无机材料学报 ›› 2025, Vol. 40 ›› Issue (12): 1373-1378.DOI: 10.15541/jim20250035 CSTR: 32189.14.jim20250035

缪鹏程1( ), 王丽君1(

), 王丽君1( ), 沈紫怡1, 黄莉1, 袁宁一1, 丁建宁2(

), 沈紫怡1, 黄莉1, 袁宁一1, 丁建宁2( )

)

收稿日期:2025-01-25

修回日期:2025-04-02

出版日期:2025-12-20

网络出版日期:2025-04-27

通讯作者:

王丽君, 讲师. E-mail: wanglj@cczu.edu.cn;作者简介:缪鹏程(1999-), 男, 硕士研究生. E-mail: 1131263037@qq.com

基金资助:

MIAO Pengcheng1( ), WANG Lijun1(

), WANG Lijun1( ), SHEN Ziyi1, HUANG Li1, YUAN Ningyi1, DING Jianning2(

), SHEN Ziyi1, HUANG Li1, YUAN Ningyi1, DING Jianning2( )

)

Received:2025-01-25

Revised:2025-04-02

Published:2025-12-20

Online:2025-04-27

Contact:

WANG Lijun, lecturer. E-mail: wanglj@cczu.edu.cn;About author:MIAO Pengcheng (1999-), male, Master candidate. E-mail: 1131263037@qq.com

Supported by:摘要:

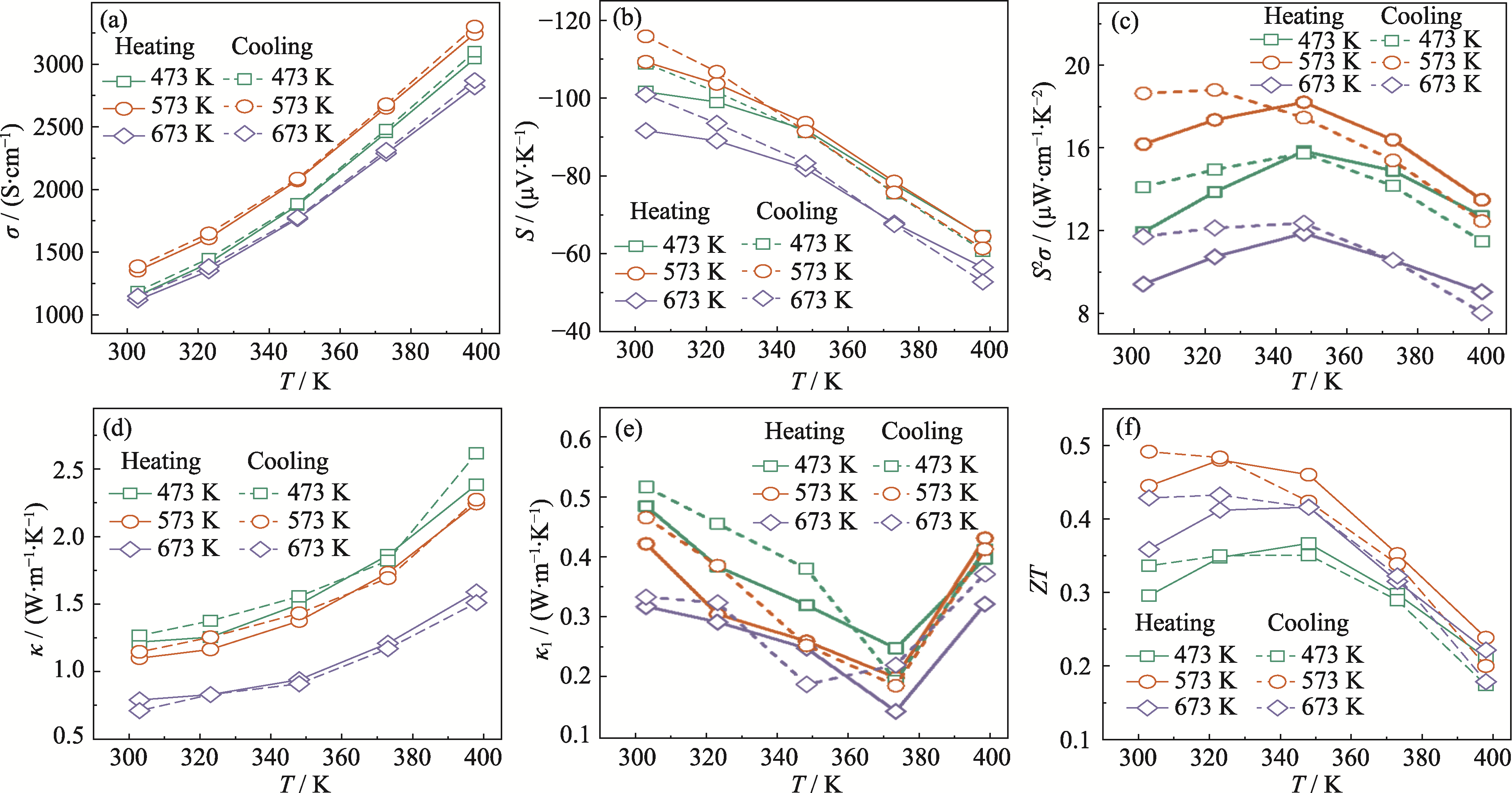

热电材料可直接将热能转化为电能, 在废热回收领域具有广泛的应用前景。Ag2Se作为一种新型低温热电材料, 因其独特的晶体结构和优异的电输运性能备受关注。本研究采用溶剂热法成功制备了微米级Ag2Se粉末, 该方法可精确控制粉末的结构、成分及晶粒尺寸。结果表明,所合成的Ag2Se粉末呈现不规则的微米柱状结构, 其晶体结构完整, Ag与Se的比例接近理论值(原子比约2 : 1)。利用放电等离子烧结(SPS)技术, 在不同温度下对Ag2Se粉末进行致密化处理, 结果显示烧结温度对其微观结构和热电性能具有显著影响。473 K烧结样品断面较为致密, 而573和673 K烧结样品中均出现了纳米孔结构。其中673 K烧结样品中纳米孔结构尤为明显, 有效降低了材料的晶格热导率(κl), 其室温κl降至0.33 W·m-1·K-1。最终, 573 K烧结条件下制得的Ag2Se块体展现出最佳热电性能, 室温热电优值(ZT)达到0.5。本研究不仅证明了溶剂热法在制备高性能微米级热电粉末中的可行性, 而且为进一步优化Ag2Se热电材料的微观结构与热电性能提供了有价值的实验依据。

中图分类号:

缪鹏程, 王丽君, 沈紫怡, 黄莉, 袁宁一, 丁建宁. 微球状Ag2Se的溶剂热合成及其热电性能研究[J]. 无机材料学报, 2025, 40(12): 1373-1378.

MIAO Pengcheng, WANG Lijun, SHEN Ziyi, HUANG Li, YUAN Ningyi, DING Jianning. Micro-spherical Ag2Se: Solvothermal Synthesis and Thermoelectric Properties[J]. Journal of Inorganic Materials, 2025, 40(12): 1373-1378.

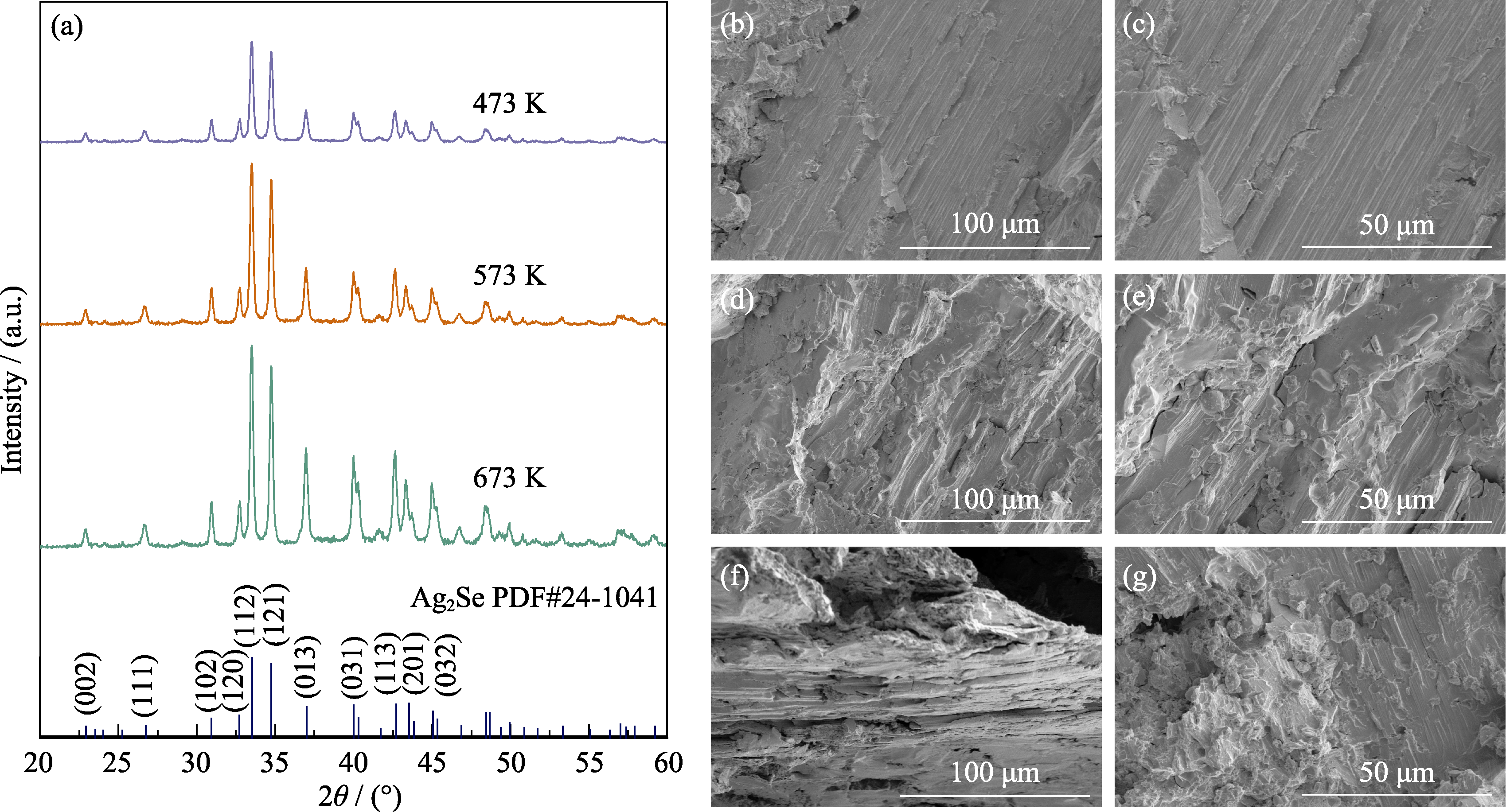

图3 (a)不同温度烧结的Ag2Se块体样品的室温XRD图谱; (b~g)在(b, c) 473、(d, e) 573、(f, g) 673 K烧结的Ag2Se块体样品的断面SEM照片

Fig. 3 (a) Room-temperature XRD patterns of Ag2Se bulk samples sintered at different temperatures; (b-g) Cross-sectional SEM images of Ag2Se bulk samples sintered at (b, c) 473, (d, e) 573 and (f, g) 673 K

图4 Ag2Se块体材料的(a)电导率、(b)塞贝克系数、(c)功率因子、(d)热导率、(e)晶格热导率、(f) ZT随温度的变化关系

Fig. 4 Temperature dependent (a) electrical conductivity, (b) Seebeck coefficient, (c) power factor, (d) thermal conductivity, (e) lattice thermal conductivity, and (f) ZT for Ag2Se bulk samples

| [1] |

LIU Y, HOU S, WANG X, et al. Passive radiative cooling enables improved performance in wearable thermoelectric generators. Small, 2022, 18(10): 2106875.

DOI URL |

| [2] | ZHANG Y, LI S, ZHANG J, et al. Thermoelectrocatalysis: an emerging strategy for converting waste heat into chemical energy. National Science Review, 2024, 11(4): 2207391. |

| [3] |

CORNETT J, CHEN B, HAIDAR S, et al. Fabrication and characterization of Bi2Te3-based chip-scale thermoelectric energy harvesting devices. Journal of Electronic Materials, 2017, 46: 2844.

DOI URL |

| [4] |

HONG M, CHEN Z G, YANG L, et al. Realizing zT of 2.3 in Ge1-x-ySbxInyTe via reducing the phase-transition temperature and introducing resonant energy doping. Advanced Materials, 2018, 30(11): 1705942.

DOI URL |

| [5] |

CABALLERO-CALERO O, ARES J R, MARTÍN-GONZÁLEZ M. Environmentally friendly thermoelectric materials: high performance from inorganic components with low toxicity and abundance in the earth. Advanced Sustainable Systems, 2021, 5(11): 2100095.

DOI URL |

| [6] | LIU Y, ZAMANIPOUR Z, VASHAEE D. Economical FeSi2-SiGe composites for thermoelectric power generation. IEEE Green Technologies Conference, Tulsa, 2012: 1-5. |

| [7] |

KUMAR A, KUMAR M, SINGH R P. Study on electronic, magnetic, optical and thermoelectric properties of manganese oxide (MnO): DFT based spin polarized calculations. Optik, 2021, 241: 167064.

DOI URL |

| [8] |

ZHENG Y, ZHANG Q, SHI C, et al. Carrier-phonon decoupling in perovskite thermoelectrics via entropy engineering. Nature Communications, 2024, 15: 7650.

DOI |

| [9] |

GORDILLO J M S, MORATA A, SIERRA C D, et al. Recent advances in silicon-based nanostructures for thermoelectric applications. APL Materials, 2023, 11(4): 040702.

DOI URL |

| [10] |

SCHIERNING G, STOETZEL J, CHAVEZ R, et al. Silicon-based nanocomposites for thermoelectric application. Physica Status Solidi (A), 2016, 213(3): 497.

DOI URL |

| [11] |

DING Y, QIU Y, CAI K, et al. High performance n-type Ag2Se film on Nylon membrane for flexible thermoelectric power generator. Nature Communications, 2019, 10: 841.

DOI |

| [12] |

DALVEN R, GILL R. Energy gap in β-Ag2Se. Physical Review, 1967, 159(3): 645.

DOI URL |

| [13] |

SINGH S, HIRATA K, BYEON D, et al. Investigation of thermoelectric properties of Ag2SxSe1-x (x=0.0, 0.2 and 0.4). Journal of Electronic Materials, 2020, 49: 2846.

DOI |

| [14] |

JOOD P, OHTA M. Temperature-dependent structural variation and Cu substitution in thermoelectric silver selenide. ACS Applied Energy Materials, 2020, 3(3): 2160.

DOI URL |

| [15] |

LI D, ZHANG J, LI J, et al. High thermoelectric performance for an Ag2Se-based material prepared by a wet chemical method. Materials Chemistry Frontiers, 2020, 4(3): 875.

DOI URL |

| [16] | KHAN J A, MAITHANI Y, SINGH J. Ag2Se nanorod arrays with ultrahigh room temperature thermoelectric performance and superior mechanical properties. ACS Applied Materials & Interfaces, 2023, 15(29): 35001. |

| [17] |

CHEN N, SCIMECA M R, PAUL S J, et al. High-performance thermoelectric silver selenide thin films cation exchanged from a copper selenide template. Nanoscale Advances, 2020, 2(1): 368.

DOI PMID |

| [18] |

ZHOU K, CHEN J, ZHENG R, et al. Non-epitaxial pulsed laser deposition of Ag2Se thermoelectric thin films for near-room temperature applications. Ceramics International, 2016, 42(10): 12490.

DOI URL |

| [19] |

NAN B, LI M, ZHANG Y, et al. Engineering of thermoelectric composites based on silver selenide in aqueous solution and ambient temperature. ACS Applied Electronic Materials, 2023, 6(5): 2807.

DOI URL |

| [20] |

JIN M, LIANG J, QIU P, et al. Investigation on low-temperature thermoelectric properties of Ag2Se polycrystal fabricated by using zone-melting method. The Journal of Physical Chemistry Letters, 2021, 12(34): 8246.

DOI URL |

| [21] | CHEN J, SUN Q, BAO D, et al. Hierarchical structures advance thermoelectric properties of porous n-type β-Ag2Se. ACS Applied Materials & Interfaces, 2020, 12(46): 51523. |

| [22] |

HSU K F, LOO S, GUO F, et al. Cubic AgPbmSbTe2+m: bulk thermoelectric materials with high figure of merit. Science, 2004, 303(5659): 818.

DOI URL |

| [23] | ZHU T, HU L, ZHAO X, et al. New insights into intrinsic point defects in V2VI3 thermoelectric materials. Advanced Science, 2016, 3(7): 1600004. |

| [24] |

TOBERER E S, MAY A F, SNYDER G J. Zintl chemistry for designing high efficiency thermoelectric materials. Chemistry of Materials, 2010, 22(3): 624.

DOI URL |

| [25] |

JIANG G, HE J, ZHU T, et al. High performance Mg2(Si, Sn) solid solutions: a point defect chemistry approach to enhancing thermoelectric properties. Advanced Functional Materials, 2014, 24(24): 3776.

DOI URL |

| [26] |

TEE S Y, TAN X Y, WANG X, et al. Aqueous synthesis, doping, and processing of n-type Ag2Se for high thermoelectric performance at near-room-temperature. Inorganic Chemistry, 2022, 61(17): 6451.

DOI URL |

| [27] |

WANG H, LIU X, ZHOU Z, et al. Constructing n-type Ag2Se/ CNTs composites toward synergistically enhanced thermoelectric and mechanical performance. Acta Materialia, 2022, 223: 117502.

DOI URL |

| [28] | LIANG J, QIU P, ZHU Y, et al. Crystalline structure-dependent mechanical and thermoelectric performance in Ag2Se1-xSx system. Research, 2020, 2020: 6591981. |

| [29] |

GATES B, MAYERS B, WU Y, et al. Synthesis and characterization of crystalline Ag2Se nanowires through a template-engaged reaction at room temperature. Advanced Functional Materials, 2002, 12(10): 679.

DOI URL |

| [30] |

DUAN H, LI Y, ZHAO K, et al. Ultra-fast synthesis for Ag2Se and CuAgSe thermoelectric materials. JOM, 2016, 68: 2659.

DOI URL |

| [31] |

YUE Y, LYU W, LIU W D, et al. Solvothermal synthesis of micro- pillar shaped Ag2Se and its thermoelectric potential. Materials Today Chemistry, 2024, 39: 102183.

DOI URL |

| [32] |

PALAPORN D, KUROSAKI K, PINITSOONTORN S. Effect of sintering temperature on the thermoelectric properties of Ag2Se fabricated by spark plasma sintering with high compression. Advanced Energy and Sustainability Research, 2023, 4(10): 2300082.

DOI URL |

| [33] |

IJAZ U, SIYAR M, PARK C. The power of pores: review on porous thermoelectric materials. RSC Sustainability, 2024, 2(4): 852.

DOI URL |

| [34] |

TIE J, XU G, LI Y, et al. The effect of SPS sintering temperatures on the structure, thermoelectric properties, and scattering mechanism of Cu2Se. Journal of Materials Research and Technology, 2023, 27: 3506.

DOI URL |

| [1] | 胡宇晨, 徐子硕, 胡悦娟, 陈立东, 姚琴. 单壁碳纳米管复合增强二维平面聚酞菁铜的热电性能[J]. 无机材料学报, 2026, 41(1): 63-69. |

| [2] | 吴华鑫, 张骐昊, YAN Haixue, 王连军, 江莞. 纳米复合MgAgSb基合金的热电输运性能优化[J]. 无机材料学报, 2025, 40(9): 997-1004. |

| [3] | 郑元顺, 余健, 叶先峰, 梁栋, 朱婉婷, 聂晓蕾, 魏平, 赵文俞, 张清杰. V取代Al位提升全赫斯勒合金Fe2VAl的热电性能[J]. 无机材料学报, 2025, 40(12): 1425-1432. |

| [4] | 吴明轩, 李珺杰, 陈硕, 鄢永高, 苏贤礼, 张清杰, 唐新峰. 区熔n型Bi1.96Sb0.04Te2.70Se0.30热电材料均匀性研究[J]. 无机材料学报, 2025, 40(11): 1252-1260. |

| [5] | 张哲, 孙婷婷, 王连军, 江莞. 不同维度Ag2Se构筑柔性热电薄膜的性能优化与器件集成研究[J]. 无机材料学报, 2024, 39(11): 1221-1227. |

| [6] | 李俊生, 曾良, 刘荣军, 王衍飞, 万帆, 李端. 锶钽氧氮化物功能陶瓷的高效合成、致密化及介电性能研究[J]. 无机材料学报, 2023, 38(8): 885-892. |

| [7] | 汪波, 余健, 李存成, 聂晓蕾, 朱婉婷, 魏平, 赵文俞, 张清杰. Gd/Bi0.5Sb1.5Te3热电磁梯度复合材料的服役稳定性[J]. 无机材料学报, 2023, 38(6): 663-670. |

| [8] | 贺丹琪, 魏明旭, 刘蕤之, 汤志鑫, 翟鹏程, 赵文俞. 一步法制备重费米子YbAl3热电材料及其性能提升[J]. 无机材料学报, 2023, 38(5): 577-582. |

| [9] | 林思琪, 李艾燃, 付晨光, 李荣斌, 金敏. Zintl相Mg3X2(X=Sb, Bi)基晶体生长及热电性能研究进展[J]. 无机材料学报, 2023, 38(3): 270-279. |

| [10] | 鲁志强, 刘可可, 李强, 胡芹, 冯利萍, 张清杰, 吴劲松, 苏贤礼, 唐新峰. p型多晶Bi0.5Sb1.5Te3合金类施主效应与热电性能[J]. 无机材料学报, 2023, 38(11): 1331-1337. |

| [11] | 江润璐, 吴鑫, 郭昊骋, 郑琦, 王连军, 江莞. UiO-67基导电复合材料的制备及其热电性能研究[J]. 无机材料学报, 2023, 38(11): 1338-1344. |

| [12] | 程成, 李建波, 田震, 王鹏将, 康慧君, 王同敏. In2O3/InNbO4复合材料的热电性能研究[J]. 无机材料学报, 2022, 37(7): 724-730. |

| [13] | 刘丹, 赵亚欣, 郭锐, 刘艳涛, 张志东, 张增星, 薛晨阳. 退火条件对磁控溅射MgO-Ag3Sb-Sb2O4柔性薄膜热电性能的影响[J]. 无机材料学报, 2022, 37(12): 1302-1310. |

| [14] | 任培安, 汪聪, 訾鹏, 陶奇睿, 苏贤礼, 唐新峰. Te与In共掺杂对Cu2SnSe3热电性能的影响[J]. 无机材料学报, 2022, 37(10): 1079-1086. |

| [15] | 张可忆, 郑琦, 王连军, 江莞. 用于喷墨打印的Ag2Se墨水的制备及表征[J]. 无机材料学报, 2022, 37(10): 1109-1115. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||