无机材料学报 ›› 2023, Vol. 38 ›› Issue (5): 477-488.DOI: 10.15541/jim20220515 CSTR: 32189.14.10.15541/jim20220515

所属专题: 【制备方法】3D打印(202506)

• 综述 • 下一篇

收稿日期:2022-09-02

修回日期:2022-10-10

出版日期:2022-10-19

网络出版日期:2022-10-19

通讯作者:

陈张伟, 教授. E-mail: chen@szu.edu.cn作者简介:苑景坤(1985-), 男, 博士. E-mail: yuanjk@szu.edu.cn

基金资助:

YUAN Jingkun( ), XIONG Shufeng, CHEN Zhangwei(

), XIONG Shufeng, CHEN Zhangwei( )

)

Received:2022-09-02

Revised:2022-10-10

Published:2022-10-19

Online:2022-10-19

Contact:

CHEN Zhangwei, Professor. E-mail: chen@szu.edu.cnAbout author:YUAN Jingkun (1985-), male, PhD. E-mail: yuanjk@szu.edu.cn

Supported by:摘要:

近年来, 增材制造技术作为一种新兴的制造技术受到了广泛关注。该技术在高性能陶瓷材料的成型制造领域具有巨大的发展潜力, 有望突破传统陶瓷加工和生产的技术瓶颈, 极大提升高性能陶瓷产品的设计和制备的自由度, 从而为高性能陶瓷材料制造技术的发展提供变革性的推动力。前驱体转化陶瓷通过化学方法制得聚合物,再经热处理转化为陶瓷材料。聚合物前驱体充分利用了自身良好的可加工性特点, 实现了目标结构的预成型, 并通过热处理工艺获得传统陶瓷工艺难以获得的先进陶瓷材料。而聚合物前驱体材料与增材制造技术的结合更受到了极大关注。本文在介绍聚合物前驱体增材制造技术特点的基础上, 系统阐述了聚合物前驱体增材制造技术的研究与应用前沿的现状与趋势, 并分析了聚合物前驱体增材制造技术面对的挑战以及未来发展方向。

中图分类号:

苑景坤, 熊书锋, 陈张伟. 聚合物前驱体转化陶瓷增材制造技术研究趋势与挑战[J]. 无机材料学报, 2023, 38(5): 477-488.

YUAN Jingkun, XIONG Shufeng, CHEN Zhangwei. Research Trends and Challenges of Additive Manufacturing of Polymer-derived Ceramics[J]. Journal of Inorganic Materials, 2023, 38(5): 477-488.

图2 聚合物前驱体转化陶瓷的增材制造过程与实例[14]

Fig. 2 Additive manufacturing of polymer-derived ceramics[14]. (a) UV-curable preceramic monomers and photoinitiator; (b) SL printing process; (c) As-printed parts; (d) As-pyrolyzed ceramic; (e) Examples of final parts

图3 四种不同的陶瓷前驱体的DLP 3D打印工艺示意图(左)及实物照片和显微照片[28]

Fig. 3 Schematic diagram (left) of DLP printing process of four different preceramic polymers, and optical microscopic images and photographs of the printed structures [28] (a, c, e, g) Optical microscopic images of the printed structures; (b, d, f, h) Photographs of the printed structures before and after pyrolysis

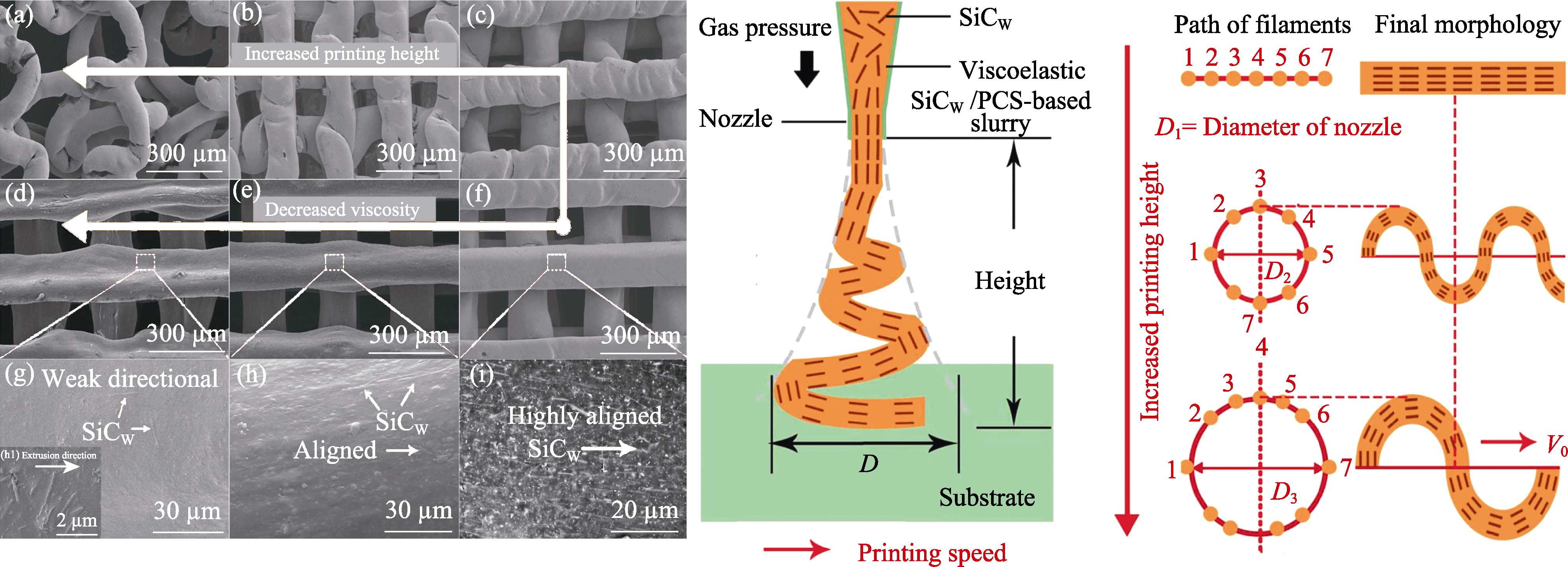

图4 SiCw/SiC矩阵在不同打印高度或不同固体负载悬浮液下的SEM照片(左)及其示意图(右)[19]

Fig. 4 SEM images of SiCw/SiC lattices under different printing height or using suspensions with different solid loading (left) and schematic illustration of the morphology of extruded filaments with different printing height (right)[19] (a-c) Printed with 62.3% solid loading (in vol.); (d-f) Printed with 57.7%, 59.9% and 62.3% solid loadings (in vol.); (g-i) Enlarged views of the squares in (d-f)

图5 1000 ℃热解处理后的开尔文点阵结构的SEM照片

Fig. 5 SEM images of Kelvin cell structures pyrolyzed at 1000 ℃[38] (a-c) Kelvin cell structures pyrolyzed at 1000 ℃ on support pillars with increasing height, to reduce shrinkage constraints from the glass substrate during pyrolysis; (d-f) Magnification of the samples shown in the upper row

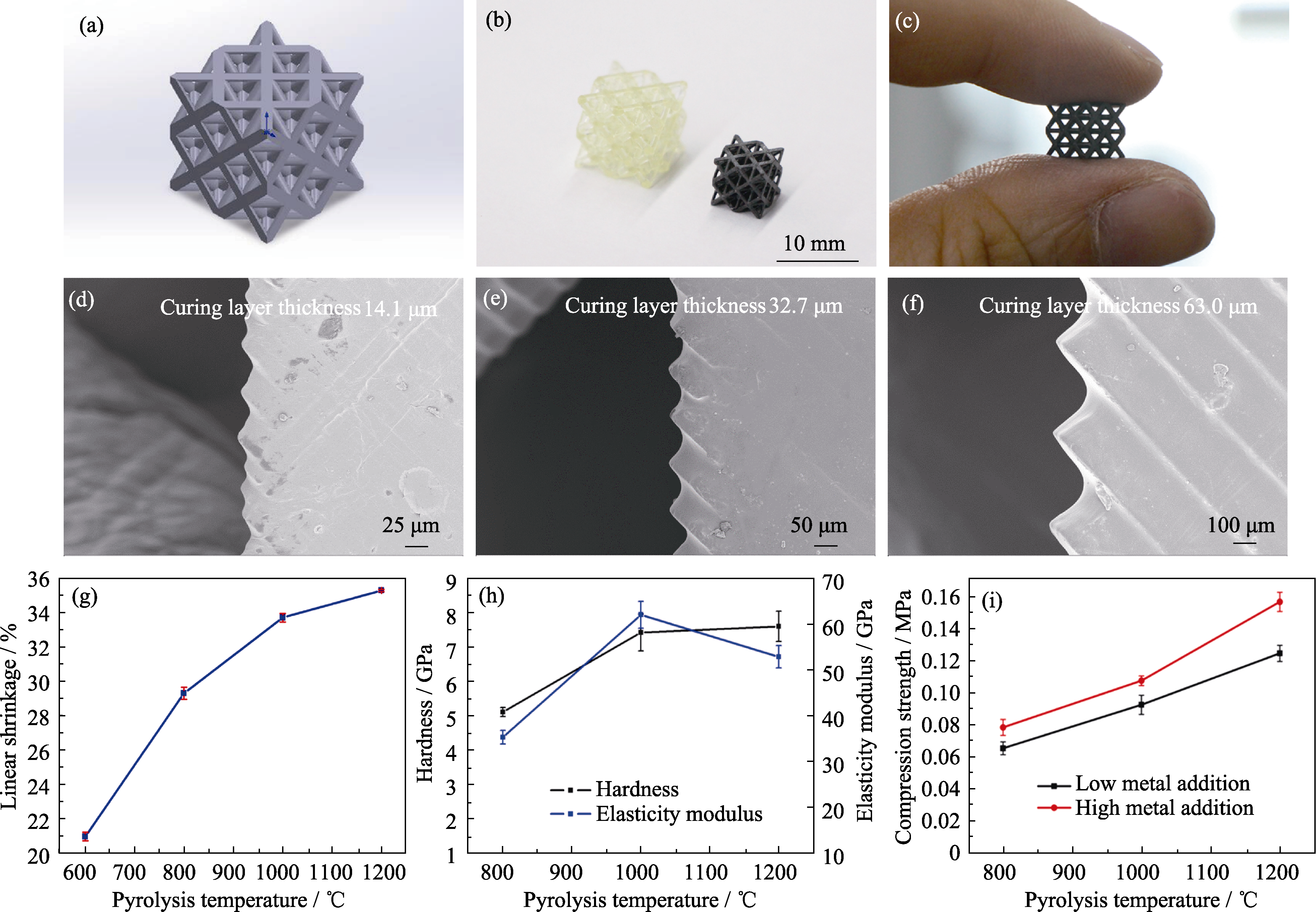

图6 3D打印双金属掺杂前驱体的照片及机械性能[41]

Fig. 6 Pictures and mechanical properties of 3D printing of bimetal-doped precursor[41] (a-c) Lattice CAD model, resin and SiOC ceramics; (d-f) SEM images of different curing layer thickness; (g-i) Mechanical properties

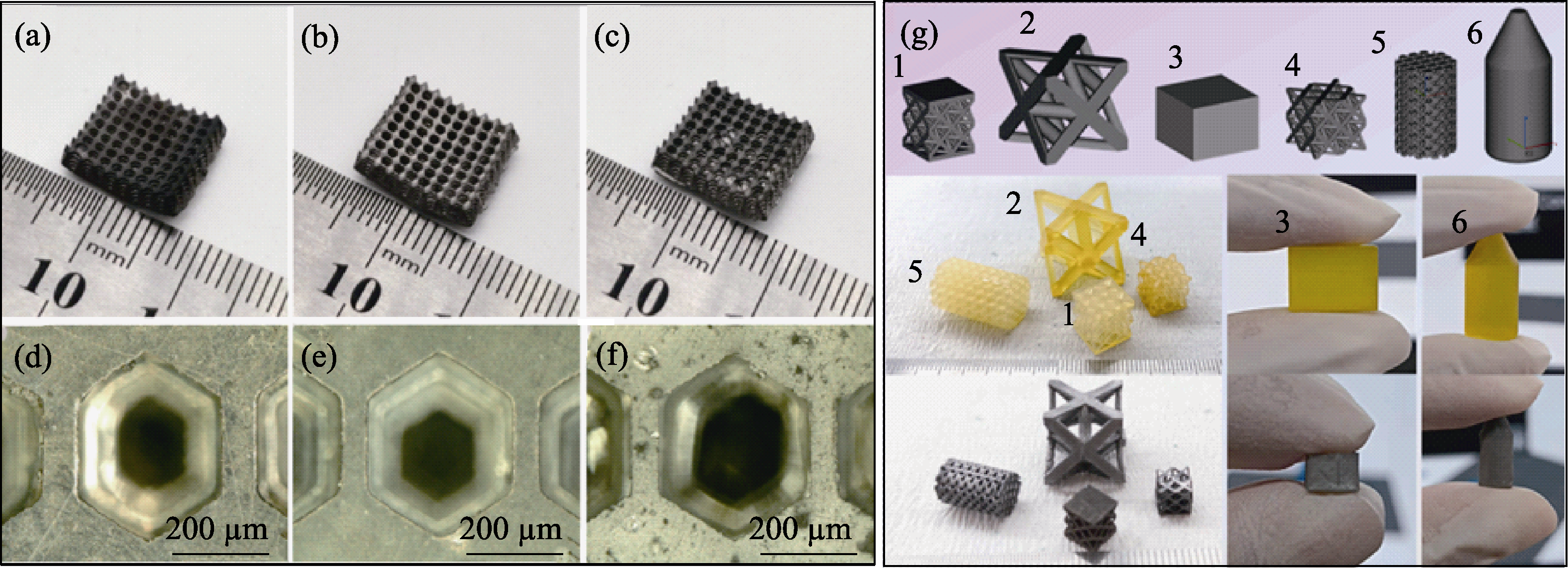

图7 点阵模型及打印件裂解后的宏(左)微(右, (a~d))观结构[44]

Fig. 7 CAD models and optical images of the samples after printing and pyrolysis (left column), SEM images of the samples’ skeleton surface after pyrolysis (right two columns, (a-d))[44]

图8 引入不同比例硅油添加剂的SiOC陶瓷热解样件的宏观(a~c)与微观(d~f)形貌照片[46], (g)添加适当比例酚醛树脂制备的样件的CAD模型、打印素坯与热解后样件宏观实物图[47]

Fig. 8 (a-c) Optical images of the SiOC ceramic samples with different proportion of silicone oil additive, (d-f) closer looks of the corresponding samples in (a-c) [46], and (g) CAD models, green and pyrolyzed samples with the addition of phenolic resin additive [47]

图9 支撑凝胶内的3D打印陶瓷前驱体的工艺流程示意图(a)及其打印示例(b)、打印样品(c~e)、热解样品(f, g)[53]

Fig. 9 Schematic of 3D printing of polymer-derived ceramics inside a support gel (a), illustration of the printing (b), printed samples (c-e), and pyrolyzed samples (f, g)[53]

图10 不同参数打印的陶瓷立方体的SEM和AFM照片以及CAD设计[58]

Fig. 10 CAD design of the nozzle compared with the final pyrolysed part and SEM images[58] Left: SEM images and AFM images (Col.1, 2 and 4) of ceramic cubes printed with different parameters, with the measured corresponding mean values of the linear shrinkage (Col.3) and the average roughness (Col.5). Upper-right: CAD designs of two different structures and final pyrolysed parts. Lower-right: CAD design of the nozzle compared with the final ceramic part with their SEM images at 0°(I.a and II.a) and 60°(I.b and II.b), and their corresponding X-ray microtomographies from different angles (a-j)

图11 4D打印过程示意图及其成型构件[59]

Fig. 11 Origami and 4D printing of PDCs via DIW-morphing-heat treatment method[59] (a) 3D printed elastomeric lattices; (b) Optical image of DIW; (c) Origami of ceramic structures; (d, e) Two 4D printing methods together with heat treatment; (f) Flat and curved cellphone back plate; (g) Top view of flat plate; (h) Curved ceramic honeycomb; Inset indicates the curvature of the honeycomb. Scale bars:1 cm

| Material | AM Tech. | Ceramic yield/% (in mass) | Monolith/ skeleton porosity/% | Density/ (g·cm-3) | Linear shrinkage/ % | Compressive strength/MPa | Tensile strength/ GPa | Hardness/ GPa | Elastic modulus/ GPa | Ref. |

|---|---|---|---|---|---|---|---|---|---|---|

| SiCN | DLP | 80 | 0 | 2.28 | 20 | - | - | 10 | 78 | [ |

| SiCN | DLP | 25.3 | 6.9 | 2.167 | 62.9 | >50 | - | >33 | [ | |

| SiOC | DLP | 44.1 | 1.5 | 2.1 | 35.4 | 0.124-0.156 | - | ~7.61 | - | [ |

| SiOC | DLP | 40.1 | 0 | 2.1 | 51.5 | 10 | 1.9 | - | 3.1 | [ |

| SiOC | DIW | 94 | 0 | - | 8 | 56.4 | - | - | 28.9 | [ |

| SiOC | DIW | - | 0 | - | 55(vol) | ∼3.1 | - | - | - | [ |

| SiOCN | DIW | 77 | 50 | 1.05 | - | 0.3-0.9 | - | - | - | [ |

| SiOC | SLS | 82 | 0 | 2.64 | 3 | 220 | - | - | - | [ |

| SiOC | DIW | 31.3-58.84 | 86.5 | 1.97 | 46.7(vol) | 2.92 | - | - | - | [ |

| SiOC | DLP | 29.63 | 3.64 | 1.60 | 42.01 | 19.08 | - | 5.82 | 46.4 | [ |

| SiOC | BJ3DP | 16.5 | 19 | 1.84 | 22.2 | 20 | - | - | - | [ |

| SiOC | DLP | ~30 | 47 | 1.95 | 30 | 12.9 | - | - | - | [ |

表1 部分前驱体转化陶瓷材料所使用的3D打印工艺和热解样件的性能总结

Table 1 Summary of various 3D printing techniques used for different PDC materials and their properties after pyrolysis

| Material | AM Tech. | Ceramic yield/% (in mass) | Monolith/ skeleton porosity/% | Density/ (g·cm-3) | Linear shrinkage/ % | Compressive strength/MPa | Tensile strength/ GPa | Hardness/ GPa | Elastic modulus/ GPa | Ref. |

|---|---|---|---|---|---|---|---|---|---|---|

| SiCN | DLP | 80 | 0 | 2.28 | 20 | - | - | 10 | 78 | [ |

| SiCN | DLP | 25.3 | 6.9 | 2.167 | 62.9 | >50 | - | >33 | [ | |

| SiOC | DLP | 44.1 | 1.5 | 2.1 | 35.4 | 0.124-0.156 | - | ~7.61 | - | [ |

| SiOC | DLP | 40.1 | 0 | 2.1 | 51.5 | 10 | 1.9 | - | 3.1 | [ |

| SiOC | DIW | 94 | 0 | - | 8 | 56.4 | - | - | 28.9 | [ |

| SiOC | DIW | - | 0 | - | 55(vol) | ∼3.1 | - | - | - | [ |

| SiOCN | DIW | 77 | 50 | 1.05 | - | 0.3-0.9 | - | - | - | [ |

| SiOC | SLS | 82 | 0 | 2.64 | 3 | 220 | - | - | - | [ |

| SiOC | DIW | 31.3-58.84 | 86.5 | 1.97 | 46.7(vol) | 2.92 | - | - | - | [ |

| SiOC | DLP | 29.63 | 3.64 | 1.60 | 42.01 | 19.08 | - | 5.82 | 46.4 | [ |

| SiOC | BJ3DP | 16.5 | 19 | 1.84 | 22.2 | 20 | - | - | - | [ |

| SiOC | DLP | ~30 | 47 | 1.95 | 30 | 12.9 | - | - | - | [ |

| [1] |

CHEN Z W, LI Z Y, LI J J, et al. 3D printing of ceramics: a review. Journal of the European Ceramic Society, 2019, 39(4): 661.

DOI |

| [2] | 刘雨, 陈张伟. 陶瓷光固化3D打印技术研究进展. 材料工程, 2020, 48(9): 1. |

| [3] | 陈张伟. 多孔陶瓷的增材制造及构性表征与关系研究. 现代技术陶瓷, 2021, 42(1/2): 43. |

| [4] |

LAKHDAR Y, TUCK C, BINNER J, et al. Additive manufacturing of advanced ceramic materials. Progress in Materials Science, 2021, 116: 100736.

DOI URL |

| [5] | MARCUS H L, BEAMAN J J, BARLOW J W, et al. Solid freeform fabrication-powder processing. American Ceramic Society Bulletin, 1990, 69(6): 1030. |

| [6] |

CHAUDHARY R P, PARAMESWARAN C, IDREES M, et al. Additive manufacturing of polymer-derived ceramics: materials, technologies, properties and potential applications. Progress in Materials Science, 2022, 128: 100969.

DOI URL |

| [7] |

GREIL P. Polymer derived engineering ceramics. Advanced Engineering Materials, 2000, 2(6): 339.

DOI URL |

| [8] |

XIA A, YIN J, CHEN X, et al. Polymer-derived Si-based ceramics: recent developments and perspectives. Crystals, 2020, 10(9): 824.

DOI URL |

| [9] | 骆春佳, 宋燕, 周睿, 等. 高性能陶瓷聚合物前驱体研究新进展. 高分子通报, 2019, 10: 53. |

| [10] | COLOMBO P, MERA G, RIEDEL R, et al. Polymer-derived ceramics: 40 years of research and innovation in advanced ceramics. Journal of the American Ceramic Society, 2010, 93(7): 1805. |

| [11] |

FU S, ZHU M, ZHU Y. Organosilicon polymer-derived ceramics: an overview. Journal of Advanced Ceramics, 2019, 8(4): 457.

DOI |

| [12] |

CAO J W, WANG P, LIU Z Y, et al. Research progress on powder-based laser additive manufacturing technology of ceramics. Journal of Inorganic Materials, 2022, 37(3): 241.

DOI |

| [13] |

熊鼎宇, 屈飘, 朱中琪, 等. 陶瓷挤出和喷射增材制造技术研究进展. 机械工程学报, 2021, 57(17): 253.

DOI |

| [14] |

ECKEL Z C, ZHOU C, MARTIN J H, et al. 3D printing additive manufacturing of polymer-derived ceramics. Science, 2016, 351(6268): 58.

DOI PMID |

| [15] |

吴甲民, 杨源祺, 王操, 等. 陶瓷光固化技术及应用. 机械工程学报, 2020, 56(19): 221.

DOI |

| [16] |

YANG W, YANG D, MEI H, et al. 3D printing of PDC- SiOC@SiC twins with high permittivity and electromagnetic interference shielding effectiveness. Journal of the European Ceramic Society, 2021, 41(11): 5437.

DOI URL |

| [17] |

HUANG K, ELSAYED H, FRANCHIN G, et al. 3D printing of polymer-derived SiOC with hierarchical and tunable porosity. Additive Manufacturing, 2020, 36: 101549.

DOI URL |

| [18] |

XU X, LI P, GE C, et al. 3D printing of complex-type SiOC ceramics derived from liquid photosensitive resin. ChemistrySelect, 2019, 4(23): 6862.

DOI URL |

| [19] |

XIONG H, ZHAO L, CHEN H, et al. 3D SiC containing uniformly dispersed, aligned SiC whiskers: printability, microstructure and mechanical properties. Journal of Alloys and Compounds, 2019, 809: 151824.

DOI URL |

| [20] |

XIONG H, CHEN H, ZHAO L, et al. SiCw/SiCpreinforced 3D-SiC ceramics using direct ink writing of polycarbosilane-based solution: microstructure, composition and mechanical properties. Journal of the European Ceramic Society, 2019, 39(8): 2648.

DOI URL |

| [21] | GYAK K W, VISHWAKARMA N K, HWANG Y H, et al. 3D-printed monolithic SiCN ceramic microreactors from a photocurable preceramic resin for the high temperature ammonia cracking process. Reaction Chemistry & Engineering, 2019, 4(8): 1393 |

| [22] |

JANA P, SANTOLIQUIDO O, ORTONA A, et al. Polymer- derived SiCN cellular structures from replica of 3D printed lattices. Journal of the American Ceramic Society, 2018, 101(7): 2732.

DOI URL |

| [23] |

AZARNOUSH S, LAUBSCHER F, ZOLI L, et al. Additive manufacturing of SiCN ceramic matrix for SiC fiber composites by flash pyrolysis of nanoscale polymer films. Journal of the American Ceramic Society, 2016, 99(6): 1855.

DOI URL |

| [24] |

IVANOVA O, WILLIAMS C, CAMPBELL T. Additive manufacturing (AM) and nanotechnology: promises and challenges. Rapid Prototyping Journal, 2013, 19(5): 353.

DOI URL |

| [25] |

YANG J, YU R, LI X, et al. Silicon carbide whiskers reinforced SiOC ceramics through digital light processing 3D printing technology. Ceramics International, 2021, 47(13): 18314.

DOI URL |

| [26] |

HE C, MA C, LI X, et al. Polymer-derived SiOC ceramic lattice with thick struts prepared by digital light processing. Additive Manufacturing, 2020, 35: 101366.

DOI URL |

| [27] |

WANG X, SCHMIDT F, HANAOR D, et al. Additive manufacturing of ceramics from preceramic polymers: a versatile stereolithographic approach assisted by thiolene click chemistry. Additive Manufacturing, 2019, 27: 80.

DOI URL |

| [28] |

MA C, HE C, WANG W, et al. Metal-doped polymer-derived SiOC composites with inorganic metal salt as the metal source by digital light processing 3D printing. Virtual and Physical Prototyping, 2020, 15(3): 294.

DOI URL |

| [29] |

HE C, LIU X, MA C, et al. Digital light processing fabrication of mullite component derived from preceramic precursor using photosensitive hydroxysiloxane as the matrix and alumina nanoparticles as the filler. Journal of the European Ceramic Society, 2021, 41(11): 5570.

DOI URL |

| [30] |

KULKARNI A, SORARU G D, PEARCE J M. Polymer-derived SiOC replica of material extrusion-based 3-D printed plastics. Additive Manufacturing, 2020, 32: 100988.

DOI URL |

| [31] |

XIAO J, LIU D, CHENG H, et al. Carbon nanotubes as light absorbers in digital light processing three-dimensional printing of SiCN ceramics from preceramic polysilazane. Ceramics International, 2020, 46(11): 19393.

DOI URL |

| [32] |

WANG M, XIE C, HE R, et al. Polymer-derived silicon nitride ceramics by digital light processing based additive manufacturing. Journal of the American Ceramic Society, 2019, 102(9): 5117.

DOI URL |

| [33] | 何汝杰, 周妮平, 张可强, 等. SiC陶瓷材料增材制造研究进展与挑战. 现代技术陶瓷, 2021, 42(1/2): 1. |

| [34] |

PIERIN G, GROTTA C, COLOMBO P, et al. Direct ink writing of micrometric SiOC ceramic structures using a preceramic polymer. Journal of the European Ceramic Society, 2016, 36(7): 1589.

DOI URL |

| [35] |

SCHMIDT J, COLOMBO P. Digital light processing of ceramic components from polysiloxanes. Journal of the European Ceramic Society, 2018, 38(1): 57.

DOI URL |

| [36] |

PELANCONI M, COLOMBO P, ORTONA A. Additive manufacturing of silicon carbide by selective laser sintering of PA12 powders and polymer infiltration and pyrolysis. Journal of the European Ceramic Society, 2021, 41(10): 5056.

DOI URL |

| [37] |

ZOCCA A, COLOMBO P, GOMES C M, et al. Additive manufacturing of ceramics: issues, potentialities, and opportunities. Journal of the American Ceramic Society, 2015, 98(7): 1983.

DOI URL |

| [38] |

BRIGO L, SCHMIDT J E M, GANDIN A, et al. 3D nanofabrication of SiOC ceramic structures. Advanced Science, 2018, 5(12): 1800937.

DOI URL |

| [39] |

ZANCHETTA E, CATTALDO M, FRANCHIN G, et al. Stereolithography of SiOC ceramic microcomponents. Advanced Materials, 2016, 28(2): 370.

DOI URL |

| [40] |

SCHMIDT J, BRIGO L, GANDIN A, et al. Multiscale ceramic components from preceramic polymers by hybridization of vat polymerization-based technologies. Additive Manufacturing, 2019, 30: 100913.

DOI URL |

| [41] |

FU Y, XU G, CHEN Z, et al. Multiple metals doped polymer- derived SiOC ceramics for 3D printing. Ceramics International, 2018, 44(10): 11030.

DOI URL |

| [42] |

CHEN Z W, LI Z Y, LI J J, et al. 3D printing of ceramics: a review. Journal of the European Ceramic Society, 2019, 39(4): 661.

DOI |

| [43] |

RASAKI S A, XIONG D, XIONG S, et al. Photopolymerization-based additive manufacturing of ceramics: a systematic review. Journal of Advanced Ceramics, 2021, 10(3): 442.

DOI |

| [44] |

LI Z, CHEN Z, LIU J, et al. Additive manufacturing of lightweight and high-strength polymer-derived SiOC ceramics. Virtual and Physical Prototyping, 2020, 15(2): 163.

DOI URL |

| [45] |

FU Y, CHEN Z, XU G, et al. Preparation and stereo lithography 3D printing of ultralight and ultrastrong ZrOC porous ceramics. Journal of Alloys and Compounds, 2019, 789: 867.

DOI URL |

| [46] |

LIU J, XIONG S F, MEI H, et al. 3D printing of complex-shaped polymer-derived ceramics with enhanced structural retention. Materials and Manufacturing Processes, 2022, 37(11): 1267.

DOI URL |

| [47] | XIONG S F, LIU J, CAO J W, et al. 3D printing of crack-free dense polymer-derived ceramic monoliths and lattice skeletons with improved thickness and mechanical performance. Additive Manufacturing, 2022, 57: 102924. |

| [48] |

TUMBLESTON J R, SHIRVANYANTS D, ERMOSHKIN N, et al. Continuous liquid interface production of 3D objects. Science, 2015, 347: 1349.

DOI URL |

| [49] | DE BEER M P, VAN DER LAAN H L, COLE M A, et al. Rapid, continuous additive manufacturing by volumetric polymerization inhibition patterning. Science Advances, 2019, 5(1): eaau8723. |

| [50] | KRUNER B, ODENWALD C, TOLOSA A, et al. Carbide-derived carbon beads with tunable nanopores from continuously produced polysilsesquioxanes for supercapacitor electrodes. Sustainable Energy & Fuels, 2017, 1(7): 1588. |

| [51] |

JANUSZIEWICZ R, TUMBLESTON J R, QUINTANILLA A L, et al. Layerless fabrication with continuous liquid interface production. Proceedings of the National Academy of Sciences of the United States of America, 2016, 113(42): 11703.

PMID |

| [52] | JOHNSON A R, CAUDILL C L, TUMBLESTON J R, et al. Single- step fabrication of computationally designed microneedles by continuous liquid interface production. PLOS ONE, 2016, 11(9): e0162518. |

| [53] | MAHMOUDI M, WANG C, MORENO S, et al. Three-dimensional printing of ceramics through "carving" a gel and "filling in" the precursor polymer. ACS Applied Materials & Interfaces, 2020, 12(28): 31984. |

| [54] | MINARY M, MAHMOUDI M. 3D printing polymer-derived ceramics using a thixotropic support bath. American Ceramic Society Bulletin, 2021, 100(3): 32. |

| [55] | 兰洪波, 李涤尘, 卢秉恒. 微纳尺度3D打印. 中国科学, 2015, 45(9): 919. |

| [56] |

VAEZI M, SEITZ H, YANG S. A review on 3D micro-additive manufacturing technologies. International Journal of Advanced Manufacturing Technology, 2013, 67(5): 1721.

DOI URL |

| [57] | KIM W S, HOUBERTZ R, LEE T H, et al. Effect of photoinitiator on photopolymerization of inorganic-organic hybrid polymers (ORMOCER (R)). Journal of Polymer Science, 2004, 42(10): 1979. |

| [58] |

KONSTANTINOU G, KAKKAVA E, HAGELUEKEN L, et al. Additive micro-manufacturing of crack-free PDCs by two-photon polymerization of a single, low-shrinkage preceramic resin. Additive Manufacturing, 2020, 35: 101343.

DOI URL |

| [59] | LIU G, ZHAO Y, WU G, et al. Origami and 4D printing of elastomer-derived ceramic structures. Science Advances, 2018, 4(8): eaat0641. |

| [60] | GYAK K W, VISHWAKARMA N K, HWANG Y H, et al. 3D-printed monolithic SiCN ceramic microreactors from a photocurable preceramic resin for the high temperature ammonia cracking process. Reaction Chemistry & Engineering, 2019, 4(8): 1393. |

| [61] |

BRODNIK N R, SCHMIDT J, COLOMBO P, et al. Analysis of multi-scale mechanical properties of ceramic trusses prepared from preceramic polymers (Revision prepared for additive manufacturing). Additive Manufacturing, 2020, 31: 100957.

DOI URL |

| [62] |

KEMP J W, HMEIDAT N S, COMPTON B G. Boron nitride- reinforced polysilazane-derived ceramic composites via direct-ink writing. Journal of the American Ceramic Society, 2020, 103(8): 4043.

DOI URL |

| [63] |

ROMAN-MANSO B, MOYANO J J, PEREZ-COLL D, et al. Polymer-derived ceramic/graphene oxide architected composite with high electrical conductivity and enhanced thermal resistance. Journal of the European Ceramic Society, 2018, 38(5): 2265.

DOI URL |

| [64] |

FRIEDEL T, TRAVITZKY N, NIEBLING F, et al. Fabrication of polymer derived ceramic parts by selective laser curing. Journal of the European Ceramic Society, 2005, 25(3): 193.

DOI URL |

| [65] |

HUANG K, ELSAYED H, FRANCHIN G, et al. 3D printing of polymer-derived SiOC with hierarchical and tunable porosity. Additive Manufacturing, 2020, 36: 101549.

DOI URL |

| [66] |

ZOCCA A, GOMES C M, STAUDE A, et al. SiOC ceramics with ordered porosity by 3D-printing of a preceramic polymer. Journal of Materials Research, 2013, 28(17): 2243.

DOI URL |

| [67] |

FENG Y R, GUO X, HUANG K, et al. Enhanced electromagnetic microwave absorption of SiOC ceramics targeting the integration of structure and function. Journal of the European Ceramic Society, 2021, 41(13): 6393.

DOI URL |

| [68] |

NGO T D, KASHANI A, IMBALZANO G, et al. Additive manufacturing (3D printing): a review of materials, methods, applications and challenges. Composites Part B-Engineering, 2018, 143: 172.

DOI URL |

| [69] |

SINGH S, RAMAKRISHNA S, SINGH R. Material issues in additive manufacturing: a review. Journal of Manufacturing Processes, 2017, 25: 185.

DOI URL |

| [1] | 朱文杰, 唐璐, 陆继长, 刘江平, 罗永明. 钙钛矿型氧化物催化氧化挥发性有机化合物的研究进展[J]. 无机材料学报, 2025, 40(7): 735-746. |

| [2] | 胡智超, 杨鸿宇, 杨鸿程, 孙成礼, 杨俊, 李恩竹. P-V-L键理论在微波介质陶瓷性能调控中的应用[J]. 无机材料学报, 2025, 40(6): 609-626. |

| [3] | 吴琼, 沈炳林, 张茂华, 姚方周, 邢志鹏, 王轲. 铅基织构压电陶瓷研究进展[J]. 无机材料学报, 2025, 40(6): 563-574. |

| [4] | 张碧辉, 刘小强, 陈湘明. Ruddlesden-Popper结构杂化非常规铁电体的研究进展[J]. 无机材料学报, 2025, 40(6): 587-608. |

| [5] | 吴杰, 杨帅, 王明文, 李景雷, 李纯纯, 李飞. 铅基织构压电陶瓷的发展历程、现状与挑战[J]. 无机材料学报, 2025, 40(6): 575-586. |

| [6] | 姜昆, 李乐天, 郑木鹏, 胡永明, 潘勤学, 吴超峰, 王轲. PZT陶瓷的低温烧结研究进展[J]. 无机材料学报, 2025, 40(6): 627-638. |

| [7] | 田睿智, 兰正义, 殷杰, 郝南京, 陈航榕, 马明. 基于微流控技术的纳米无机生物材料制备: 原理及其研究进展[J]. 无机材料学报, 2025, 40(4): 337-347. |

| [8] | 张继国, 吴田, 赵旭, 杨钒, 夏天, 孙士恩. 钠离子电池正极材料循环稳定性提升策略及产业化进程[J]. 无机材料学报, 2025, 40(4): 348-362. |

| [9] | 殷杰, 耿佳毅, 王康龙, 陈忠明, 刘学建, 黄政仁. SiC陶瓷的3D打印成形与致密化新进展[J]. 无机材料学报, 2025, 40(3): 245-255. |

| [10] | 李紫薇, 弓伟露, 崔海峰, 叶丽, 韩伟健, 赵彤. 前驱体法制备(Zr, Hf, Nb, Ta, W)C-SiC复相陶瓷及性能研究[J]. 无机材料学报, 2025, 40(3): 271-280. |

| [11] | 谌广昌, 段小明, 朱金荣, 龚情, 蔡德龙, 李宇航, 杨东雷, 陈彪, 李新民, 邓旭东, 余瑾, 刘博雅, 何培刚, 贾德昌, 周玉. 直升机特定结构先进陶瓷材料研究进展与应用展望[J]. 无机材料学报, 2025, 40(3): 225-244. |

| [12] | 范晓波, 祖梅, 杨向飞, 宋策, 陈晨, 王子, 罗文华, 程海峰. 质子调控型电化学离子突触研究进展[J]. 无机材料学报, 2025, 40(3): 256-270. |

| [13] | 海热古·吐逊, 郭乐, 丁嘉仪, 周嘉琪, 张学良, 努尔尼沙·阿力甫. 上转换荧光探针辅助的光学成像技术在肿瘤显影中的应用研究进展[J]. 无机材料学报, 2025, 40(2): 145-158. |

| [14] | 孙树娟, 郑南南, 潘昊坤, 马猛, 陈俊, 黄秀兵. 单原子催化剂制备方法的研究进展[J]. 无机材料学报, 2025, 40(2): 113-127. |

| [15] | 陶桂龙, 支国伟, 罗添友, 欧阳佩东, 衣新燕, 李国强. 空腔型薄膜体声波滤波器的关键技术进展[J]. 无机材料学报, 2025, 40(2): 128-144. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||