无机材料学报 ›› 2023, Vol. 38 ›› Issue (10): 1117-1132.DOI: 10.15541/jim20230037 CSTR: 32189.14.10.15541/jim20230037

所属专题: 【结构材料】高导热陶瓷(202506)

• 综述 • 下一篇

收稿日期:2023-01-20

修回日期:2023-04-07

出版日期:2023-10-20

网络出版日期:2023-05-24

通讯作者:

李江涛, 研究员. E-mail: lijiangtao@mail.ipc.ac.cn;作者简介:付 师(1995-), 男, 博士研究生. E-mail: fushi18@mails.ucas.ac.cn

基金资助:

FU Shi1,2( ), YANG Zengchao1(

), YANG Zengchao1( ), LI Jiangtao1,2(

), LI Jiangtao1,2( )

)

Received:2023-01-20

Revised:2023-04-07

Published:2023-10-20

Online:2023-05-24

Contact:

LI Jiangtao, professor. E-mail: lijiangtao@mail.ipc.ac.cn;About author:FU Shi (1995-), male, PhD candidate. E-mail: fushi18@mails.ucas.ac.cn

Supported by:摘要:

随着以SiC和GaN为代表的第三代宽禁带半导体的崛起, 电力电子器件向高输出功率和高功率密度的方向快速发展, 对用于功率模块封装的陶瓷基板材料提出更高的性能要求。传统的Al2O3和AlN陶瓷由于热导率较低或力学性能较差, 均不能满足新一代功率模块封装的应用需求, 相较之下, 新发展的Si3N4陶瓷因兼具高强度和高热导率, 成为最具潜力的绝缘性散热基板材料。近年来, 研究人员通过筛选有效的烧结助剂体系, 并对烧结工艺进行优化, 在制备高强度高热导率Si3N4陶瓷方面取得一系列突破性进展。另外, 伴随覆铜Si3N4陶瓷基板工程应用的推进, 对其制成的基板的力、热和电学性能的评价也成为研究热点。本文从影响Si3N4陶瓷热导率的关键因素出发, 重点对通过烧结助剂的选择和烧结工艺的改进来提高Si3N4陶瓷热导率的国内外工作进行综述。此外, 首次系统总结并介绍了Si3N4陶瓷基板的介电击穿强度以及覆铜后性能评价研究的最新进展, 最后展望了高热导率Si3N4陶瓷基板的未来发展方向。

中图分类号:

付师, 杨增朝, 李江涛. 功率模块封装用高强度高热导率Si3N4陶瓷的研究进展[J]. 无机材料学报, 2023, 38(10): 1117-1132.

FU Shi, YANG Zengchao, LI Jiangtao. Progress of High Strength and High Thermal Conductivity Si3N4 Ceramics for Power Module Packaging[J]. Journal of Inorganic Materials, 2023, 38(10): 1117-1132.

| Material | Al2O3 | AlN | Si3N4 |

|---|---|---|---|

| Density/(g·cm-3) | 3.9 | 3.3 | 3.2 |

| Elasticity modulus/GPa | 370 | 310 | 320 |

| Bending strength/MPa | 300-400 | 220-310 | 600-750 |

| Fracture toughness/(MPa·m1/2) | 3.5-4.0 | 3.0-3.5 | 6.5-7.5 |

| Thermal expansion coefficient/ (×10-6, K-1) | 7-8 | 4.6 | 2.7-3.4 |

| Thermal conductivity/ (W·m-1·K-1) | 18-24 | 67-150 | 27-54 |

| Dielectric strength/(kV·mm-1) | 10-18 | 14-16 | 12-18 |

| Resistivity/(Ω·m) | >1012 | >1012 | >1012 |

| Relative permittivity | 9-10 | 6.0-8.5 | 7-9 |

表1 Al2O3、AlN和Si3N4三种陶瓷基板材料的性能[8]

Table 1 Properties of Al2O3, AlN and Si3N4 ceramic substrate materials[8]

| Material | Al2O3 | AlN | Si3N4 |

|---|---|---|---|

| Density/(g·cm-3) | 3.9 | 3.3 | 3.2 |

| Elasticity modulus/GPa | 370 | 310 | 320 |

| Bending strength/MPa | 300-400 | 220-310 | 600-750 |

| Fracture toughness/(MPa·m1/2) | 3.5-4.0 | 3.0-3.5 | 6.5-7.5 |

| Thermal expansion coefficient/ (×10-6, K-1) | 7-8 | 4.6 | 2.7-3.4 |

| Thermal conductivity/ (W·m-1·K-1) | 18-24 | 67-150 | 27-54 |

| Dielectric strength/(kV·mm-1) | 10-18 | 14-16 | 12-18 |

| Resistivity/(Ω·m) | >1012 | >1012 | >1012 |

| Relative permittivity | 9-10 | 6.0-8.5 | 7-9 |

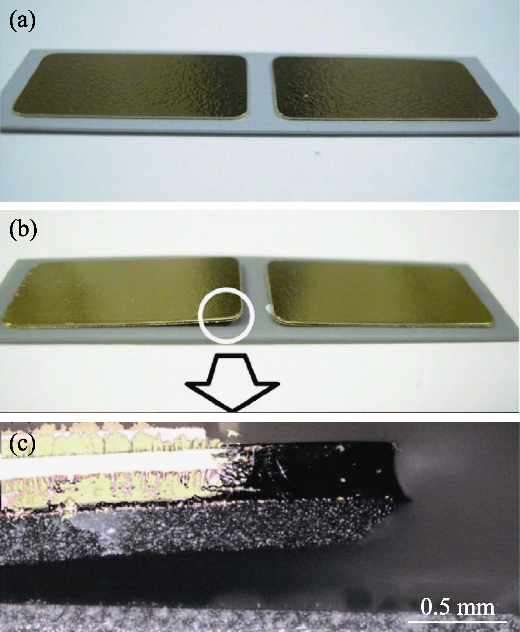

图2 (a)Si3N4覆铜基板在-40~250 ℃热循环1000次后的外观; (b)AlN覆铜基板在-40~250 ℃热循环7次后的外观; (c)Cu板分层脱落的侧视图((b)中白色圆圈内)[9]

Fig. 2 Appearance of (a) Si3N4 coppered substrate after 1000 thermal cycles of -40 to 250 ℃, (b) AlN coppered substrate after 7 cycles of -40 to 250 ℃, and (c) side view of the delaminated Cu plate indicated by white circle in (b) [9]

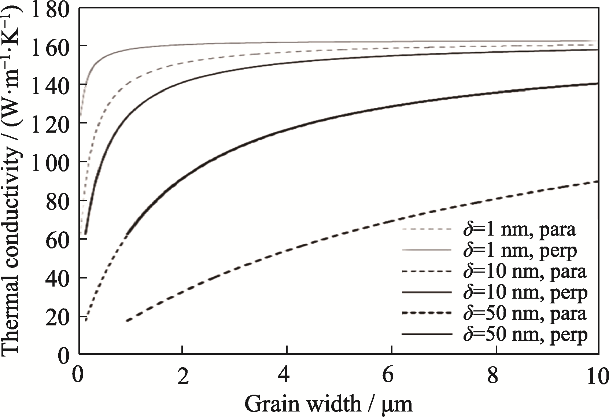

图4 晶粒尺寸对不同晶界膜厚度β-Si3N4热导率的影响规律[35]

Fig. 4 Effect of grain size on the thermal conductivity of β-Si3N4 with various grain-boundary film thicknesses[35] Grain-boundary film thickness δ=1, 10 and 50 nm. Calculations were performed using the aspect ratio at 5 and the volume fraction of grain boundary phase at 6%. ‘Para’ and ‘perp’ indicate thermal conductivity parallel and perpendicular to the hot-press direction, respectively

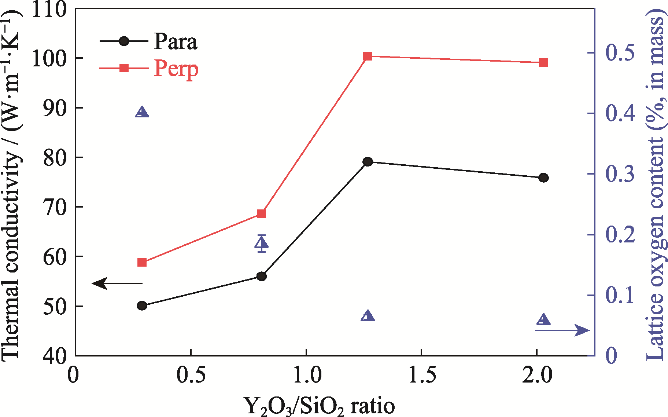

图5 通过调控Y2O3/SiO2比率改变β-Si3N4的热导率和晶格氧含量[18]

Fig. 5 Thermal conductivity and lattice oxygen content of β-Si3N4 changed by adjusting the ratio of Y2O3/SiO2[18]

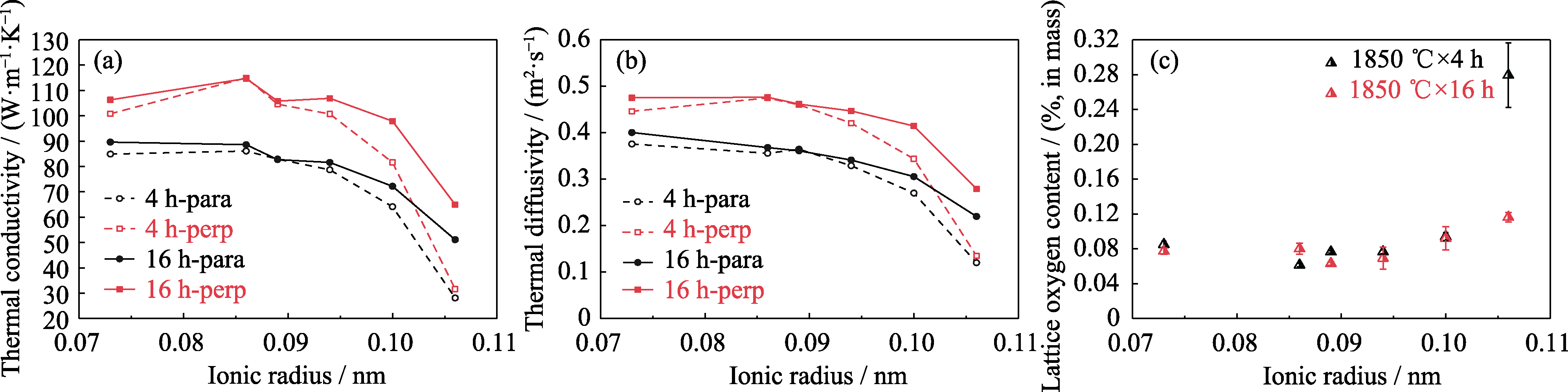

图6 稀土氧化物烧结助剂离子半径对β-Si3N4(a)热导率、(b)热扩散系数和(c)晶格氧含量的影响[43]

Fig. 6 Relationships between ionic radii of rare-earth oxide additives and (a) thermal conductivity, (b) thermal diffusivity and (c) lattice oxygen content of β-Si3N4[43]

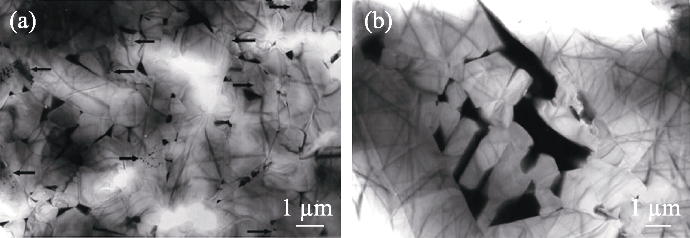

图7 Si3N4样品的明场TEM照片[46]

Fig. 7 Bright-field (BF) TEM images of Si3N4 samples[46] (a) Containing lattice defects (indicated by black arrows); (b) No lattice defects included

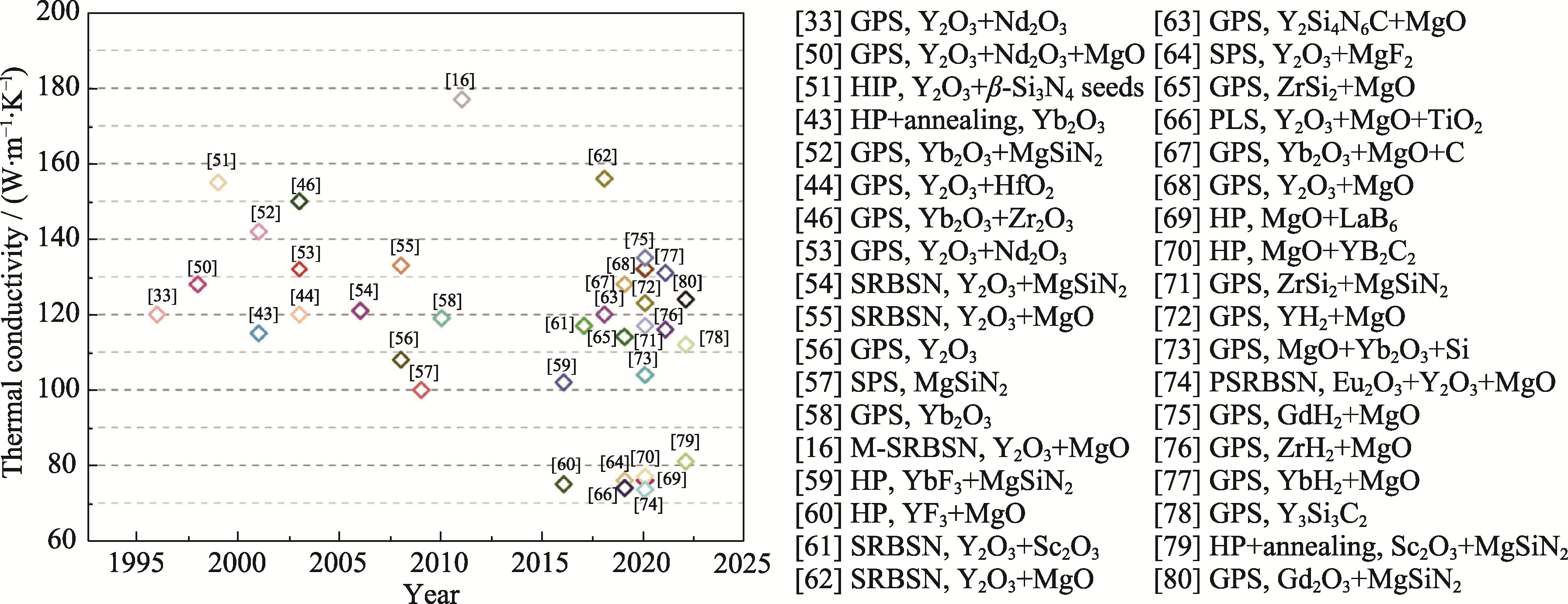

图8 不同烧结助剂体系和烧结方法制备高热导率Si3N4陶瓷的研究进展

Fig. 8 Developments of high thermal conductivity Si3N4 ceramics with different sintering additives systems and sintering methods GPS: Gas pressure sintering, HIP: Hot isostatic pressing, HP: Hot pressed, SRBSN: Sintering of reaction-bonded Si3N4, M-SRBSN: Modified sintering of reaction-bonded Si3N4, SPS: Spark plasma sintering, PLS: pressless sintering, PSRBSN: Pressure-sintered reaction-bonded Si3N4. Numbers in the chart represent relevant references

图9 Si3N4 陶瓷的(a)平均晶粒尺寸、(b)弯曲强度、(c)断裂韧性和(d)热导率随稀土离子半径的变化[79]

Fig. 9 Change of (a) average grain size, (b) bending strength, (c) fracture toughness, and (d) thermal conductivity of Si3N4 ceramics with radius of rare earth ion[79] REM: Before annealing; REMH: After annealing

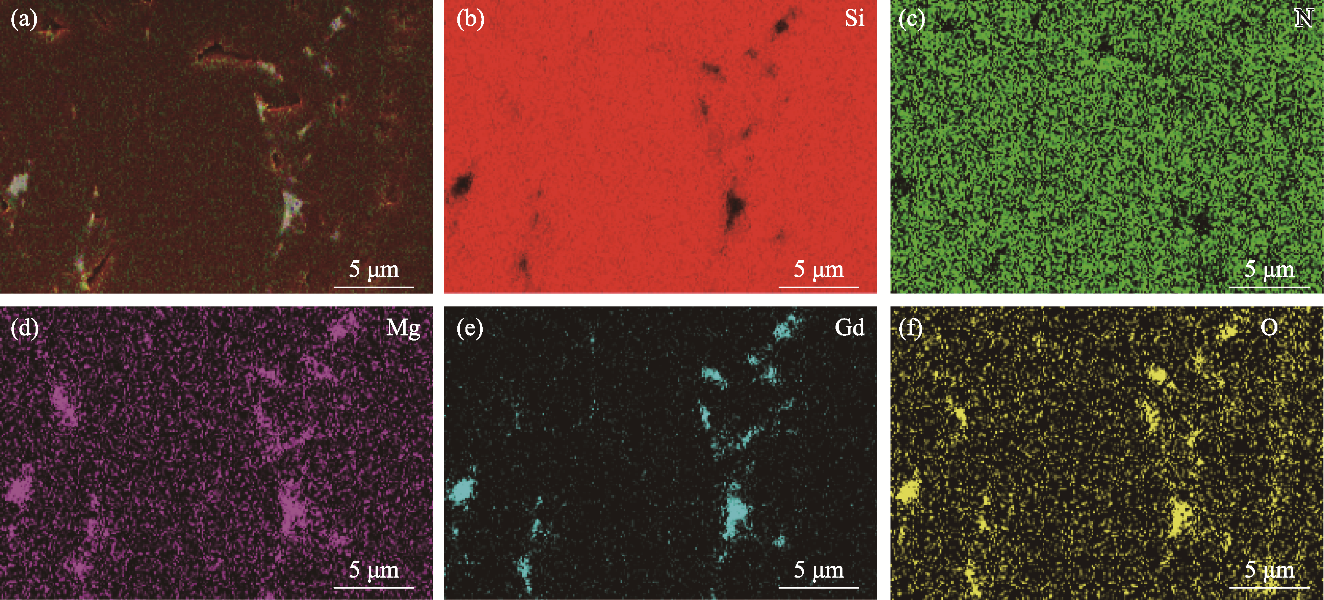

图10 含Gd2O3-MgSiN2烧结助剂的Si3N4 1900 ℃烧结12 h后抛光表面的元素分布图[80]

Fig. 10 Elemental distributions of the polished surface of Si3N4 with Gd2O3-MgSiN2 additives after sintering at 1900 ℃ for 12 h[80]

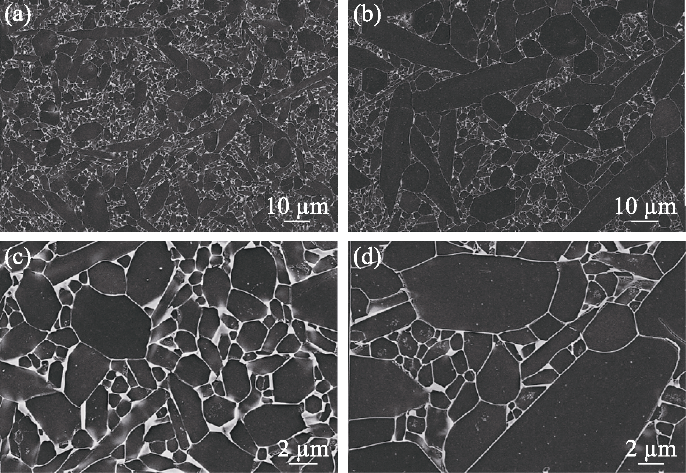

图12 添加碳对Si3N4陶瓷微结构的影响[67]

Fig. 12 Effect of carbon addition on the microstructure of Si3N4 ceramics[67] (a, b) Low-magnification images of (a) SN and (b) SNC; (c, d) High- magnification images of (c) SN and (d) SNC. SN: Carbon free; SNC: Containing carbon

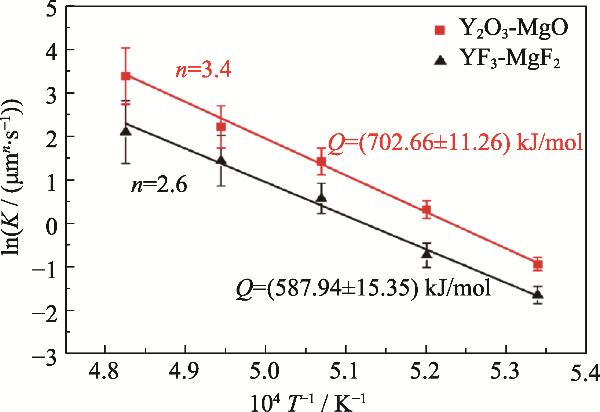

图13 含Y2O3-MgO和YF3-MgF2烧结助剂Si3N4样品的β-Si3N4晶粒生长动力学研究[88]

Fig. 13 Kinetic analysis of β-Si3N4 grain growth in Si3N4 samples with Y2O3-MgO and YF3-MgF2 additives[88]

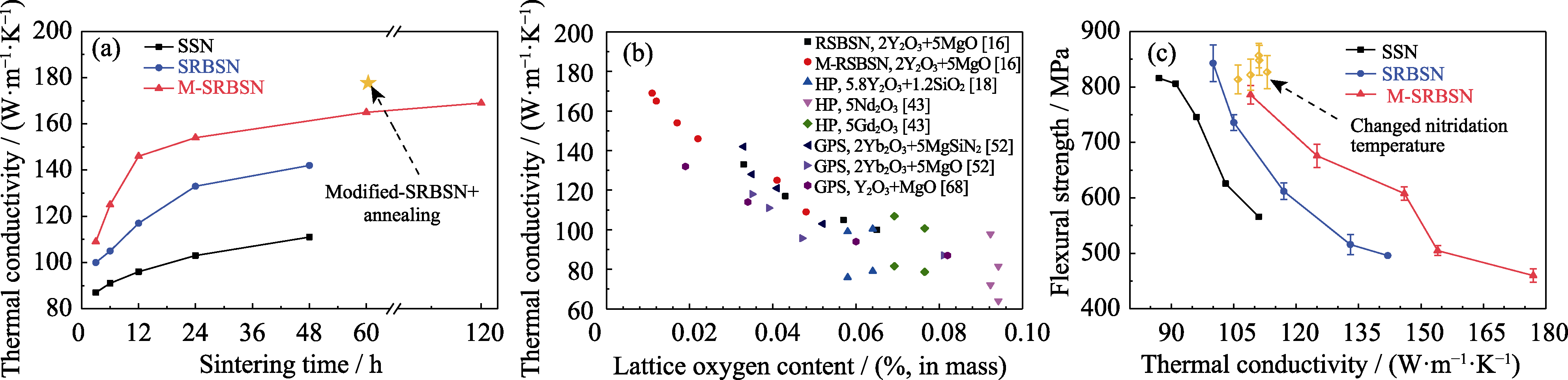

图14 不同烧结工艺制备Si3N4陶瓷热导率和(a)烧结时间和(b)晶格氧含量及其与(c)弯曲强度之间的关系[16,93,94]

Fig. 14 Relationships between thermal conductivity of Si3N4 ceramics prepared by different sintering processes and (a) sintering time, (b) lattice oxygen content and (c) flexural strength[16,93,94]

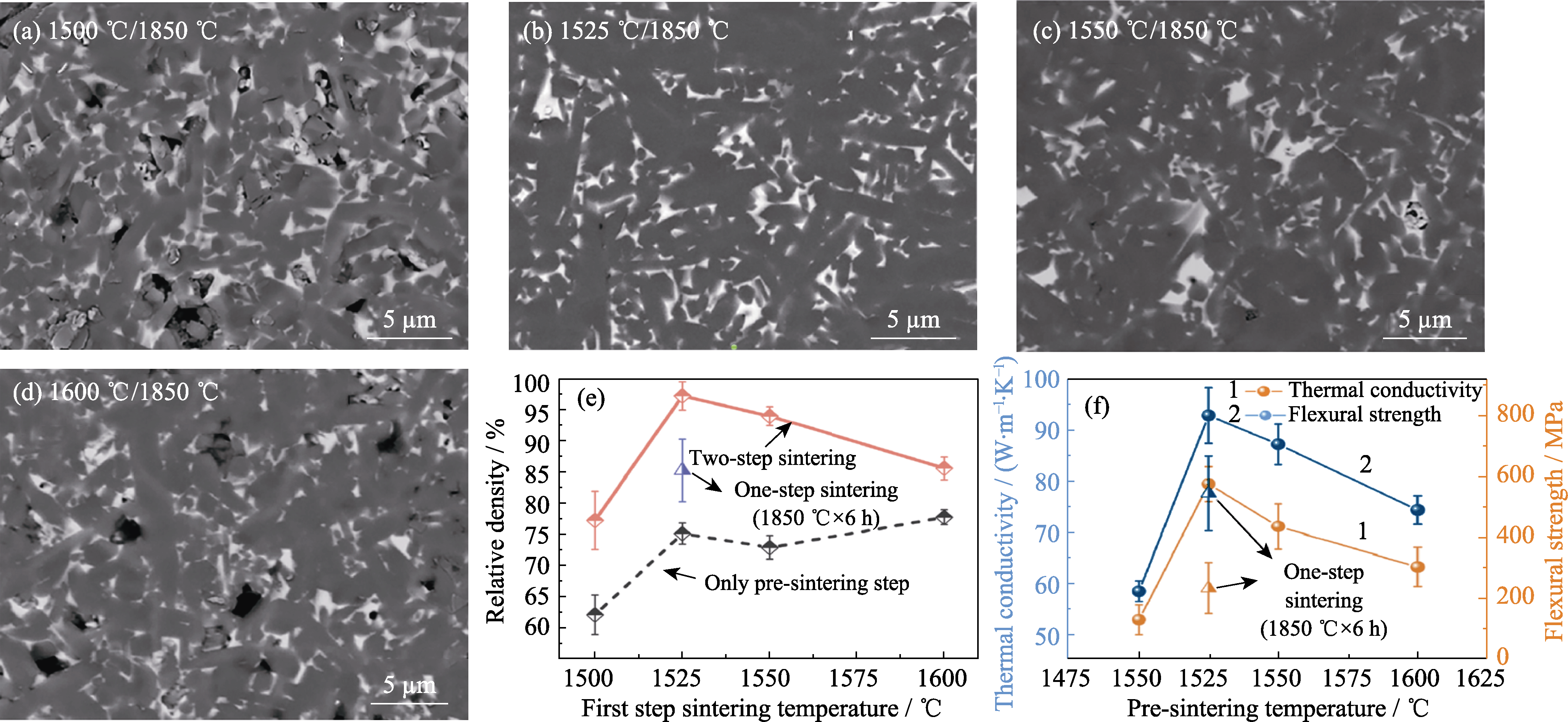

图16 不同预烧结温度对两步烧结后Si3N4微结构的影响((a)1500 ℃, (b)1525 ℃, (c)1550 ℃和(d)1600 ℃); (e)预烧结和两步烧结后Si3N4样品的相对密度; (f)两步烧结后Si3N4的热导率和弯曲强度[97]

Fig. 16 Effect of different pre-sintering temperature on the microstructure of Si3N4 after two-step sintering((a) 1500 ℃, (b) 1525 ℃, (c) 1550 ℃ and (d) 1600 ℃), (e) relative density of Si3N4 samples after pre-sintering and two-step sintering, and (f) thermal conductivity and flexural strength of Si3N4 samples after two-step sintering[97]

图17 不同烧结方法和烧结助剂制备Si3N4陶瓷的热导率、弯曲强度和断裂韧性

Fig. 17 Thermal conductivity, bending strength and fracture toughness of Si3N4 ceramics prepared by different sintering methods and additives Numbers in the chart represent relevant references

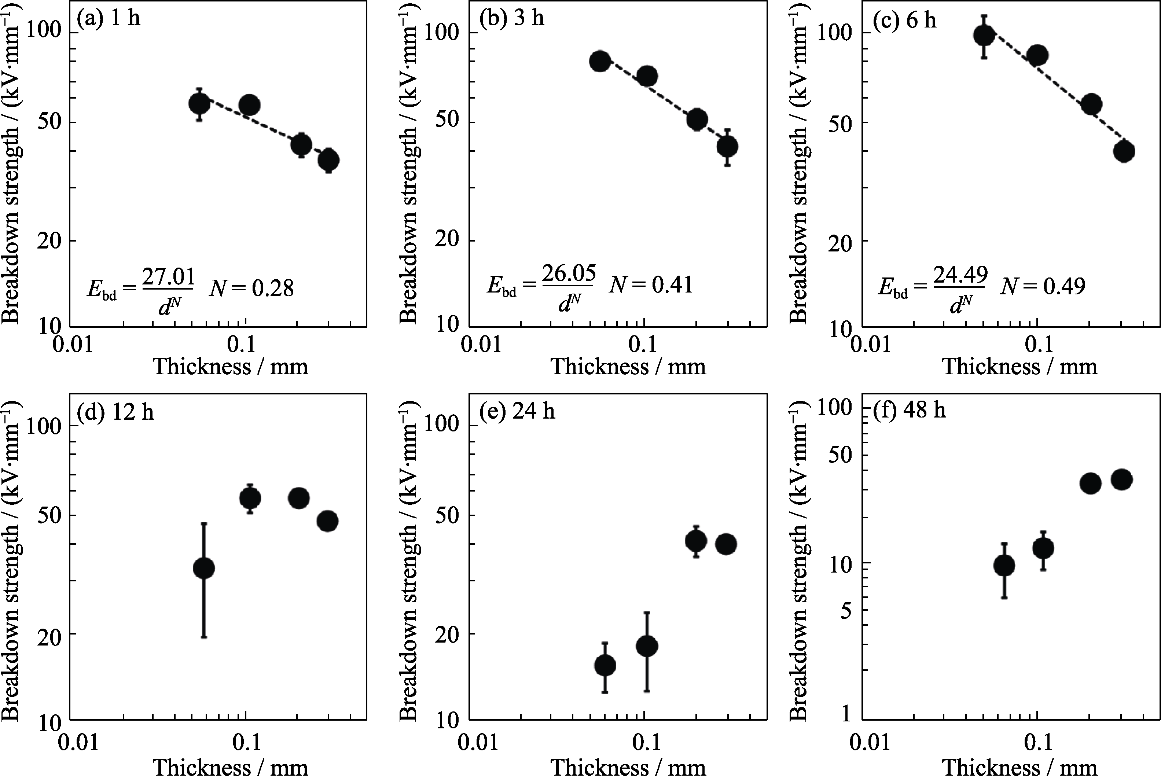

图18 基板厚度对烧结(a)1, (b)3, (c)6, (d)12, (e)24和(f)48 h的Si3N4陶瓷介电击穿强度(DBS)的影响[117]

Fig. 18 Effect of substrate thickness on the dielectric breakdown strength (DBS) of Si3N4 ceramics sintered for (a) 1, (b) 3, (c) 6, (d) 12, (e) 24, and (f) 48 h[117]

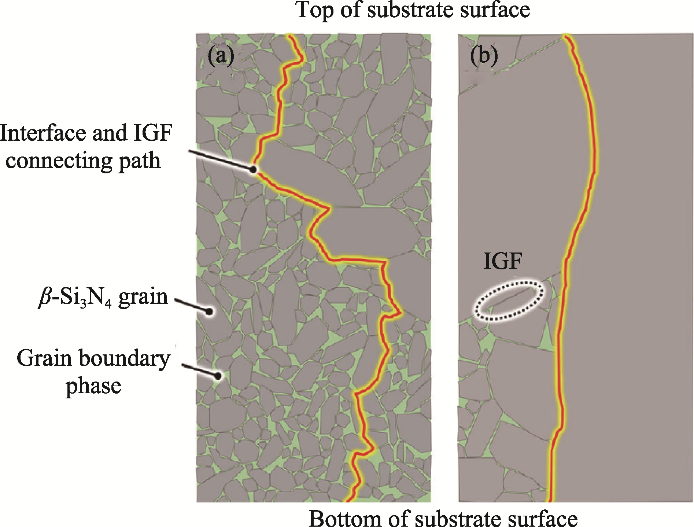

图19 β-Si3N4晶粒与晶界相/晶间玻璃薄膜(IGFs)之间界面的连接路径示意图[117]

Fig. 19 Schematic images of the connecting path for the interface between β-Si3N4 grain and grain boundary phases/ intergranular glassy films (IGFs) in the substrates which have (a) smaller and (b) larger ratio of grain size to substrate thickness[117]

| Ceramic substrate (Material code) | Flexural strength/MPa | Fracture toughness/(MPa·m1/2) | Thermal conductivity/(W·m-1·K-1) |

|---|---|---|---|

| Si3N4 (SN-1) | 669±29 | 10.5±0.2 | 140 |

| Si3N4 (SN-2) | 909±303 | 5.2±0.2 | 21 |

| Si3N4 (SN-3) | 977±79 | 5.5±0.1 | - |

| Si3N4 (SN-4) | 604±25 | 8.0±0.4 | 90 |

| AlN | 461±62 | 3.2±0.2 | 180 |

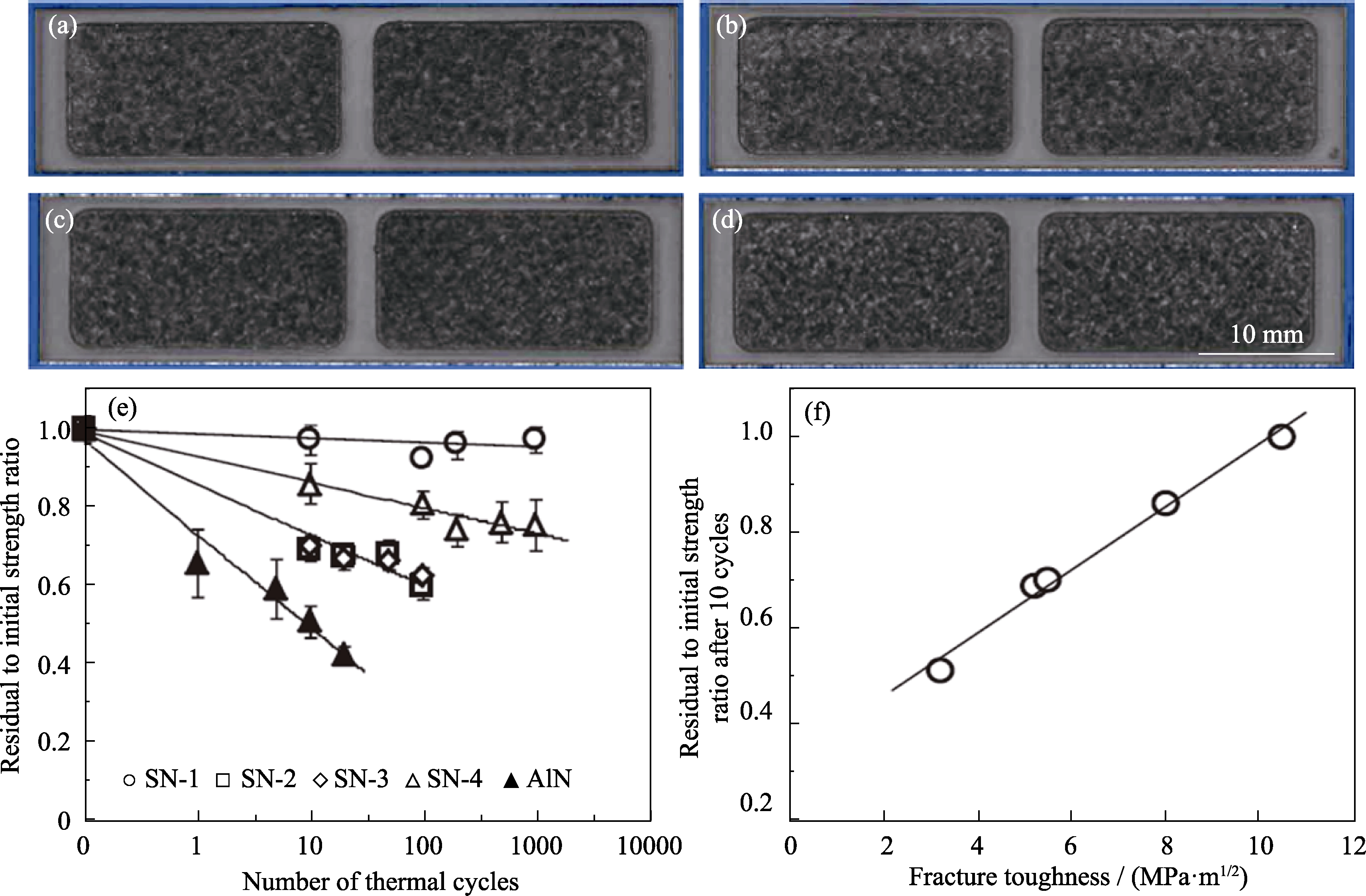

表2 用于热循环测试的Si3N4陶瓷基板和AlN陶瓷基板的力学和热学性能[118]

Table 2 Mechanical and thermal properties of Si3N4 ceramic substrates and AlN ceramic substrates for thermal cycle testing[118]

| Ceramic substrate (Material code) | Flexural strength/MPa | Fracture toughness/(MPa·m1/2) | Thermal conductivity/(W·m-1·K-1) |

|---|---|---|---|

| Si3N4 (SN-1) | 669±29 | 10.5±0.2 | 140 |

| Si3N4 (SN-2) | 909±303 | 5.2±0.2 | 21 |

| Si3N4 (SN-3) | 977±79 | 5.5±0.1 | - |

| Si3N4 (SN-4) | 604±25 | 8.0±0.4 | 90 |

| AlN | 461±62 | 3.2±0.2 | 180 |

图20 SN-1覆铜基板不同热循环次数后的照片((a)10次, (b)100次, (c)200次和(d)1000次); (e)陶瓷覆铜基板剩余/起始强度比随热循环次数的变化; (f)10次热循环后Si3N4覆铜基板的剩余强度/初始强度比与断裂韧性的关系[118]

Fig. 20 Images of the SN-1 coppered substrate after different thermal cycles ((a) 10 cycles, (b) 100 cycles, (c) 200 cycles, and (d) 1000 cycles), (e) plots of residual to initial strength ratio vs. thermal cycle number of the coppered substrates, and (f) relationship between residual to initial strength ratio and fracture toughness of the Si3N4 coppered substrates after 10 cycles[118]

| [1] | CHOI U M, BLAABJERG F, JORGENSEN S, et al. Power cycling test and failure analysis of molded intelligent power IGBT module under different temperature swing durations. Microelectronics Reliability, 2016, 64: 403. |

| [2] | CABELLO M, SOLER V, RIUS G, et al. Advanced processing for mobility improvement in 4H-SiC MOSFETs: a review. Materials Science in Semiconductor Processing, 2018, 78: 22. |

| [3] |

BUTTAY C, PLANSON D, ALLARD B, et al. State of the art of high temperature power electronics. Materials Science and Engineering: B, 2011, 176(4): 283.

DOI URL |

| [4] |

EDDY C R, GASKILL D K. Silicon carbide as a platform for power electronics. Science, 2009, 324(5933): 1398.

DOI URL |

| [5] |

MURAYAMA N, HIRAO K, SANDO M, et al. High-temperature electro-ceramics and their application to SiC power modules. Ceramics International, 2018, 44(4): 3523.

DOI URL |

| [6] |

OKUMURA H. Present status and future prospect of widegap semiconductor high-power devices. Japanese Journal of Applied Physics, 2006, 45(10A): 7565.

DOI |

| [7] | HIRAO K, ZHOU Y, MIYAZAKI H. 3-Substrate. Wide bandgap power semiconductor packaging. Woodhead Publishing, 2018: 81. |

| [8] | KITAYAMA M. High thermal conductivity ceramics. Encyclopedia of materials:technical ceramics and glasses. Oxford: Elsevier, 2021:165. |

| [9] |

FUKUDA S, SHIMADA K, IZU N, et al. Crack generation in electroless nickel plating layers on copper-metallized silicon nitride substrates during thermal cycling. Journal of Materials Science: Materials in Electronics, 2017, 28(11): 8278.

DOI URL |

| [10] |

RILEY F L. Silicon nitride and related materials. Journal of the American Ceramic Society, 2000, 83(2): 245.

DOI URL |

| [11] | HAGGERTY J S, LIGHTFOOT A. Opportunities for enhancing the thermal conductivities of SiC and Si3N4 ceramics through improved processing. Ceramic Engineering and Science Proceedings. 1995: 475. |

| [12] |

KRSTIC Z, KRSTIC V D. Silicon nitride: the engineering material of the future. Journal of Materials Science, 2012, 47(2): 535.

DOI URL |

| [13] |

HIRAO K, WATARI K, HAYASHI H, et al. High thermal conductivity silicon nitride ceramic. MRS Bulletin, 2001, 26(6): 451.

DOI URL |

| [14] |

HIRAO K, ZHOU Y, HYUGA H, et al. High thermal conductivity silicon nitride ceramics. Journal of the Korean Ceramic Society, 2012, 49(4): 380.

DOI URL |

| [15] |

WATARI K. High thermal conductivity non-oxide ceramics. Journal of the Ceramic Society of Japan, 2001, 109(1): S7.

DOI URL |

| [16] |

ZHOU Y, HYUGA H, KUSANO D, et al. A tough silicon nitride ceramic with high thermal conductivity. Advanced Materials, 2011, 23(39): 4563.

DOI |

| [17] |

KITAYAMA M, HIRAO K, TSUGE A, et al. Oxygen content in ß-Si3N4 crystal lattice. Journal of the American Ceramic Society, 1999, 82(11): 3263.

DOI URL |

| [18] |

KITAYAMA M, HIRAO K, TSUGE A, et al. Thermal conductivity of β-Si3N4: II, effect of lattice oxygen. Journal of the American Ceramic Society, 2000, 83(8): 1985.

DOI URL |

| [19] |

KUSANO D, NODA Y, SHIBASAKI H, et al. Effects of impurity iron content on characteristics of sintered reaction-bonded silicon nitride. International Journal of Applied Ceramic Technology, 2013, 10(4): 690.

DOI URL |

| [20] |

MATSUNAGA C, ZHOU Y, KUSANO D, et al. Dielectric breakdown of silicon nitride substrates with various thicknesses. Journal of the Ceramic Society of Japan, 2018, 126(9): 693.

DOI URL |

| [21] |

NAKASHIMA Y, HYUGA H, HIRAO K, et al. Thickness dependence of dielectric breakdown strength for silicon nitride substrate. Journal of the Ceramic Society of Japan, 2021, 129(12): 761.

DOI URL |

| [22] |

FUKUDA S, SHIMADA K, IZU N, et al. Relationship between the thermal stress and structures of thermal-cycling-induced cracks in electroless nickel plating on metalized substrates. Journal of Materials Science: Materials in Electronics, 2019, 30(6): 5820.

DOI |

| [23] |

MIYAZAKI H, HIRAO K, HYUGA H. Round-robin exercise on the three- and four-point flexural strength of thin ceramic plates for power modules. International Journal of Applied Ceramic Technology, 2019, 16(6): 2121.

DOI URL |

| [24] | WAKASUGI N, CHEN C, HIRAO K, et al. Thermal evaluation of metalized ceramic substrates for use in next-generation power modules toward international standardization. 2020 IEEE 8th Electronics System-Integration Technology Conference (ESTC), 2020. |

| [25] |

HIRAO K, ZHOU Y, HYUGA H, et al. Evaluation of thermal resistance for metalized ceramic substrates using a microheater chip. International Journal of Applied Ceramic Technology, 2021, 19(1): 232.

DOI URL |

| [26] |

SLACK G A. Nonmetallic crystals with high thermal conductivity. Journal of Physics and Chemistry of Solids, 1973, 34(2): 321.

DOI URL |

| [27] |

SLACK G A, TANZILLI R A, POHL R O, et al. The intrinsic thermal conductivity of AIN. Journal of Physics and Chemistry of Solids, 1987, 48(7): 641.

DOI URL |

| [28] | TAKEDA Y. Development of high-thermal-conductivity SiC ceramics. American Ceramic Society Bulletin, 1988, 67(12): 1961. |

| [29] |

NAKANO H, WATARI K, HAYASHI H, et al. Microstructural characterization of high-thermal-conductivity aluminum nitride ceramic. Journal of the American Ceramic Society, 2002, 85(12): 3093.

DOI URL |

| [30] |

HAMPSHIRE S, PARK H K, THOMPSON D P, et al. α’-Sialon ceramics. Nature, 1978, 274(5674): 880.

DOI |

| [31] |

KRäMER M, WITTMÜSS D, KÜPPERS H, et al. Relations between crystal structure and growth morphology of β-Si3N4. Journal of Crystal Growth, 1994, 140(1): 157.

DOI URL |

| [32] |

THOMAS A, MÜLLER G. Determination of the concentration of oxygen dissolved in the AlN lattice by hot gas extraction from AlN ceramics. Journal of the European Ceramic Society, 1991, 8(1): 11.

DOI URL |

| [33] |

HIROSAKI N, OKAMOTO Y, ANDO M, et al. Thermal conductivity of gas-pressure-sintered silicon nitride. Journal of the American Ceramic Society, 1996, 79(11): 2878.

DOI URL |

| [34] |

HIROSAKI N, OKAMOTO Y, ANDO M, et al. Effect of grain growth on the thermal conductivity of silicon nitride. Journal of the Ceramic Society of Japan, 1996, 104(1205): 49.

DOI URL |

| [35] |

KITAYAMA M, HIRAO K, TORIYAMA M, et al. Thermal conductivity of ß-Si3N4: I, effects of various microstructural factors. Journal of the American Ceramic Society, 1999, 82(11): 3105.

DOI URL |

| [36] |

PRIEST H F, BURNS F C, PRIEST G L, et al. Oxygen content of alpha silicon nitride. Journal of the American Ceramic Society, 1973, 56(7): 395.

DOI URL |

| [37] | PEUCKERT M, GREIL P. Oxygen distribution in silicon nitride powders. Journal of Materials Science, 1987, 22: 3717. |

| [38] |

KIJIMA K, KATO K, INOUE Z, et al. Oxygen content of α-Si3N4 single crystals. Journal of Materials Science, 1975, 10(2): 362.

DOI URL |

| [39] | HIROSAKI N, OKADA A, MATOBA K. Sintering of Si3N4 with the addition of rare-earth-oxides. Journal of the American Ceramic Society, 1988, 71(3): C144. |

| [40] |

KITAYAMA M, HIRAO K, KANZAKI S. Effect of rare earth oxide additives on the phase transformation rates of Si3N4. Journal of the American Ceramic Society, 2006, 89(8): 2612.

DOI URL |

| [41] |

BECHER P F, PAINTER G S, SHIBATA N, et al. Effects of rare-earth (RE) intergranular adsorption on the phase transformation, microstructure evolution, and mechanical properties in silicon nitride with RE2O3+MgO additives: RE=La, Gd, and Lu. Journal of the American Ceramic Society, 2008, 91(7): 2328.

DOI URL |

| [42] |

BECHER P F, SHIBATA N, PAINTER G S, et al. Observations on the influence of secondary Me oxide additives (Me=Si, Al, Mg) on the microstructural evolution and mechanical behavior of silicon nitride ceramics containing RE2O3(RE=La, Gd, Lu). Journal of the American Ceramic Society, 2010, 93(2): 570.

DOI URL |

| [43] |

KITAYAMA M, HIRAO K, WATARI K, et al. Thermal conductivity of β-Si3N4: III, effect of rare-earth (RE = La, Nd, Gd, Y, Yb, and Sc) oxide additives. Journal of the American Ceramic Society, 2001, 84(2): 353.

DOI URL |

| [44] |

YOKOTA H, YAMADA S, IBUKIYAMA M. Effect of large β-Si3N4 particles on the thermal conductivity of β-Si3N4 ceramics. Journal of the European Ceramic Society, 2003, 23(8): 1175.

DOI URL |

| [45] |

YOKOTA H, IBUKIYAMA M. Effect of lattice impurities on the thermal conductivity of β-Si3N4. Journal of the European Ceramic Society, 2003, 23(1): 55.

DOI URL |

| [46] |

YOKOTA H, ABE H, IBUKIYAMA M. Effect of lattice defects on the thermal conductivity of β-Si3N4. Journal of the European Ceramic Society, 2003, 23(10): 1751.

DOI URL |

| [47] |

YOKOTA H, IBUKIYAMA M. Effect of the addition of β-Si3N4 nuclei on the thermal conductivity of β-Si3N4ceramics. Journal of the European Ceramic Society, 2003, 23(8): 1183.

DOI URL |

| [48] |

YOKOTA H, IBUKIYAMA M. Microstructure tailoring for high thermal conductivity of β-Si3N4 ceramics. Journal of the American Ceramic Society, 2003, 86(1): 197.

DOI URL |

| [49] |

NEGITA K. Effective sintering aids for Si3N4 ceramics. Journal of Materials Science Letters, 1985, 4(6): 755.

DOI URL |

| [50] |

OKAMOTO Y, HIROSAKI N, ANDO M, et al. Effect of sintering additive composition on the thermal conductivity of silicon nitride. Journal of Materials Research, 1998, 13(12): 3473.

DOI URL |

| [51] |

HIROSAKI N, OKAMOTO Y, MUNAKATA F, et al. Effect of seeding on the thermal conductivity of self-reinforced silicon nitride. Journal of the European Ceramic Society, 1999, 19(12): 2183.

DOI URL |

| [52] |

HAYASHI H, HIRAO K, TORIYAMA M, et al. MgSiN2 addition as a means of increasing the thermal conductivity of β-silicon nitride. Journal of the American Ceramic Society, 2001, 84(12): 3060.

DOI URL |

| [53] |

YE J, OKADA A. Microthermal analysis of heat conduction in silicon nitrides. Journal of the American Ceramic Society, 2003, 86(8): 1365.

DOI URL |

| [54] |

ZHU X, ZHOU Y, HIRAO K, et al. Processing and thermal conductivity of sintered reaction-bonded silicon nitride. I: effect of Si powder characteristics. Journal of the American Ceramic Society, 2006, 89(11): 3331.

DOI URL |

| [55] |

ZHOU Y, ZHU X, HIRAO K, et al. Sintered reaction-bonded silicon nitride with high thermal conductivity and high strength. International Journal of Applied Ceramic Technology, 2008, 5(2): 119.

DOI URL |

| [56] |

ZHU X W, SAKKA Y, ZHOU Y, et al. Effect of MgSiN2 addition on gas pressure sintering and thermal conductivity of silicon nitride with Y2O3. Journal of the Ceramic Society of Japan, 2008, 116(1354): 706.

DOI URL |

| [57] |

PENG G H, LIANG M, LIANG Z H, et al. Spark plasma sintered silicon nitride ceramics with high thermal conductivity using MgSiN2as additives. Journal of the American Ceramic Society, 2009, 92(9): 2122.

DOI URL |

| [58] |

ZHU X, ZHOU Y, HIRAO K, et al. Potential use of only Yb2O3 in producing dense Si3N4 ceramics with high thermal conductivity by gas pressure sintering. Science and Technology of Advanced Materials, 2010, 11(6): 065001.

DOI URL |

| [59] |

LEE H M, LEE E B, KIM D L, et al. Comparative study of oxide and non-oxide additives in high thermal conductive and high strength Si3N4 ceramics. Ceramics International, 2016, 42(15): 17466.

DOI URL |

| [60] |

LIANG H, ZENG Y, ZUO K, et al. Mechanical properties and thermal conductivity of Si3N4 ceramics with YF3 and MgO as sintering additives. Ceramics International, 2016, 42(14): 15679.

DOI URL |

| [61] |

KIM J M, KO S I, KIM H N, et al. Effects of microstructure and intergranular glassy phases on thermal conductivity of silicon nitride. Ceramics International, 2017, 43(7): 5441.

DOI URL |

| [62] |

ZHOU Y, HYUGA H, KUSANO D, et al. Effects of yttria and magnesia on densification and thermal conductivity of sintered reaction-bonded silicon nitrides. Journal of the American Ceramic Society, 2019, 102(4): 1579.

DOI URL |

| [63] |

LI Y, KIM H N, WU H, et al. Enhanced thermal conductivity in Si3N4ceramic with the addition of Y2Si4N6C. Journal of the American Ceramic Society, 2018, 101(9): 4128.

DOI URL |

| [64] |

YANG C, LIU Q, ZHANG B, et al. Effect of MgF2 addition on mechanical properties and thermal conductivity of silicon nitride ceramics. Ceramics International, 2019, 45(10): 12757.

DOI URL |

| [65] |

WANG W, YAO D, CHEN H, et al. ZrSi2-MgO as novel additives for high thermal conductivity of β‐Si3N4 ceramics. Journal of the American Ceramic Society, 2019, 103(3): 2090.

DOI URL |

| [66] |

DUAN Y, ZHANG J, LI X, et al. High thermal conductivity silicon nitride ceramics prepared by pressureless sintering with ternary sintering additives. International Journal of Applied Ceramic Technology, 2019, 16(4): 1399.

DOI URL |

| [67] |

LI Y, KIM H N, WU H, et al. Enhanced thermal conductivity in Si3N4 ceramic by addition of a small amount of carbon. Journal of the European Ceramic Society, 2019, 39(2/3): 157.

DOI URL |

| [68] | LI Y, KIM H N, WU H, et al. Microstructure and thermal conductivity of gas-pressure-sintered Si3N4 ceramic: the effects of Y2O3 additive content. Journal of the European Ceramic Society, 2021, 41(1): 274. |

| [69] |

LIANG H, WANG W, ZUO K, et al. Effect of LaB6 addition on mechanical properties and thermal conductivity of silicon nitride ceramics. Ceramics International, 2020, 46(11): 17776.

DOI URL |

| [70] |

LIANG H, WANG W, ZUO K, et al. YB2C2: a new additive for fabricating Si3N4 ceramics with superior mechanical properties and medium thermal conductivity. Ceramics International, 2020, 46(4): 5239.

DOI URL |

| [71] |

WANG W, YAO D, LIANG H, et al. Effect of the binary nonoxide additives on the densification behavior and thermal conductivity of Si3N4ceramics. Journal of the American Ceramic Society, 2020, 103(10): 5891.

DOI URL |

| [72] |

WANG W, YAO D, LIANG H, et al. Effect of in-situ formed Y2O3 by metal hydride reduction reaction on thermal conductivity of β-Si3N4 ceramics. Journal of the European Ceramic Society, 2020, 40(15): 5316.

DOI URL |

| [73] |

WANG W, YAO D, LIANG H, et al. Novel silicothermic reduction method to obtain Si3N4 ceramics with enhanced thermal conductivity and fracture toughness. Journal of the European Ceramic Society, 2021, 41(2): 1735.

DOI URL |

| [74] |

WU L X, ZHU L L, YOU Y, et al. Fabrication and properties of pressure-sintered reaction-bonded Si3N4 ceramics with addition of Eu2O3-MgO-Y2O3. Ceramics International, 2021, 47(1): 935.

DOI URL |

| [75] |

WANG W, YAO D, LIANG H, et al. Improved thermal conductivity of β-Si3N4 ceramics through the modification of the liquid phase by using GdH2 as a sintering additive. Ceramics International, 2021, 47(4): 5631.

DOI URL |

| [76] | WANG W, YAO D, LIANG H, et al. Enhanced thermal conductivity in Si3N4 ceramics prepared by using ZrH2 as an oxygen getter. Journal of Alloys and Compounds, 2021, 855: 157451. |

| [77] |

WANG W D, CHEN H B, LI S S, et al. Preparation of silicon nitride with high thermal conductivity and high flexural strength using YbH2-MgO as sintering additive. Journal of Inorganic Materials, 2021, 36(9): 959.

DOI URL |

| [78] |

HUANG M, HUANG Y, OU J, et al. Effect of a new nonoxide additive Y3Si2C2 on the thermal conductivity and mechanical properties of Si3N4 ceramics. International Journal of Applied Ceramic Technology, 2022, 19(6): 3403.

DOI URL |

| [79] |

FU S, YANG Z C, LI H H, et al. Mechanical properties and thermal conductivity of Si3N4 ceramics with composite sintering additives. Journal of Inorganic Materials, 2022, 37(9): 947.

DOI URL |

| [80] |

FU S, YANG Z, LI H, et al. Effects of Gd2O3 and MgSiN2 sintering additives on the thermal conductivity and mechanical properties of Si3N4 ceramics. International Journal of Applied Ceramic Technology, 2023, 20(3): 1855.

DOI URL |

| [81] | UCHIDA N, KOIZUMI M, SHIMADA M. Fabrication of Si3N4 ceramics with metal nitride additives by isostatic hot-pressing. Journal of the American Ceramic Society, 1985, 68(2): C-38. |

| [82] |

ABE O. Sintering of silicon-nitride with alkaline-earth nitrides. Ceramics International, 1990, 16(1): 53.

DOI URL |

| [83] |

PENG G H, JIANG G J, ZHUANG H R, et al. A novel route for preparing MgSiN2 powder by combustion synthesis. Materials Science and Engineering: A, 2005, 397(1/2): 65.

DOI URL |

| [84] | 杨建辉, 陈义祥, 刘光华, 等. 自蔓延高温合成制备单相氮化硅镁粉体. 硅酸盐学报, 2011, 39(2): 177. |

| [85] |

YANG J H, QIU J F, LI J T. Preparation of single-phase magnesium silicon nitride powder by a two-step process. Ceramics International, 2011, 37(2): 673.

DOI URL |

| [86] |

NAKASHIMA Y, OZEKI Y, ZHOU Y, et al. Synthesis of MgSiN2 under 0.1 MPa of nitrogen pressure via combustion. Ceramics International, 2021, 47(22): 31383.

DOI URL |

| [87] |

WANG W, YAO D, LIANG H, et al. Improved thermal conductivity of β‐Si3N4 ceramics by lowering SiO2/Y2O3 ratio using YH2 as sintering additive. Journal of the American Ceramic Society, 2020, 103(10): 5567.

DOI URL |

| [88] |

LIAO S, ZHOU L, JIANG C, et al. Thermal conductivity and mechanical properties of Si3N4 ceramics with binary fluoride sintering additives. Journal of the European Ceramic Society, 2021, 41(14): 6971.

DOI URL |

| [89] |

LIAO S, ZHUANG Y, WANG J, et al. Synergistic effect of binary fluoride sintering additives on the properties of silicon nitride ceramics. Ceramics International, 2022, 48(15): 21832.

DOI URL |

| [90] | KUMAR K, PARK Y J, KIM M J, et al. Influence of ternary oxide additives on thermal conductivity of pressureless sintered Si3N4. Materials Letters, 2022, 328: 133189. |

| [91] |

GUO W M, WU L X, MA T, et al. Rapid fabrication of Si3N4 ceramics by reaction-bonding and pressureless sintering. Journal of the European Ceramic Society, 2016, 36(16): 3919.

DOI URL |

| [92] |

LI W, WU Y, HUANG R, et al. Effect of Si addition on the mechanical and thermal properties of sintered reaction bonded silicon nitride. Journal of the European Ceramic Society, 2017, 37(15): 4491.

DOI URL |

| [93] |

ZHOU Y, HYUGA H, KUSANO D, et al. Development of high-thermal-conductivity silicon nitride ceramics. Journal of Asian Ceramic Societies, 2015, 3(3): 221.

DOI URL |

| [94] |

NAKASHIMA Y, ZHOU Y, TANABE K, et al. Effects of nitridation temperature on properties of sintered reaction‐bonded silicon nitride. International Journal of Applied Ceramic Technology, 2023, 20(2): 1071.

DOI URL |

| [95] |

ZHU X, SAKKA Y, ZHOU Y, et al. The effect of embedding conditions on the thermal conductivity of β-Si3N4. Journal of the Ceramic Society of Japan, 2006, 114(1335): 1093.

DOI URL |

| [96] |

HU F, ZHU T, XIE Z, et al. Elimination of grain boundaries and its effect on the properties of silicon nitride ceramics. Ceramics International, 2020, 46(8): 12606.

DOI URL |

| [97] |

HU J, ZHANG B, LI C, et al. Fabrication of Si3N4 ceramics with high thermal conductivity and flexural strength via novel two-step gas-pressure sintering. Journal of the European Ceramic Society, 2022, 42(12): 4846.

DOI URL |

| [98] |

ZHU X, HAYASHI H, ZHOU Y, et al. Influence of additive composition on thermal and mechanical properties of β-Si3N4ceramics. Journal of Materials Research, 2004, 19(11): 3270.

DOI URL |

| [99] |

ZHU X, SAKKA Y, ZHOU Y, et al. Processing and properties of sintered reaction-bonded silicon nitride with Y2O3-MgSiN2: effects of Si powder and Li2O addition. Acta Materialia, 2007, 55(16): 5581.

DOI URL |

| [100] |

KUSANO D, ADACHI S, TANABE G, et al. Effects of impurity oxygen content in raw Si powder on thermal and mechanical properties of sintered reaction-bonded silicon nitrides. International Journal of Applied Ceramic Technology, 2012, 9(2): 229.

DOI URL |

| [101] |

KUSANO D, HYUGA H, ZHOU Y, et al. Effect of aluminum content on mechanical properties and thermal conductivities of sintered reaction-bonded silicon nitride. International Journal of Applied Ceramic Technology, 2014, 11(3): 534.

DOI URL |

| [102] | LI S, CHEN H, WANG W, et al. Effects of Y2O3/MgO ratio on mechanical properties and thermal conductivity of silicon nitride ceramics. International Journal of Applied Ceramic Technology, 2022, 19(5): 2873. |

| [103] |

LI S, XIA Y, YAO D, et al. Enhanced thermal conductivity and flexural strength of sintered reaction-bonded silicon nitride with addition of (Y0.96Eu0.04)2O3. International Journal of Applied Ceramic Technology, 2023, 20(1): 465.

DOI URL |

| [104] |

DUAN Y, ZHANG J, LI X, et al. Low temperature pressureless sintering of silicon nitride ceramics for circuit substrates in powder electronic devices. Ceramics International, 2018, 44(4): 4375.

DOI URL |

| [105] |

LIU W, TONG W, LU X, et al. Effects of different types of rare earth oxide additives on the properties of silicon nitride ceramic substrates. Ceramics International, 2019, 45(9): 12436.

DOI URL |

| [106] | 鲁欣欣, 刘伟, 李林, 等. MgO-Y2O3-Re2O3添加对氮化硅陶瓷微观组织及性能的影响. 粉末冶金材料科学与工程, 2019, 24(6): 536. |

| [107] |

YANG L, DITTA A, FENG B, et al. Study of the comparative effect of sintering methods and sintering additives on the microstructure and performance of Si3N4 ceramic. Materials, 2019, 12(13): 2142.

DOI URL |

| [108] |

ZHANG J, CUI W, LI F, et al. Effects of MgSiN2 addition and post-annealing on mechanical and thermal properties of Si3N4 ceramics. Ceramics International, 2020, 46(10): 15719.

DOI URL |

| [109] |

DUAN Y, LIU N, ZHANG J, et al. Cost effective preparation of Si3N4 ceramics with improved thermal conductivity and mechanical properties. Journal of the European Ceramic Society, 2020, 40(2): 298.

DOI URL |

| [110] |

OH H M, LEE H K. Controlling the width of particle size distribution of Si powder and properties of sintered reaction- bonded silicon nitride (SRBSN) ceramics with high thermal conductivity. Ceramics International, 2020, 46(8): 12517.

DOI URL |

| [111] |

YE C, LIU Y, WANG C, et al. Investigation on thermal conductivity and mechanical properties of Si3N4 ceramics via one-step sintering. Ceramics International, 2021, 47(23): 33353.

DOI URL |

| [112] |

HU F, ZHU T, XIE Z, et al. Effect of composite sintering additives containing non-oxide on mechanical, thermal and dielectric properties of silicon nitride ceramics substrate. Ceramics International, 2021, 47(10): 13635.

DOI URL |

| [113] |

DOW H S, NA M, JUNG Y W, et al. Effect of oxygen impurity on thermal conduction rate of polycrystalline Si3N4. Advanced Engineering Materials, 2021, 23(10): 2170037.

DOI URL |

| [114] | JIANG C, ZHUANG Y, WANG J, et al. Preparation, microstructure, and properties of GPS silicon nitride ceramics with β-Si3N4 seeds and nanophase additives. International Journal of Applied Ceramic Technology, 2022, 19(5): 2533. |

| [115] |

WANG Y, TIAN J, WU H, et al. Thermal and mechanical properties of Si3N4 ceramics obtained via two-step sintering. Ceramics International, 2022, 48(13): 18294.

DOI URL |

| [116] |

IMAMURA H, KAWATA T, HONDA S, et al. A facile method to produce rodlike β-Si3N4 seed crystallites for bimodal structure controlling. Journal of the American Ceramic Society, 2023, 106(3): 1694.

DOI URL |

| [117] |

NAKASHIMA Y, ZHOU Y, TANABE K, et al. Effect of microstructures on dielectric breakdown strength of sintered reaction-bonded silicon nitride ceramics. Journal of the American Ceramic Society, 2023, 106(2): 1139.

DOI URL |

| [118] |

MIYAZAKI H, ZHOU Y, IWAKIRI S, et al. Improved resistance to thermal fatigue of active metal brazing substrates for silicon carbide power modules using tough silicon nitrides with high thermal conductivity. Ceramics International, 2018, 44(8): 8870.

DOI URL |

| [119] |

ZHOU Y, OHJI T, HYUGA H, et al. Fracture resistance behavior of high-thermal-conductivity silicon nitride ceramics. International Journal of Applied Ceramic Technology, 2014, 11(5): 872.

DOI URL |

| [120] | MIYAZAKI H, YOSHIZAWA Y I, HIRAO K, et al. Evaluation of fracture toughness of ceramic thin plates through modified single edge-precracked plate method. Scripta Materialia, 2015, 103: 34. |

| [1] | 朱文杰, 唐璐, 陆继长, 刘江平, 罗永明. 钙钛矿型氧化物催化氧化挥发性有机化合物的研究进展[J]. 无机材料学报, 2025, 40(7): 735-746. |

| [2] | 魏志帆, 陈国清, 祖宇飞, 刘渊, 李明浩, 付雪松, 周文龙. ZrB2-HfSi2复相陶瓷显微组织及其核-周结构形成机制[J]. 无机材料学报, 2025, 40(7): 817-825. |

| [3] | 胡智超, 杨鸿宇, 杨鸿程, 孙成礼, 杨俊, 李恩竹. P-V-L键理论在微波介质陶瓷性能调控中的应用[J]. 无机材料学报, 2025, 40(6): 609-626. |

| [4] | 吴琼, 沈炳林, 张茂华, 姚方周, 邢志鹏, 王轲. 铅基织构压电陶瓷研究进展[J]. 无机材料学报, 2025, 40(6): 563-574. |

| [5] | 张碧辉, 刘小强, 陈湘明. Ruddlesden-Popper结构杂化非常规铁电体的研究进展[J]. 无机材料学报, 2025, 40(6): 587-608. |

| [6] | 吴杰, 杨帅, 王明文, 李景雷, 李纯纯, 李飞. 铅基织构压电陶瓷的发展历程、现状与挑战[J]. 无机材料学报, 2025, 40(6): 575-586. |

| [7] | 姜昆, 李乐天, 郑木鹏, 胡永明, 潘勤学, 吴超峰, 王轲. PZT陶瓷的低温烧结研究进展[J]. 无机材料学报, 2025, 40(6): 627-638. |

| [8] | 陈义, 邱海鹏, 陈明伟, 徐昊, 崔恒. SiC/SiC复合材料基体硼改性方法及其力学性能研究[J]. 无机材料学报, 2025, 40(5): 504-510. |

| [9] | 崔宁, 张玉新, 王鲁杰, 李彤阳, 于源, 汤华国, 乔竹辉. (TiVNbMoW)Cx高熵陶瓷的单相形成过程与碳空位调控[J]. 无机材料学报, 2025, 40(5): 511-520. |

| [10] | 田睿智, 兰正义, 殷杰, 郝南京, 陈航榕, 马明. 基于微流控技术的纳米无机生物材料制备: 原理及其研究进展[J]. 无机材料学报, 2025, 40(4): 337-347. |

| [11] | 张继国, 吴田, 赵旭, 杨钒, 夏天, 孙士恩. 钠离子电池正极材料循环稳定性提升策略及产业化进程[J]. 无机材料学报, 2025, 40(4): 348-362. |

| [12] | 殷杰, 耿佳毅, 王康龙, 陈忠明, 刘学建, 黄政仁. SiC陶瓷的3D打印成形与致密化新进展[J]. 无机材料学报, 2025, 40(3): 245-255. |

| [13] | 李紫薇, 弓伟露, 崔海峰, 叶丽, 韩伟健, 赵彤. 前驱体法制备(Zr, Hf, Nb, Ta, W)C-SiC复相陶瓷及性能研究[J]. 无机材料学报, 2025, 40(3): 271-280. |

| [14] | 高晨光, 孙晓亮, 陈君, 李达鑫, 陈庆庆, 贾德昌, 周玉. 基于湿法纺丝技术的SiBCN-rGO陶瓷纤维的组织结构、力学和吸波性能[J]. 无机材料学报, 2025, 40(3): 290-296. |

| [15] | 谌广昌, 段小明, 朱金荣, 龚情, 蔡德龙, 李宇航, 杨东雷, 陈彪, 李新民, 邓旭东, 余瑾, 刘博雅, 何培刚, 贾德昌, 周玉. 直升机特定结构先进陶瓷材料研究进展与应用展望[J]. 无机材料学报, 2025, 40(3): 225-244. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||