无机材料学报 ›› 2023, Vol. 38 ›› Issue (2): 213-218.DOI: 10.15541/jim20220155 CSTR: 32189.14.10.15541/jim20220155

所属专题: 【信息功能】柔性材料(202506); 【能源环境】钙钛矿(202506); 【能源环境】太阳能电池(202506)

张万文1( ), 罗建强1(

), 罗建强1( ), 刘淑娟1, 马建国1, 张小平1, 杨松旺2(

), 刘淑娟1, 马建国1, 张小平1, 杨松旺2( )

)

收稿日期:2022-03-21

修回日期:2022-07-21

出版日期:2023-02-20

网络出版日期:2022-08-04

通讯作者:

罗建强, 教授. E-mail: luojianqiang@163.com;作者简介:张万文(1994-), 男, 硕士研究生. E-mail: 2352937300@qq.com

ZHANG Wanwen1( ), LUO Jianqiang1(

), LUO Jianqiang1( ), LIU Shujuan1, MA Jianguo1, ZHANG Xiaoping1, YANG Songwang2(

), LIU Shujuan1, MA Jianguo1, ZHANG Xiaoping1, YANG Songwang2( )

)

Received:2022-03-21

Revised:2022-07-21

Published:2023-02-20

Online:2022-08-04

Contact:

LUO Jianqiang, professor. E-mail: luojianqiang@163.com;About author:: ZHANG Wanwen (1994-), male, Master candidate. E-mail: 2352937300@qq.com

Supported by:摘要:

氧化钛/氧化锆/碳三层结构钙钛矿太阳能电池(Perovskite solar cells, PSCs)具有原材料廉价、制备工艺易放大和稳定性好等优势, 受到了广泛关注。但三层结构PSCs的低温制备研究进展缓慢, 主要原因之一在于难以在低温条件下构建合适的氧化锆间隔层。本研究以尿素为孔隙率调节剂, 用简单的喷涂法制备多孔氧化锆间隔层用于三层结构PSCs。通过调节喷涂次数优化氧化锆层厚度为1100 nm时, 电池的性能最优, 单电池功率转换效率达到14.7%, 5块电池串联模块(5×0.9 cm×2.5 cm)达到10.8%。PSCs在恒温恒湿箱(25 ℃, 湿度40%)保存200 d, 功率转换效率保持稳定, 没有明显下降。柔性基底上的氧化锆层经50次弯曲测试后保持完整, 未见脱落。与传统的丝网印刷氧化锆间隔层制备方法相比, 本研究的喷涂方法具有方法简便、操作温度低、与柔性基底兼容性好的优点。

中图分类号:

张万文, 罗建强, 刘淑娟, 马建国, 张小平, 杨松旺. 氧化锆间隔层的低温喷涂制备及其三层结构钙钛矿太阳能电池应用性能[J]. 无机材料学报, 2023, 38(2): 213-218.

ZHANG Wanwen, LUO Jianqiang, LIU Shujuan, MA Jianguo, ZHANG Xiaoping, YANG Songwang. Zirconia Spacer: Preparation by Low Temperature Spray-coating and Application in Triple-layer Perovskite Solar Cells[J]. Journal of Inorganic Materials, 2023, 38(2): 213-218.

Fig. 2 SEM images of the zirconia film prepared by spray- coating without urea (a), with w(zirconia) : w(urea)= 2 : 1 (b) and 1 : 1 (c), cross-sectional SEM images of PSCs containing zirconia layer prepared with w(zirconia) : w(urea)= 2 : 1(d) and 1 : 1 (e) Circled areas in (d) are not completely filled

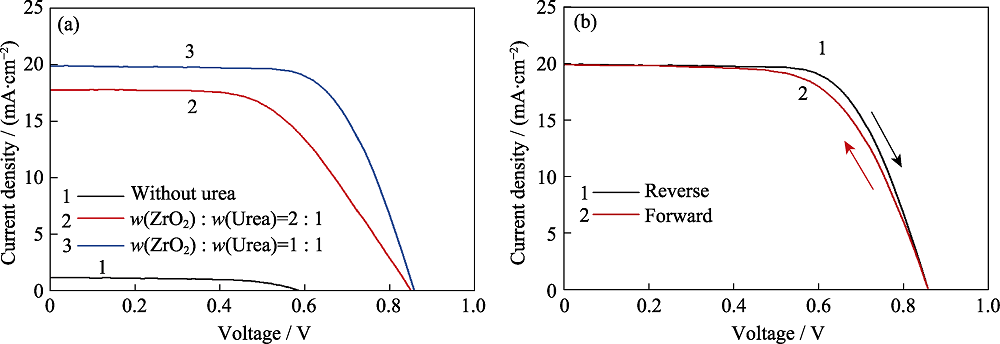

Fig. 3 J-V curves of PSCs prepared with w(zirconia) : w(urea)=2 : 1 and 1 : 1(a), and J-V curves from forward and reverse scanning of PSC prepared with w(zirconia) : w(urea)=1 : 1 (Zirconia layer thickness at ~1000 nm) (b)

Fig. 4 J-V curves of the triple-layer PSCs with spray-coated and screen-printed zirconia layer(a), IPCE spectrum and corresponding integrated current density of the PSC with 1100 nm thick zirconia layer(b), PCE distribution of 30 chips with three different thicknesses of zirconia layer(c), and stabilized power output of PSCs with optimized spray-coated zirconia layer (d)

Fig. S3 Cross-sectional SEM images of PSCs before filling perovskite with the zirconia thickness of (a, b) 750, (c, d) 1100 nm and (e, f) 1500 nm((a, c, e) before and (b, d, f) after filling perovkite)

Fig. S4 (a) J-V curves of the cell with different illumination areas with inset showing the tested cell photograph; (b) J-V curve of PSCs module with five cells connected in series with inset showing the tested cell photograph

| [1] |

KOJIMA A, TESHIMA K, SHIRAI Y, et al. Organometal halide perovskites as visible-light sensitizers for photovoltaic cells. J. Am. Chem. Soc., 2009, 131(17): 6050.

DOI PMID |

| [2] |

LEE M M, TEUSCHER J, MIYASAKA T, et al. Efficient hybrid solar cells based on meso-superstructured organometal halide perovskites. Science, 2012, 338(6107): 643.

DOI PMID |

| [3] |

BURSCHKA J, PELLET N, MOON S J, et al. Sequential deposition as a route to high-performance perovskite-sensitized solar cells. Nature, 2013, 499(7458): 316.

DOI URL |

| [4] | HUANG L, ZHOU X, XUE R, et al. Low-temperature growing anatase TiO2/SnO2 multi-dimensional heterojunctions at MXene conductive network for high-efficient perovskite solar cells. Nanomicro Lett., 2020, 12(1): 44. |

| [5] |

PATIL P, MANN D S, NAKATE U T, et al. Hybrid interfacial ETL engineering using PCBM-SnS2 for high-performance p-i-n structured planar perovskite solar cells. Chem. Eng. J., 2020, 397: 125504.

DOI URL |

| [6] |

JUNG E H, JEON N J, PARK E Y, et al. Efficient, stable and scalable perovskite solar cells using poly(3-hexylthiophene). Nature, 2019, 567(7749): 511.

DOI URL |

| [7] |

PARK M, CHO W, LEE G, et al. Highly reproducible large-area perovskite solar cell fabrication via continuous megasonic spray coating of CH3NH3PbI3. Small, 2019, 15(1): 1804005.

DOI URL |

| [8] |

MCMEEKIN D P, MAHESH S, NOEL N K, et al. Solution- processed all-perovskite multi-junction solar cells. Joule, 2019, 3(2): 387.

DOI URL |

| [9] |

YOO J J, SEO G, CHUA M R, et al. Efficient perovskite solar cells via improved carrier management. Nature, 2021, 590(7847): 587.

DOI URL |

| [10] |

MEI A, LI X, LIU L, et al. A hole-conductor-free, fully printable mesoscopic perovskite solar cell with high stability. Science, 2014, 345(6194): 295.

DOI PMID |

| [11] |

TAN H, JAIN A, VOZNYY O, et al. Efficient and stable solution- processed planar perovskite solar cells via contact passivation. Science, 2017, 355(6326): 722.

DOI URL |

| [12] |

LIU X, CHENG Y, LIU C, et al. 20.7% highly reproducible inverted planar perovskite solar cells with enhanced fill factor and eliminated hysteresis. Energy Environ. Sci., 2019, 12(5): 1622.

DOI URL |

| [13] |

ZHOU Z, LIAN H J, XIE J, et al. Non-selective adsorption of organic cations enables conformal surface capping of perovskite grains for stabilized photovoltaic operation. Cell Reports Physical Science, 2022, 3(2): 100760.

DOI URL |

| [14] |

LIU X, LIAN H, ZHOU Z, et al. Stoichiometric dissolution of defective CsPbI2Br surfaces for inorganic solar cells with 17.5% efficiency. Adv. Energy. Mater., 2022, 12(14): 2103933.

DOI URL |

| [15] |

RONG Y, HU Y, MEI A, et al. Challenges for commercializing perovskite solar cells. Science, 2018, 361(6408): eaat8235.

DOI URL |

| [16] |

LUO J, YANG H B, ZHUANG M, et al. Making fully printed perovskite solar cells stable outdoor with inorganic superhydrophobic coating. J. Energy Chem., 2020, 50: 332.

DOI URL |

| [17] |

YANG K, LIU S, DU J K, et al. Improving hole-conductor-free fully printable mesoscopic perovskite solar cells' performance with enhanced open-circuit voltage via the octyltrimethylammonium chloride additive. Solar RRL, 2021, 5(4): 2000825.

DOI URL |

| [18] |

WANG Y, ZHANG T, XU F, et al. A facile low temperature fabrication of high performance CsPbI2Br all-inorganic perovskite solar cells. Solar RRL, 2018, 2(1): 1700180.

DOI URL |

| [19] |

HU L, ZHAO Q, HUANG S, et al. Flexible and efficient perovskite quantum dot solar cells via hybrid interfacial architecture. Nat. Commun., 2021, 12(1): 466.

DOI URL |

| [20] |

YANG D, YANG R, ZHANG J, et al. High efficiency flexible perovskite solar cells using superior low temperature TiO2. Energy Environ. Sci., 2015, 8(11): 3208.

DOI URL |

| [21] |

DAGAR J, CASTRO-HERMOSA S, GASBARRI M, et al. Efficient fully laser-patterned flexible perovskite modules and solar cells based on low-temperature solution-processed SnO2/mesoporous-TiO2 electron transport layers. Nano Research, 2018, 11(5): 2669.

DOI URL |

| [22] |

YANG D, YANG R, PRIYA S, et al. Recent advances in flexible perovskite solar cells: fabrication and applications. Angew. Chem. Int. Ed., 2019, 58(14): 4466.

DOI PMID |

| [23] |

MATSUI T, SEO J Y, SALIBA M, et al. Room-temperature formation of highly crystalline multication perovskites for efficient, low-cost solar cells. Adv. Mater., 2017, 29(15): 1606258.

DOI URL |

| [24] |

DI GIACOMO F, FAKHARUDDIN A, JOSE R, et al. Progress, challenges and perspectives in flexible perovskite solar cells. Energy Environ. Sci., 2016, 9(10): 3007.

DOI URL |

| [25] | HAQUE S A, PALOMARES E, UPADHYAYA H M, et al. Flexible dye sensitised nanocrystalline semiconductor solar cells. Chem. Commun., 2003, (24): 3008. |

| [26] |

JIANG P, JONES T W, DUFFY N W, et al. Fully printable perovskite solar cells with highly-conductive, low-temperature, perovskite- compatible carbon electrode. Carbon, 2018, 129: 830.

DOI URL |

| [27] |

LUO J, CHEN J, WU B, et al. Surface rutilization of anatase TiO2 for efficient electron extraction and stable Pmax output of perovskite solar cells. Chem, 2018, 4(4): 911.

DOI URL |

| [28] |

RONG Y, HOU X, HU Y, et al. Synergy of ammonium chloride and moisture on perovskite crystallization for efficient printable mesoscopic solar cells. Nat. Commun., 2017, 8: 14555.

DOI PMID |

| [29] |

ZHANG Y H, LI Y. Interface materials for perovskite solar cells. Rare Met., 2021, 40(11): 2993.

DOI URL |

| [30] |

CHANG J H, LIU K, LIN S Y, et al. Solution-processed perovskite solar cells. Journal of Central South University, 2020, 27(4): 1104.

DOI URL |

| [31] |

DENG Y, PENG E, SHAO Y, et al. Scalable fabrication of efficient organolead trihalide perovskite solar cells with doctor-bladed active layers. Energy Environ Sci, 2015, 8(5): 1544.

DOI URL |

| [32] |

WU Y, YANG X, CHEN W, et al. Perovskite solar cells with 18.21% efficiency and area over 1 cm2 fabricated by heterojunction engineering. Nat Energy, 2016, 1(11): 16148.

DOI URL |

| [33] |

KIERMASCH D, GIL-ESCRIG L, BOLINK H J, et al. effects of masking on open-circuit voltage and fill factor in solar cells. Joule, 2019, 3(1): 16.

DOI URL |

| [1] | 余乐洋阳, 赵芳霞, 张舒心, 徐以祥, 牛亚然, 张振忠, 郑学斌. 感应等离子球化技术制备喷涂用高熵硼化物粉体[J]. 无机材料学报, 2025, 40(7): 808-816. |

| [2] | 杨燕, 张发强, 马名生, 王墉哲, 欧阳琪, 刘志甫. 基于CuO-TiO2-Nb2O5复合氧化物烧结助剂的ZnAl2O4陶瓷低温烧结研究[J]. 无机材料学报, 2025, 40(6): 711-718. |

| [3] | 姜昆, 李乐天, 郑木鹏, 胡永明, 潘勤学, 吴超峰, 王轲. PZT陶瓷的低温烧结研究进展[J]. 无机材料学报, 2025, 40(6): 627-638. |

| [4] | 尹长志, 成名飞, 雷微程, 蔡弋炀, 宋小强, 付明, 吕文中, 雷文. Ga3+掺杂对SrAl2Si2O8陶瓷晶体结构及微波介电性能的影响[J]. 无机材料学报, 2025, 40(6): 704-710. |

| [5] | 梁锐辉, 钟鑫, 洪督, 黄利平, 牛亚然, 郑学斌. Yb2O3改性硅黏结层的环境障涂层体系耐高温水氧腐蚀行为研究[J]. 无机材料学报, 2025, 40(4): 425-432. |

| [6] | 马文, 申喆, 刘琪, 高元明, 白玉, 李荣星. 悬浮液等离子喷涂制备Y2O3涂层及耐等离子刻蚀性[J]. 无机材料学报, 2024, 39(8): 929-936. |

| [7] | 肖梓晨, 何世豪, 邱诚远, 邓攀, 张威, 戴维德仁, 缑炎卓, 李金华, 尤俊, 王贤保, 林俍佑. 钙钛矿太阳能电池纳米纤维改性电子传输层研究[J]. 无机材料学报, 2024, 39(7): 828-834. |

| [8] | 李捷, 罗志新, 崔阳, 张广珩, 孙鲁超, 王京阳. 大气等离子喷涂Y3Al5O12/Al2O3陶瓷涂层的CMAS腐蚀抗力[J]. 无机材料学报, 2024, 39(6): 671-680. |

| [9] | 张慧, 许志鹏, 朱从潭, 郭学益, 杨英. 大面积有机-无机杂化钙钛矿薄膜及其光伏应用研究进展[J]. 无机材料学报, 2024, 39(5): 457-466. |

| [10] | 陈甜, 罗媛, 朱刘, 郭学益, 杨英. 有机-无机共添加增强柔性钙钛矿太阳能电池机械弯曲及环境稳定性能[J]. 无机材料学报, 2024, 39(5): 477-484. |

| [11] | 于嫚, 高荣耀, 秦玉军, 艾希成. 上转换发光纳米材料对钙钛矿太阳能电池迟滞效应和离子迁移动力学的影响[J]. 无机材料学报, 2024, 39(4): 359-366. |

| [12] | 刘锁兰, 栾福园, 吴子华, 寿春晖, 谢华清, 杨松旺. 原位生长钙钛矿太阳能电池共形氧化锡薄膜[J]. 无机材料学报, 2024, 39(12): 1397-1403. |

| [13] | 周泽铸, 梁子辉, 李静, 吴聪聪. 基于挥发性溶剂制备MAPbI3钙钛矿太阳能电池/模组[J]. 无机材料学报, 2024, 39(11): 1197-1204. |

| [14] | 厉佥元, 李纪伟, 张钰涵, 刘焱康, 孟阳, 储余, 朱一佳, 徐诺言, 朱亮, 张传香, 陶海军. PbTiO3修饰和极化处理提升钙钛矿太阳能电池性能[J]. 无机材料学报, 2024, 39(11): 1205-1211. |

| [15] | 江强, 施立志, 陈政燃, 周志勇, 梁瑞虹. 高于居里温度极化的硬性PZT压电陶瓷的制备及叠层驱动器性能研究[J]. 无机材料学报, 2024, 39(10): 1091-1099. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||