无机材料学报 ›› 2025, Vol. 40 ›› Issue (12): 1425-1432.DOI: 10.15541/jim20250041 CSTR: 32189.14.jim20250041

郑元顺1( ), 余健2(

), 余健2( ), 叶先峰1, 梁栋1, 朱婉婷1, 聂晓蕾1, 魏平1, 赵文俞1(

), 叶先峰1, 梁栋1, 朱婉婷1, 聂晓蕾1, 魏平1, 赵文俞1( ), 张清杰1

), 张清杰1

收稿日期:2025-02-02

修回日期:2025-04-13

出版日期:2025-12-20

网络出版日期:2025-04-27

通讯作者:

余 健, 副教授. E-mail: yujian@jju.edu;作者简介:郑元顺(1999-), 男, 硕士研究生. E-mail: yszheng@whut.edu.cn

ZHENG Yuanshun1( ), YU Jian2(

), YU Jian2( ), YE Xianfeng1, LIANG Dong1, ZHU Wanting1, NIE Xiaolei1, WEI Ping1, ZHAO Wenyu1(

), YE Xianfeng1, LIANG Dong1, ZHU Wanting1, NIE Xiaolei1, WEI Ping1, ZHAO Wenyu1( ), ZHANG Qingjie1

), ZHANG Qingjie1

Received:2025-02-02

Revised:2025-04-13

Published:2025-12-20

Online:2025-04-27

Contact:

YU Jian, associate professor. E-mail: yujian@jju.edu;About author:ZHENG Yuanshun (1999-), male, Master candidate. E-mail: yszheng@whut.edu.cn

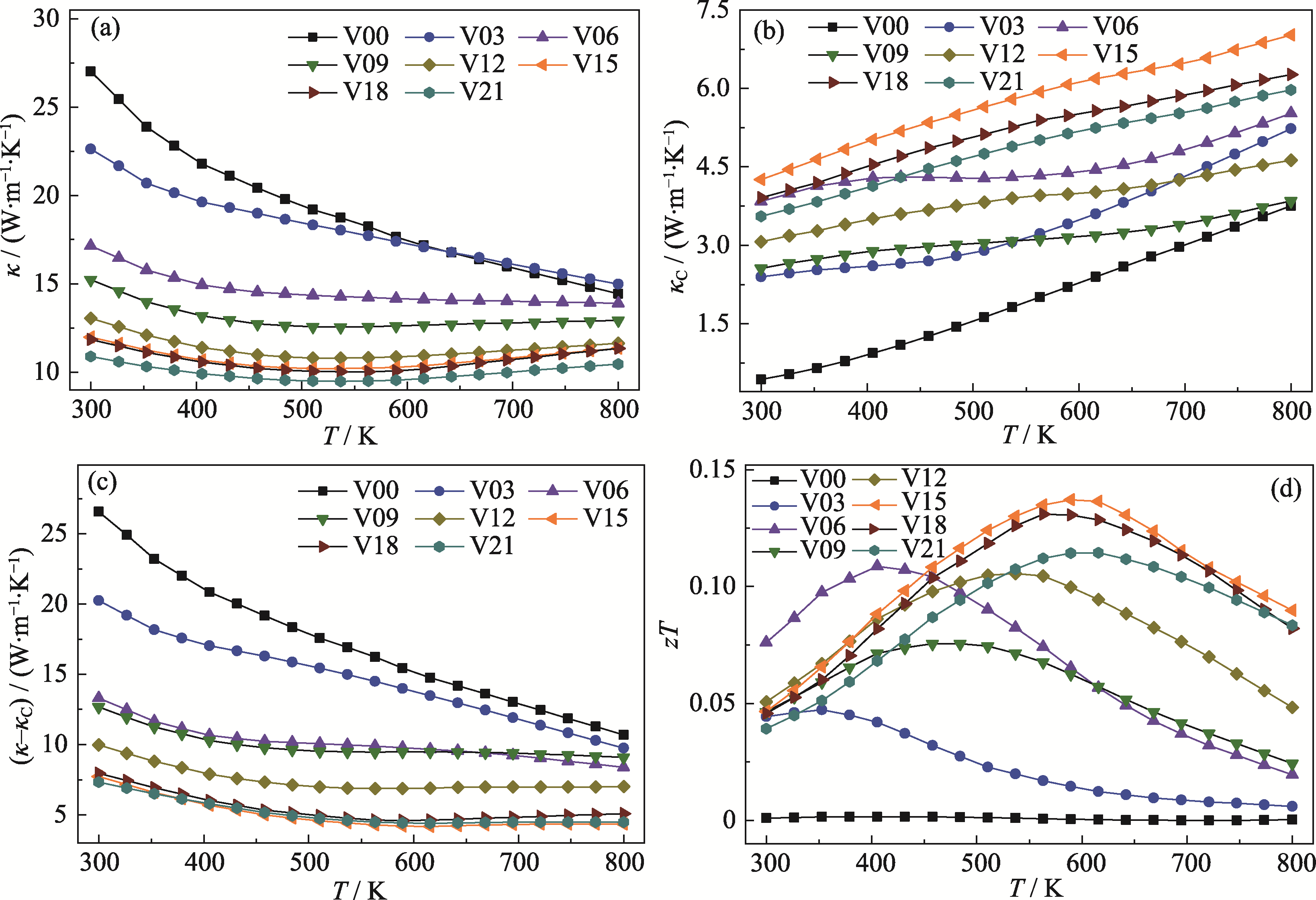

Supported by:摘要: 全赫斯勒合金Fe2VAl具有机械强度较高、电输运性能好和组成元素地球丰度高的优势, 在热电领域受到广泛关注。然而, 该合金的高晶格热导率极大限制了热电优值(zT)的提升。本研究采用电弧熔炼法制备了一系列名义化学成分为Fe2V1+xAl1-x(x=0~0.21)的块体材料, 系统研究了V取代Al位对物相组成、显微结构、能带结构和热电输运性能的影响。结果表明, 所有材料均为部分无序的B2单相结构。V掺杂可将费米能级上移至导带, 大幅度增大载流子浓度, 并将功率因子提升至4.5 mW·K-2·m-1。同时, 由于质量与应力波动引起的声子散射作用增强, 晶格热导率显著降低。最终, x=0.15的材料的最大zT达到0.14, 与未掺杂Fe2VAl材料相比提升近280倍。该研究表明V取代Al位可以有效提升Fe2VAl合金的热电性能。

中图分类号:

郑元顺, 余健, 叶先峰, 梁栋, 朱婉婷, 聂晓蕾, 魏平, 赵文俞, 张清杰. V取代Al位提升全赫斯勒合金Fe2VAl的热电性能[J]. 无机材料学报, 2025, 40(12): 1425-1432.

ZHENG Yuanshun, YU Jian, YE Xianfeng, LIANG Dong, ZHU Wanting, NIE Xiaolei, WEI Ping, ZHAO Wenyu, ZHANG Qingjie. Boosting the Thermoelectric Performance of Full-Heusler Fe2VAl Alloy via Substituting Al Site with V[J]. Journal of Inorganic Materials, 2025, 40(12): 1425-1432.

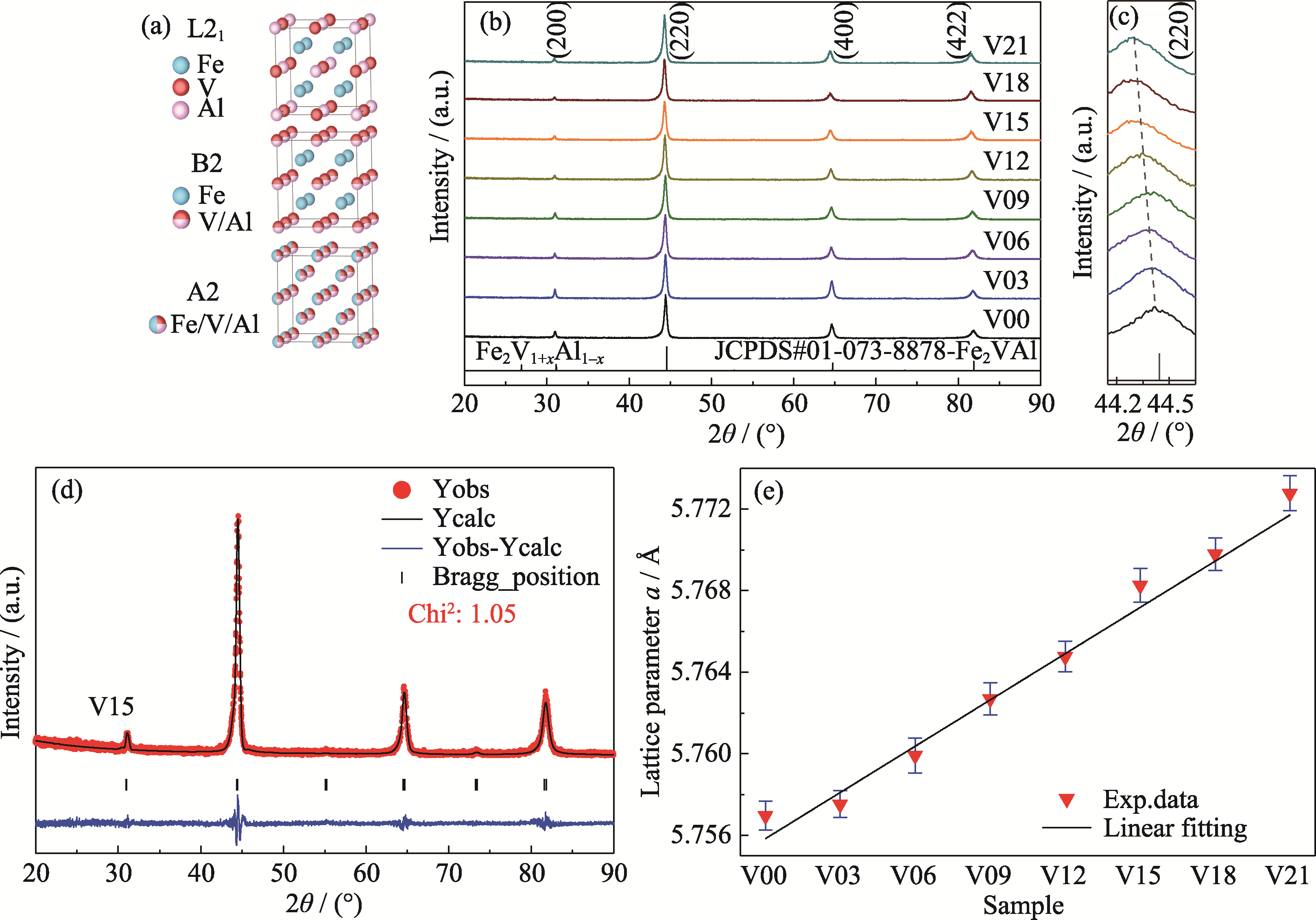

Fig. 1 Crystal structure and phase composition obtained from XRD analysis (a) L21, B2, and A2 type crystal structures of Fe2VAl; (b) Powder XRD patterns of all Fe2V1+xAl1-x materials; (c) Changes of the diffraction peak of (220) plane with the doping amount increasing; (d) XRD Rietveld refinement result of V15; (e) Lattice parameter of all Fe2V1+xAl1-x materials obtained through Rietveld refinement

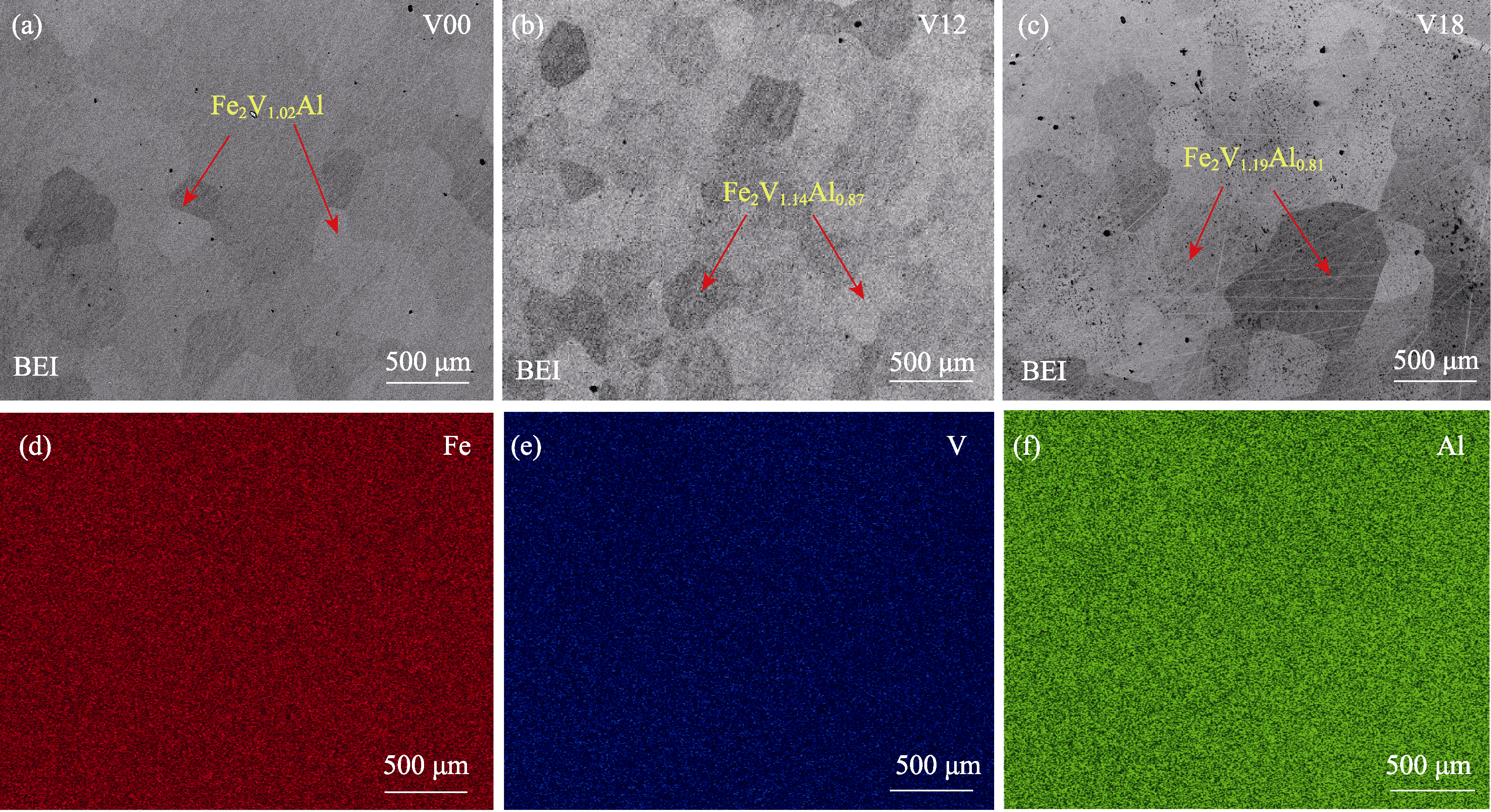

Fig. 2 Backscattered electron images and EDS mappings of selected Fe2V1+xAl1-x alloys (a-c) Backscattered electron images of (a) V00, (b) V12, and (c) V18; (d-f) EDS elemental mappings of V18

| Nom. Comp. | EDS Comp. | n/(×1020, cm-3) | μ/(cm2·V-1·s-1) | Nom. Comp. | EDS Comp. | n/(×1020, cm-3) | μ/(cm2·V-1·s-1) |

|---|---|---|---|---|---|---|---|

| Fe2VAl | Fe2V1.02Al | 3.5 | 11.5 | Fe2V1.12Al0.88 | Fe2V1.14Al0.87 | -29.6 | 5.9 |

| Fe2V1.03Al0.97 | Fe2V1.05Al0.95 | -10.0 | 10.1 | Fe2V1.15Al0.85 | Fe2V1.16Al0.82 | -57.8 | 4.7 |

| Fe2V1.06Al0.94 | Fe2V1.07Al0.91 | -13.7 | 13.4 | Fe2V1.18Al0.82 | Fe2V1.19Al0.81 | -59.5 | 4.2 |

| Fe2V1.09Al0.91 | Fe2V1.11Al0.90 | -35.5 | 3.8 | Fe2V1.21Al0.79 | Fe2V1.24Al0.77 | -86.0 | 2.7 |

Table 1 Nominal compositions, EDS-measured compositions, carrier concentrations, and carrier mobilities of Fe2V1+xAl1-x alloys at 300 K

| Nom. Comp. | EDS Comp. | n/(×1020, cm-3) | μ/(cm2·V-1·s-1) | Nom. Comp. | EDS Comp. | n/(×1020, cm-3) | μ/(cm2·V-1·s-1) |

|---|---|---|---|---|---|---|---|

| Fe2VAl | Fe2V1.02Al | 3.5 | 11.5 | Fe2V1.12Al0.88 | Fe2V1.14Al0.87 | -29.6 | 5.9 |

| Fe2V1.03Al0.97 | Fe2V1.05Al0.95 | -10.0 | 10.1 | Fe2V1.15Al0.85 | Fe2V1.16Al0.82 | -57.8 | 4.7 |

| Fe2V1.06Al0.94 | Fe2V1.07Al0.91 | -13.7 | 13.4 | Fe2V1.18Al0.82 | Fe2V1.19Al0.81 | -59.5 | 4.2 |

| Fe2V1.09Al0.91 | Fe2V1.11Al0.90 | -35.5 | 3.8 | Fe2V1.21Al0.79 | Fe2V1.24Al0.77 | -86.0 | 2.7 |

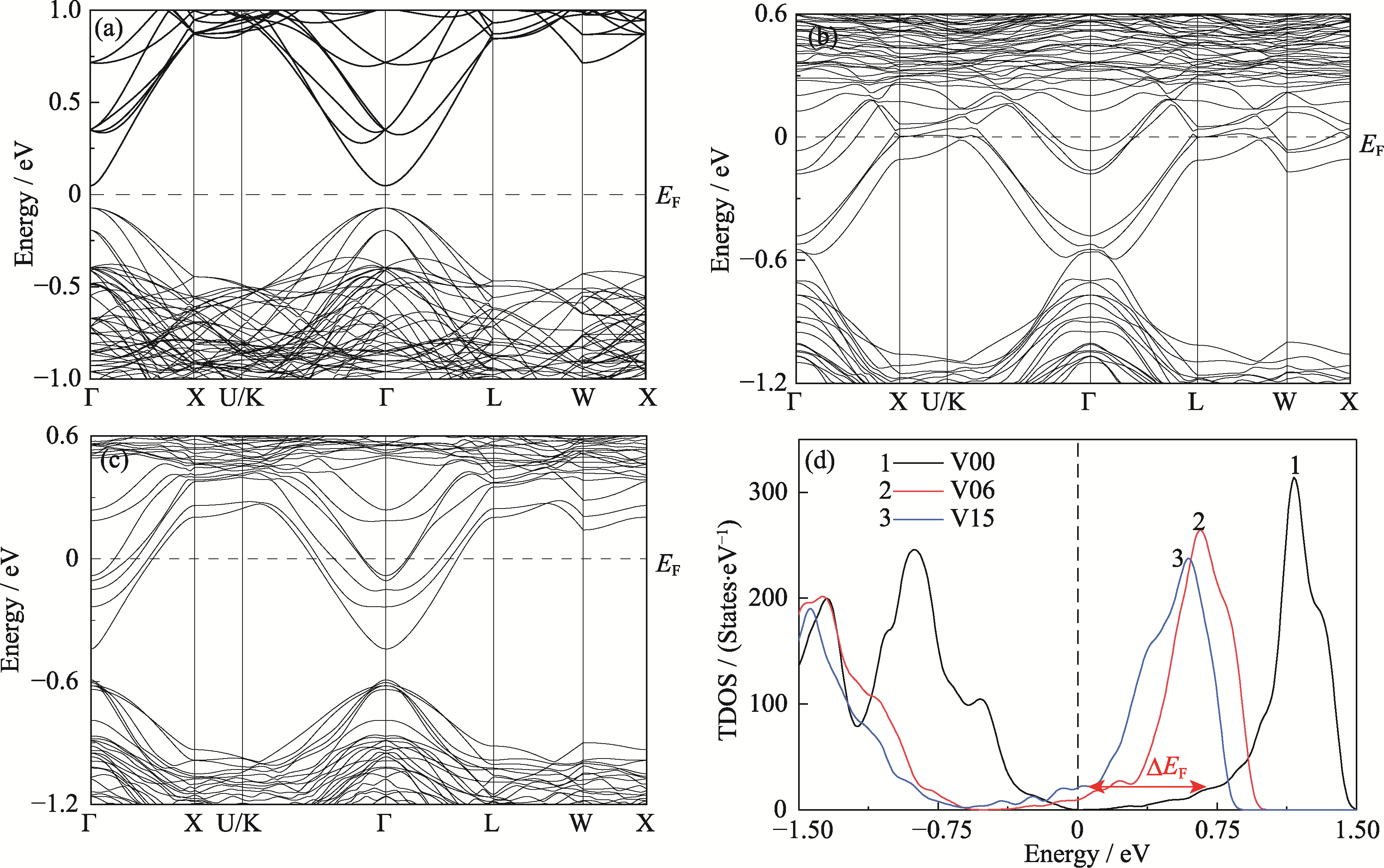

Fig. 3 Band structure and total density of states (TDOS) diagrams of the Fe2V1+xAl1-x alloys (a-c) Energy band structure diagrams for (a) V00, (b) V06 and (c) V15; (d) Corresponding TDOS diagram showing the rigid band shift of the Fermi level caused by doping

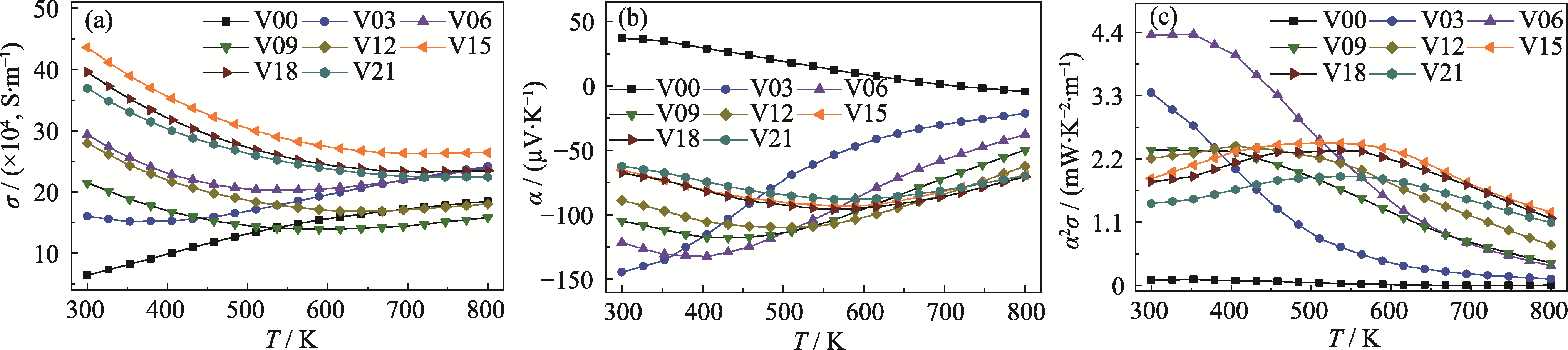

Fig. 4 Temperature dependence of (a) electrical conductivity, (b) Seebeck coefficient, and (c) power factor for all Fe2V1+xAl1-x materials in the temperature range of 300-800 K

Fig. 5 Temperature dependence of (a) thermal conductivity, (b) electronic thermal conductivity, (c) lattice thermal conductivity, and (d) zT for all Fe2V1+xAl1-x alloys in the temperature range of 300-800 K

| [1] |

YANG G S, SANG L A, ZHANG C, et al. The role of spin in thermoelectricity. Nature Reviews Physics, 2023, 5(8): 466.

DOI |

| [2] | KIM H S, LIU W S, REN Z F. The bridge between the materials and devices of thermoelectric power generators. Energy & Environmental Science, 2017, 10(1): 69. |

| [3] |

PEI Y, SHI X, LALONDE A, et al. Convergence of electronic bands for high performance bulk thermoelectrics. Nature, 2011, 473(7345): 66.

DOI |

| [4] |

HEREMANS J P, JOVOVIC V, TOBERER E S, et al. Enhancement of thermoelectric efficiency in PbTe by distortion of the electronic density of states. Science, 2008, 321(5888): 554.

DOI PMID |

| [5] |

LABORATORY M, LIMITED D I, MIYUKIGAOKA. Improvement of the efficiency of thermoelectric energy conversion by utilizing potential barriers. Japanese Journal of Applied Physics, 1997, 36(1): 170.

DOI |

| [6] |

ZHAO L D, LO S H, ZHANG Y, et al. Ultralow thermal conductivity and high thermoelectric figure of merit in SnSe crystals. Nature, 2014, 508(7496): 373.

DOI |

| [7] |

LAN Y C, MINNICH A J, CHEN G, et al. Enhancement of thermoelectric figure-of-merit by a bulk nanostructuring approach. Advanced Functional Materials, 2010, 20(3): 357.

DOI URL |

| [8] |

MAHAN G D, SOFO J O. The best thermoelectric. Proceedings of the National Academy of Sciences of the United States of America, 1996, 93(15): 7436.

PMID |

| [9] | TAVARES S S, YANG K S, MEYERS M A. Heusler alloys: past, properties, new alloys, and prospects. Progress in Materials Science, 2023, 137: 101017. |

| [10] |

GRAF T, FELSER C, PARKIN S S P. Simple rules for the understanding of Heusler compounds. Progress in Solid State Chemistry, 2011, 39(1): 1.

DOI URL |

| [11] |

VAN DER REST C, DUPONT V, ERAUW J P, et al. On the reactive sintering of Heusler Fe2VAl-based thermoelectric compounds. Intermetallics, 2020, 125: 106890.

DOI URL |

| [12] |

HARI S R, SRINIVAS V, LI C R, et al. Thermoelectric properties of rare-earth doped Fe2VAl Heusler alloys. Journal of Physics- Condensed Matter, 2020, 32(35): 355706.

DOI URL |

| [13] |

KAWAHARADA Y, KUROSAKI K. Thermophysical properties of Fe2VAl. Journal of Alloys and Compounds, 2003, 352(1/2): 48.

DOI URL |

| [14] |

SHAMIM S K, DEVI P, SINGH S, et al. Thermoelectric properties of Fe2VAl in the temperature range 300-800 K: a combined experimental and theoretical study. Physica B-Condensed Matter, 2024, 673: 415496.

DOI URL |

| [15] |

HINTERLEITNER B, KNAPP I, PONEDER M, et al. Thermoelectric performance of a metastable thin-film Heusler alloy. Nature, 2019, 576(7785): 85.

DOI |

| [16] |

GARMROUDI F, PARZER M, RISS A, et al. Solubility limit and annealing effects on the microstructure & thermoelectric properties of Fe2V1-xTaxAl1-ySiy Heusler compounds. Acta Materialia, 2021, 212: 116867.

DOI URL |

| [17] | FUKUTA K, TSUCHIYA K, MIYAZAKI H, et al. Improving thermoelectric performance of Fe2VAl-based Heusler compounds via high-pressure torsion. Applied Physics A: Materials Science & Processing, 2022, 128(3): 184. |

| [18] |

ALLENO E. Review of the thermoelectric properties in nanostructured Fe2VAl. Metals, 2018, 8(11): 864.

DOI URL |

| [19] |

ALLENO E, DIACK-RASSELIO A, NOUTACK M S T. Optimization of the thermoelectric properties in self-substituted Fe2VAl. Physical Review Materials, 2023, 7(7): 075403.

DOI URL |

| [20] |

MIYAZAKI H, TANAKA S, IDE N, et al. Thermoelectric properties of Heusler-type off-stoichiometric Fe2V1+xAl1-x alloys. Materials Research Express, 2014, 1(1): 015901.

DOI URL |

| [21] |

DIACK-RASSELIO A, ROULEAU O, COULOMB L, et al. Influence of self-substitution on the thermoelectric Fe2VAl Heusler alloy. Journal of Alloys and Compounds, 2022, 920: 166037.

DOI URL |

| [22] |

GARMROUDI F, PARZER M, RISS A, et al. Anderson transition in stoichiometric Fe2VAl: high thermoelectric performance from impurity bands. Nature Communications, 2022, 13: 3599.

DOI |

| [23] |

CUI X, FENG Z, JIN Y. AutoFP: a GUI for highly automated Rietveld refinement using an expert system algorithm based on FullProf. Journal of Applied Crystallography, 2015, 48(5): 1581.

DOI URL |

| [24] |

PERDEW J P, RUZSINSZKY A, CSONKA G I, et al. Exchange and correlation in open systems of fluctuating electron number. Physical Review A, 2007, 76(4): 040501.

DOI URL |

| [25] | SHAM L J, KOHN W. One-particle properties of an inhomogeneous interacting electron gas. Physical Review B, 1966, 145(2): 561. |

| [26] |

MAIER S, DENIS S, ADAM S, et al. Order-disorder transitions in the Fe2VAl Heusler alloy. Acta Materialia, 2016, 121: 126.

DOI URL |

| [27] |

HINTERLEITNER B, GARMROUDI F, REUMANN N, et al. The electronic pseudo band gap states and electronic transport of the full-Heusler compound Fe2VAl. Journal of Materials Chemistry C, 2021, 9(6): 2073.

DOI URL |

| [28] |

OKAMURA H, KAWAHARA J, NANBA T, et al. Pseudogap formation in the intermetallic compounds (Fe1-xVx)3Al. Physical Review Letters, 2000, 84(16): 3674.

PMID |

| [29] |

NISHINO Y, KATO M, ASANO S, et al. Semiconductor-like behavior of electrical resistivity in Heusler-type Fe2VAl compound. Physical Review Letters, 1997, 79(10): 1909.

DOI URL |

| [30] |

KNAPP I, BUDINSKA B, MILOSAVLJEVIC D, et al. Impurity band effects on transport and thermoelectric properties of Fe2-xNixVAl. Physical Review B, 2017, 96(4): 045204.

DOI URL |

| [31] |

GARMROUDI F, RUSS A, PARZER M, et al. Boosting the thermoelectric performance of Fe2VAl-type Heusler compounds by band engineering. Physical Review B, 2021, 103(8): 085202.

DOI URL |

| [32] | SHIN W H, ROH J W, RYU B, et al. Enhancing thermoelectric performances of bismuth antimony telluride via synergistic combination of multiscale structuring and band alignment by FeTe2 Incorporation. ACS Applied Materials & Interfaces, 2018, 10(4): 3689. |

| [33] |

KIM H S, GIBBS Z M, TANG Y L. Characterization of Lorenz number with Seebeck coefficient measurement. APL Materials, 2015, 3(4): 041506.

DOI URL |

| [34] |

YE X F, YU J, KE S Q, et al. Excellent thermoelectric performance of Fe2NbAl alloy induced by strong crystal anharmonicity and high band degeneracy. npj Quantum Materials, 2024, 9(1): 60.

DOI |

| [1] | 胡宇晨, 徐子硕, 胡悦娟, 陈立东, 姚琴. 单壁碳纳米管复合增强二维平面聚酞菁铜的热电性能[J]. 无机材料学报, 2026, 41(1): 63-69. |

| [2] | 韩伟伟, 黄东, 李廷松, 李江. 包边复合结构Sm:LuAG/Nd:LuAG激光陶瓷的制备及性能研究[J]. 无机材料学报, 2026, 41(1): 113-118. |

| [3] | 吴华鑫, 张骐昊, YAN Haixue, 王连军, 江莞. 纳米复合MgAgSb基合金的热电输运性能优化[J]. 无机材料学报, 2025, 40(9): 997-1004. |

| [4] | 缪鹏程, 王丽君, 沈紫怡, 黄莉, 袁宁一, 丁建宁. 微球状Ag2Se的溶剂热合成及其热电性能研究[J]. 无机材料学报, 2025, 40(12): 1373-1378. |

| [5] | 吴明轩, 李珺杰, 陈硕, 鄢永高, 苏贤礼, 张清杰, 唐新峰. 区熔n型Bi1.96Sb0.04Te2.70Se0.30热电材料均匀性研究[J]. 无机材料学报, 2025, 40(11): 1252-1260. |

| [6] | 汪波, 余健, 李存成, 聂晓蕾, 朱婉婷, 魏平, 赵文俞, 张清杰. Gd/Bi0.5Sb1.5Te3热电磁梯度复合材料的服役稳定性[J]. 无机材料学报, 2023, 38(6): 663-670. |

| [7] | 贺丹琪, 魏明旭, 刘蕤之, 汤志鑫, 翟鹏程, 赵文俞. 一步法制备重费米子YbAl3热电材料及其性能提升[J]. 无机材料学报, 2023, 38(5): 577-582. |

| [8] | 林思琪, 李艾燃, 付晨光, 李荣斌, 金敏. Zintl相Mg3X2(X=Sb, Bi)基晶体生长及热电性能研究进展[J]. 无机材料学报, 2023, 38(3): 270-279. |

| [9] | 鲁志强, 刘可可, 李强, 胡芹, 冯利萍, 张清杰, 吴劲松, 苏贤礼, 唐新峰. p型多晶Bi0.5Sb1.5Te3合金类施主效应与热电性能[J]. 无机材料学报, 2023, 38(11): 1331-1337. |

| [10] | 江润璐, 吴鑫, 郭昊骋, 郑琦, 王连军, 江莞. UiO-67基导电复合材料的制备及其热电性能研究[J]. 无机材料学报, 2023, 38(11): 1338-1344. |

| [11] | 程成, 李建波, 田震, 王鹏将, 康慧君, 王同敏. In2O3/InNbO4复合材料的热电性能研究[J]. 无机材料学报, 2022, 37(7): 724-730. |

| [12] | 洪督, 牛亚然, 李红, 钟鑫, 郑学斌. 等离子喷涂TiC-Graphite复合涂层摩擦磨损性能[J]. 无机材料学报, 2022, 37(6): 643-650. |

| [13] | 刘丹, 赵亚欣, 郭锐, 刘艳涛, 张志东, 张增星, 薛晨阳. 退火条件对磁控溅射MgO-Ag3Sb-Sb2O4柔性薄膜热电性能的影响[J]. 无机材料学报, 2022, 37(12): 1302-1310. |

| [14] | 任培安, 汪聪, 訾鹏, 陶奇睿, 苏贤礼, 唐新峰. Te与In共掺杂对Cu2SnSe3热电性能的影响[J]. 无机材料学报, 2022, 37(10): 1079-1086. |

| [15] | 李铭清, 王林伟, 丁栋舟, 冯鹤. Mg共掺杂Gd3(Al,Ga)5O12:Ce晶体快发光的作用机理[J]. 无机材料学报, 2022, 37(10): 1123-1128. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||