无机材料学报 ›› 2026, Vol. 41 ›› Issue (1): 113-118.DOI: 10.15541/jim20250142 CSTR: 32189.14.10.15541/jim20250142

收稿日期:2025-04-06

修回日期:2025-05-04

出版日期:2026-01-20

网络出版日期:2025-06-10

通讯作者:

李 江, 研究员. E-mail: lijiang@mail.sic.ac.cn作者简介:韩伟伟(1998-), 男, 硕士研究生. E-mail: hw18800205253@163.com

基金资助:

HAN Weiwei1,2( ), HUANG Dong2, LI Tingsong2, LI Jiang2,3(

), HUANG Dong2, LI Tingsong2, LI Jiang2,3( )

)

Received:2025-04-06

Revised:2025-05-04

Published:2026-01-20

Online:2025-06-10

Contact:

LI Jiang, professor. E-mail: lijiang@mail.sic.ac.cnAbout author:HAN Weiwei (1998-), male, Master candidate. E-mail: hw18800205253@163.com

Supported by:摘要:

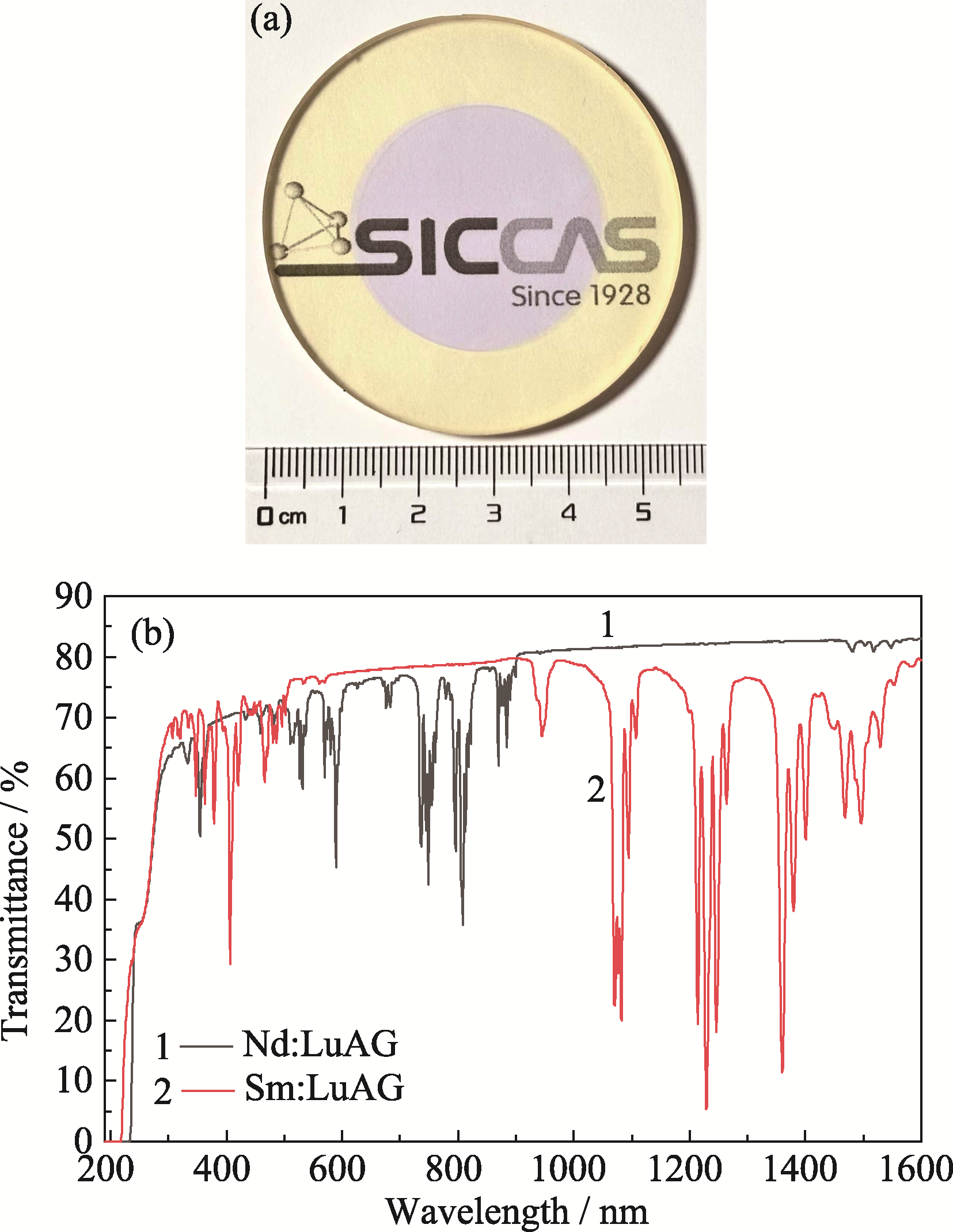

在高功率的泵浦模式下, 热效应是限制激光器性能提升的主要因素之一, 通过增大增益介质的口径可以增强热量扩散, 从而降低热效应。然而, 随着增益介质的横纵比增大, 横向于主光束传播放大的自发辐射会消耗上能级反转粒子数, 产生寄生振荡效应。对增益介质侧面进行包边的结构设计, 能够有效吸收横向辐射光, 抑制寄生振荡效应。对于具有高重复频率的高能固体激光器, 应优先选择具有合适饱和通量的增益介质, 其中Nd:LuAG透明陶瓷因其优异的光学、机械和热力学综合性能, 展现出更大的发展潜力。Sm:LuAG透明陶瓷在1064 nm处具有高的吸收系数, 在808 nm处具有优异的理论光学透过率, 且与Nd:LuAG具有相近的折射率, 是应用于Nd:LuAG激光陶瓷包边层的最佳材料之一。本研究以商业Lu2O3、α-Al2O3、Nd2O3及Sm2O3粉体作为实验原料, 采用正硅酸乙酯(TEOS, Tetraethoxysilane)和CaO作为烧结助剂, 经过真空预烧(1825 ℃×20 h)结合热等静压烧结(1750 ℃×3 h)制备了5% Sm:LuAG/1% Nd:LuAG(均为原子百分数)包边复合激光陶瓷(φ56.0 mm×4.8 mm)。包边陶瓷中Nd:LuAG增益区在1064 nm处的直线透过率达到81.5%, Sm:LuAG包边区在808 nm处的直线透过率为78.6%。

中图分类号:

韩伟伟, 黄东, 李廷松, 李江. 包边复合结构Sm:LuAG/Nd:LuAG激光陶瓷的制备及性能研究[J]. 无机材料学报, 2026, 41(1): 113-118.

HAN Weiwei, HUANG Dong, LI Tingsong, LI Jiang. Sm:LuAG/Nd:LuAG Composite Laser Ceramics with Cladding Structure: Fabrication and Properties[J]. Journal of Inorganic Materials, 2026, 41(1): 113-118.

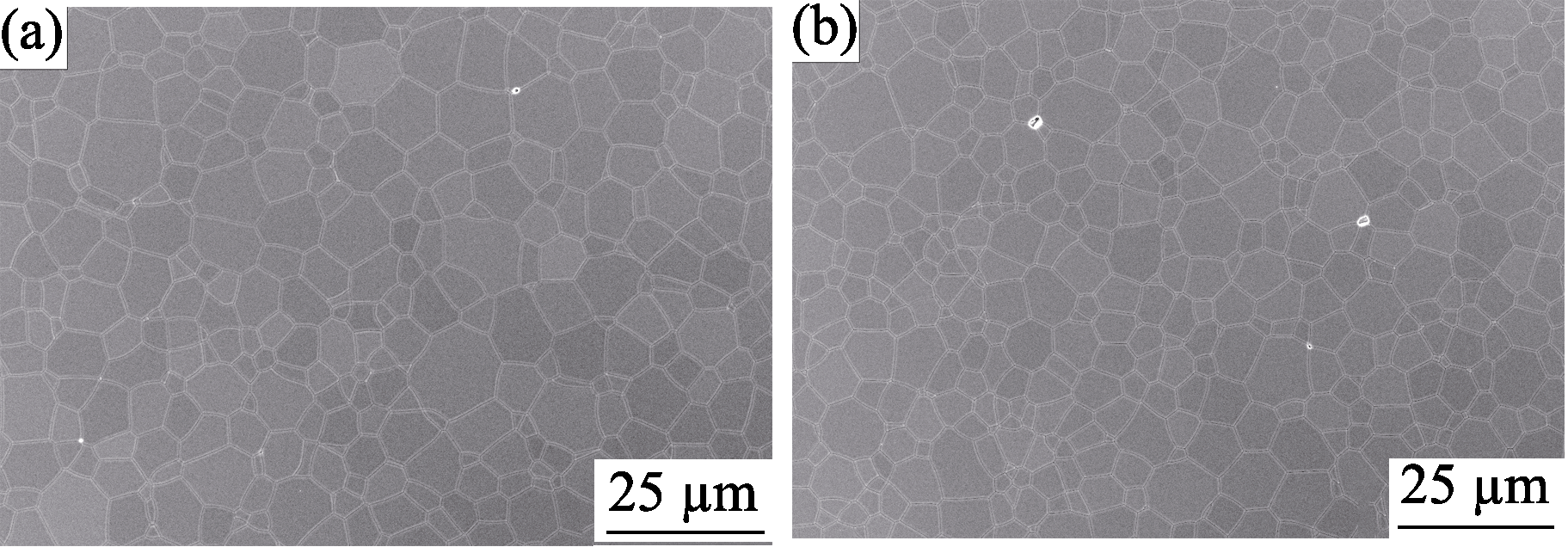

图2 经1825 ℃×20 h真空预烧后5% Sm:LuAG/1% Nd:LuAG包边复合陶瓷的FESEM照片

Fig. 2 FESEM images of the 5% Sm:LuAG/1% Nd:LuAG cladding structure composite ceramics pre-sintered at 1825 ℃ for 20 h (a) Gain area; (b) Cladding area

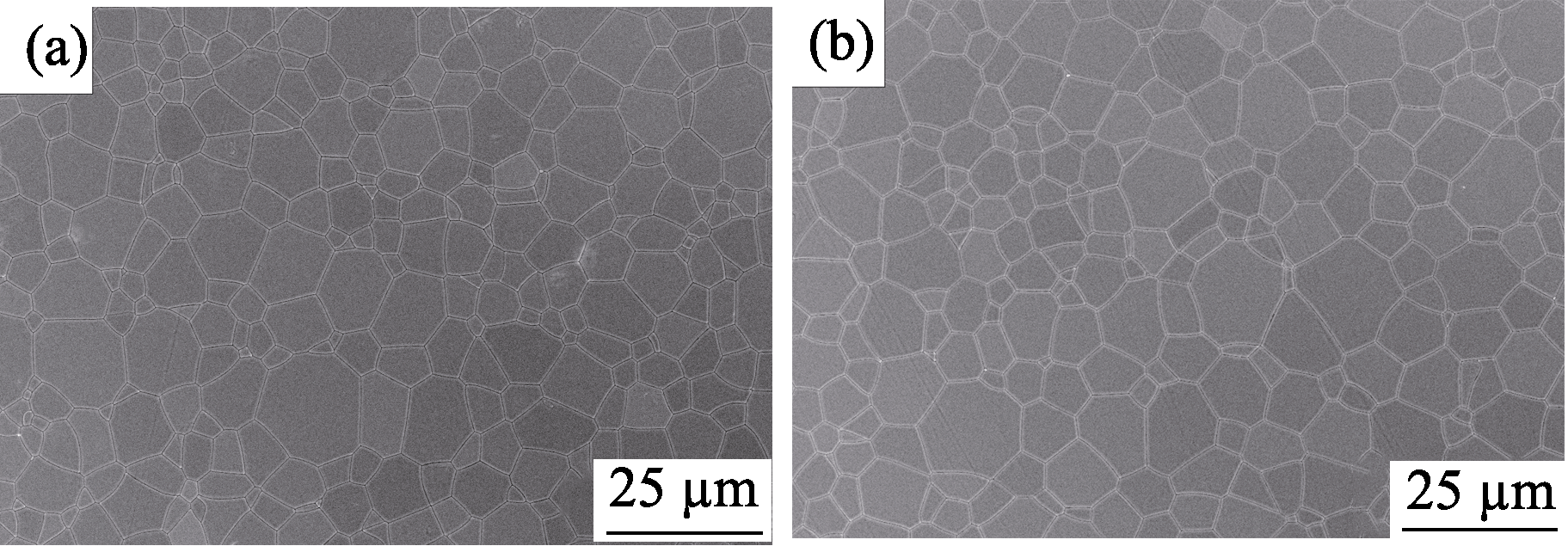

图3 经1825 ℃×20 h真空预烧及1750 ℃×3 h HIP后处理的包边复合结构5% Sm:LuAG/1% Nd:LuAG陶瓷的FESEM照片

Fig. 3 FESEM images of the 5% Sm:LuAG/1% Nd:LuAG cladding structure composite ceramics pre-sintered at 1825 ℃ for 20 h and HIP post-treated at 1750 ℃ for 3 h (a) Gain area; (b) Cladding area

图4 HIP后包边复合结构5% Sm:LuAG/1% Nd:LuAG陶瓷的实物图(a)及直线透过率曲线(b)

Fig. 4 Photograph (a) and in-line transmittance (b) of the 5% Sm:LuAG/1% Nd:LuAG cladding structure composite ceramics after HIP post-treatment

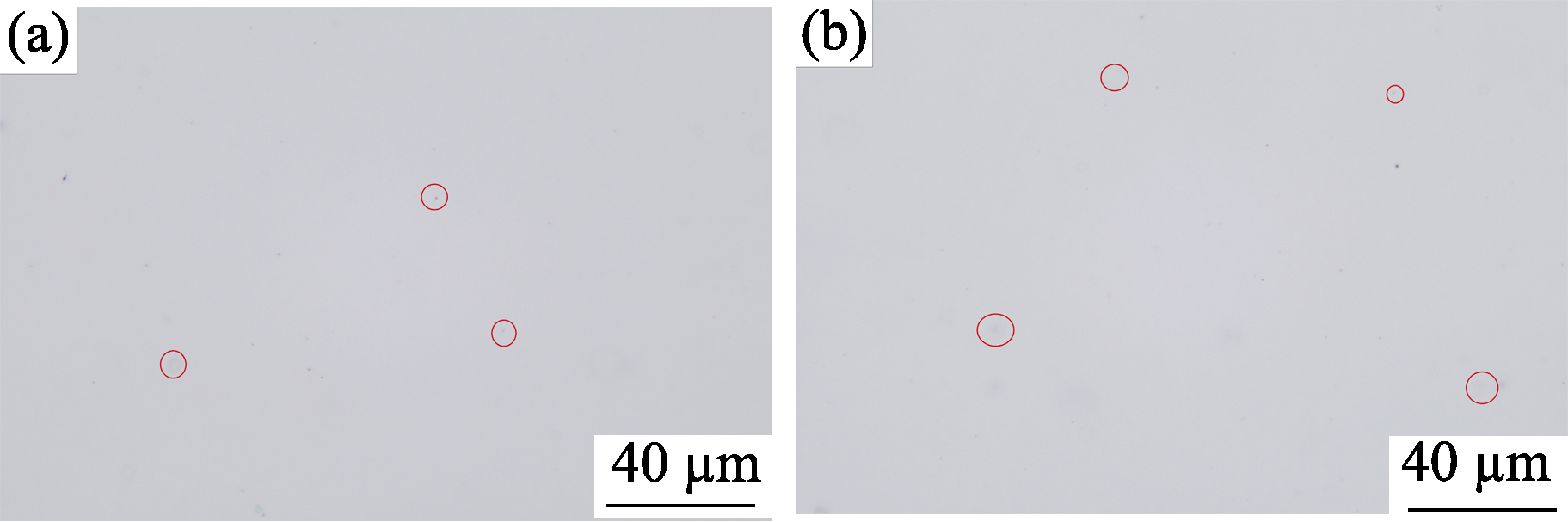

图5 HIP后包边复合结构5% Sm:LuAG/1% Nd:LuAG陶瓷的光学显微镜照片

Fig. 5 Optical microscopic images of the 5% Sm:LuAG/1% Nd:LuAG cladding structure composite ceramics after HIP post- treatment (a) Gain area; (b) Cladding area

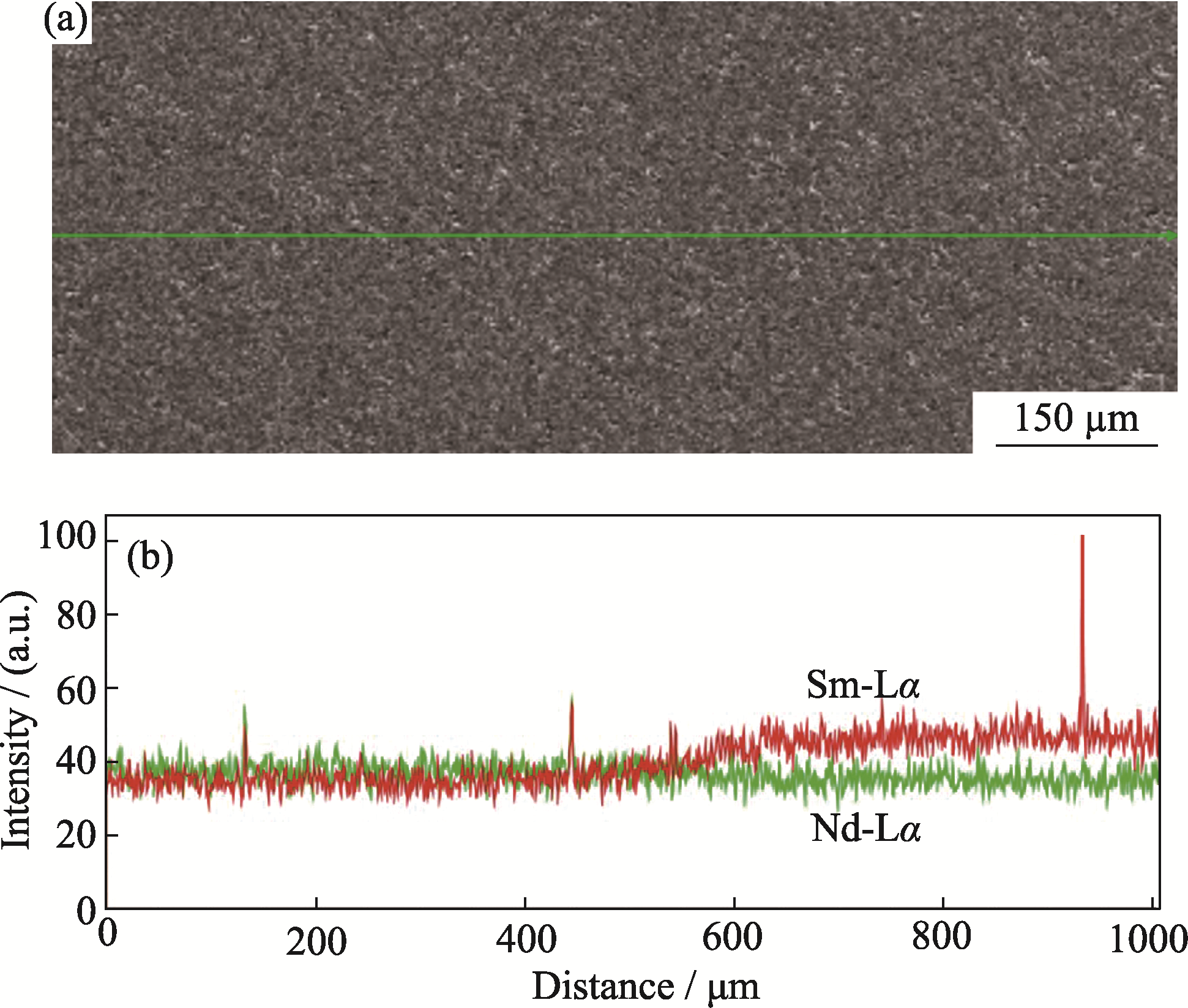

图6 HIP后包边复合结构5% Sm:LuAG/1% Nd:LuAG陶瓷交界面的FESEM照片(a)和元素分布线扫描图(b)

Fig. 6 FESEM image (a) and linear scanning image (b) of the interface for the 5% Sm:LuAG/1% Nd:LuAG cladding structure composite ceramics after HIP post-treatment

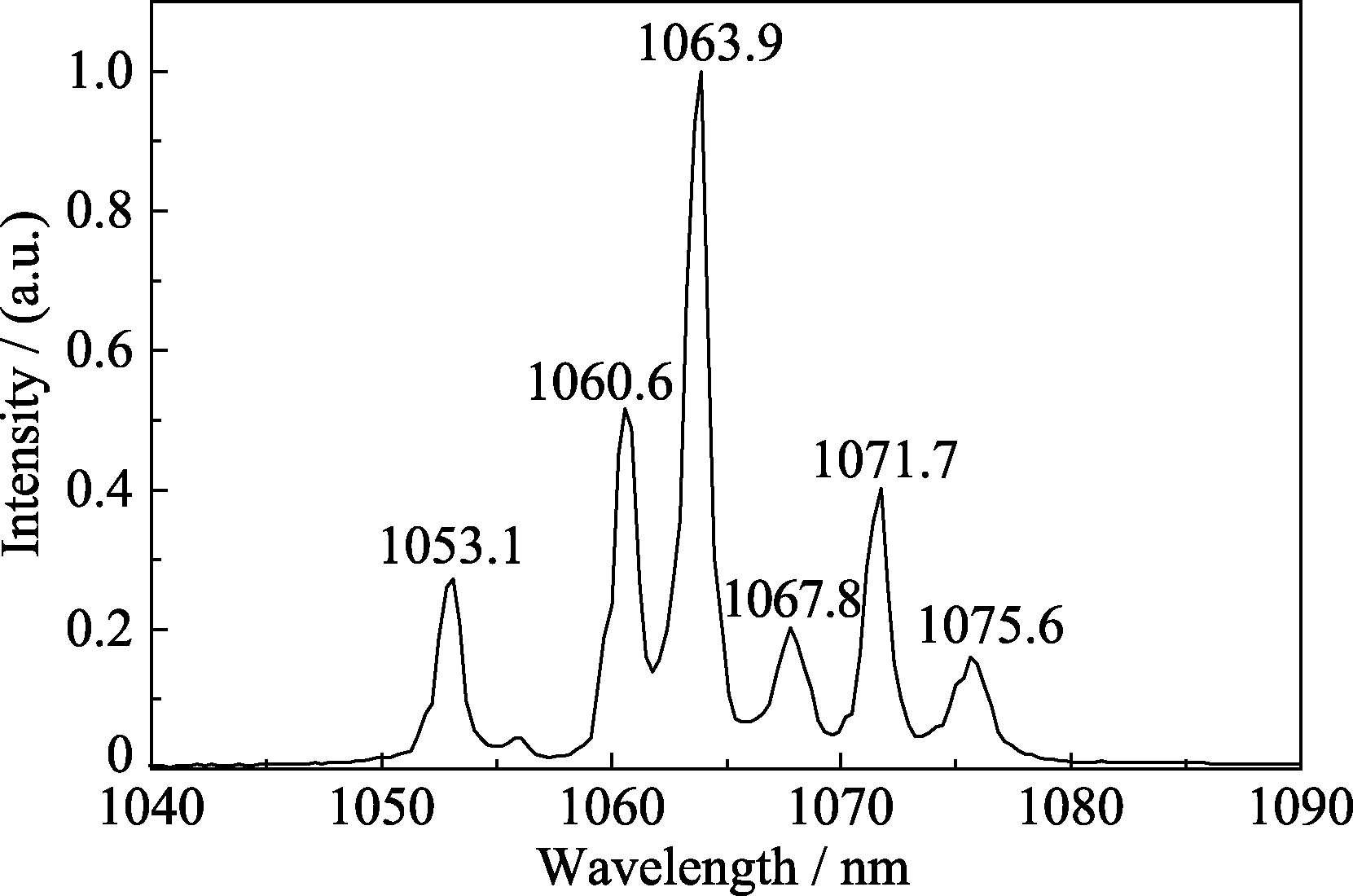

图7 HIP后包边复合结构5% Sm:LuAG/1% Nd:LuAG陶瓷增益区在1.06 μm附近的发射光谱

Fig. 7 Emission spectrum of gain area around 1.06 μm for the 5% Sm:LuAG/1% Nd:LuAG cladding structure composite ceramics after HIP post-treatment

| [1] |

SPAETH M L, MANES K R, KALANTAR D H, et al. Description of the NIF laser. Fusion Science and Technology, 2016, 69(1): 25.

DOI URL |

| [2] |

BAYRAMIAN A, ACEVES S, ANKLAM T, et al. Compact, efficient laser systems required for laser inertial fusion energy. Fusion Science and Technology, 2011, 60(1): 28.

DOI URL |

| [3] | DANSON C N, HAEFNER C, BROMAGE J, et al. Petawatt and exawatt class lasers worldwide. High Power Laser Science and Engineering, 2019, 7(3): 172. |

| [4] |

ZHU Z D, LV S W, ZHANG H Y, et al. Highly efficient actively Q-switched Nd:YAG laser. Optics Express, 2021, 29(20): 32325.

DOI PMID |

| [5] |

BANERJEES, ERTEL K, MASON P D, et al. DiPOLE: a 10 J, 10 Hz cryogenic gas cooled multi-slab nanosecond Yb:YAG laser. Optics Express, 2015, 23(15): 19542.

DOI PMID |

| [6] |

BROWND C, MCMILLEN C D, MOORE C, et al. Spectral properties of hydrothermally-grown Nd:LuAG, Yb:LuAG, and Yb:Lu2O3 laser materials. Journal of Luminescence, 2014, 148: 26.

DOI URL |

| [7] |

GONCALVES T, ALBACH D, VINCENT B, et al. 14 J/2 Hz Yb3+:YAG diode pumped solid state laser chain. Optics Express, 2013, 21(1): 855.

DOI URL |

| [8] | 冯亚刚, 田丰, 刘子玉, 等. 层状复合结构YAG/Yb:YAG透明陶瓷的制备与性能研究. 人工晶体学报, 2024, 53(11): 1901. |

| [9] |

YAGI H, BISSON J F, UEDA K, et al. Y3Al5O12 ceramic absorbers for the suppression of parasitic oscillation in high-power Nd:YAG lasers. Journal of Luminescence, 2006, 121(1): 88.

DOI URL |

| [10] | HAEFNER C L, BAYRAMIAN A, BETTS S, et al. High average power diode pumped petawatt laser systems a new generation of lasers enabling precision science and commercial applications. Proceedings of SPIE, 2017, 10241: 1024102. |

| [11] | LEBEGUE P, DE SOUSA J, RAPENOU C. Coherent combining of large-aperture high-energy Nd:glass laser amplifiers. High Power Laser Science and Engineering, 2025, 13: 4. |

| [12] | RONG X F, YANG Y M, PENG S Z, et al. Sub-nanosecond diode-pumped passively Q-switched Nd:LuAG ceramic microchip lasers. Optics & Laser Technology, 2023, 158:108901. |

| [13] |

FU Y L, LI J, LIU Y, et al. Fabrication, microstructure and laser performance of Nd3+-doped Lu3Al5O12 transparent ceramics. Journal of the European Ceramic Society, 2016, 36(3): 655.

DOI URL |

| [14] |

LIU T H, FENG T, SUI Z, et al. 50 mm-aperture Nd:LuAG ceramic nanosecond laser amplifier producing 10 J at 10 Hz. Optics Express, 2019, 27(11): 15595.

DOI PMID |

| [15] | ZHANG W S, LI L J, LIANG H. Efficient acousto-optically Q-switched Tm:LuAG laser end-pumped by a laser diode at 1.7 μm. Applied Physics B-Lasers and Optics, 2025, 131(3): 65. |

| [16] |

IKESUEA, FURUSATO I, KAMATA K, et al. Fabrication of polycrystal line, transparent YAG ceramics by a solid-state reaction method. Journal of the American Ceramic Society, 1995, 78(1): 225.

DOI URL |

| [17] |

TIAN F, IKESUEA , LI J. Progress and perspectives on composite laser ceramics: a review. Journal of the European Ceramic Society, 2022, 42(5): 1833.

DOI URL |

| [18] |

LIU Z Y, FENG Y G, CHEN H H, et al. Microstructure and properties characterization of Yb:Lu2O3 transparent ceramics from co-precipitated nano-powders. International Journal of Applied Ceramic Technology, 2023, 20(6): 3365.

DOI URL |

| [19] |

LI X Y, ZHANG L X, HU D J, et al. Fabrication and characterizations of Tb3Al5O12-based magneto-optical ceramics. International Journal of Applied Ceramic Technology, 2023, 20(1): 493.

DOI URL |

| [20] |

LI X, HU C, LIU Q, et al. Fluoride transparent ceramics for solid-state lasers: a review. Journal of Advanced Ceramics, 2024, 13(12): 1891.

DOI URL |

| [21] |

YE J H, ZHOU Z Z, HU C, et al. Yb:Sc2O3 Transparent ceramics fabricated from co-precipitated nano-powders: microstructure and optical property. Journal of Inorganic Materials, 2025, 40(2): 215.

DOI URL |

| [22] |

HUSS R, WILHELM R, KOLLECK C, et al. Suppression of parasitic oscillations in a core-doped ceramic Nd:YAG laser by Sm:YAG cladding. Optics Express, 2010, 18(12): 13094.

DOI PMID |

| [23] |

TIMOSHENKO A D, MATVIENKO O O, DOROSHENKO A G, et al. Highly-doped YAG:Sm3+ transparent ceramics: effect of Sm3+ ions concentration. Ceramics International, 2023, 49(5): 7524.

DOI URL |

| [24] | WANG X, YU H, LI P, et al. Femtosecond laser-based processing methods and their applications in optical device manufacturing: a review. Optics & Laser Technology, 2021, 135: 106687. |

| [25] | JI S H, HUANG W F, FENG T, et al. Modeling and measurement of thermal effect in a flashlamp-pumped direct-liquid-cooled split-disk Nd:LuAG ceramic laser amplifier. Nature Photonics, 2021, 8(4): 97. |

| [26] | HUß R, WILHELM R, NEUMANN J, et al. Passively Q-switched core-doped ceramic Nd:YAG laser with Sm:YAG cladding. Lasers and Electro-Optics, 2007, 5:1303. |

| [27] | YAGI H, YANAGITANI T. Recent progress in transparent polycrystalline ceramics for optical applications. Laser & Photonics Reviews, 2011, 39(5): 300. |

| [28] |

MA J, LU T T, ZHU X L, et al. 1.57 MW peak power pulses generated by a diode-pumped Q-switched Nd:LuAG ceramic laser. Chinese Optics Letters, 2017, 15(12): 121402.

DOI URL |

| [29] |

KONG W, TSUNEKANE M, TAIRA T, et al. Diode edge-pumped passively Q-switched microchip laser. Optical Engineering, 2015, 54(9): 090501.

DOI URL |

| [30] |

STEVENSON A J, LI X, MARTINEZ M A, et al. Effect of SiO2 on densification and microstructure development in Nd:YAG transparent ceramics. Journal of the American Ceramic Society, 2011, 94(5): 1380.

DOI URL |

| [31] |

JING Y Q, TIAN F, GUO L H, et al. Effect of TEOS content on microstructure evolution and optical properties of Sm:YAG transparent ceramics. Optical Materials, 2024, 147: 114681.

DOI URL |

| [32] | LIN Z, HUANG X, LAN J, et al. Efficient and compact diode-pumped Nd:YAG lasers at 1073 and 1078 nm. IEEE Photonic, 2016, 8(2): 1500808. |

| [1] | 叶君豪, 周真真, 胡辰, 王雁斌, 荆延秋, 李廷松, 程梓秋, 吴俊林, IVANOV Maxim, HRENIAK Dariusz, 李江. 共沉淀纳米粉体制备Yb:Sc2O3透明陶瓷的微结构与光学性能[J]. 无机材料学报, 2025, 40(2): 215-224. |

| [2] | 郑元顺, 余健, 叶先峰, 梁栋, 朱婉婷, 聂晓蕾, 魏平, 赵文俞, 张清杰. V取代Al位提升全赫斯勒合金Fe2VAl的热电性能[J]. 无机材料学报, 2025, 40(12): 1425-1432. |

| [3] | 吕朝阳, 徐勇, 杨久延, 涂广升, 涂兵田, 王皓. MgF2助剂对MgAl1.9Ga0.1O4透明陶瓷的制备与光学性能的影响[J]. 无机材料学报, 2024, 39(5): 531-538. |

| [4] | 顾军毅, 范武刚, 张兆泉, 姚琴, 展红全. 还原制备Pr2O3粉体及其结构和光学性能研究[J]. 无机材料学报, 2023, 38(7): 771-777. |

| [5] | 李悦, 张旭良, 景芳丽, 胡章贵, 吴以成. 铈掺杂硼酸钙镧晶体的生长与性能研究[J]. 无机材料学报, 2023, 38(5): 583-588. |

| [6] | 王海东, 王燕, 朱昭捷, 李坚富, LAKSHMINARAYANA Gandham, 涂朝阳. Dy3+掺杂SrGdGa3O7晶体的晶体生长, 结构、光学和可见光荧光特性[J]. 无机材料学报, 2023, 38(12): 1475-1482. |

| [7] | 李文俊, 王皓, 涂兵田, 谌强国, 郑凯平, 王为民, 傅正义. 宽光谱透过Mg0.9Al2.08O3.97N0.03透明陶瓷的制备与性能研究[J]. 无机材料学报, 2022, 37(9): 969-975. |

| [8] | 刘强, 王倩, 陈鹏辉, 李晓英, 章立轩, 谢腾飞, 李江. 两步烧结法制备红色Ce:8YSZ透明陶瓷及其性能研究[J]. 无机材料学报, 2022, 37(8): 911-917. |

| [9] | 洪督, 牛亚然, 李红, 钟鑫, 郑学斌. 等离子喷涂TiC-Graphite复合涂层摩擦磨损性能[J]. 无机材料学报, 2022, 37(6): 643-650. |

| [10] | 孙鲁超, 周翠, 杜铁锋, 吴贞, 雷一明, 李家麟, 苏海军, 王京阳. 光悬浮区熔定向凝固Al2O3/Er3Al5O12和Al2O3/Yb3Al5O12共晶陶瓷的制备与性能研究[J]. 无机材料学报, 2021, 36(6): 652-658. |

| [11] | 刘子玉, TOCI Guido, PIRRI Angela, PATRIZI Barbara, 冯亚刚, 陈肖朴, 胡殿君, 田丰, 吴乐翔, VANNINIMatteo, 李江. 固体激光用Nd:Lu2O3透明陶瓷的制备和光学性能研究[J]. 无机材料学报, 2021, 36(2): 210-216. |

| [12] | 黄新友, 刘玉敏, 刘洋, 李晓英, 冯亚刚, 陈肖朴, 陈鹏辉, 刘欣, 谢腾飞, 李江. 醇水共沉淀法制备Yb:YAG透明陶瓷及其性能研究[J]. 无机材料学报, 2021, 36(2): 217-224. |

| [13] | 韦家蓓, TOCIGuido, PIRRIAngela, PATRIZIBarbara, 冯亚刚, VANNINIMatteo, 李江. 共沉淀纳米粉体制备Yb:CaF2激光陶瓷及其性能研究[J]. 无机材料学报, 2019, 34(12): 1341-1348. |

| [14] | 刘小元, 刘宝丹, 姜亚南, 王柯, 周洋, 杨兵, 张兴来, 姜辛. 形貌可控及光学吸收性能可调的钙钛矿型SrTiO3纳米结构的原位生长[J]. 无机材料学报, 2019, 34(1): 65-71. |

| [15] | 杨锁龙, 王晓方, 蒋春丽, 赵雅文, 曾荣光, 王怀胜, 赖新春. InP量子点的掺杂及其光学性能[J]. 无机材料学报, 2016, 31(10): 1051-1057. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||