无机材料学报 ›› 2022, Vol. 37 ›› Issue (3): 325-332.DOI: 10.15541/jim20210654 CSTR: 32189.14.10.15541/jim20210654

李乔磊1,2, 顾玥3, 于雪华4, 张朝威1, 邹明科1, 梁静静1,3( ), 李金国1,3(

), 李金国1,3( )

)

收稿日期:2021-10-23

修回日期:2021-11-28

出版日期:2022-03-20

网络出版日期:2022-01-06

通讯作者:

梁静静, 研究员. E-mail: jjliang@imr.ac.cn; 李金国, 研究员. E-mail: jgli@imr.ac.cn

作者简介:李乔磊(1993-), 男, 博士研究生. E-mail: lql_614@163.com

基金资助:

LI Qiaolei1,2, GU Yue3, YU Xuehua4, ZHANG Chaowei1, ZOU Mingke1, LIANG Jingjing1,3( ), LI Jinguo1,3(

), LI Jinguo1,3( )

)

Received:2021-10-23

Revised:2021-11-28

Published:2022-03-20

Online:2022-01-06

Contact:

LIANG Jingjing, professor. E-mail: jjliang@imr.ac.cn; LI Jinguo, professor. E-mail: jgli@imr.ac.cn

About author:LI Qiaolei (1993-), male, PhD candidate. E-mail: lql_614@163.com

Supported by:摘要:

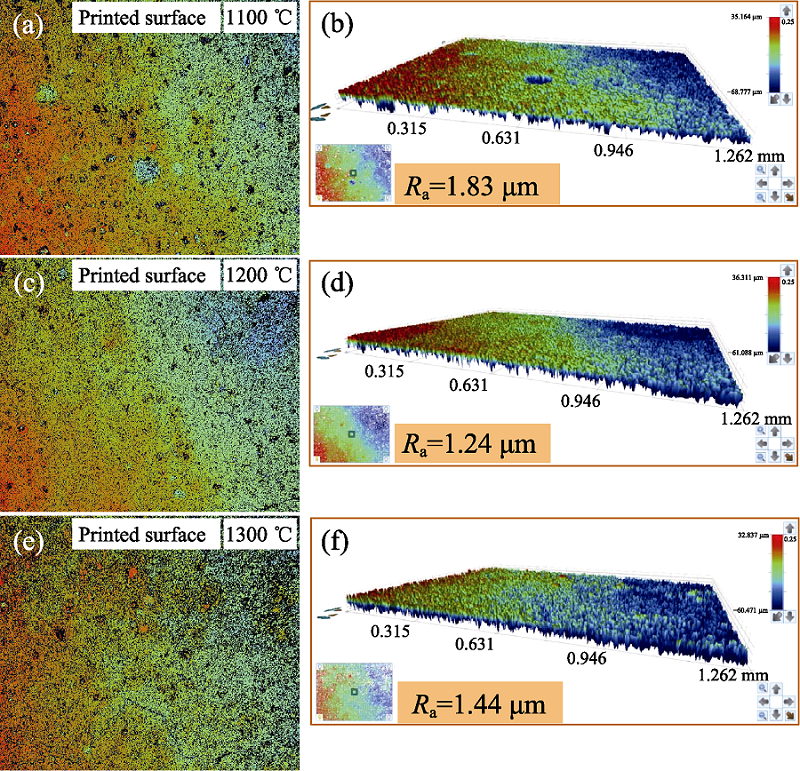

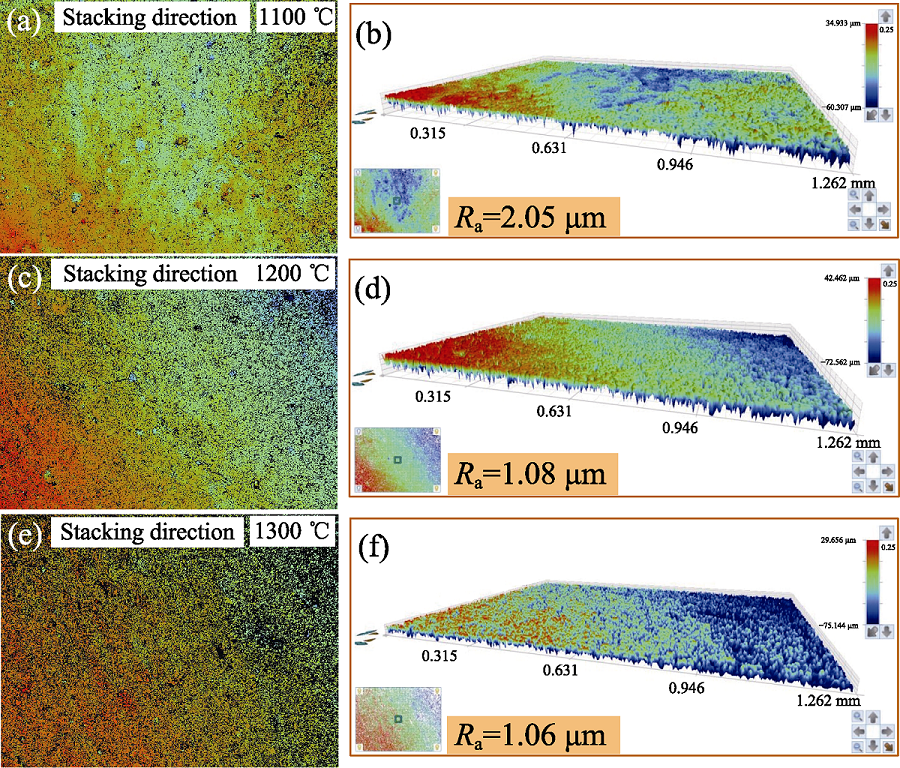

单晶高温合金空心叶片是航空发动机的重要部件, 其内腔结构是采用陶瓷型芯制备的。随着航空发动机推重比提高, 型芯结构越来越复杂, 传统制备工艺受限, 光固化3D打印陶瓷型芯技术为复杂结构型芯的制备提供了一种可行方案。为了改善光固化3D打印陶瓷型芯因台阶效应导致的表面粗糙度较大的问题, 本研究利用固含量体积分数63%的硅基型芯浆料进行光固化3D打印型芯, 并在1100~1300 ℃对型芯素坯进行烧结, 对烧成的硅基陶瓷型芯的微观结构、元素分布、相组成、型芯打印面和打印堆积方向的表面形貌和粗糙度进行分析。研究发现型芯打印面平整, 无明显表面缺陷, 1100、1200和1300 ℃烧结型芯的打印面粗糙度分别为1.83、1.24和1.44 μm; 片层堆积方向的表面有片层结构特征, 片层间出现微裂纹, 1200 ℃以上烧结的型芯表面粗糙度达到空心叶片使用要求(Ra≤2.0 μm)。结果表明不同烧结温度会改变型芯烧结过程中的液相含量、莫来石生成量、莫来石生成形态和颗粒间玻璃相的分布, 从而对光固化3D打印硅基陶瓷型芯的表面粗糙度产生明显影响。光固化3D打印陶瓷型芯技术结合烧结工艺能制备出满足先进空心叶片用硅基陶瓷型芯表面要求的粗糙度。

中图分类号:

李乔磊, 顾玥, 于雪华, 张朝威, 邹明科, 梁静静, 李金国. 烧结温度对3D打印硅基陶瓷型芯表面形貌及粗糙度的影响[J]. 无机材料学报, 2022, 37(3): 325-332.

LI Qiaolei, GU Yue, YU Xuehua, ZHANG Chaowei, ZOU Mingke, LIANG Jingjing, LI Jinguo. Effect of Sintering Temperature on Surface Morphology and Roughness of 3D-printed Silicon Ceramic Cores[J]. Journal of Inorganic Materials, 2022, 37(3): 325-332.

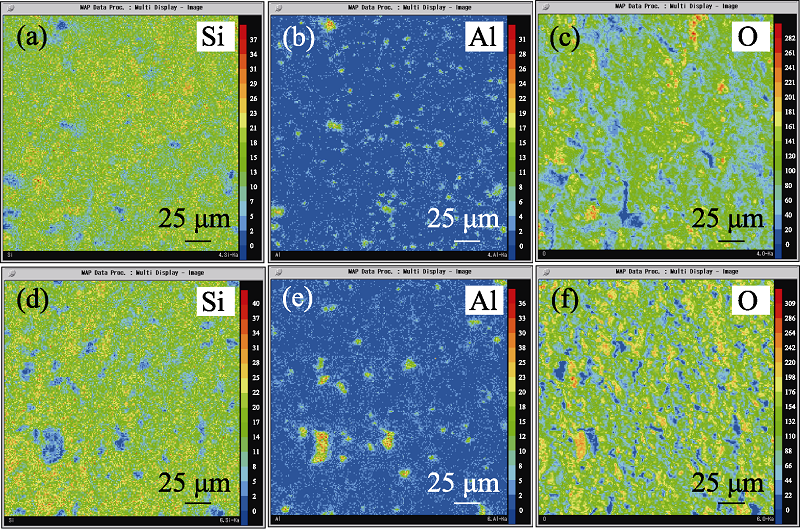

图4 1250 ℃烧结陶瓷型芯的原始样品(a~c)和经1500 ℃模拟浇铸样品(d~f)的元素分布结果

Fig. 4 Element distributions of the ceramic cores sintered at 1250 ℃ for as-obtained sample (a-c) and simulated casting samples at 1500 ℃ (d-f)

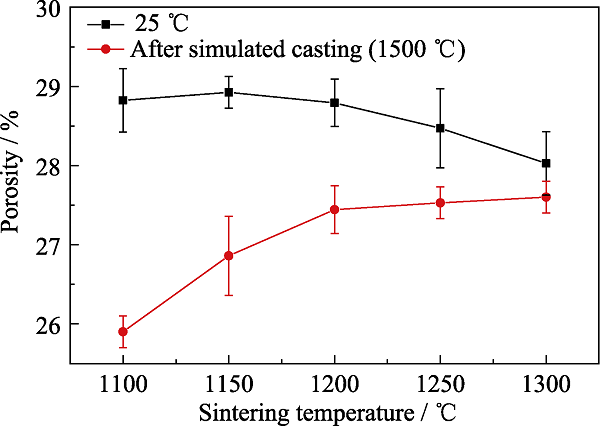

图6 不同温度烧结陶瓷型芯的原始样品和经1500 ℃模拟浇铸样品的开气孔率

Fig. 6 Open porosities of the ceramic cores sintered at different temperatures for as-obtained samples and simulated casting (1500 ℃) samples

图7 不同温度烧结陶瓷型芯打印面的表面二维、三维形貌和粗糙度

Fig. 7 2D and 3D surface morphologies and roughnesses of the printed surfaces of ceramic cores sintered at different temperatures

图8 不同温度烧结陶瓷型芯打印面的表面二维、三维形貌 (商业形貌分析软件Vision64建立参考面)

Fig. 8 2D and 3D surface morphologies of the printed surfaces of ceramic cores sintered at different temperatures The reference surface was established by commercial morphology analysis software Vision64

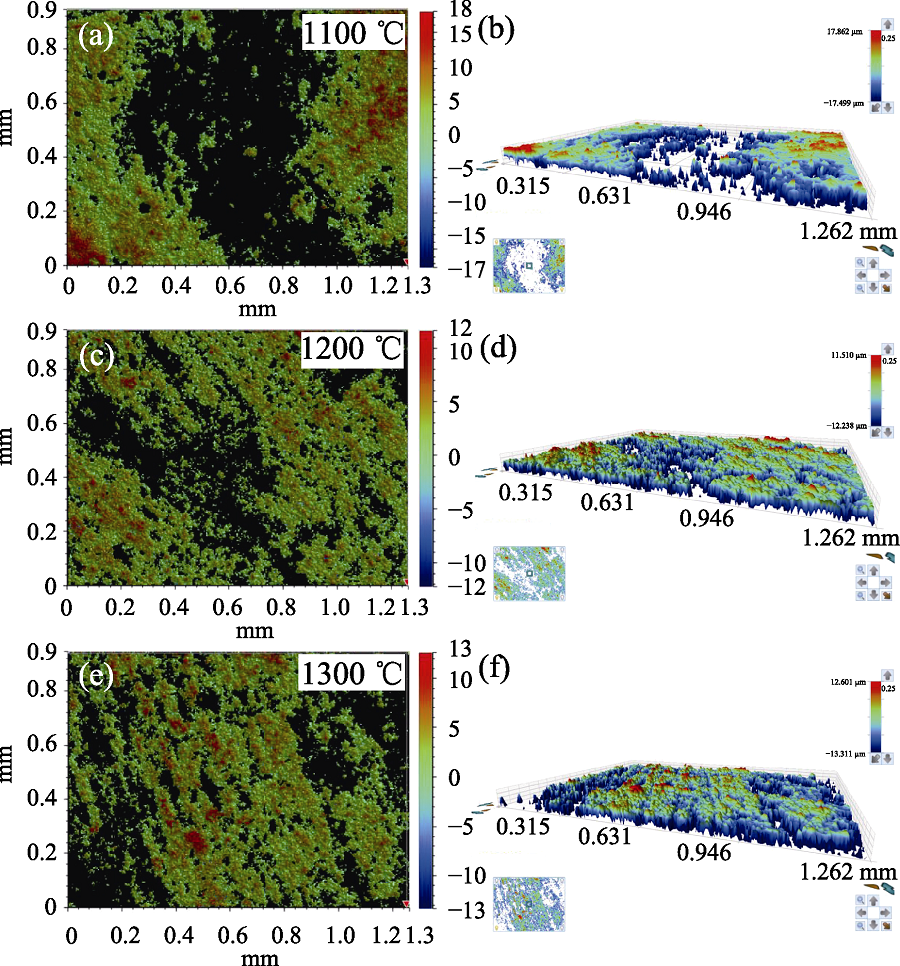

图9 不同温度烧结陶瓷型芯打印堆积方向的表面二维、三维形貌和粗糙度

Fig. 9 2D and 3D surface morphologies and roughnesses of ceramic cores sintered at different temperatures in printing stacking direction

图10 不同温度烧结陶瓷型芯打印堆积方向的表面二维、三维形貌(商业形貌分析软件Vision64建立参考面)

Fig. 10 2D and 3D surface morphologies of ceramic cores sintered at different temperatures in printing stacking direction The reference surface was established by commercial morphology analysis software Vision64

| [1] |

POLLOCK T M. Alloy design for aircraft engines. Nature Materials, 2016, 15(8): 809-815.

DOI URL |

| [2] |

PADTURE N P, GELL M, JORDAN E H. Thermal barrier coatings for gas-turbine engine applications. Science, 2002, 296(5566): 280-284.

DOI URL |

| [3] |

LIANG X, ZHAO Y T, MA D, et al. Study on the preparation and microstructure of a single-crystal hollow turbine blade. Materials and Manufacturing Processes, 2017, 32(16): 1887-1892.

DOI URL |

| [4] |

GUO Z, SONG Z, FAN J, et al. Experimental and analytical investigation on service life of film cooling structure for single crystal turbine blade. International Journal of Fatigue, 2021, 150: 106318.

DOI URL |

| [5] | LIANG J, LIN Q, ZHANG X, et al. Effects of alumina on cristobalite crystallization and properties of silica-based ceramic cores. Journal of Materials Science & Technology, 2017, 33(2): 204-209. |

| [6] |

XU W, LU Z, TIAN G, et al. Fabrication of single-crystal superalloy hollow blade based on integral ceramic mold. Journal of Materials Processing Technology, 2019, 271: 615-622.

DOI URL |

| [7] | WALALE A, CHAUHAN A S, SATYANARAYANA A, et al. Analysis of shrinkage & warpage in ceramic injection molding of HPT vane leading edge core of a gas turbine casting. Materials Today: Proceedings, 2018, 5(9): 19471-19479. |

| [8] | CHAUHAN A S, ANIRUDH B, SATYANARAYANA A, et al. FEA optimization of injection parameters in ceramic core development for investment casting of a gas turbine blade. Materials Today: Proceedings, 2020, 26: 2190-2199. |

| [9] | LI Q, MA D W, JIANG Y H, et al. Effcet of cristoablite content on the properties of ceramic core in making directionally solidified hollow blade. Journal of Materials Engineering, 1994(5): 18-19. |

| [10] |

DONG Y, LI X, ZHAN Q, et al. Modeling of shrinkage during investment casting of thin-walled hollow turbine blades. Journal of Materials Processing Technology, 2017, 244: 190-203.

DOI URL |

| [11] |

MUKHTARKHANOV M, PERVEEN A, TALAMONA D. Application of stereolithography based 3D printing technology in investment casting. Micromachines, 2020, 11(10): 946.

DOI URL |

| [12] |

PARK H Y, KIM E H, CHO G H, et al. Process development of fabricating ceramic core using 3D printing technique. Materials Chemistry and Physics, 2019, 231: 382-387.

DOI URL |

| [13] |

HALLORAN J W, TOMECKOVA V, GENTRY S, et al. Photopolymerization of powder suspensions for shaping ceramics. Journal of the European Ceramic Society, 2011, 31(14): 2613-2619.

DOI URL |

| [14] |

GENTRY S P, HALLORAN J W. Absorption effects in photopolymerized ceramic suspensions. Journal of the European Ceramic Society, 2013, 33(10): 1989-1994.

DOI URL |

| [15] |

GENTRY S P, HALLORAN J W. Depth and width of cured lines in photopolymerizable ceramic suspensions. Journal of the European Ceramic Society, 2013, 33(10): 1981-1988.

DOI URL |

| [16] |

TOMECKOVA V, HALLORAN J W. Cure depth for photopolymerization of ceramic suspensions. Journal of the European Ceramic Society, 2010, 30(15): 3023-3033.

DOI URL |

| [17] |

TOMECKOVA V, HALLORAN J W. Predictive models for the photopolymerization of ceramic suspensions. Journal of the European Ceramic Society, 2010, 30(14): 2833-2840.

DOI URL |

| [18] |

BAE C J, HALLORAN J W. Integrally cored ceramic mold fabricated by ceramic stereolithography. International Journal of Applied Ceramic Technology, 2011, 8(6): 1255-1262.

DOI URL |

| [19] |

BAE C J, KIM D, HALLORAN J W. Mechanical and kinetic studies on the refractory fused silica of integrally cored ceramic mold fabricated by additive manufacturing. Journal of the European Ceramic Society, 2019, 39(2/3): 618-623.

DOI URL |

| [20] |

LI H, LIU Y, COLOMBO P, et al. The influence of sintering procedure and porosity on the properties of 3D printed alumina ceramic cores. Ceramics International, 2021, 47(19): 27668-27676.

DOI URL |

| [21] |

LI H, HU K, LIU Y, et al. Improved mechanical properties of silica ceramic cores prepared by 3D printing and sintering processes. Scripta Materialia, 2021, 194: 113665.

DOI URL |

| [22] |

LI H, LIU Y, LIU Y, et al. Silica strengthened alumina ceramic cores prepared by 3D printing. Journal of the European Ceramic Society, 2021, 41(4): 2938-2947.

DOI URL |

| [23] |

LI H, LIU Y, LIU Y, et al. Evolution of the microstructure and mechanical properties of stereolithography formed alumina cores sintered in vacuum. Journal of the European Ceramic Society, 2020, 40(14): 4825-4836.

DOI URL |

| [24] |

QIAN C, HU K, LU Z, et al. Volume shrinkage and conversion rate of Al2O3 ceramic stereolithography suspension polymerised by ultraviolet light. Materials Chemistry and Physics, 2021, 267: 124661.

DOI URL |

| [25] |

LI X, HU K, LU Z. Effect of light attenuation on polymerization of ceramic suspensions for stereolithography. Journal of the European Ceramic Society, 2019, 39(7): 2503-2509.

DOI URL |

| [26] |

QIAN C, HU K, LI J, et al. The effect of light scattering in stereolithography ceramic manufacturing. Journal of the European Ceramic Society, 2021, 41(14): 7141-7154.

DOI URL |

| [27] | LI Q, AN X, LIANG J, et al. Balancing flexural strength and porosity in DLP-3D printing Al2O3 cores for hollow turbine blades. Journal of Materials Science & Technology, 2022, 104: 19-32. |

| [28] |

LI Q, LIANG J, ZHANG Y, et al. Fused silica ceramic core based on network-structured zircon design via 3D printing. Scripta Materialia, 2022, 208: 114342.

DOI URL |

| [29] |

OLEVSKY E A. Theory of sintering: from discrete to continuum. Materials Science and Engineering: R: Reports, 1998, 23(2): 41-100.

DOI URL |

| [30] |

SUNDARESAN S, AKSAY I A. Mullitization of diphasic aluminosilicate gels. Journal of the American Ceramic Society, 1991, 74(10): 2388-2392.

DOI URL |

| [31] |

CAHOON H P, CHRISTENSEN C J. Sintering and grain growth of alpha-alumina. Journal of the American Ceramic Society, 1956, 39(10): 337-344.

DOI URL |

| [32] |

SMOTHERS W J, REYNOLDS H J. Sintering and grain growth of alumina. Journal of the American Ceramic Society, 1954, 37(12): 588-595.

DOI URL |

| [33] | PAN J Y, LIU X F, HE L M, et al. Research progress of silica-base ceramic core. Foundry, 2012, 61(2): 174-178. |

| [1] | 朱俊逸, 张成, 罗忠强, 曹继伟, 刘志远, 王沛, 刘长勇, 陈张伟. 脱脂工艺对光固化3D打印堇青石陶瓷性能的影响[J]. 无机材料学报, 2022, 37(3): 317-324. |

| [2] | 耿瑞文, 杨晓京, 谢启明, 李芮, 罗良. 基于划刻实验的单晶锗材料去除机理研究[J]. 无机材料学报, 2019, 34(8): 867-872. |

| [3] | 姚秀敏, 王晓洁, 刘学建, 陈忠明, 黄政仁. 碳化硅/碳化钨硬面密封摩擦副的摩擦磨损性能和机理研究[J]. 无机材料学报, 2019, 34(6): 673-678. |

| [4] | 李鑫,牛书鑫,姚建省,唐定中,曹春晓,闫军浩. 金属Al粉对氧化硅基陶瓷型芯的性能及组织的影响[J]. 无机材料学报, 2019, 34(2): 207-212. |

| [5] | 杨治刚, 余建波, 李传军, 玄伟东, 张振强, 邓 康, 任忠鸣. 热固性硅树脂压注法制备多孔硅基陶瓷型芯研究[J]. 无机材料学报, 2015, 30(2): 147-152. |

| [6] | 张小锋, 周克崧, 张吉阜, 韩 滔, 宋进兵, 刘 敏. 粗糙度对热障涂层冲蚀失效的影响及模型建立[J]. 无机材料学报, 2014, 29(3): 294-300. |

| [7] | 陈晓琴, 陈雪宁, 朱向东, 蔡 兵, 范红松, 张兴栋. 羟基磷灰石表面形貌对人成骨肉瘤细胞生物学性能的影响[J]. 无机材料学报, 2013, 28(8): 901-906. |

| [8] | 侯维敏, 于 云, 胡学兵, 于 洋, 米 乐, 宋力昕. Al2O3微滤膜的超疏水改性研究[J]. 无机材料学报, 2013, 28(8): 864-868. |

| [9] | 朱明星, 石 彪, 陈 义, 刘学超, 施尔畏. 4H-SiC高速同质外延研究[J]. 无机材料学报, 2012, 27(8): 785-789. |

| [10] | 王宝全, 余建波, 任忠鸣, 曾宇平. 多孔铝基陶瓷型芯的制备及其性能[J]. 无机材料学报, 2012, 27(3): 239-244. |

| [11] | 原子健,朱夏明,王 雄,张莹莹,万正芬,邱东江,吴惠桢,杜滨阳. 氧化铟薄膜制备及其特性研究[J]. 无机材料学报, 2010, 15(2): 141-144. |

| [12] | 曹 丰,李东旭,管自生. 生物模板法制备具有特殊表面形貌的二氧化硅中空微球[J]. 无机材料学报, 2009, 24(3): 501-506. |

| [13] | 刘翠霞,杨延清,黄斌,张荣军,罗贤,任晓霞. 化学气相沉积SiC膜{111}取向生长的原子尺度模拟[J]. 无机材料学报, 2008, 23(5): 933-937. |

| [14] | 张磊磊,李贺军,李克智,李新涛,翟言强,张雨雷. 碳/碳复合材料表面粗糙度对成骨细胞生长行为的影响[J]. 无机材料学报, 2008, 23(2): 341-345. |

| [15] | 朱宏喜,毛卫民,冯惠平,吕反修,Vlasov I I,Ralchenko V G,Khomich A V. 甲烷浓度对CVD金刚石薄膜晶体学生长过程的影响[J]. 无机材料学报, 2007, 22(3): 570-576. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||