,3, ZHAI Dong2, XIE Jianjun1( ), ZHU Yufang2(

), ZHU Yufang2( )

)

Received:2022-10-27

Revised:2022-11-23

Published:2023-12-30

Online:2022-12-28

Contact:

XIE Jianjun, associate professor. E-mail: xiejianjun@shu.edu.cn;About author:SHI Zhe (1998-), male, Master candidate. E-mail: zheshi1998@163.com

Supported by:摘要:

具备良好成骨性能和降解速率的生物陶瓷骨组织工程支架在骨修复领域极具应用潜力。镁黄长石(Ca2MgSi2O7)因其具有良好的力学性能、生物降解能力以及促成骨性能而备受关注。本研究以硅树脂为聚合物前驱体、碳酸钙与氧化镁为活性填料制备打印浆料, 采用挤出式3D打印技术在室温条件下制备支架素坯, 并在惰性气氛下高温烧结制备了镁黄长石生物陶瓷支架, 并对比研究了镁黄长石支架与斜硅钙石(Ca2SiO4)、镁橄榄石(Mg2SiO4)支架在结构、抗压强度、体外降解能力以及体外生物学性能等方面的差异。结果表明: 镁黄长石支架与斜硅钙石、镁橄榄石支架具有相似的三维多孔结构, 抗压强度、降解速率介于镁橄榄石和斜硅钙石之间, 但促进骨髓间充质干细胞的成骨基因表达能力显著强于镁橄榄石和斜硅钙石支架。本研究证实采用3D打印制备的镁黄长石支架有望作为骨组织工程较理想的支架。

中图分类号:

施哲, 刘伟业, 翟东, 谢建军, 朱钰方. 3D打印制备镁黄长石生物陶瓷骨组织工程支架及其性能[J]. 无机材料学报, 2023, 38(7): 763-770.

SHI Zhe, LIU Weiye, ZHAI Dong, XIE Jianjun, ZHU Yufang. Akermanite Scaffolds for Bone Tissue Engineering: 3D Printing Using Polymer Precursor and Scaffold Properties[J]. Journal of Inorganic Materials, 2023, 38(7): 763-770.

图2 (a1, a2)C2S、(b1, b2)AKT和(c1, c2)M2S 生物陶瓷支架的表面SEM照片

Fig. 2 SEM images of the surfaces of bioceramic scaffolds (a1, a2) C2S, (b1, b2) AKT and (c1, c2) M2S

图3 (a1~a3)C2S、(b1~b3)AKT和(c1~c3)M2S生物陶瓷支架的断面SEM照片

Fig. 3 SEM images of the fracture surfaces of bioceramic scaffolds (a1-a3) C2S, (b1-b3) AKT and (c1-c3) M2S

图4 C2S、AKT和M2S生物陶瓷支架的(a)孔隙率和(b)抗压强度

Fig. 4 (a) Porosities and (b) compressive strengths of C2S, AKT and M2S bioceramic scaffolds *P < 0.05; **P < 0.01; ***P < 0.001

图5 (a) C2S、AKT和M2S支架在Tris-HCl溶液中浸泡21 d的降解剩余质量和 (b) 溶液的pH变化曲线

Fig. 5 (a) Residual mass curves and (b) pH changes of C2S, AKT and M2S bioceramic scaffolds after soaking in Tris-HCl buffer for 21 d

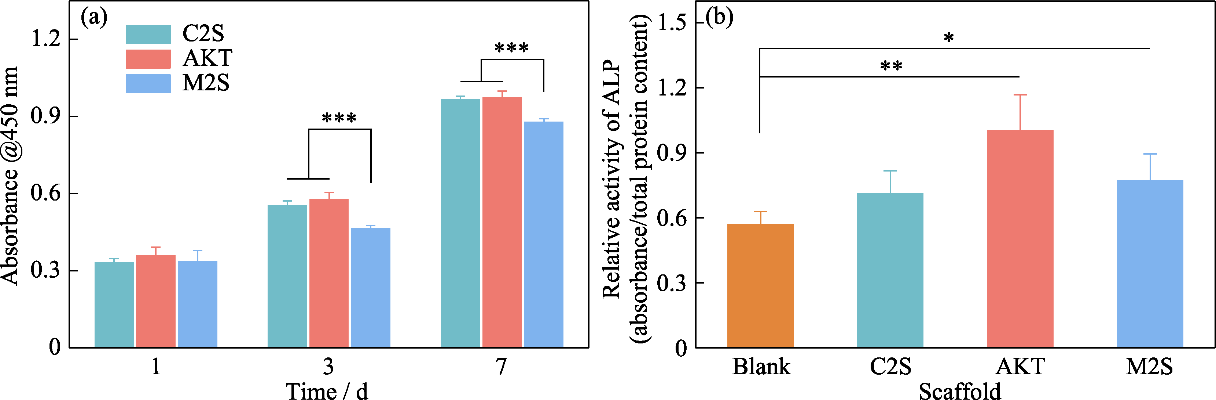

图6 rBMSCs在C2S、AKT和M2S支架上(a)培养1、3和7 d的细胞增殖情况和(b)培养7 d的碱性磷酸酶(ALP)相对活性表达

Fig. 6 (a) Cell proliferation of culturing for 1, 3 and 7 d and (b) relative activity of alkaline phosphatase of rBMSCs culturing for 7 d on C2S, AKT and M2S bioceramic scaffolds, respectively *P < 0.05; **P < 0.01; ***P < 0.001

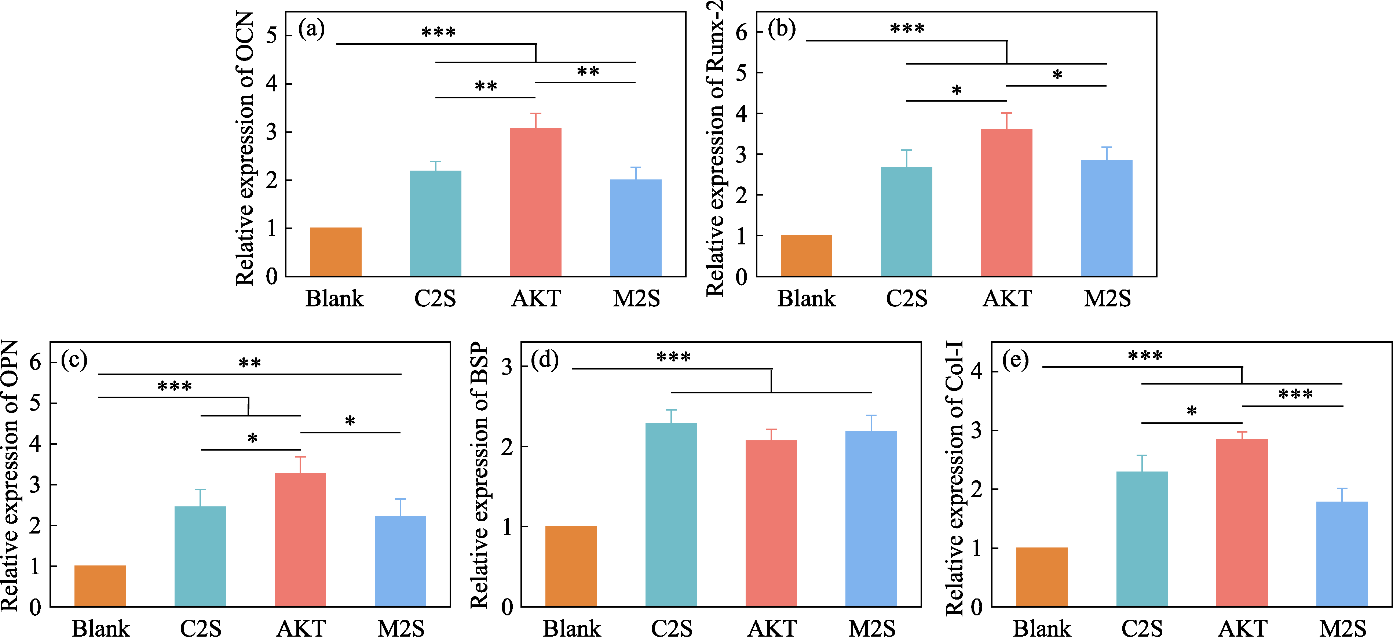

图7 rBMSCs在C2S、AKT和M2S支架上培养7 d的相关成骨基因的表达

Fig. 7 Related osteogenic gene expression of rBMSCs on C2S, AKT and M2S scaffolds after culturing for 7 d (a) OCN; (b) Runx-2; (c) OPN; (d) BSP; (e) Col-Ⅰ *P < 0.05; **P < 0.01; ***P < 0.001

| [1] |

YAO Y X, QIN W, XING B H, et al. High performance hydroxyapatite ceramics and a triply periodic minimum surface structure fabricated by digital processing 3D printing. Journal of Advanced Ceramics, 2021, 10(1):39.

DOI |

| [2] |

PAN M Z, HUA S B, WU J M, et al. Preparation and properties of T-ZnOw enhanced BCP scaffolds with double-layer structure by digital light processing. Journal of Advanced Ceramics, 2022, 11(4):570.

DOI |

| [3] |

HAUGEN H J, LYNGSTADAAS S P, ROSSI F, et al. Bone grafts: which is the ideal biomaterial. J. Clin. Periodontology, 2019, 46(Suppl 21):92.

DOI URL |

| [4] |

WANG C, HUANG W, ZHOU Y, et al. 3D printing of bone tissue engineering scaffolds. Bioactive Materials, 2020, 5(1):82.

DOI PMID |

| [5] |

KOONS G L, DIBA M, MIKOS A G. Materials design for bone- tissue engineering. Nature Reviews Materials, 2020, 5(8):584.

DOI |

| [6] |

ZHANG Y, LIU X, ZENG L, et al. Polymer fiber scaffolds for bone and cartilage tissue engineering. Advanced Functional Materials, 2019, 29(36):1903279.

DOI URL |

| [7] | XU C, WU F, YANG J, et al. 3D printed long-term structurally stable bioceramic dome scaffolds with controllable biodegradation favorable for guided bone regeneration. Chemical Engineering Journal, 2022, 450: 138003. |

| [8] | WANG J, PENG Y, CHEN M, et al. Next-generation finely controlled graded porous antibacterial bioceramics for high- efficiency vascularization in orbital reconstruction. Bioactive Materials, 2022, 16: 334. |

| [9] |

TURNBULL G, CLARKE J, PICARD F, et al. 3D bioactive composite scaffolds for bone tissue engineering. Bioactive Materials, 2018, 3(3):278.

DOI PMID |

| [10] | MA H S, FENG C, CHANG J, et al. 3D-printed bioceramic scaffolds: from bone tissue engineering to tumor therapy. Acta Biomaterialia, 2018, 79: 37. |

| [11] |

ELIAZ N, METOKI N. Calcium phosphate bioceramics: a review of their history, structure, properties, coating technologies and biomedical applications. Materials, 2017, 10(4):334.

DOI URL |

| [12] | YU X, WU C. Recent development on function improvements of 3D printed bioceramics. Journal of the Chinese Ceramic Society, 2021, 49(5):829. |

| [13] |

LI T, ZHAI D, MA B, et al. 3D printing of hot dog-like biomaterials with hierarchical architecture and distinct bioactivity. Advanced Science, 2019, 6(19):1901146.

DOI URL |

| [14] |

WU C T, CHANG J. A novel akermanite bioceramic: preparation and characteristics. Journal of Biomaterials Applications, 2006, 21(2):119.

PMID |

| [15] |

LIU Q H, CEN L, YIN S, et al. A comparative study of proliferation and osteogenic differentiation of adipose-derived stem cells on akermanite and beta-TCP ceramics. Biomaterials, 2008, 29(36):4792.

DOI PMID |

| [16] |

CASTILHO M, RODRIGUES J, PIRES I, et al. Fabrication of individual alginate-TCP scaffolds for bone tissue engineering by means of powder printing. Biofabrication, 2015, 7(1):015004.

DOI URL |

| [17] |

ZHANG M, LIN R C, WANG X, et al. 3D printing of Haversian bone-mimicking scaffolds for multicellular delivery in bone regeneration. Science Advances, 2020, 6(12):eaaz6725.

DOI URL |

| [18] |

FENG C, ZHANG W J, DENG C J, et al. 3D printing of lotus root-like biomimetic materials for cell delivery and tissue regeneration. Advanced Science, 2017, 4(12):1700401.

DOI URL |

| [19] |

WU C, CHANG J. Degradation, bioactivity, and cytocompatibility of diopside, akermanite, and bredigite ceramics. Journal of Biomedical Materials Research Part B-Applied Biomaterials, 2007, 83B(1):153

DOI URL |

| [20] |

YU W, SUN X, MENG H Y, et al. 3D printed porous ceramic scaffolds for bone tissue engineering: a review. Biomaterials Science, 2017, 5(9):1690.

DOI PMID |

| [21] | HAN Z K, FENG P, GAO C D, et al. Microstructure, mechanical properties and in vitro bioactivity of akermanite scaffolds fabricated by laser sintering. Biomedical Materials and Engineering, 2014, 24(6): 2073. |

| [22] |

WU C T, CHANG J A, ZHAI W Y, et al. Porous akermanite scaffolds for bone tissue engineering: preparation, characterization, and in vitro studies. Journal of Biomedical Materials Research Part B-Applied Biomaterials, 2006, 78B(1):47.

DOI URL |

| [23] |

CHEN L, ZHAI D, WU C T, et al. Poly(D, L-lactic)-reinforced akermanite bioceramic scaffolds: preparation and characterization. Ceramics International, 2014, 40(8):12765.

DOI URL |

| [24] | NAJAFINEZHAD A, ABDELLAHI M, NASIRI-HARCHEGANI S, et al. On the synthesis of nanostructured akermanite scaffolds via space holder method: the effect of the spacer size on the porosity and mechanical properties. Journal of the Mechanical Behavior of Biomedical Materials, 2017, 69: 242. |

| [25] |

FU S Y, ZHU M, ZHU Y F. Organosilicon polymer-derived ceramics: an overview. Journal of Advanced Ceramics, 2019, 8(4):457.

DOI |

| [26] |

ZOCCA A, ELSAYED H, BERNARDO E, et al. 3D-printed silicate porous bioceramics using a non-sacrificial preceramic polymer binder. Biofabrication, 2015, 7(2):025008.

DOI URL |

| [27] | FIOCCO L, LI S, STEVENS M M, et al. Biocompatibility and bioactivity of porous polymer-derived Ca-Mg silicate ceramics. Acta Biomaterialia, 2017, 50: 56. |

| [28] |

FIOCCO L, ELSAYED H, FERRONI L, et al. Bioactive wollastonite-diopside foams from preceramic polymers and reactive oxide fillers. Materials, 2015, 8(5):2480.

DOI URL |

| [29] |

ELSAYED H, ZOCCA A, BERNARDO E, et al. Development of bioactive silicate-based glass-ceramics from preceramic polymer and fillers. Journal of the European Ceramic Society, 2015, 35(2):731.

DOI URL |

| [30] | FU S Y, HU H R, CHEN J J, et al. Silicone resin derived larnite/C scaffolds via 3D printing for potential tumor therapy and bone regeneration. Chemical Engineering Journal, 2020, 382: 122928. |

| [31] |

LIU W Y, ZUO R T, ZHU T L, et al. Forsterite-hydroxyapatite composite scaffolds with photothermal antibacterial activity for bone repair. Journal of Advanced Ceramics, 2021, 10(5):1095.

DOI |

| [32] |

BERNARDO E, FIOCCO L, GIFFIN G A, et al. Microstructure development and dielectric characterization of forsterite-based ceramics from silicone resins and oxide fillers. Advanced Engineering Materials, 2014, 16(6):806.

DOI URL |

| [33] |

ELSAYED H, CARRARO F, AGNOLI S, et al. Direct ink writing of silica-carbon-calcite composite scaffolds from a silicone resin and fillers. Journal of the European Ceramic Society, 2018, 38(15):5200.

DOI URL |

| [34] |

ANDRIANOV N T, ABDEL'-GAVAD S R, ZENKOVA N V. Synthesis and sintering of cordierite sol-gel powders based on different magnesium salts. Glass and Ceramics, 2006, 63(11/12):415.

DOI URL |

| [35] |

LIU W, WANG T, YANG C, et al. Alkaline biodegradable implants for osteoporotic bone defects-importance of microenvironment pH. Osteoporosis International, 2016, 27(1):93.

DOI URL |

| [36] |

WANG C, XUE Y, LIN K, et al. The enhancement of bone regeneration by a combination of osteoconductivity and osteostimulation using β-CaSiO3/β-Ca3(PO4)2 composite bioceramics. Acta Biomaterialia, 2012, 8(1):350.

DOI URL |

| [37] | LI M, BAI J, TAO H, et al. Rational integration of defense and repair synergy on PEEK osteoimplants via biomimetic peptide clicking strategy. Bioactive Mateirials, 2022, 8: 309. |

| [38] | CHEN M W, HU Y, HOU Y H, et al. Magnesium/gallium-layered nanosheets on titanium implants mediate osteogenic differentiation of MSCs and osseointegration under osteoporotic condition. Chemical Engineering Journal, 2022, 427: 130982. |

| [39] |

LANGER R, VACANTI J P. Tissue engineering. Science, 1993, 260(5110):920.

DOI PMID |

| [40] |

JO S, HAN J, LEE Y L, et al. Regulation of osteoblasts by alkaline phosphatase in ankylosing spondylitis. International Journal of Rheumatic Diseases, 2019, 22(2):252.

DOI PMID |

| [41] | PEREIRA D D, DAVISON N, HABIBOVIC P. Human osteoclast formation and resorptive function on biomineralized collagen. Bioactive Materials, 2022, 8: 241. |

| [42] |

JUNG G Y, PARK Y J, HAN J S. Effects of HA released calcium ion on osteoblast differentiation. Journal of Materials Science- Materials in Medicine, 2010, 21(5):1649.

DOI URL |

| [43] | ZHANG X Z, ZU H Y, ZHAO D W, et al. Ion channel functional protein kinase TRPM7 regulates Mg ions to promote the osteoinduction of human osteoblast via PI3K pathway: In vitro simulation of the bone-repairing effect of Mg-based alloy implant. Acta Biomaterialia, 2017, 63: 369. |

| [44] |

QIAO W, WONG K H M, SHEN J, et al. TRPM7 kinase-mediated immunomodulation in macrophage plays a central role in magnesium ion-induced bone regeneration. Nature Communications, 2021, 12(1):2885.

DOI PMID |

| [45] |

YAN L X, LI H Y, XIA W L. Bioglass could increase cell membrane fluidity with ion products to develop its bioactivity. Cell Proliferation, 2020, 53(11):e12906.

DOI URL |

| [1] | 陈曦, 袁媛, 谭业强, 刘昌胜. 无机非金属生物材料发展战略研究[J]. 无机材料学报, 2025, 40(5): 449-456. |

| [2] | 殷杰, 耿佳毅, 王康龙, 陈忠明, 刘学建, 黄政仁. SiC陶瓷的3D打印成形与致密化新进展[J]. 无机材料学报, 2025, 40(3): 245-255. |

| [3] | 李紫薇, 弓伟露, 崔海峰, 叶丽, 韩伟健, 赵彤. 前驱体法制备(Zr, Hf, Nb, Ta, W)C-SiC复相陶瓷及性能研究[J]. 无机材料学报, 2025, 40(3): 271-280. |

| [4] | 陈梦杰, 王倩倩, 吴成铁, 黄健. 基于DFT的描述符预测生物陶瓷的降解性[J]. 无机材料学报, 2024, 39(10): 1175-1181. |

| [5] | 郑嘉乾, 卢霄, 鲁亚杰, 王迎军, 王臻, 卢建熙. 医用生物陶瓷的功能性生物适配机制及应用[J]. 无机材料学报, 2024, 39(1): 1-16. |

| [6] | 苑景坤, 熊书锋, 陈张伟. 聚合物前驱体转化陶瓷增材制造技术研究趋势与挑战[J]. 无机材料学报, 2023, 38(5): 477-488. |

| [7] | 王鲁凯, 冯军宗, 姜勇刚, 李良军, 冯坚. 直写3D打印陶瓷基多孔结构的研究进展[J]. 无机材料学报, 2023, 38(10): 1133-1148. |

| [8] | 盛丽丽, 常江. 光/磁热Fe2SiO4/Fe3O4双相生物陶瓷及其复合电纺丝膜制备及抗菌性能研究[J]. 无机材料学报, 2022, 37(9): 983-990. |

| [9] | 杨勇, 郭啸天, 唐杰, 常浩天, 黄政仁, 胡秀兰. 非氧化物陶瓷光固化增材制造研究进展及展望[J]. 无机材料学报, 2022, 37(3): 267-277. |

| [10] | 李琪, 黄羿, 钱滨, 许贝贝, 陈莉英, 肖文戈, 邱建荣. 橙黄光玻璃陶瓷的光固化成型与无压烧结[J]. 无机材料学报, 2022, 37(3): 289-296. |

| [11] | 朱俊逸, 张成, 罗忠强, 曹继伟, 刘志远, 王沛, 刘长勇, 陈张伟. 脱脂工艺对光固化3D打印堇青石陶瓷性能的影响[J]. 无机材料学报, 2022, 37(3): 317-324. |

| [12] | 李乔磊, 顾玥, 于雪华, 张朝威, 邹明科, 梁静静, 李金国. 烧结温度对3D打印硅基陶瓷型芯表面形貌及粗糙度的影响[J]. 无机材料学报, 2022, 37(3): 325-332. |

| [13] | 许宏一, 翟东, 曹琬婷, 陈振华, 钱文昊, 陈蕾. Li2Ca2Si2O7生物陶瓷的矿化活性研究[J]. 无机材料学报, 2021, 36(7): 753-760. |

| [14] | 吴重草, 郇志广, 朱钰方, 吴成铁. 3D打印HA微球支架的制备与表征[J]. 无机材料学报, 2021, 36(6): 601-607. |

| [15] | 张力, 杨现锋, 徐协文, 郭金玉, 周哲, 刘鹏, 谢志鹏. 熔融沉积法3D打印制备氧化锆陶瓷及其力学性能研究[J]. 无机材料学报, 2021, 36(4): 436-442. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||