无机材料学报 ›› 2025, Vol. 40 ›› Issue (3): 271-280.DOI: 10.15541/jim20240385 CSTR: 32189.14.10.15541/jim20240385

所属专题: 【结构材料】高导热陶瓷(202506); 【结构材料】高熵陶瓷(202506)

李紫薇1,2( ), 弓伟露1,2, 崔海峰1, 叶丽1(

), 弓伟露1,2, 崔海峰1, 叶丽1( ), 韩伟健1, 赵彤1,2

), 韩伟健1, 赵彤1,2

收稿日期:2024-08-21

修回日期:2024-10-16

出版日期:2025-03-20

网络出版日期:2025-03-12

通讯作者:

叶 丽, 副研究员. E-mail: yeli@iccas.ac.cn作者简介:李紫薇(1998-), 女, 硕士研究生. E-mail: liziwi21@iccas.ac.cn

LI Ziwei1,2( ), GONG Weilu1,2, CUI Haifeng1, YE Li1(

), GONG Weilu1,2, CUI Haifeng1, YE Li1( ), HAN Weijian1, ZHAO Tong1,2

), HAN Weijian1, ZHAO Tong1,2

Received:2024-08-21

Revised:2024-10-16

Published:2025-03-20

Online:2025-03-12

Contact:

YE Li, associate professor. E-mail: yeli@iccas.ac.cnAbout author:LI Ziwei (1998-), female, Master candidate. E-mail: liziwi21@iccas.ac.cn

摘要:

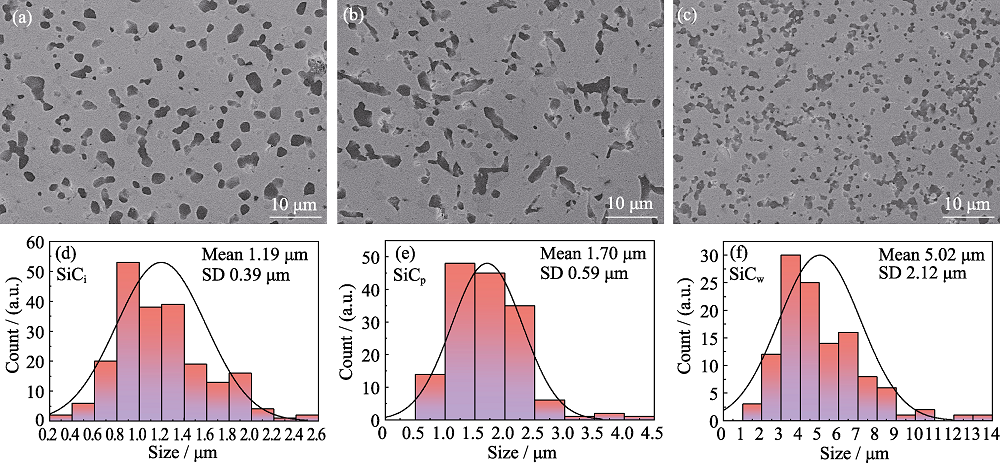

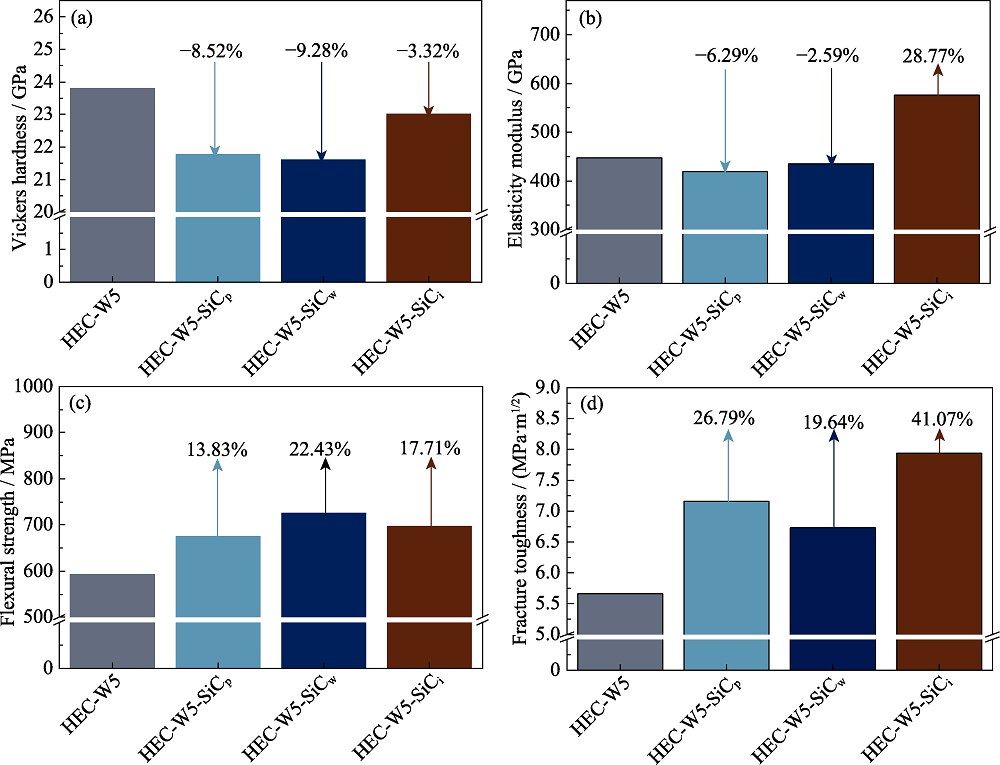

高熵碳化物(HEC)陶瓷具有硬度高、抗氧化、耐腐蚀、耐磨以及高导热等优点, 在极端环境下具有巨大应用潜力。但高熵陶瓷往往脆性较大, 限制了其进一步应用。为了对HEC陶瓷进行增韧, 本工作在(Zr, Hf, Nb, Ta, W)C高熵陶瓷前驱体中加入碳化硅(SiC)的前驱体聚碳硅烷(PCS), 利用PCS裂解过程中原位生成的SiC(SiCi)对HEC陶瓷进行增韧。结果表明, 裂解所得陶瓷中SiC的体积分数为23.38%, SiC相晶粒尺寸小(1.19 μm), 且在高熵陶瓷相中均匀分布。通过研究陶瓷前驱体的裂解过程, 发现PCS裂解产物在温度较低时以无定形的Ox-Si-Cy形式存在, 在1500 ℃以上才开始出现SiC结晶相。以1600 ℃裂解所得(Zr, Hf, Nb, Ta, W)C-SiCi复相陶瓷粉体为原料, 经热压制备了(Zr, Hf, Nb, Ta, W)C-SiCi陶瓷块体, 研究了陶瓷块体的力学性能, 并与添加商品化SiC纳米粉体及SiC晶须增韧的复相陶瓷进行对比。研究发现, 与(Zr, Hf, Nb, Ta, W)C陶瓷相比, 所有复相陶瓷块体的弯曲强度和断裂韧性均得到明显提升, 其中采用聚合物前驱体法原位生成SiC的增韧效果最为明显, 所得陶瓷的弯曲强度和断裂韧性分别为(698±9) MPa和(7.9±0.6) MPa·m1/2, 相比(Zr, Hf, Nb, Ta, W)C陶瓷分别提升了17.71%和41.07%。由于液相聚合物前驱体法制备的复相陶瓷中, SiC的晶粒尺寸最小且分布更加均匀, 在受力时可以消耗更多能量, 阻碍裂纹扩展, 因此陶瓷的断裂韧性得到了大幅提高。

中图分类号:

李紫薇, 弓伟露, 崔海峰, 叶丽, 韩伟健, 赵彤. 前驱体法制备(Zr, Hf, Nb, Ta, W)C-SiC复相陶瓷及性能研究[J]. 无机材料学报, 2025, 40(3): 271-280.

LI Ziwei, GONG Weilu, CUI Haifeng, YE Li, HAN Weijian, ZHAO Tong. (Zr, Hf, Nb, Ta, W)C-SiC Composite Ceramics: Preparation via Precursor Route and Properties[J]. Journal of Inorganic Materials, 2025, 40(3): 271-280.

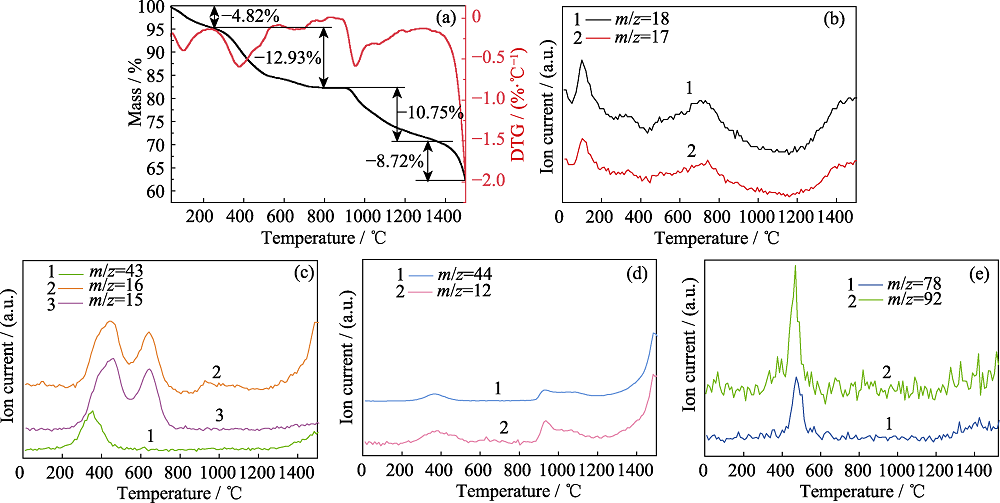

图1 PHEC-PCS固化物的TG-DTG曲线(a)和PHEC-PCS固化物裂解过程气体释放的MS曲线(b~e)

Fig. 1 (a) TG-DTG curves of cured PHEC-PCS and (b-e) MS spectra of gases released during pyrolysis of cured PHEC-PCS

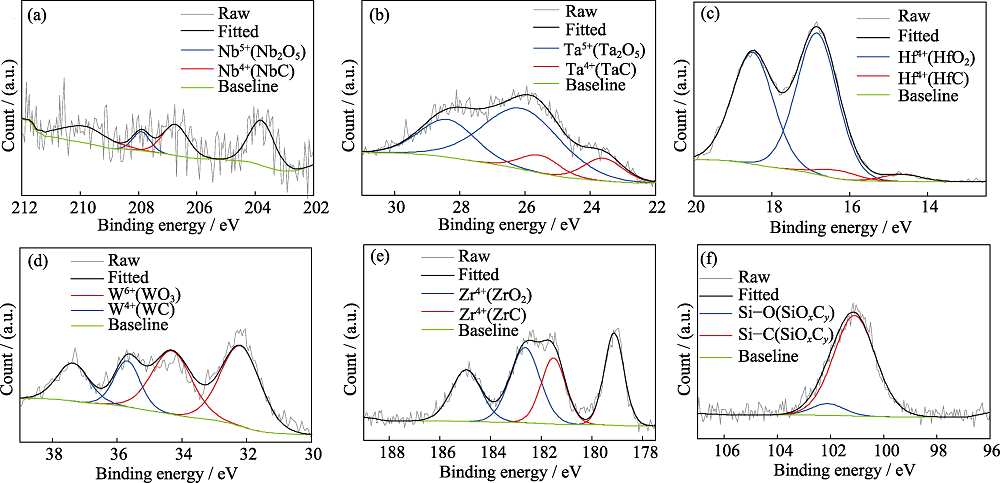

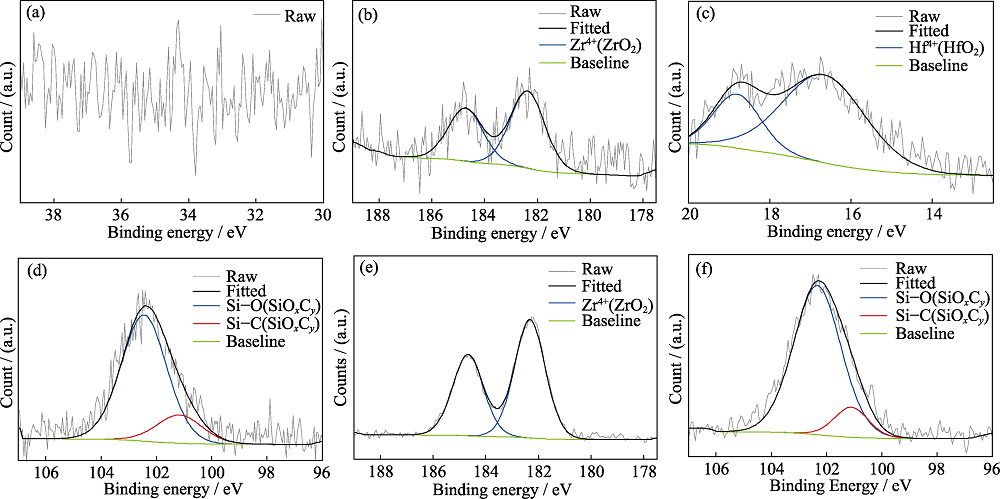

图2 不同温度裂解所得HEC-W5-SiCi样品的XPS图谱

Fig. 2 XPS spectra of HEC-W5-SiCi obtained at different pyrolysis temperatures (a, b) Nb3d and Ta4f of HEC-W5-SiCi-1000; (c, d) Hf4f and W4f of HEC-W5-SiCi-1200; (e, f) Zr3d and Si2p of HEC-W5-SiCi-1400. Colorful figures are available on website

图6 HEC-W5-SiCi(a, d)、HEC-W5-SiCp(b, e)和HEC-W5-SiCw(c, f)复相陶瓷的表面SEM照片(a~c)及其中SiC相的晶粒尺寸(d~f)

Fig. 6 (a-c) Surface SEM images and (d-f) grain size statistics of SiC in (a, d) HEC-W5-SiCi, (b, e) HEC-W5-SiCp, and (c, f) HEC-W5-SiCw bulk ceramics

图7 HEC-W5、HEC-W5-SiCp、HEC-W5-SiCw和HEC-W5-SiCi复相陶瓷的力学性能

Fig. 7 Mechanical properties of HEC-W5, HEC-W5-SiCp, HEC-W5-SiCw, and HEC-W5-SiCi ceramics (a) Vickers hardness; (b) Elasticity modulus; (c) Flexural strength; (d) Fracture toughness

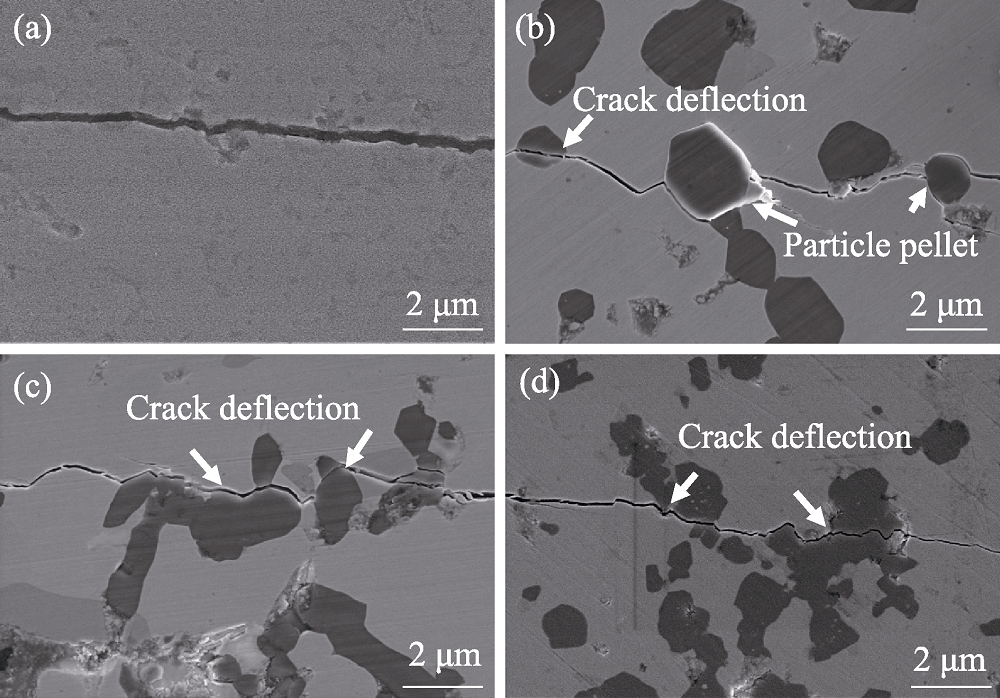

图8 维氏硬度测试后陶瓷的裂纹扩展形貌图

Fig. 8 Morphologies of crack extension of ceramics after Vickers hardness test (a) HEC-W5; (b) HEC-W5-SiCp; (c) HEC-W5-SiCw; (d) HEC-W5-SiCi

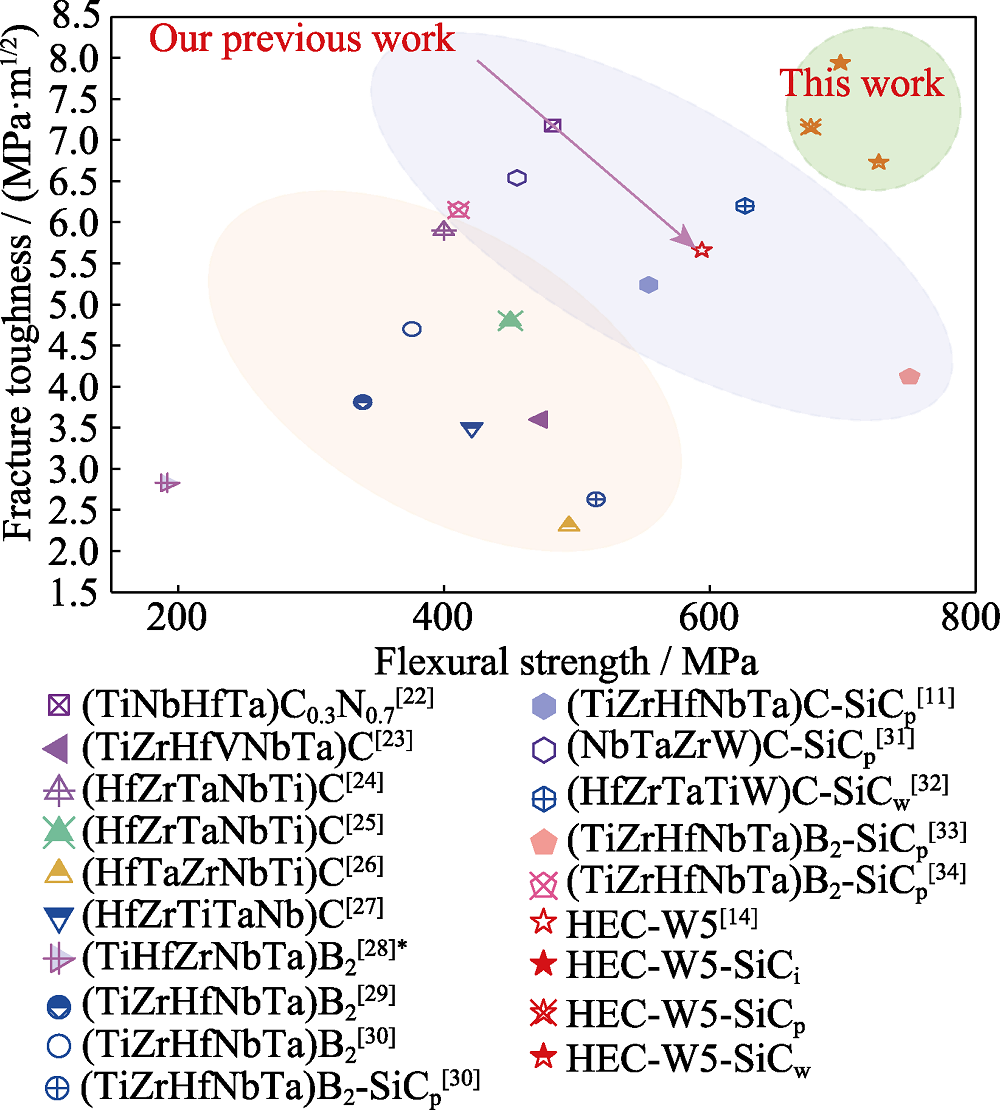

图9 HEC-W5-SiCi复相陶瓷的弯曲强度和断裂韧性与文献[11,14,22⇓⇓⇓⇓⇓⇓⇓⇓⇓⇓⇓ -34]数据的对比

Fig. 9 Flexural strength and fracture toughness of HEC-W5- SiCi ceramics of this work and data in literature[11,14,22⇓⇓⇓⇓⇓⇓⇓⇓⇓⇓⇓ -34] *This literature only has fracture toughness data.

| Empirical formula | Content/(%, in mass) | |||||||

|---|---|---|---|---|---|---|---|---|

| Zr | Hf | Nb | Ta | W | Si | C | O | |

| (Zr0.238Hf0.237Nb0.237Ta0.237W0.05)-Si0.347C1.405O0.031 | 13.1 | 25.6 | 13.3 | 25.9 | 5.5 | 5.9 | 10.2 | 0.3 |

表S1 HEC-W5-SiCi-1600样品的元素含量分析

Table S1 Elemental content analysis of HEC-SiCi-1600

| Empirical formula | Content/(%, in mass) | |||||||

|---|---|---|---|---|---|---|---|---|

| Zr | Hf | Nb | Ta | W | Si | C | O | |

| (Zr0.238Hf0.237Nb0.237Ta0.237W0.05)-Si0.347C1.405O0.031 | 13.1 | 25.6 | 13.3 | 25.9 | 5.5 | 5.9 | 10.2 | 0.3 |

| Sample | Vickers hardness/GPa | Elasticity modulus/GPa | Flexural strength/MPa | Fracture toughness/ (MPa·m1/2) | Shape factor, Y |

|---|---|---|---|---|---|

| HEC-W5 | 23.82±0.49 | 447.07±3.71 | 593±15 | 5.6±0.2 | 2.537 |

| HEC-W5-SiCp | 21.79±0.78 | 418.96±5.24 | 675±12 | 7.1±0.5 | 2.535 |

| HEC-W5-SiCw | 21.61±0.35 | 435.50±4.38 | 726±18 | 6.7±0.3 | 2.533 |

| HEC-W5-SiCi | 23.03±0.63 | 575.70±8.25 | 698±9 | 7.9±0.6 | 2.534 |

表S2 HEC-W5、HEC-W5-SiCp、HEC-W5-SiCw和HEC-W5-SiCi的力学性能

Table S2 Mechanical properties of HEC-W5, HEC-W5-SiCp, HEC-W5-SiCw, and HEC-W5-SiCi ceramics

| Sample | Vickers hardness/GPa | Elasticity modulus/GPa | Flexural strength/MPa | Fracture toughness/ (MPa·m1/2) | Shape factor, Y |

|---|---|---|---|---|---|

| HEC-W5 | 23.82±0.49 | 447.07±3.71 | 593±15 | 5.6±0.2 | 2.537 |

| HEC-W5-SiCp | 21.79±0.78 | 418.96±5.24 | 675±12 | 7.1±0.5 | 2.535 |

| HEC-W5-SiCw | 21.61±0.35 | 435.50±4.38 | 726±18 | 6.7±0.3 | 2.533 |

| HEC-W5-SiCi | 23.03±0.63 | 575.70±8.25 | 698±9 | 7.9±0.6 | 2.534 |

| Sample | Flexural strength/MPa | Fracture toughness/(MPa·m1/2) | Ref. |

|---|---|---|---|

| (Ti0.25Nb0.25Hf0.25Ta0.25)C0.3N0.7 | 481±56b | 7.17±0.62c | [22] |

| (TiZrHfVNbTa)C | 473±21b | 3.6±0.2c | [23] |

| (Hf0.2Zr0.2Ta0.2Nb0.2Ti0.2)C | 400b | 5.9c | [24] |

| (Hf0.2Zr0.2Ta0.2Nb0.2Ti0.2)C | 450±64b | 4.8±0.2c | [25] |

| (Hf0.2Ta0.2Zr0.2Nb0.2Ti0.2)C | 494b | 2.306d | [26] |

| (Hf0.2Zr0.2Ti0.2Ta0.2Nb0.2)C | 421±27a | 3.5±0.3d | [27] |

| (Ti0.2Hf0.2Zr0.2Nb0.2Ta0.2)B2 | - | 2.83±0.15e | [28] |

| (Hf0.2Nb0.2Ta0.2Ti0.2Zr0.2)B2 | 376±25b | 4.70±0.27c | [29] |

| (Ti0.2Zr0.2Hf0.2Nb0.2Ta0.2)B2 | 339±17a | 3.81±0.40c | [30] |

| (Ti0.2Zr0.2Hf0.2Nb0.2Ta0.2)B2-20SiCp | 447±45a | 4.85±0.33c | [30] |

| (NbTaZrW)C-50SiCP | 455b | 6.54c | [31] |

| (HfZrTaTiW)C-1.5wt%SiCnw | 626.5b | 6.2e | [32] |

| (Ti0.2Zr0.2Hf0.2Nb0.2Ta0.2)B2-20SiCp | 750±43b | 4.12±0.20e | [33] |

| (Ti0.2Zr0.2Hf0.2Nb0.2Ta0.2)B2-20SiCp | 476±42b | 4.63±0.23c | [34] |

| (Ti0.2Zr0.2Hf0.2Nb0.2Ta0.2)C-20SiCp | 554±73a | 5.24±0.41c | [11] |

| HEC-W5 | 593±15b | 5.6±0.2c | [14] |

| HEC-W5-SiCp | 675±12b | 7.1±0.5c | This work |

| HEC-W5-SiCw | 726±18b | 6.7±0.3c | This work |

| HEC-W5-SiCi | 698±9b | 7.9±0.6c | This work |

表S3 HEC-W5-SiCi复相陶瓷与已报道陶瓷的弯曲强度和断裂韧性数据汇总[11,14,22⇓⇓⇓⇓⇓⇓⇓⇓⇓⇓⇓ -34]

Table S3 Flexural strength and fracture toughness of HEC-W5-SiCi ceramics and previous studies[11,14,22⇓⇓⇓⇓⇓⇓⇓⇓⇓⇓⇓ -34]

| Sample | Flexural strength/MPa | Fracture toughness/(MPa·m1/2) | Ref. |

|---|---|---|---|

| (Ti0.25Nb0.25Hf0.25Ta0.25)C0.3N0.7 | 481±56b | 7.17±0.62c | [22] |

| (TiZrHfVNbTa)C | 473±21b | 3.6±0.2c | [23] |

| (Hf0.2Zr0.2Ta0.2Nb0.2Ti0.2)C | 400b | 5.9c | [24] |

| (Hf0.2Zr0.2Ta0.2Nb0.2Ti0.2)C | 450±64b | 4.8±0.2c | [25] |

| (Hf0.2Ta0.2Zr0.2Nb0.2Ti0.2)C | 494b | 2.306d | [26] |

| (Hf0.2Zr0.2Ti0.2Ta0.2Nb0.2)C | 421±27a | 3.5±0.3d | [27] |

| (Ti0.2Hf0.2Zr0.2Nb0.2Ta0.2)B2 | - | 2.83±0.15e | [28] |

| (Hf0.2Nb0.2Ta0.2Ti0.2Zr0.2)B2 | 376±25b | 4.70±0.27c | [29] |

| (Ti0.2Zr0.2Hf0.2Nb0.2Ta0.2)B2 | 339±17a | 3.81±0.40c | [30] |

| (Ti0.2Zr0.2Hf0.2Nb0.2Ta0.2)B2-20SiCp | 447±45a | 4.85±0.33c | [30] |

| (NbTaZrW)C-50SiCP | 455b | 6.54c | [31] |

| (HfZrTaTiW)C-1.5wt%SiCnw | 626.5b | 6.2e | [32] |

| (Ti0.2Zr0.2Hf0.2Nb0.2Ta0.2)B2-20SiCp | 750±43b | 4.12±0.20e | [33] |

| (Ti0.2Zr0.2Hf0.2Nb0.2Ta0.2)B2-20SiCp | 476±42b | 4.63±0.23c | [34] |

| (Ti0.2Zr0.2Hf0.2Nb0.2Ta0.2)C-20SiCp | 554±73a | 5.24±0.41c | [11] |

| HEC-W5 | 593±15b | 5.6±0.2c | [14] |

| HEC-W5-SiCp | 675±12b | 7.1±0.5c | This work |

| HEC-W5-SiCw | 726±18b | 6.7±0.3c | This work |

| HEC-W5-SiCi | 698±9b | 7.9±0.6c | This work |

图S1 HEC-W5-SiCi样品的XPS图谱

Fig. S1 XPS spectra of HEC-W5-SiCi (a-d) W4f, Zr3d, Hf4f and Si2p of HEC-W5-SiCi-1000; (e, f) Zr3d and Si2p of HEC-W5-SiCi-1200

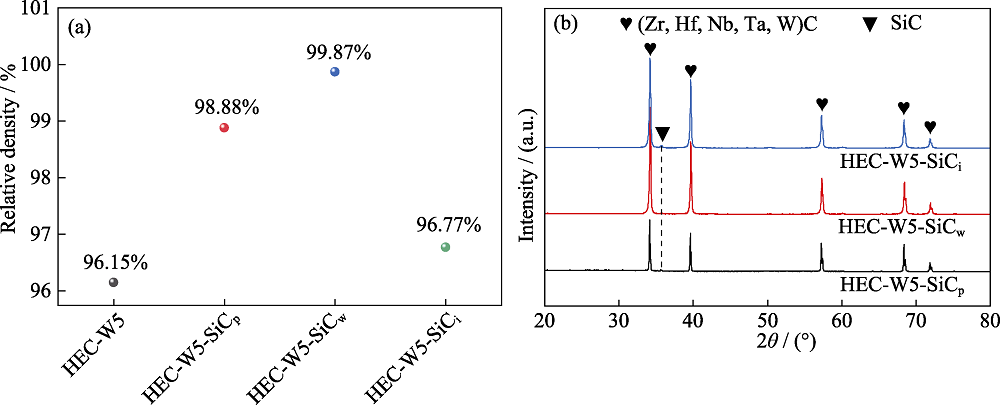

图S3 (a)HEC-W5和HEC-W5-SiC陶瓷的致密度, (b)不同HEC-W5-SiC陶瓷的XRD图谱

Fig. S3 (a) Relative density of HEC-W5 ceramics and HEC-W5-SiC ceramics, (b) XRD patterns of different EC-W5-SiC ceramics

| [1] | DUBE T C, ZHANG J. Underpinning the relationship between synthesis and properties of high entropy ceramics: a comprehensive review on borides, carbides and oxides. Journal of the European Ceramic Society, 2024, 44(3): 1335. |

| [2] | YE B L, WEN T Q, NGUYEN M C, et al. First-principles study, fabrication and characterization of (Zr0.25Nb0.25Ti0.25V0.25)C high- entropy ceramics. Acta Materialia, 2019, 170: 15. |

| [3] | YE B L, WEN T Q, HUANG K H, et al. First-principles study, fabrication, and characterization of (Hf0.2Zr0.2Ta0.2Nb0.2Ti0.2)C high-entropy ceramic. Journal of the American Ceramic Society, 2019, 102(7): 4344. |

| [4] | MA M D, SUN Y N, WU Y J, et al. Nanocrystalline high-entropy carbide ceramics with improved mechanical properties. Journal of the American Ceramic Society, 2022, 105(1): 606. |

| [5] | YE B L, WEN T Q, CHU Y H. High-temperature oxidation behavior of (Hf0.2Zr0.2Ta0.2Nb0.2Ti0.2)C high-entropy ceramics in air. Journal of the American Ceramic Society, 2020, 103(1): 500. |

| [6] | YE B L, WEN T Q, LIU D, et al.Oxidation behavior of (Hf0.2Zr0.2Ta0.2Nb0.2Ti0.2)C high-entropy ceramics at 1073-1473 K in air. Corrosion Science, 2019, 153: 327. |

| [7] | WANG Y C, ZHANG B H, ZHANG C Y, et al. Ablation behaviour of (Hf-Ta-Zr-Nb)C high entropy carbide ceramic at temperatures above 2100 ℃. Journal of Materials Science & Technology, 2022, 113: 40. |

| [8] | WANG F, YAN X L, WANG T Y, et al. Irradiation damage in (Zr0.25Ta0.25Nb0.25Ti0.25)C high-entropy carbide ceramics. Acta Materialia, 2020, 195: 739. |

| [9] | CAO Z N, SUN J L, MENG L T, et al. Progress in densification and toughening of high entropy carbide ceramics. Journal of Materials Science & Technology, 2023, 161: 10. |

| [10] | RITCHIE R O. Toughening materials: enhancing resistance to fracture. Philosophical Transactions of the Royal Society A: Mathematical Physical and Engineering Sciences, 2021, 379(2203): 20200437. |

| [11] | LU K, LIU J X, WEI X F, et al. Microstructures and mechanical properties of high-entropy (Ti0.2Zr0.2Hf0.2Nb0.2Ta0.2)C ceramics with the addition of SiC secondary phase. Journal of the European Ceramic Society, 2020, 40(5): 1839. |

| [12] | LUO S C, GUO W M, ZHOU Y Z, et al. Textured and toughened high-entropy (Ti0.2Zr0.2Hf0.2Nb0.2Ta0.2)C-SiCw ceramics. Journal of Materials Science & Technology, 2021, 94: 99. |

| [13] | SUN J L, ZHAO J Z, CHEN Y C, et al. Macro-micro-nano multistage toughening in nano-laminated graphene ceramic composites. Materials Today Physics, 2022, 22: 100595. |

| [14] | GONG W L, YE L, SONG R H, et al. Polymer-derived W-doping (Zr, Hf, Nb, Ta)C high entropy ceramics: preparation, properties and DFT calculation. Ceramics International, 2024, 50(5): 8284. |

| [15] | YU Y X, GUO Y D, CHENG X, et al. Pyrolysis behavior of titanium-containing polycarbosilane in air. Journal of Inorganic and Organometallic Polymers and Materials, 2010, 20(4): 714. |

| [16] | LYU Y, TANG H T, ZHAO G D. Effect of Hf and B incorporation on the SiOC precursor architecture and high-temperature oxidation behavior of SiHfBOC ceramics. Journal of the European Ceramic Society, 2020, 40(2): 324. |

| [17] | WANG X Z, ZHANG L Y, WANG Y F. Preparation of HfC-SiC ultra-high-temperature ceramics by the copolycondensation of HfC and SiC precursors. Journal of Materials Science, 2022, 57(7): 4467. |

| [18] | WU Y H, CHEN F H, HAN W J, et al. Synthesis and pyrolysis of non-oxide precursors for ZrC/SiC and HfC/SiC composite ceramics. Ceramics International, 2020, 46(14): 22102. |

| [19] | WU S B, SONG K R, SHI F Y, et al. Polymer precursor synthesis of novel ZrC-SiC ultrahigh-temperature ceramics and modulation of their molecular structure. Ceramics International, 2023, 49(1): 707. |

| [20] | RAO X H, ZHANG F H, LUO X H, et al. Characterization of hardness, elastic modulus and fracture toughness of RB-SiC ceramics at elevated temperature by Vickers test. Materials Science and Engineering: A, 2019, 744: 426. |

| [21] | 朱和国, 王天驰, 贾阳, 等. 复合材料原理(第2版). 北京: 电子工业出版社, 2016:55-73. |

| [22] | WANG H Y, BI J Q, YANG Y, et al. Preparation, characterization and performance of high-entropy carbonitride ceramics. Ceramics International, 2024, 50(2): 3034. |

| [23] | CHEN L, ZHANG W, TAN Y Q, et al. Influence of vanadium content on the microstructural evolution and mechanical properties of (TiZrHfVNbTa)C high-entropy carbides processed by pressureless sintering. Journal of the European Ceramic Society, 2021, 41(16): 60. |

| [24] | WANG F, ZHANG X, YAN X L, et al. The effect of submicron grain size on thermal stability and mechanical properties of high-entropy carbide ceramics. Journal of the American Ceramic Society, 2020, 103(8): 4463. |

| [25] | YU D, YIN J, ZHANG B H, et al. Pressureless sintering and properties of (Hf0.2Zr0.2Ta0.2Nb0.2Ti0.2)C high-entropy ceramics: the effect of pyrolytic carbon. Journal of the European Ceramic Society, 2021, 41(6): 3823. |

| [26] | SUN K B, YANG Z W, MU R J, et al. Densification and joining of a (HfTaZrNbTi)C high-entropy ceramic by hot pressing. Journal of the European Ceramic Society, 2021, 41(6): 3196. |

| [27] | FENG L, CHEN W T, FAHRENHOLTZ W G, et al. Strength of single-phase high-entropy carbide ceramics up to 2300 ℃. Journal of the American Ceramic Society, 2020, 104(1): 419. |

| [28] | GU J F, ZOU J, SUN S K, et al. Dense and pure high-entropy metal diboride ceramics sintered from self-synthesized powders via boro/carbothermal reduction approach. Science China Materials, 2019, 62(12): 1898. |

| [29] | QIAO L G, LIU Y, GAO Y, et al. First-principles prediction, fabrication and characterization of (Hf0.2Nb0.2Ta0.2Ti0.2Zr0.2)B2 high-entropy borides. Ceramics International, 2022, 48(12): 17234. |

| [30] | LIU J X, SHEN X Q, WU Y, et al. Mechanical properties of hot-pressed high-entropy diboride-based ceramics. Journal of Advanced Ceramics, 2020, 9(4): 503. |

| [31] | PENG F, WEI Z, SONG Q Q, et al. Simultaneous hardening and toughening of a high-entropy (NbTaZrW)C ceramic carbide using SiC particle. Journal of the American Ceramic Society, 2023, 106(7): 4443. |

| [32] | SUN J L, ZHAO J, CHEN Y, et al. Toughening in low-dimensional nanomaterials high-entropy ceramic nanocomposite. Composites Part B: Engineering, 2022, 231: 109586. |

| [33] | KOMBAMUTHU V, ÜNSAL H, CHLUP Z, et al. Effect of SiC on densification, microstructure and mechanical properties of high entropy diboride (Ti0.2Zr0.2Hf0.2Nb0.2Ta0.2)B2. Journal of the European Ceramic Society, 2024, 106(7): 5358. |

| [34] | HUANG F L, WANG H L, FANG C, et al. Improved damage tolerance and oxidation resistance of (Ti0.2Zr0.2Hf0.2Nb0.2Ta0.2) B2-SiC by introducing chopped carbon fibers. Journal of Advanced Ceramics, 2024, 13(1): 101. |

| [1] | 王鲁杰, 张玉新, 李彤阳, 于源, 任鹏伟, 王建章, 汤华国, 姚秀敏, 黄毅华, 刘学建, 乔竹辉. 深海服役环境下碳化硅陶瓷材料的腐蚀及磨损行为[J]. 无机材料学报, 2025, 40(7): 799-807. |

| [2] | 陈义, 邱海鹏, 陈明伟, 徐昊, 崔恒. SiC/SiC复合材料基体硼改性方法及其力学性能研究[J]. 无机材料学报, 2025, 40(5): 504-510. |

| [3] | 崔宁, 张玉新, 王鲁杰, 李彤阳, 于源, 汤华国, 乔竹辉. (TiVNbMoW)Cx高熵陶瓷的单相形成过程与碳空位调控[J]. 无机材料学报, 2025, 40(5): 511-520. |

| [4] | 高晨光, 孙晓亮, 陈君, 李达鑫, 陈庆庆, 贾德昌, 周玉. 基于湿法纺丝技术的SiBCN-rGO陶瓷纤维的组织结构、力学和吸波性能[J]. 无机材料学报, 2025, 40(3): 290-296. |

| [5] | 穆浩洁, 张源江, 喻彬, 付秀梅, 周世斌, 李晓东. ZrO2掺杂Y2O3-MgO纳米复相陶瓷的制备及性能研究[J]. 无机材料学报, 2025, 40(3): 281-289. |

| [6] | 李伟, 许志明, 苟燕子, 尹森虎, 余艺平, 王松. SiC纤维烧结陶瓷的制备及其性能研究[J]. 无机材料学报, 2025, 40(2): 177-183. |

| [7] | 鲍伟超, 郭晓杰, 辛晓婷, 彭湃, 王新刚, 刘吉轩, 张国军, 许钫钫. 在碳化物陶瓷中构筑金属原子层分相共生结构[J]. 无机材料学报, 2025, 40(1): 17-22. |

| [8] | 王浩, 刘学超, 郑重, 潘秀红, 徐锦涛, 朱新锋, 陈锟, 邓伟杰, 汤美波, 郭辉, 高攀. 非本征背照触发平面型4H-SiC光导开关性能研究[J]. 无机材料学报, 2024, 39(9): 1070-1076. |

| [9] | 范武刚, 曹雄, 周响, 李玲, 赵冠楠, 张兆泉. 8YSZ陶瓷在模拟压水堆水环境中的耐腐蚀性能[J]. 无机材料学报, 2024, 39(7): 803-809. |

| [10] | 王康龙, 殷杰, 陈晓, 王力, 刘学建, 黄政仁. 颗粒级配对选区激光烧结打印结合常压固相烧结制备碳化硅陶瓷性能的影响[J]. 无机材料学报, 2024, 39(7): 754-760. |

| [11] | 王伟明, 王为得, 粟毅, 马青松, 姚冬旭, 曾宇平. 以非氧化物为烧结助剂制备高导热氮化硅陶瓷的研究进展[J]. 无机材料学报, 2024, 39(6): 634-646. |

| [12] | 孙海洋, 季伟, 王为民, 傅正义. TiB-Ti周期序构复合材料设计、制备及性能研究[J]. 无机材料学报, 2024, 39(6): 662-670. |

| [13] | 蔡飞燕, 倪德伟, 董绍明. 高熵碳化物超高温陶瓷的研究进展[J]. 无机材料学报, 2024, 39(6): 591-608. |

| [14] | 刘国昂, 王海龙, 方成, 黄飞龙, 杨欢. B4C含量对(Ti0.25Zr0.25Hf0.25Ta0.25)B2-B4C陶瓷力学性能及抗氧化性能的影响[J]. 无机材料学报, 2024, 39(6): 697-706. |

| [15] | 粟毅, 史扬帆, 贾成兰, 迟蓬涛, 高扬, 马青松, 陈思安. 浆料浸渍辅助PIP工艺制备C/HfC-SiC复合材料的微观结构及性能研究[J]. 无机材料学报, 2024, 39(6): 726-732. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||