无机材料学报 ›› 2024, Vol. 39 ›› Issue (9): 965-978.DOI: 10.15541/jim20240050 CSTR: 32189.14.10.15541/jim20240050

所属专题: 【制备方法】3D打印(202506); 【信息功能】介电、铁电、压电材料(202506); 【信息功能】柔性材料(202506)

• 综述 • 下一篇

收稿日期:2024-01-29

修回日期:2024-02-29

出版日期:2024-09-20

网络出版日期:2024-03-08

通讯作者:

陈张伟, 教授. E-mail: chen@szu.edu.cn作者简介:魏相霞(1989-), 女, 助教. E-mail: xiangxia@qdu.edu.cn

基金资助:

WEI Xiangxia1( ), ZHANG Xiaofei1, XU Kailong2, CHEN Zhangwei3(

), ZHANG Xiaofei1, XU Kailong2, CHEN Zhangwei3( )

)

Received:2024-01-29

Revised:2024-02-29

Published:2024-09-20

Online:2024-03-08

Contact:

CHEN Zhangwei, professor. E-mail: chen@szu.edu.cnAbout author:WEI Xiangxia (1989-), female, assistant professor. E-mail: xiangxia@qdu.edu.cn

Supported by:摘要:

柔性压电材料作为一类重要的功能材料, 具有韧性好、可塑性强、轻量化等优点, 可以实现机械能和电能的相互转换, 并贴附在人体上实时获取人体或环境信息, 在运动检测、健康监测、人机交互等领域具有广阔的应用前景。为满足人们对柔性压电材料结构不断提高的要求, 增材制造技术被广泛用于制造压电材料。该技术有望突破传统压电材料加工和生产的技术瓶颈, 极大提升柔性压电产品的结构自由度和性能, 从而推动柔性压电材料应用的变革。本文在介绍压电材料分类和性能的基础上, 系统阐述了增材制造柔性压电材料的主要工艺种类, 包括熔融沉积、墨水直写、选择性激光烧结、电辅助直写、光固化和墨水喷射等; 总结了增材制造柔性压电材料的结构, 主要有多层结构、多孔结构和叉指结构; 介绍了增材制造柔性压电材料在能量收集、压电传感器、人机交互和生物工程中的应用进展; 最后总结和展望了增材制造柔性压电材料面临的挑战以及未来发展趋势。

中图分类号:

魏相霞, 张晓飞, 徐凯龙, 陈张伟. 增材制造柔性压电材料的现状与展望[J]. 无机材料学报, 2024, 39(9): 965-978.

WEI Xiangxia, ZHANG Xiaofei, XU Kailong, CHEN Zhangwei. Current Status and Prospects of Additive Manufacturing of Flexible Piezoelectric Materials[J]. Journal of Inorganic Materials, 2024, 39(9): 965-978.

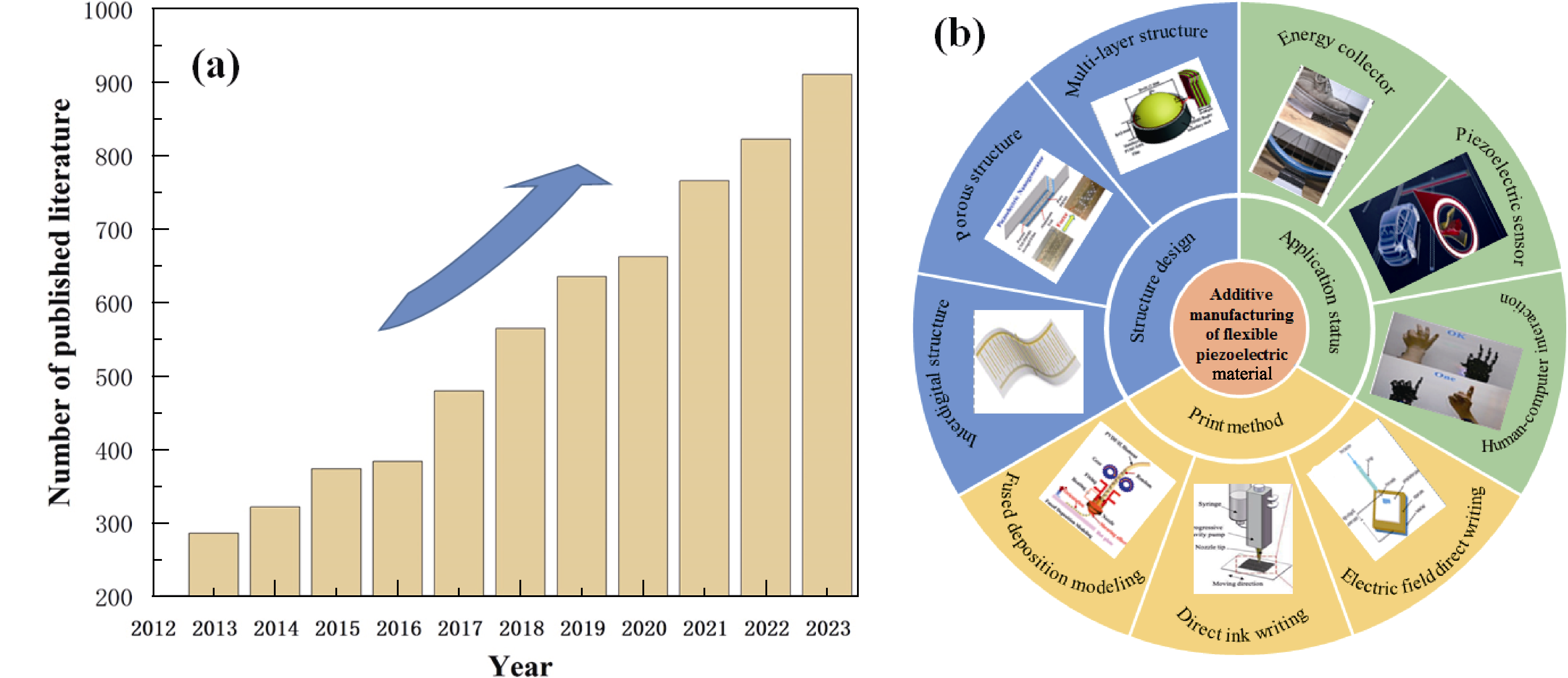

图1 增材制造柔性压电材料概况

Fig. 1 Overview of additive manufacturing of flexible piezoelectric materials (a) Amount of published papers (data from Web of Science); (b) Additive manufacturing approaches, structural design and applications of flexible piezoelectric materials

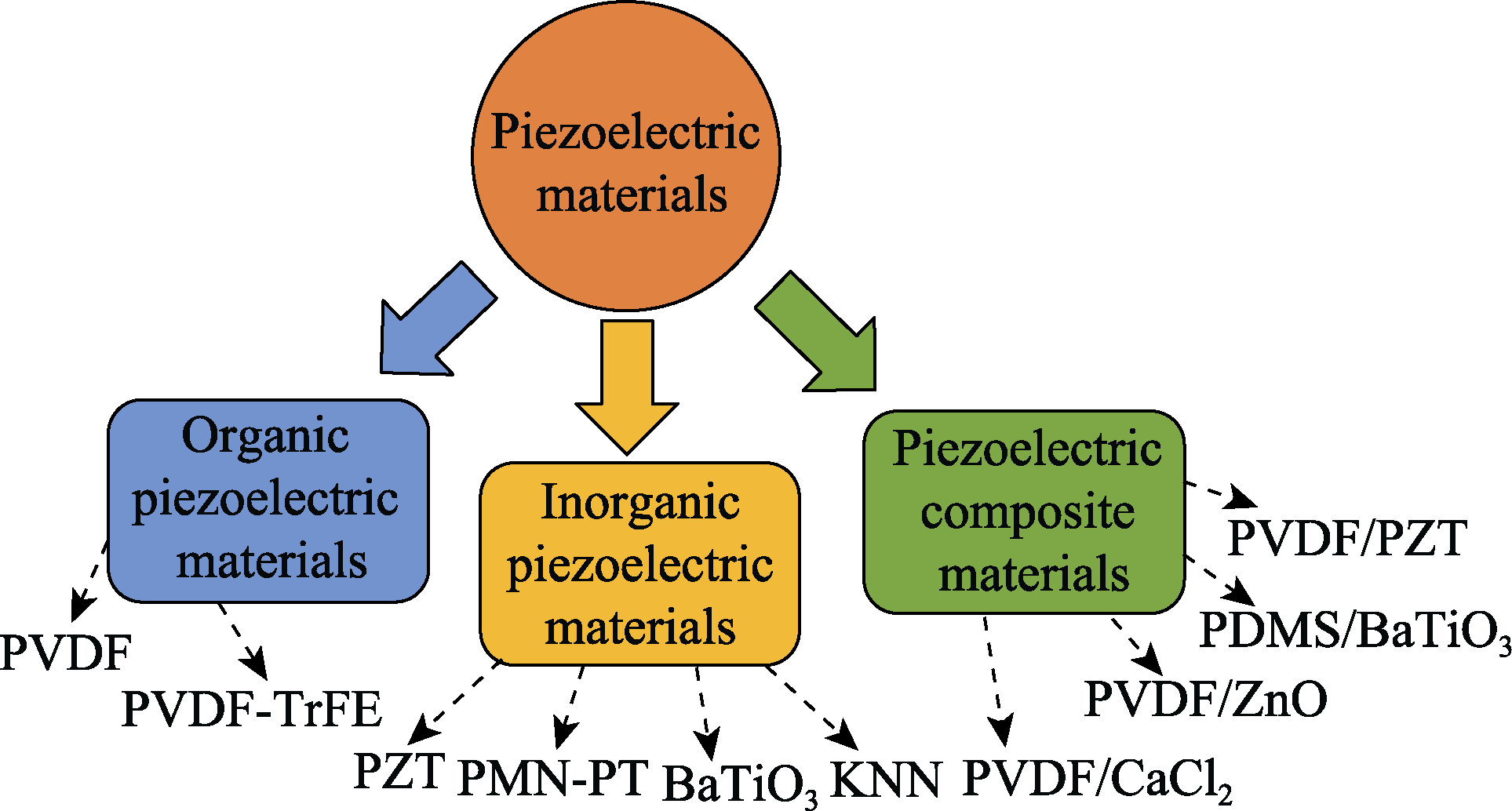

图2 压电材料分类总结

Fig. 2 Summary of classification of piezoelectric materials PVDF: Polyvinylidene fluoride; PVDF-TrFE: Polyvinylidene fluoride-trifluoroethylene; PZT: Lead zirconate titanate; PMN-PT: Lead magnesium niobate-lead titanate; KNN: Potassium sodium niobate; PDMS: Polydimethylsiloxane

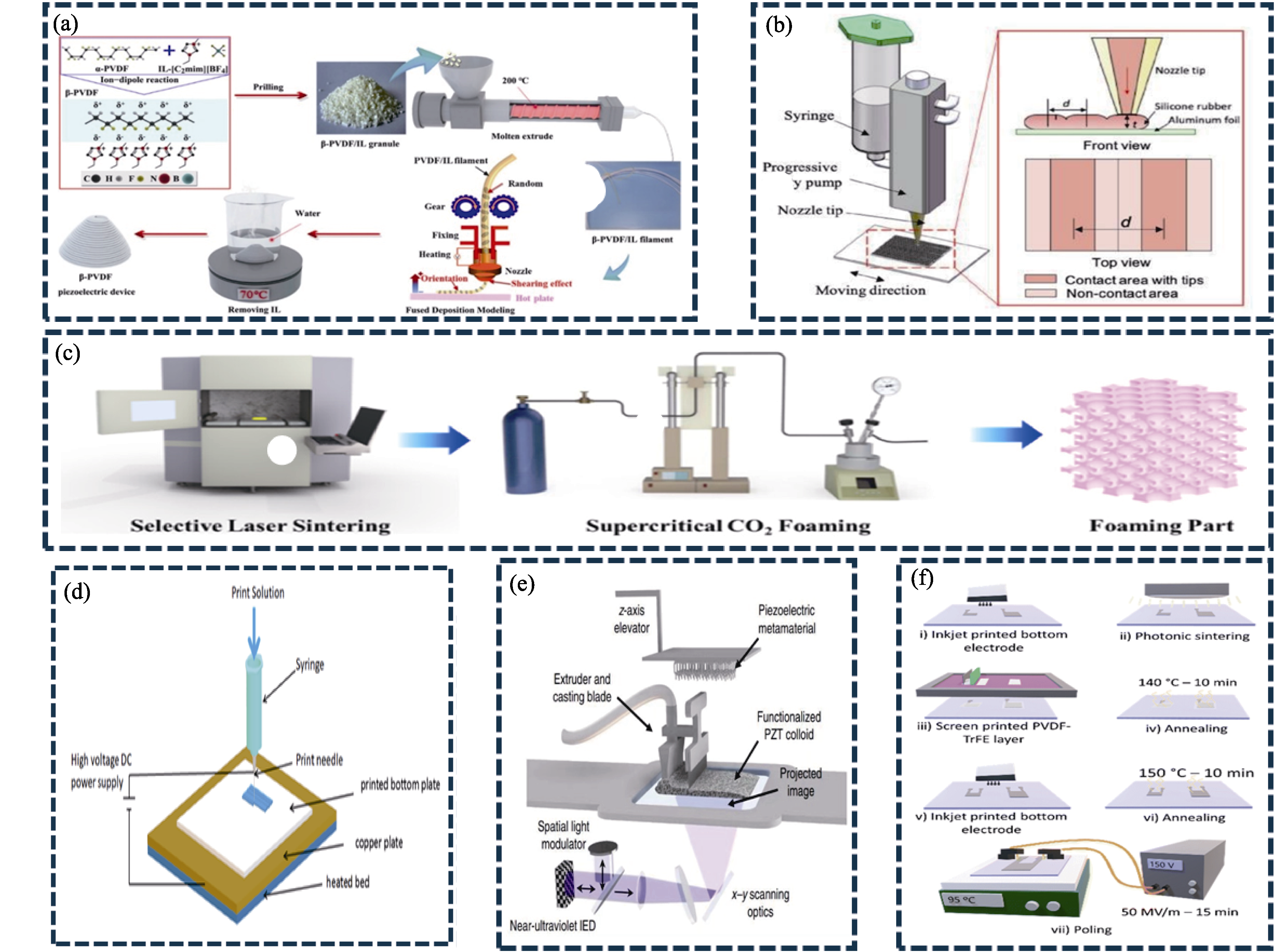

图3 增材制造工艺种类示意图

Fig. 3 Schematic diagrams of additive manufacturing processes (a) Fused deposition modeling[37]; (b) Direct ink writing[54] ; (c) Selective laser sintering[31]; (d) Electric-assisted direct writing [49]; (e) Stereolithography[50]; (f) Inkjet printing[53]

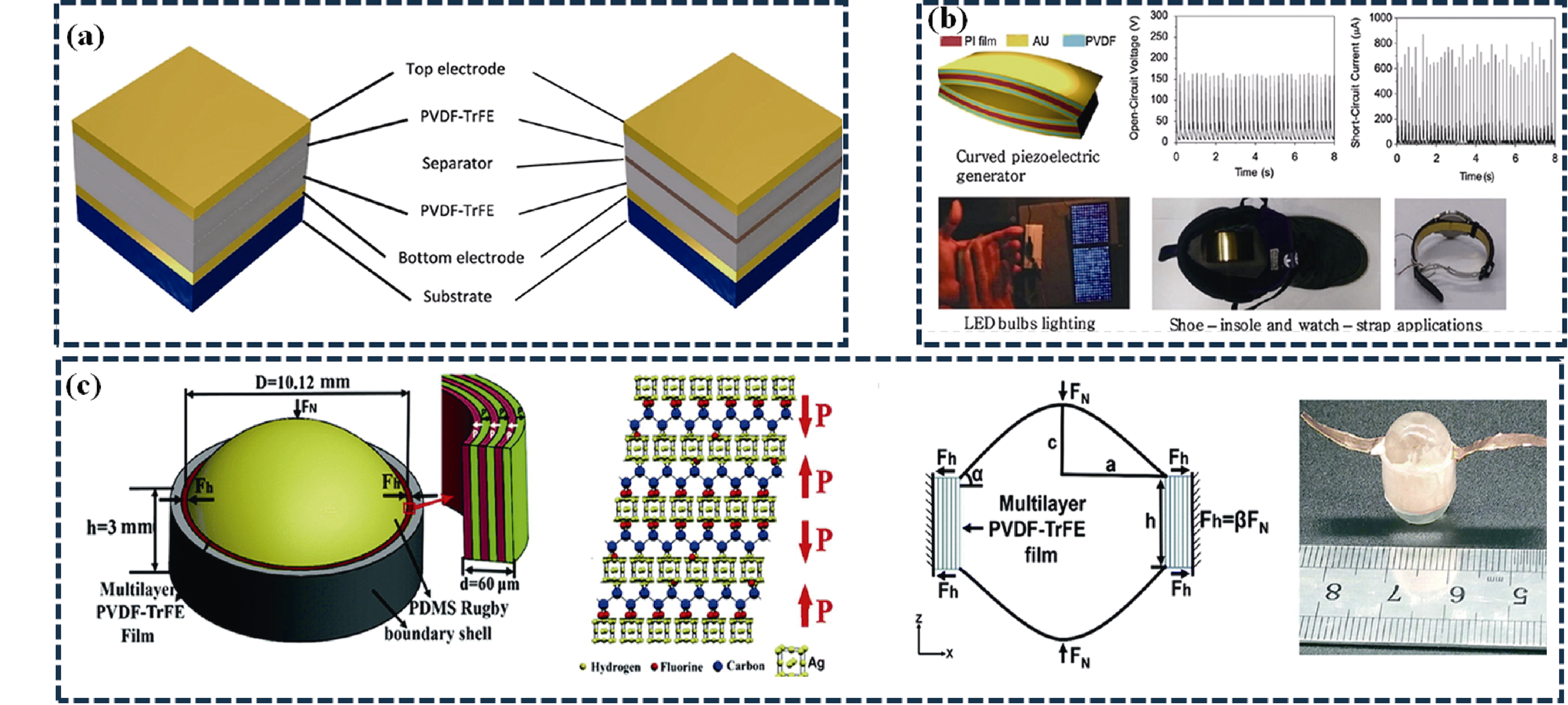

图4 柔性压电材料多层结构示意图

Fig. 4 Schematic diagrams of multi-layer structures of flexible piezoelectric materials (a) PVDF-TrFE composite multi-layer structures[55]; (b) Curved multi-layer piezoelectric structures[57]; (c) Rugby structures[58]

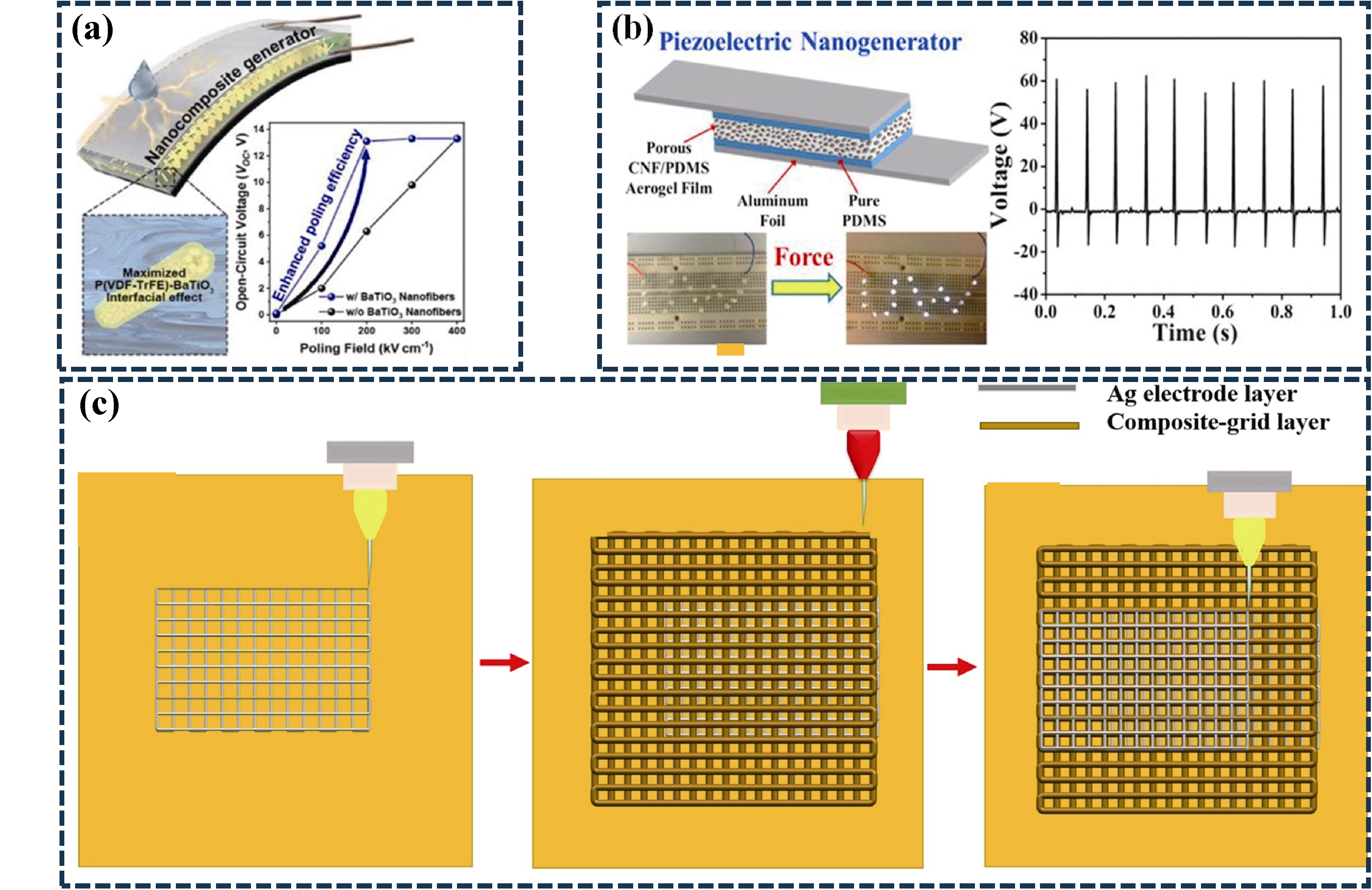

图5 柔性压电材料多孔结构示意图

Fig. 5 Schematic diagrams of porous structures of flexible piezoelectric materials (a) PVDF-TrFE/BaTiO3 porous structures[60]; (b) CNF/PDMS porous structures[61]; (c) Grid structures[62]

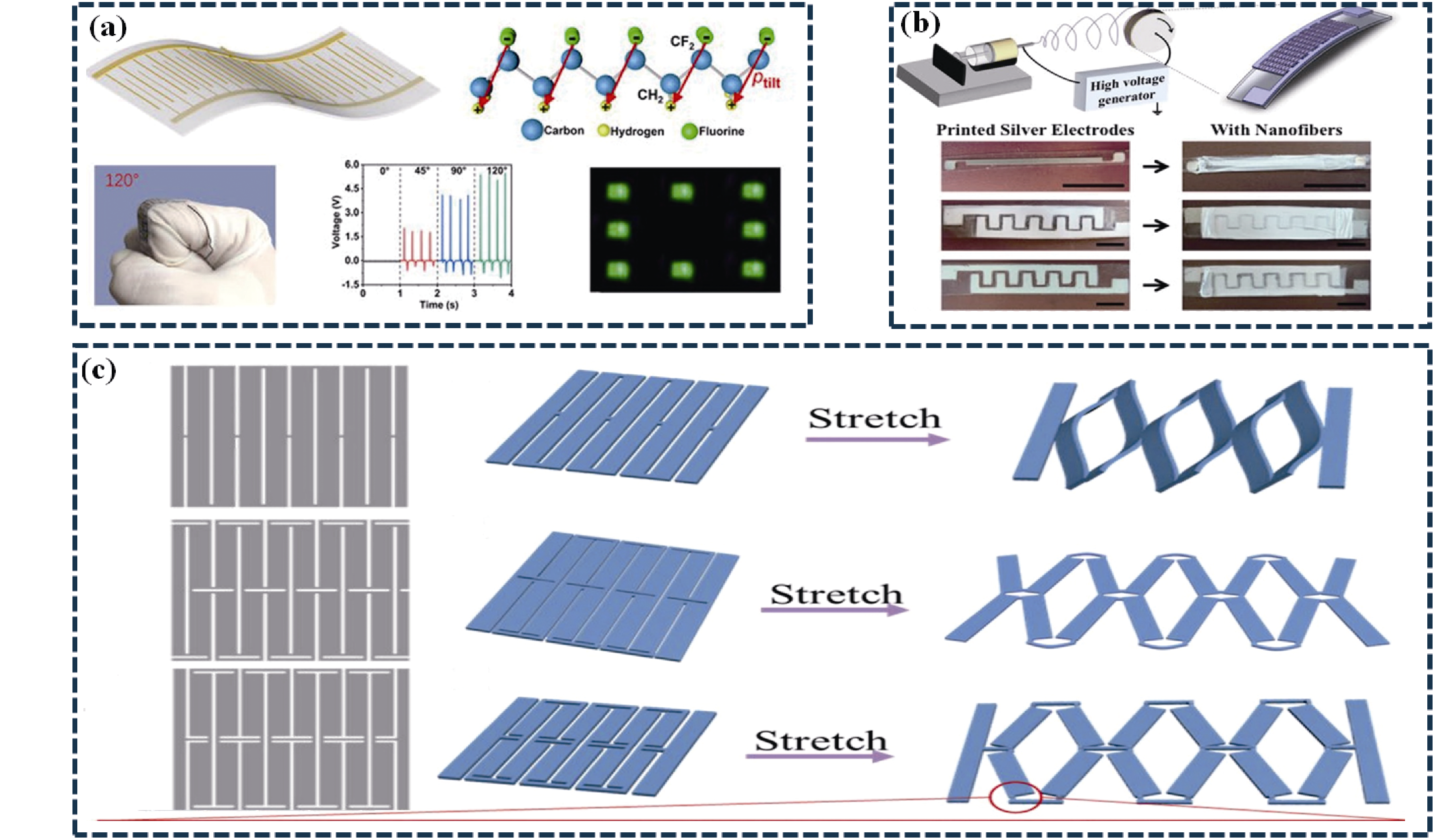

图6 柔性压电材料叉指结构示意图

Fig. 6 Schematic diagrams of interdigital structures of flexible piezoelectric materials (a) Alternately tilted interdigital structures[63]; (b) Pt/Ti conductive interdigital structures[64]; (c) Origami structures[65]

| Material | Filler | 3D printing method | Fraction (β phase)/% | d33(d31)/(pC·N-1) | Output voltage | Output current | Ref. |

|---|---|---|---|---|---|---|---|

| PVDF | BT (10%) | DIW | 78 | - | 4 V | - | [ |

| PVDF | TrFE (30%) | DIW | 75-80 | - | 298.3 mV | - | [ |

| PVDF | GR (0.03%) | DIW | 61.52 | d33=-8.7 | 0.35 V | - | [ |

| PVDF | GR (1.5%) | SLS | - | - | 16.97 V | 274 nA | [ |

| PVDF | BT/Ag | SLS | - | - | 10 V | 142 nA | [ |

| PVDF | BT/Carbon | SLS | 92.2 | - | 5.7 V | 79.8 nA | [ |

| PVDF | BT (30%) | FDM | 84.9 | d33=4.2 | 11.5 V | 220 nA | [ |

| PVDF | IL | FDM | 93.3 | - | 8.69 V | 90.8 nA | [ |

| PVDF | TPPC (5%) | FDM | 83.8 | d33=11.85 | 6.62 V | 108.15 nA/cm2 | [ |

| PVDF | BT2 | FDM | 95.9 | - | 10.9 V | 126.9 nA | [ |

| PVDF | IL (2%) | FDM | 90 | - | 6 V | 83 nA | [ |

| PVDF | IL (15%) | FDM | 97.4 | - | 8.2 V | 300 nA | [ |

| PVDF | No fillers | FDM | 56.83 | d31=0.048 | - | 0.106 nA | [ |

| PDMS | MWCNTs | DIW | - | d33=1070 | 550 mV | - | [ |

| PDMS | BaTiO3 | DIW | - | - | 80 V | 25 mA | [ |

| PDMS | PNN-PZT | DIW | - | d33=24 | 5 V | 0.1 μA | [ |

| PDMS | BT (80%) | DIW | - | - | 45 V | 2.7 μA | [ |

| PVDF | TrFE | IJP | - | - | 3.6 V | 2.3μA | [ |

表1 3D打印技术制造压电能量收集器的性能比较

Table 1 Performance comparison of piezoelectric energy harvesters manufactured by 3D printing technology

| Material | Filler | 3D printing method | Fraction (β phase)/% | d33(d31)/(pC·N-1) | Output voltage | Output current | Ref. |

|---|---|---|---|---|---|---|---|

| PVDF | BT (10%) | DIW | 78 | - | 4 V | - | [ |

| PVDF | TrFE (30%) | DIW | 75-80 | - | 298.3 mV | - | [ |

| PVDF | GR (0.03%) | DIW | 61.52 | d33=-8.7 | 0.35 V | - | [ |

| PVDF | GR (1.5%) | SLS | - | - | 16.97 V | 274 nA | [ |

| PVDF | BT/Ag | SLS | - | - | 10 V | 142 nA | [ |

| PVDF | BT/Carbon | SLS | 92.2 | - | 5.7 V | 79.8 nA | [ |

| PVDF | BT (30%) | FDM | 84.9 | d33=4.2 | 11.5 V | 220 nA | [ |

| PVDF | IL | FDM | 93.3 | - | 8.69 V | 90.8 nA | [ |

| PVDF | TPPC (5%) | FDM | 83.8 | d33=11.85 | 6.62 V | 108.15 nA/cm2 | [ |

| PVDF | BT2 | FDM | 95.9 | - | 10.9 V | 126.9 nA | [ |

| PVDF | IL (2%) | FDM | 90 | - | 6 V | 83 nA | [ |

| PVDF | IL (15%) | FDM | 97.4 | - | 8.2 V | 300 nA | [ |

| PVDF | No fillers | FDM | 56.83 | d31=0.048 | - | 0.106 nA | [ |

| PDMS | MWCNTs | DIW | - | d33=1070 | 550 mV | - | [ |

| PDMS | BaTiO3 | DIW | - | - | 80 V | 25 mA | [ |

| PDMS | PNN-PZT | DIW | - | d33=24 | 5 V | 0.1 μA | [ |

| PDMS | BT (80%) | DIW | - | - | 45 V | 2.7 μA | [ |

| PVDF | TrFE | IJP | - | - | 3.6 V | 2.3μA | [ |

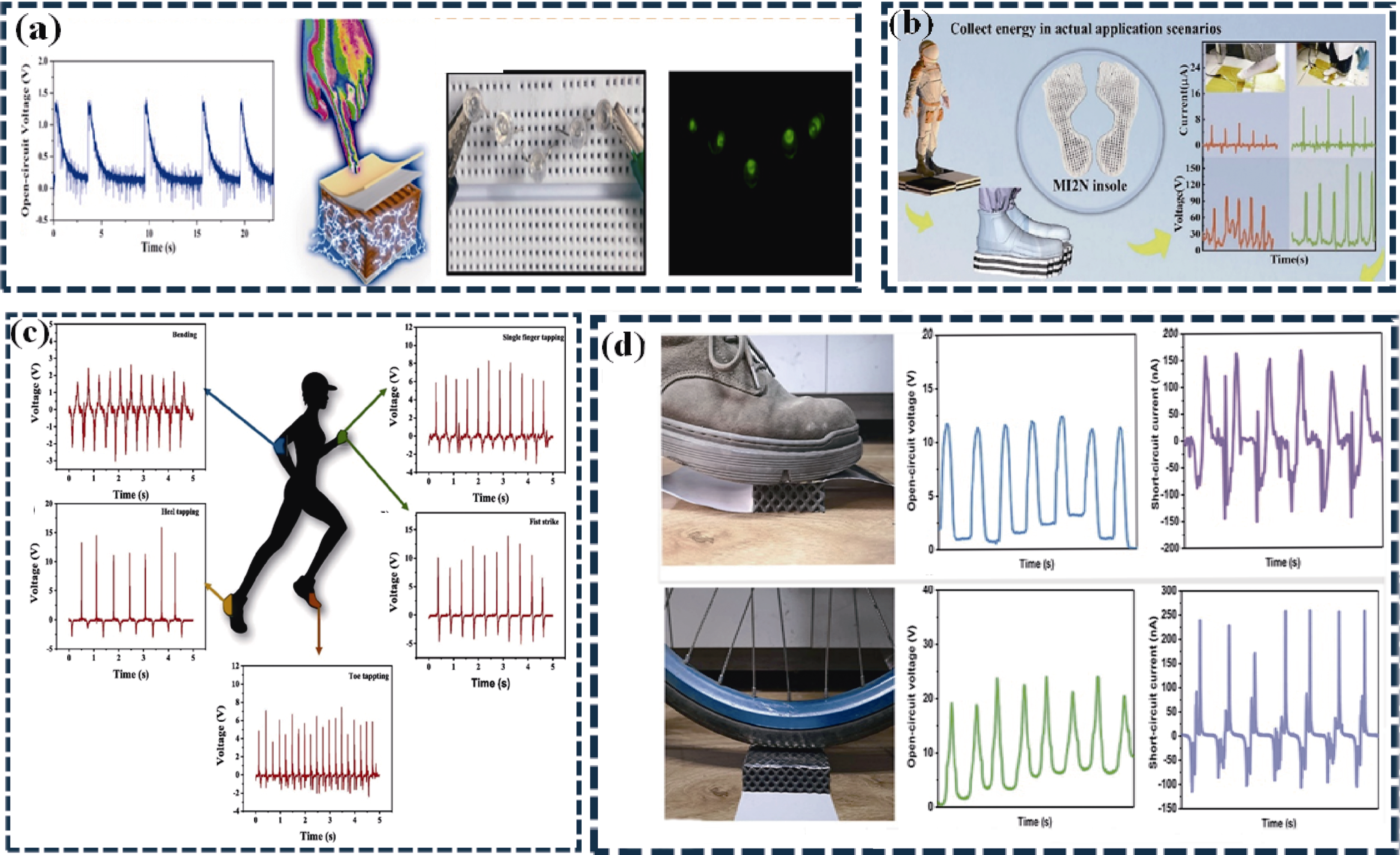

图7 3D打印柔性压电材料在能量收集中的应用

Fig. 7 Application of 3D-printed flexible piezoelectric materials in energy harvesting (a) Energy collection and illumination of LED lights by pressing with fingers[67]; (b) Application of M12N insoles[68]; (c) Piezoelectric energy harvester installed on wearable electronic devices[69]; (d) Road energy harvester[46]

图8 3D打印柔性压电材料在压电传感中的应用

Fig. 8 Application of 3D-printed flexible piezoelectric materials in piezoelectric sensing (a) Piezoelectric sensors incorporated into insoles to adapt to human movements[76]; (b) Self-powered traffic monitoring system based on PVDF[84]; (c) Schematic diagrams of wireless self-sensing boxing gloves[85]

图9 3D打印柔性压电材料在人机交互中的应用

Fig. 9 Application of 3D-printed flexible piezoelectric materials in human-computer interaction (a) Movement of the fingers translates into a change in voltage[90]; (b) Self-powered smart bracelet[91]; (c) Movements of robotic hands controlled by the movements of human hands[92]

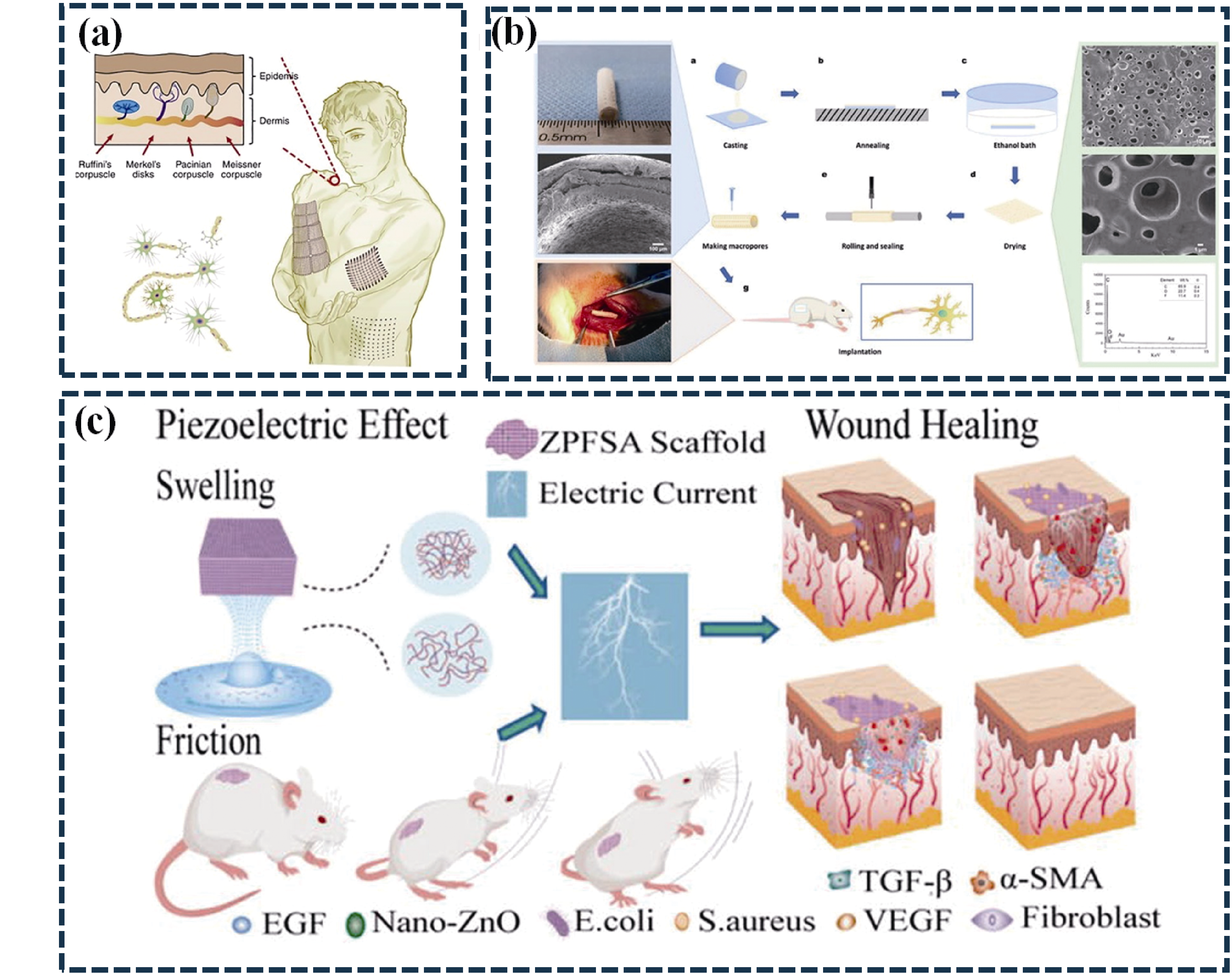

图10 3D打印柔性压电材料在生物工程中的应用

Fig. 10 Application of 3D-printed flexible piezoelectric materials in bioengineering (a) Schematic diagram of electronic skin[93]; (b) Tissue engineering scaffold composed of PVDF/PCL[94]; (c) Piezoelectric hydrogel scaffold fabricated by 3D printing technology[95]

| [1] | TUMALA M M, SALISU A, NMADU Y B. Climate change fossil fuel prices: a GARCH-MIDAS analysis. Energy Economics, 2023, 124: 106792. |

| [2] | WU Y L, MA Y L, ZHENG H Y, et al. Piezoelectric materials for flexible and wearable electronics: a review. Materials & Design, 2021, 211: 110164. |

| [3] | CHEN C, WANG X, WANG Y, et al. Additive manufacturing of piezoelectric materials. Advanced Functional Materials, 2020, 30(52): 2005141. |

| [4] | ZHENG Q, SHI B J, LI Z, et al. Recent progress on piezoelectric and triboelectric energy harvesters in biomedical systems. Advanced Science, 2017, 4(7): 1700029. |

| [5] | MEGDICH A, HABIBI M, LAPERRIERE L, et al. A review on 3D printed piezoelectric energy harvesters: materials, 3D printing techniques, and applications. Materials Today Communications, 2023, 35: 105541. |

| [6] | BICY K, GUEYE A B, ROUXEL D, et al. Lithium-ion battery separators based on electrospun PVDF: a review. Surfaces and Interfaces, 2022, 31: 101977. |

| [7] | LEE J E, SHIN Y E, LEE G H, et al. Polyvinylidene fluoride (PVDF)/cellulose nanocrystal (CNC) nanocomposite fiber and triboelectric textile sensors. Composites Part B: Engineering, 2021, 223: 109098. |

| [8] | RIBEIRO S, MEIRA R M, CORREIA D M, et al. Silica nanoparticles surface charge modulation of the electroactive phase content and physical-chemical properties of poly(vinylidene fluoride) nanocomposites. Composites Part B: Engineering, 2020, 185: 107786. |

| [9] | TU N D K, NOH M S, KO Y, et al. Enhanced electromechanical performance of P(VDF-TrFE-CTFE) thin films hybridized with highly dispersed carbon blacks. Composites Part B: Engineering, 2018, 152: 133. |

| [10] | JEONG K, KIM D H, CHUNG Y S, et al. Effect of processing parameters of the continuous wet spinning system on the crystal phase of PVDF fibers. Journal of Applied Polymer Science, 2017, 133(3): 45712. |

| [11] | SHARAFKHANI S, KOKABI M. High performance flexible actuator: PVDF nanofibers incorporated with axially aligned carbon nanotubes. Composites Part B: Engineering, 2021, 222: 109060. |

| [12] | CHEN J, AYRANCI C, TANG T. Piezoelectric performance of electrospun PVDF and PVDF composite fibers: a review and machine learning-based analysis. Materials Today Chemistry, 2023, 30: 101571. |

| [13] | WANG Y, LEI D, WU L K, et al. Effects of stretching on phase transformation of PVDF and its copolymers: a review. Open Physics, 2023, 21(1): 20220255. |

| [14] | BARRAU S, FERRI A, DACOSTA A, et al. Nanoscale investigations of α- and γ-crystal phases in PVDF-based nanocomposites. ACS Applied Materials & Interfaces, 2018, 10(15): 13092. |

| [15] | JIN L, MA S Y, DENG W L, et al. Polarization-free high- crystallization β-PVDF piezoelectric nanogenerator toward self- powered 3D acceleration sensor. Nano Energy, 2018, 50: 632. |

| [16] | WANG S, SHAO H Q, LIU Y, et al. Boosting piezoelectric response of PVDF-TrFE via MXene for self-powered linear pressure sensor. Composites Science and Technology, 2021, 202: 108600. |

| [17] | YADAV P, RAJU T D, BADHULIKA S. Self-poled hBN-PVDF nanofiber mat-based low-cost, ultrahigh-performance piezoelectric nanogenerator for biomechanical energy harvesting. ACS Applied Energy Materials, 2020, 2(7): 1970. |

| [18] | KHAN F, KOWALCHIK T, ROUNDY S, et al. Stretching-induced phase transitions in barium titanate-poly(vinylidene fluoride) flexible composite piezoelectric films. Scripta Materialia, 2021, 193: 64. |

| [19] | GEBREKRSTOS A, MADRAS G, BOSE S. Journey of electroactive β-polymorph of poly(vinylidenefluoride) from crystal growth to design to applications. Crystal Growth & Design, 2019, 19(9): 5441. |

| [20] | LU L J, DING W Q, LIU J Q, et al. Flexible PVDF based piezoelectric nanogenerators. Nano Energy, 2020, 78: 105251. |

| [21] | YANG L, WANG H, FANG S P, et al. Research progress on energy storage performance enhancement strategies for polyvinylidene fluoride based composites. Journal of Alloys and Compounds, 2023, 960: 170831. |

| [22] |

LI H, SONG H, LONG M J, et al. Mortise-tenon joint structured hydrophobic surface-functionalized barium titanate/polyvinylidene fluoride nanocomposites for printed self-powered wearable sensors. Nanoscale, 2021, 13(4): 2542.

DOI PMID |

| [23] | WANG C, DONG C, PENG W, et al. Research progress of lead-free piezoelectric ceramics. China Ceramics, 2017, 53(11): 1. |

| [24] | GAO X Y, WU J G, YU Y, et al. Giant piezoelectric coefficients in relaxor piezoelectric ceramic PNN-PZT for vibration energy harvesting. Advanced Functional Materials, 2018, 28(30): 1706895. |

| [25] |

LIU K, SUN C, SHI Y S, et al. Current status and prospect of additive manufacturing piezoceramics. Journal of Inorganic Materials, 2022, 37(3): 278.

DOI |

| [26] | PEDDIGARI M, PARK J H, HAN J H, et al. Flexible self- charging, ultrafast, high-power-density ceramic capacitor system. ACS Energy Letters, 2021, 6(4): 1383. |

| [27] | ZHANG Y, JEONG C K, YANG T N, et al. Bioinspired elastic piezoelectric composites for high-performance mechanical energy harvesting. Journal of Materials Chemistry A, 2018, 6(30): 14546. |

| [28] | GAO W X, YOU L, WANG Y J, et al. Flexible PbZr0.52Ti0.48O3 capacitors with giant piezoelectric response and dielectric tunability. Advanced Electronic Materials, 2017 3(8): 1600542. |

| [29] | ZENG Z, GAI L L, WANG X, et al. A plastic-composite-plastic structure high performance flexible energy harvester based on PIN-PMN-PT single crystal/epoxy 2-2 composite. Applied Physics Letters, 2017, 110(10): 103501. |

| [30] | KIM H, NGUYEN D C, LUU T T, et al. Recent advances in functional fiber-based wearable triboelectric nanogenerators. Nanomaterials, 2023, 13(19): 2718. |

| [31] | YANG C, SONG S P, CHEN F, et al. Fabrication of PVDF/ BaTiO3/CNT piezoelectric energy harvesters with bionic balsa wood structures through 3D printing and supercritical carbon dioxide foaming. ACS Applied Materials & Interfaces, 2021, 13(35): 41723. |

| [32] | SONG L, DAI R X, LI Y J, et al. Polyvinylidene fluoride energy harvester with boosting piezoelectric performance through 3D printed biomimetic bone structures. ACS Sustainable Chemistry & Engineering, 2021, 9(22): 7561. |

| [33] | WANG Z H, CHENG J, HU R C, et al. An approach combining additive manufacturing and dielectrophoresis for 3D-structured flexible lead-free piezoelectric composites for electromechanical energy conversion. Journal of Materials Chemistry A, 2021, 9(47): 26767. |

| [34] | HUAN Y, ZHANG X S, SONG J A, et al. High-performance piezoelectric composite nanogenerator based on Ag/(K, Na)NbO3 heterostructure. Nano Energy, 2018, 50: 62. |

| [35] | PEI H R, SHI S H, CHEN Y H, et al. Combining solid state shear milling and FFF 3D-printing strategy to fabricate high-performance biomimetic wearable fish-scale PVDF-based piezoelectric energy harvesters. ACS Applied Materials & Interfaces, 2022, 14(13): 15346. |

| [36] | SORIMPUK N P, CHOONG W H, CHUA B L. Thermoforming characteristics of PLA/TPU multi-material specimens fabricated with fused deposition modelling under different temperatures. Polymers, 2022, 14(20): 4304. |

| [37] | LIU X G, SHANG Y H, ZHANG J H, et al. Ionic liquid assisted 3D printing of self-polarized β-PVDF for flexible piezoelectric energy harvesting. ACS Applied Materials & Interfaces, 2021, 13(12): 14347. |

| [38] | IKRAM H, ALRASHID A, KOC M. Additive manufacturing of smart polymeric composites: literature review and future perspectives. Polymer Composites, 2022, 43(9): 6355. |

| [39] | WANG Z H, YUAN X T, YANG J K, et al. 3D-printed flexible, Ag-coated PNN-PZT ceramic-polymer grid-composite for electromechanical energy conversion. Nano Energy, 2020, 73: 104737. |

| [40] | CHEN F, YANG C, AN Z M, et al. Direct-ink-writing of multistage-pore structured energy collector with ultrahigh ceramic content and toughness. Materials & Design, 2022, 217: 110652. |

| [41] | HAN C, HE L R, WANG Q, et al. Solvent-exchange-assisted 3D printing of self-polarized high β-PVDF for advanced piezoelectric energy harvesting. ACS Applied Electronic Materials, 2022, 4(6): 3125. |

| [42] | SIPONKOSKI T, NELO M, JANTUNEN H, et al. A printable P(VDF-TrFE)-PZT composite with very high piezoelectric coefficient. Applied Materials Today, 2020, 20: 100696. |

| [43] | BODKHE S, TURCOT G, GOSSELIN F P, et al. One-step solvent evaporation-assisted 3D printing of piezoelectric PVDF nanocomposite structures. ACS Applied Materials & Interfaces, 2017, 9(24): 20833. |

| [44] | TU R W, SPRAGUE E, SODANO H A, et al. Precipitation-printed high-β phase poly(vinylidene fluoride) for energy harvesting. ACS Applied Materials & Interfaces, 2020, 12(52): 58072. |

| [45] | TABRIZ A G, KUOFIE H, SCOBLE J, et al. Selective laser sintering for printing pharmaceutical dosage forms. Journal of Drug Delivery Science and Technology, 2023, 86: 104699. |

| [46] | SONG S P, HAN Y, LI Y J, et al. 3D printed piezoelectric porous structure with enhanced output performance and stress-electricity response for road energy harvesting. Additive Manufacturing, 2023, 72: 103625. |

| [47] | LOW Z X, CHUA Y T, RAY B M, et al. Perspective on 3D printing of separation membranes and comparison to related unconventional fabrication techniques. Journal of Membrane Science, 2017, 523: 596. |

| [48] | LIU H C, MUKHERJEE S, LIU Y, et al. Recent studies on electrospinning preparation of patterned, core-shell, and aligned scaffolds. Journal of Applied Polymer Science, 2018, 135(31): 45670. |

| [49] | WANG A D, LIU J H, SHAO C K, et al. Electro-assisted 3D printing multi-layer PVDF/CaCl2 composite films and sensors. Coatings, 2022, 12(6): 820. |

| [50] |

CUI H C, HENSLEIGH R, YAO D S, et al. Three-dimensional printing of piezoelectric materials with designed anisotropy and directional response. Nature Materials, 2019, 18(3): 234.

DOI PMID |

| [51] | FEI J H, RONG Y J, ZHU L S, et al. Progress in photocurable 3D printing of photosensitive polyurethane: a review. Macromolecular Rapid Communications, 2023, 44(18): 2300211. |

| [52] | SMIRNOV A, CHUGUNOV S, KHOLODKOVA A, et al. Progress and challenges of 3D-printing technologies in the manufacturing of piezoceramics. Ceramics International, 2021, 47(8): 10478. |

| [53] | ALIQUE M, MOYA A, KREUZER M, et al. Controlled poling of a fully printed piezoelectric PVDF-TrFE device as a multifunctional platform with inkjet-printed silver electrodes. Journal of Materials Chemistry C, 2022, 10(32): 11555. |

| [54] | LI H, LI R H, FANG X T, et al. 3D printed flexible triboelectric nanogenerator with viscoelastic inks for mechanical energy harvesting. Nano Energy, 2019, 58: 447. |

| [55] |

CHUNG M H, YOO S, KIM H J, et al. Enhanced output performance on LbL multilayer PVDF-TrFE piezoelectric films for charging supercapacitor. Scientific Reports, 2019, 9: 6581.

DOI PMID |

| [56] | LEE H, CHOI B. A multilayer PVDF composite cantilever in the Helmholtz resonator for energy harvesting from sound pressure. Smart Materials and Strutures, 2013, 22(11): 115025. |

| [57] | JUNG W S, LEE M J, KANG M G, et al. Powerful curved piezoelectric generator for wearable applications. Nano Energy, 2015, 13: 174. |

| [58] | YUAN X T, GAO X Y, YANG J K, et al. The large piezoelectricity and high power density of a 3D-printed multilayer copolymer in a rugby ball-structured mechanical energy harvester. Energy & Environmental Science, 2020, 13(1): 152. |

| [59] | BHATTA T, MAHARJAN P, CHO H O, et al. High-performance triboelectric nanogenerator based on Mxene functionalized polyvinylidene fluoride composite nanofibers. Nano Energy, 2021, 81: 105670. |

| [60] | KIM Y G, KIM K T, PARK S C, et al. Enhanced poling efficiency via a maximized organic-inorganic interfacial effect for water droplet-driven energy harvesting. Nano Energy, 2022, 98: 107238. |

| [61] | ZHENG Q F, ZHANG H L, MI H Y, et al. High-performance flexible piezoelectric nanogenerators consisting of porous cellulose nanofibril (CNF)/poly(dimethylsiloxane) (PDMS) aerogel films. Nano Energy, 2016, 26: 504. |

| [62] | YAN A, YUAN X T, LI Z M, et al. 3D-printed flexible, layered ceramic-polymer composite grid with integrated structural-self- sensing function. Sensors and Actuators A: Physical, 2021, 332: 113187. |

| [63] | YUAN X T, GAO X Y, SHEN X Y, et al. A 3D-printed, alternatively tilt-polarized PVDF-TrFE polymer with enhanced piezoelectric effect for self-powered sensor application. Nano Energy, 2021, 85: 105985. |

| [64] | LIU Y, DING L B, DAI L, et al. All-ceramic flexible piezoelectric energy harvester. Advanced Functional Materials, 2022, 32(52): 2209297. |

| [65] | ZHOU X R, PARIDA K, HALEVI O, et al. All 3D-printed stretchable piezoelectric nanogenerator with non-protruding kirigami structure. Nano Energy, 2020, 72: 104676. |

| [66] | TIAN H G, SHAN X B, WANG H, et al. Enhanced piezoelectric energy harvesting performance using trailing-edge flap. Ocean Engineering, 2023, 285: 115443. |

| [67] | PEI H R, XIE Y P, XIONG Y, et al. A novel polarization free 3D printing strategy for fabrication of poly(vinylidene fluoride) based nanocomposite piezoelectric energy harvester. Composites Part B: Engineering, 2021, 225: 109312. |

| [68] | CHEN F, AN Z M, CHEN Y H, et al. Multi-material 3D printing of piezoelectric and triboelectric integrated nanogenerators with voxel structure. Chemical Engineering Journal, 2023, 471: 144770. |

| [69] |

PAWAR O Y, LIM S. 3D-Printed piezoelectric nanogenerator with aligned graphitic carbon nitrate nanosheets for enhancing piezoelectric performance. Journal of Colloid and Interface Science, 2023, 654: 868.

DOI PMID |

| [70] | CHEN C F, CAI F X, ZHU Y, et al. 3D printing of electroactive PVDF thin films with high β-phase content. Smart Materials and Structures, 2019, 28(6): 065017. |

| [71] | SONG S P, LI Y J, WANG Q, et al. Boosting piezoelectric performance with a new selective laser sintering 3D printable PVDF/graphene nanocomposite. Composites Part A: Applied Science and Manufacturing, 2021, 147: 106452. |

| [72] | SHUAI C J, LIU G F, YANG Y W, et al. A strawberry-like Ag- decorated barium titanate enhances piezoelectric and antibacterial activities of polymer scaffold. Nano Energy, 2020, 74: 104825. |

| [73] | QI F W, ZENG Z C, YAO J, et al. Constructing core-shell structured BaTiO3 carbon boosts piezoelectric activity and cell response of polymer scaffolds. Biomaterials Advances, 2021, 126: 112129. |

| [74] | LIU J F, SHANG Y H, SHAO Z Z, et al. Three-dimensional printing to translate simulation to architecting for three-dimensional high performance piezoelectric energy harvester. Industrial & Engineering Chemistry Research, 2021, 61(1): 433. |

| [75] | LIU X G, SHANG Y H, LIU J F, et al. 3D printing-enabled in-situ orientation of BaTi2O5 nanorods in β-PVDF for high-efficiency piezoelectric energy harvesters. ACS Applied Materials & Interfaces, 2022, 14(11): 13361. |

| [76] | HE L R, LU J, HAN C, et al. Electrohydrodynamic pulling consolidated high-efficiency 3D printing to architect unusual self-polarized β-PVDF arrays for advanced piezoelectric sensing. Small, 2022, 18(15): 2200114. |

| [77] | LIU X G, LIU J F, HE L R, et al. 3D printed piezoelectric regulable cells with customized electromechanical response distribution for intelligent sensing. Advanced Functional Materials, 2022, 32(26): 2201274. |

| [78] | KIM H, TORRES F, WU Y Y, et al. Integrated 3D printing and corona poling process of PVDF piezoelectric films for pressure sensor application. Smart Materials and Structures, 2017, 26(8): 085027. |

| [79] | ZASZCZYŃSKA A, GRADYS A, SAJKIEWICZ P, et al. Progress in the applications of smart piezoelectric materials for medical devices. Polymers, 2020, 12(11): 2754. |

| [80] | MAAMER B, BOUGHAMOURA A, ELBAB A M R F, et al. A review on design improvements and techniques for mechanical energy harvesting using piezoelectric and electromagnetic schemes. Energy Conversion and Management, 2019, 199: 111973. |

| [81] | TAKAHASHI K, ONO K, ARAI H, et al. Detection of pathologic heart murmurs using a piezoelectric sensor. Sensors, 2021, 21(4): 1376. |

| [82] | SAWANE M, PRASAD M. MEMS piezoelectric sensor for self- powered devices: a review. Materials Science in Semiconductor Processing, 2023, 158: 107324. |

| [83] | YANG X, MENG J S, WANG Y, et al. Novel formation of Bi@BiFe-glycolate hollow spheres and their conversion into Bi2O3/BiFeO3 composite hollow spheres with enhanced activity and durability in visible photocatalysis. New Journal of Chemistry, 2018, 42(13): 10697. |

| [84] | AZIMI S, ABOLHASANI A, MOOSAVI S M, et al. Development of a vehicle passage sensor based on a PVDF nanogenerator. ACS Applied Electronic Materials, 2021, 3(11): 4689. |

| [85] | YAO D S, CUI H C, HENSLEIGH R, et al. Achieving the upper bound of piezoelectric response in tunable, wearable 3D printed nanocomposites. Advanced Functional Materials, 2019, 29(42): 1903866. |

| [86] | CACUCCIOLO V, SHINTAKE J, KUWAJIMA Y, et al. Stretchable pumps for soft machines. Nature, 2019, 572: 516. |

| [87] | YANG T, PAN H, TIAN G, et al. Hierarchically structured PVDF/ZnO core-shell nanofibers for self-powered physiological monitoring electronics. Nano Energy, 2020, 72: 104706. |

| [88] | LIANG X W, ZHAO T, JIANG W, et al. Highly transparent triboelectric nanogenerator utilizing in-situ chemically welded silver nanowire network as electrode for mechanical energy harvesting and body motion monitoring. Nano Energy, 2019, 59: 508. |

| [89] | GAUR A, TIWARI S, KUMAR C, et al. Flexible, lead-free nanogenerators using poly(vinylidene fluoride) nanocomposites. Energy & Fuels, 2020, 34(5): 6239. |

| [90] | SU H X, WANG X B, LI C Y, et al. Enhanced energy harvesting ability of polydimethylsiloxane-BaTiO3-based flexible piezoelectric nanogenerator for tactile imitation application. Nano Energy, 2021, 83: 105809. |

| [91] | QI F W, CHEN N, WANG Q. Preparation of PA11/BaTiO3nanocomposite powders with improved processability, dielectric and piezoelectric properties for use in selectivelaser sintering. Materials & Design, 2017, 131: 135. |

| [92] | DENG W L, YANG T, JIN L, et al. Cowpea-structured PVDF/ZnO nanofibers based flexible self-powered piezoelectric bending motion sensor towards remote control of gestures. Nano Energy, 2019, 55: 516. |

| [93] |

HUA Q L, SUN J L, LIU H T, et al. Skin-inspired highly stretchable and conformable matrix networks for multifunctional sensing. Nature Communications, 2018, 9: 244.

DOI PMID |

| [94] | CHENG Y, XU Y, QIAN Y, et al. 3D structured self-powered PVDF/PCL scaffolds for peripheral nerve regeneration. Nano Energy, 2020, 69: 104411. |

| [95] | LIANG J C, ZENG H J, QIAO L, et al. 3D Printed piezoelectric wound dressing with dual piezoelectric response models for scar- prevention wound healing. ACS Applied Materials & Interfaces, 2022, 14(27): 30507. |

| [1] | 朱文杰, 唐璐, 陆继长, 刘江平, 罗永明. 钙钛矿型氧化物催化氧化挥发性有机化合物的研究进展[J]. 无机材料学报, 2025, 40(7): 735-746. |

| [2] | 余艺平, 肖鹏, 赵长浩, 徐梦迪, 姚立冬, 李伟, 王松. 耐高温层状Ta/Ta0.5Hf0.5C金属陶瓷的高频等离子体风洞烧蚀行为研究[J]. 无机材料学报, 2025, 40(7): 790-798. |

| [3] | 余乐洋阳, 赵芳霞, 张舒心, 徐以祥, 牛亚然, 张振忠, 郑学斌. 感应等离子球化技术制备喷涂用高熵硼化物粉体[J]. 无机材料学报, 2025, 40(7): 808-816. |

| [4] | 魏志帆, 陈国清, 祖宇飞, 刘渊, 李明浩, 付雪松, 周文龙. ZrB2-HfSi2复相陶瓷显微组织及其核-周结构形成机制[J]. 无机材料学报, 2025, 40(7): 817-825. |

| [5] | 胡智超, 杨鸿宇, 杨鸿程, 孙成礼, 杨俊, 李恩竹. P-V-L键理论在微波介质陶瓷性能调控中的应用[J]. 无机材料学报, 2025, 40(6): 609-626. |

| [6] | 何国强, 张恺恒, 王震涛, 包健, 席兆琛, 方振, 王昌昊, 王威, 王鑫, 姜佳沛, 李祥坤, 周迪. Ba(Nd1/2Nb1/2)O3: 一种被低估的K40微波介质陶瓷[J]. 无机材料学报, 2025, 40(6): 639-646. |

| [7] | 张家维, 陈宁, 程原, 王博, 朱建国, 金城. Bi4Ti3O12铋层状压电陶瓷的A/B位掺杂及其电学性能[J]. 无机材料学报, 2025, 40(6): 690-696. |

| [8] | 唐莹, 李洁, 相怀成, 方维双, 林慧兴, 杨俊峰, 方亮. Rattling效应: 一种影响微波介质陶瓷谐振频率温度系数的新机制[J]. 无机材料学报, 2025, 40(6): 656-666. |

| [9] | 吴琼, 沈炳林, 张茂华, 姚方周, 邢志鹏, 王轲. 铅基织构压电陶瓷研究进展[J]. 无机材料学报, 2025, 40(6): 563-574. |

| [10] | 张碧辉, 刘小强, 陈湘明. Ruddlesden-Popper结构杂化非常规铁电体的研究进展[J]. 无机材料学报, 2025, 40(6): 587-608. |

| [11] | 吴杰, 杨帅, 王明文, 李景雷, 李纯纯, 李飞. 铅基织构压电陶瓷的发展历程、现状与挑战[J]. 无机材料学报, 2025, 40(6): 575-586. |

| [12] | 周阳阳, 张艳艳, 于子怡, 傅正钱, 许钫钫, 梁瑞虹, 周志勇. 通过Bi3+自掺杂增强CaBi4Ti4O15基陶瓷压电性能[J]. 无机材料学报, 2025, 40(6): 719-728. |

| [13] | 杨燕, 张发强, 马名生, 王墉哲, 欧阳琪, 刘志甫. 基于CuO-TiO2-Nb2O5复合氧化物烧结助剂的ZnAl2O4陶瓷低温烧结研究[J]. 无机材料学报, 2025, 40(6): 711-718. |

| [14] | 黄子鹏, 贾文晓, 李玲霞. (Ti0.5W0.5)5+掺杂MgNb2O6陶瓷的晶体结构与太赫兹介电性能[J]. 无机材料学报, 2025, 40(6): 647-655. |

| [15] | 姜昆, 李乐天, 郑木鹏, 胡永明, 潘勤学, 吴超峰, 王轲. PZT陶瓷的低温烧结研究进展[J]. 无机材料学报, 2025, 40(6): 627-638. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||