无机材料学报 ›› 2024, Vol. 39 ›› Issue (6): 671-680.DOI: 10.15541/jim20240001 CSTR: 32189.14.10.15541/jim20240001

所属专题: 【结构材料】热障与环境障涂层(202506)

李捷1,2( ), 罗志新1, 崔阳1, 张广珩1,2, 孙鲁超1(

), 罗志新1, 崔阳1, 张广珩1,2, 孙鲁超1( ), 王京阳1(

), 王京阳1( )

)

收稿日期:2024-01-02

修回日期:2024-02-29

出版日期:2024-06-20

网络出版日期:2024-03-05

通讯作者:

孙鲁超, 研究员. E-mail: lcsun@imr.ac.cn;作者简介:李捷(1999-), 女, 博士研究生. E-mail: jli20s@imr.ac.cn

基金资助:

LI Jie1,2( ), LUO Zhixin1, CUI Yang1, ZHANG Guangheng1,2, SUN Luchao1(

), LUO Zhixin1, CUI Yang1, ZHANG Guangheng1,2, SUN Luchao1( ), WANG Jingyang1(

), WANG Jingyang1( )

)

Received:2024-01-02

Revised:2024-02-29

Published:2024-06-20

Online:2024-03-05

Contact:

SUN Luchao, professor. E-mail: lcsun@imr.ac.cn;About author:LI Jie (1999-), female, PhD candidate. E-mail: jli20s@imr.ac.cn

Supported by:摘要:

探索能够有效抵抗1300 ℃及以上温度钙镁铝硅酸盐(Calcium-Magnesium-Aluminum-Silicate, CMAS)腐蚀的新材料是近年来先进航空发动机用环境障涂层研究的重点任务。本工作围绕具有超强CMAS腐蚀抗力的YAG(Y3Al5O12)/Al2O3体系, 采用大气等离子喷涂(Atmospheric Plasma Spraying, APS)技术制备了具有共晶成分的YAG/Al2O3涂层。通过在1100、1300和1500 ℃对制备态涂层进行热处理, 获得了具有不同微观结构的YAG/Al2O3涂层。利用不同表征手段研究了YAG/Al2O3涂层抵抗1300 ℃ CMAS腐蚀的性能及微观结构对涂层腐蚀抗性的影响。研究结果发现, 经不同温度热处理的YAG/Al2O3涂层与CMAS的反应产物均为石榴石结构固溶体、CaAl2Si2O8和Ca2MgSi2O7。腐蚀机制研究发现, 1100 ℃热处理YAG/Al2O3涂层与CMAS反应界面的近连续分布石榴石固溶体层可有效阻隔CMAS腐蚀元素的扩散; 1500 ℃热处理YAG/Al2O3涂层晶粒尺寸的增加及晶界数量的减少可降低涂层材料在CMAS中的溶解速率, 二者均可通过影响腐蚀过程中的离子传输速率而影响各生成物的竞争析出, 进而提升涂层的CMAS腐蚀抗力。本工作为YAG/Al2O3涂层热处理工艺优化提供了借鉴, 并为通过微观结构优化调控YAG/Al2O3涂层的CMAS腐蚀抗力提供了新思路。

中图分类号:

李捷, 罗志新, 崔阳, 张广珩, 孙鲁超, 王京阳. 大气等离子喷涂Y3Al5O12/Al2O3陶瓷涂层的CMAS腐蚀抗力[J]. 无机材料学报, 2024, 39(6): 671-680.

LI Jie, LUO Zhixin, CUI Yang, ZHANG Guangheng, SUN Luchao, WANG Jingyang. CMAS Corrosion Resistance of Y3Al5O12/Al2O3 Ceramic Coating Deposited by Atmospheric Plasma Spraying[J]. Journal of Inorganic Materials, 2024, 39(6): 671-680.

| Current/A | Ar flow rate/slpm | H2 flow rate/slpm | Rotation velocity/% | Distance/mm |

|---|---|---|---|---|

| 650 | 40 | 12 | 30 | 110 |

表1 YAG/Al2O3涂层的大气等离子喷涂参数

Table 1 Atmospheric plasma spraying parameters for YAG/Al2O3 coating

| Current/A | Ar flow rate/slpm | H2 flow rate/slpm | Rotation velocity/% | Distance/mm |

|---|---|---|---|---|

| 650 | 40 | 12 | 30 | 110 |

图1 经1300 ℃ CMAS腐蚀(a) 1、(b) 4和(c) 25 h后YAG/Al2O3涂层表面的XRD图谱

Fig. 1 XRD patterns of the surfaces of YAG/Al2O3 coatings after CMAS corrosion at 1300 ℃ for (a) 1, (b) 4, and (c) 25 h Colorful patterns are available on website

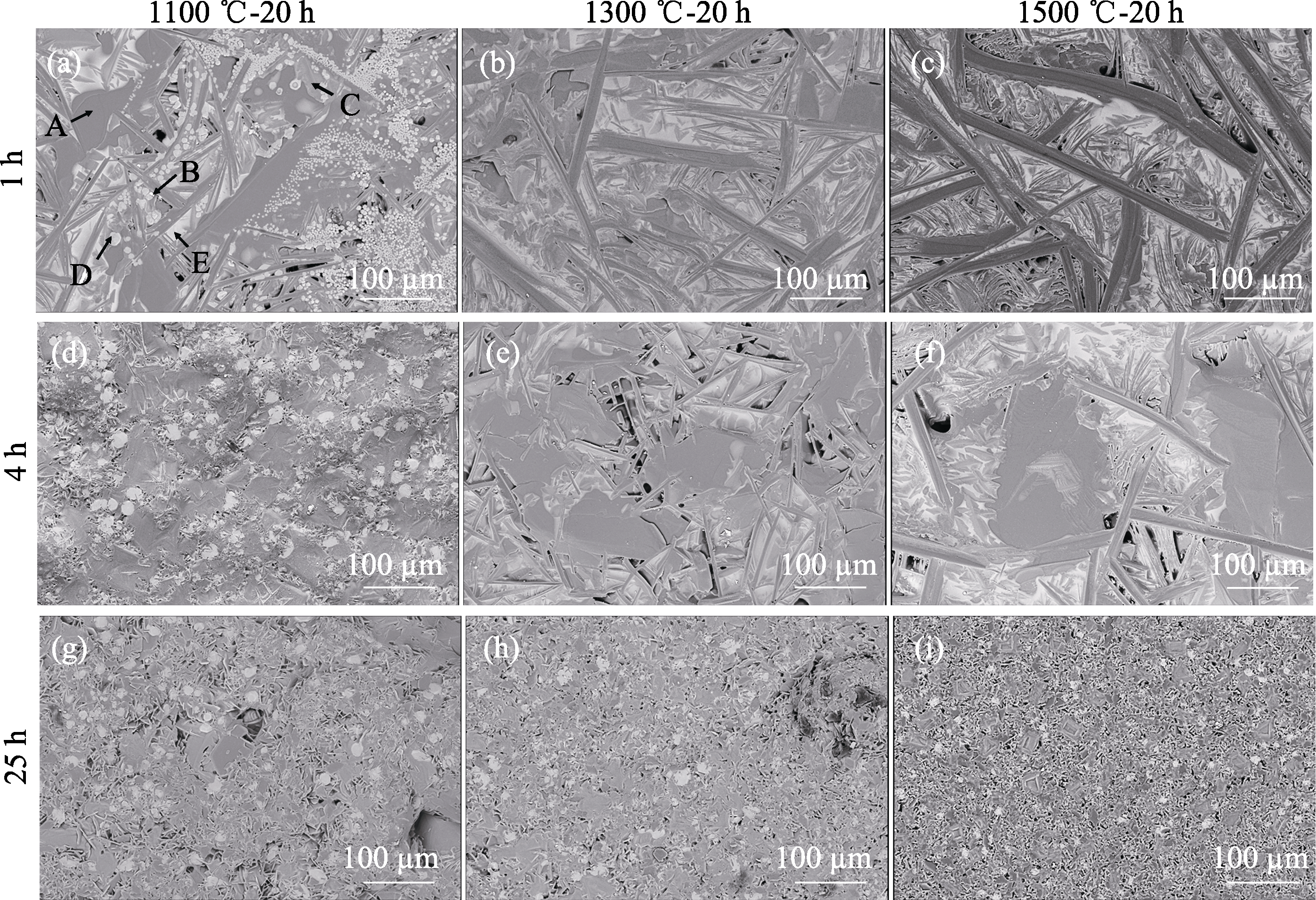

图2 YAG/Al2O3涂层经CMAS腐蚀试验后的表面形貌

Fig. 2 Surface morphologies of YAG/Al2O3 coatings after CMAS corrosion Coatings annealed at 1100, 1300, and 1500 ℃ after CMAS corrosion for (a-c) 1, (d-f) 4, and (g-i) 25 h

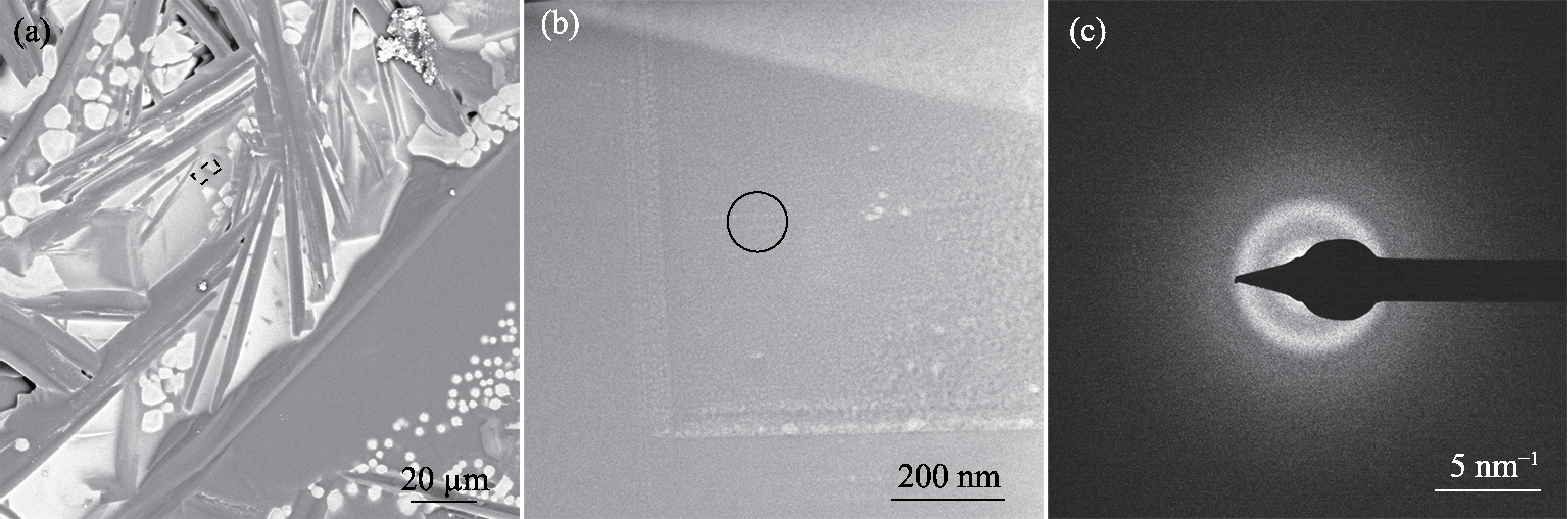

图3 1100 ℃热处理YAG/Al2O3涂层经CMAS腐蚀1 h后的TEM分析

Fig. 3 TEM analyses of YAG/Al2O3 coating annealed at 1100 ℃ after CMAS corrosion for 1 h (a) Selected area for TEM sample preparation via FIB; (b) Bright-field TEM image from the region indicated by black dashed box in (a); (c) SAED pattern of area marked with black circle in (b)

| Region | O | Mg | Al | Si | Ca | Y | Phase |

|---|---|---|---|---|---|---|---|

| A | 50.41±1.59 | — | 17.47±0.70 | 22.27±0.71 | 10.16±0.45 | — | CaAl2Si2O8 |

| B | 54.10±3.25 | — | 16.47±0.78 | 19.42±0.95 | 10.00±1.84 | — | CaAl2Si2O8 |

| C | 58.95±0.44 | 5.60±0.29 | 3.79±0.49 | 16.57±0.32 | 15.09±0.20 | — | Ca2MgSi2O7 |

| D | 39.07±1.11 | 3.70±0.34 | 17.29±0.53 | 17.48±0.52 | 12.41±0.50 | 10.06±0.62 | YAG |

| E | 49.54±1.04 | 3.23±0.40 | 4.73±0.18 | 23.34±0.41 | 13.81±1.60 | 5.34±0.71 | CMAS |

表2 1100 ℃热处理YAG/Al2O3涂层经CMAS腐蚀1 h后的表面SEM-EDS分析结果(%, 原子分数)

Table 2 SEM-EDS analytical results of the phases on the surface of YAG/Al2O3 coating annealed at 1100 ℃ after CMAS corrosion for 1 h (%, in atom)

| Region | O | Mg | Al | Si | Ca | Y | Phase |

|---|---|---|---|---|---|---|---|

| A | 50.41±1.59 | — | 17.47±0.70 | 22.27±0.71 | 10.16±0.45 | — | CaAl2Si2O8 |

| B | 54.10±3.25 | — | 16.47±0.78 | 19.42±0.95 | 10.00±1.84 | — | CaAl2Si2O8 |

| C | 58.95±0.44 | 5.60±0.29 | 3.79±0.49 | 16.57±0.32 | 15.09±0.20 | — | Ca2MgSi2O7 |

| D | 39.07±1.11 | 3.70±0.34 | 17.29±0.53 | 17.48±0.52 | 12.41±0.50 | 10.06±0.62 | YAG |

| E | 49.54±1.04 | 3.23±0.40 | 4.73±0.18 | 23.34±0.41 | 13.81±1.60 | 5.34±0.71 | CMAS |

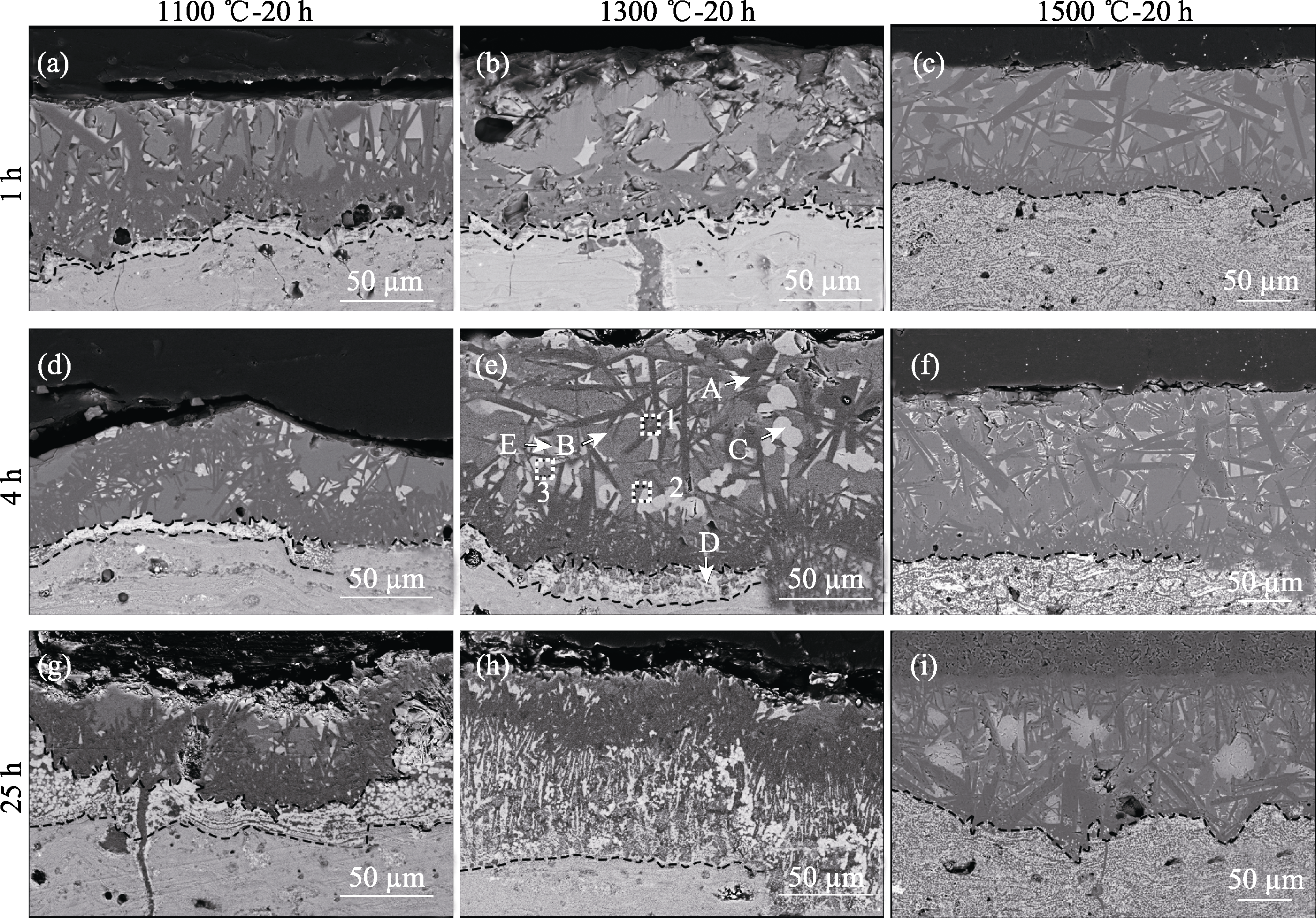

图4 YAG/Al2O3涂层经CMAS腐蚀试验后的截面形貌

Fig. 4 Cross-sectional morphologies of YAG/Al2O3 coatings after CMAS corrosion Coatings annealed at 1100, 1300, and 1500 ℃ after CMAS corrosion for (a-c) 1, (d-f) 4, and (g-i) 25 h

| Region | O | Mg | Al | Si | Ca | Y | Phase |

|---|---|---|---|---|---|---|---|

| A | 24.15±0.56 | — | 24.40±0.29 | 34.29±0.21 | 17.16±0.22 | — | CaAl2Si2O8 |

| B | 23.06±3.46 | 5.43±0.30 | 11.72±0.42 | 28.70±1.50 | 31.09±1.49 | — | CMAS |

| C | 18.45±2.17 | 3.63±0.42 | 8.98±0.70 | 35.71±1.30 | 20.57±0.38 | 12.67±0.82 | YAG |

| D | 26.70±2.79 | 2.13±0.61 | 29.42±0.78 | 14.12±1.62 | 10.47±0.54 | 17.18±0.81 | YAG |

| E | 31.18±1.51 | 1.40±0.17 | 10.56±0.53 | 31.3±0.53 | 21.09±0.73 | 4.47±0.14 | CMAS |

表3 1300 ℃热处理YAG/Al2O3涂层经CMAS腐蚀4 h后的截面SEM-EDS分析结果(%, 原子分数)

Table 3 SEM-EDS analytical results of phases in the cross-section of YAG/Al2O3 coating annealed at 1300 ℃ after CMAS corrosion for 4 h (%, in atom)

| Region | O | Mg | Al | Si | Ca | Y | Phase |

|---|---|---|---|---|---|---|---|

| A | 24.15±0.56 | — | 24.40±0.29 | 34.29±0.21 | 17.16±0.22 | — | CaAl2Si2O8 |

| B | 23.06±3.46 | 5.43±0.30 | 11.72±0.42 | 28.70±1.50 | 31.09±1.49 | — | CMAS |

| C | 18.45±2.17 | 3.63±0.42 | 8.98±0.70 | 35.71±1.30 | 20.57±0.38 | 12.67±0.82 | YAG |

| D | 26.70±2.79 | 2.13±0.61 | 29.42±0.78 | 14.12±1.62 | 10.47±0.54 | 17.18±0.81 | YAG |

| E | 31.18±1.51 | 1.40±0.17 | 10.56±0.53 | 31.3±0.53 | 21.09±0.73 | 4.47±0.14 | CMAS |

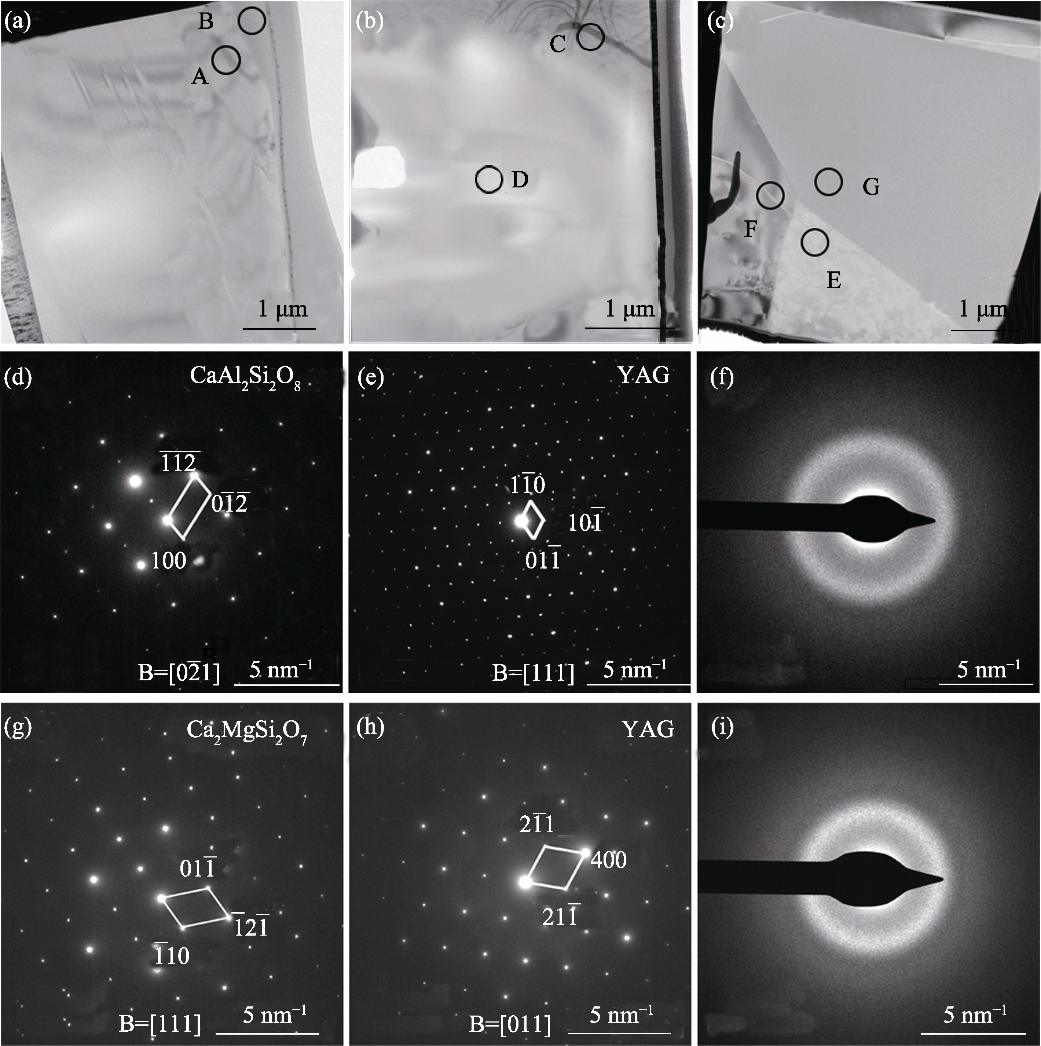

图5 1300 ℃热处理YAG/Al2O3涂层经CMAS腐蚀4 h后的TEM分析

Fig. 5 TEM analyses of YAG/Al2O3 coating annealed at 1300 ℃ after CMAS corrosion for 4 h (a-c) Bright-field TEM images from regions indicated by dashed box with numbers 1, 2 and 3 in Fig. 4(e), respectively; (d) SAED pattern of area in (a) marked with letter A; (e-i) SAED patterns of areas in (a) marked with letters C-G, respectively

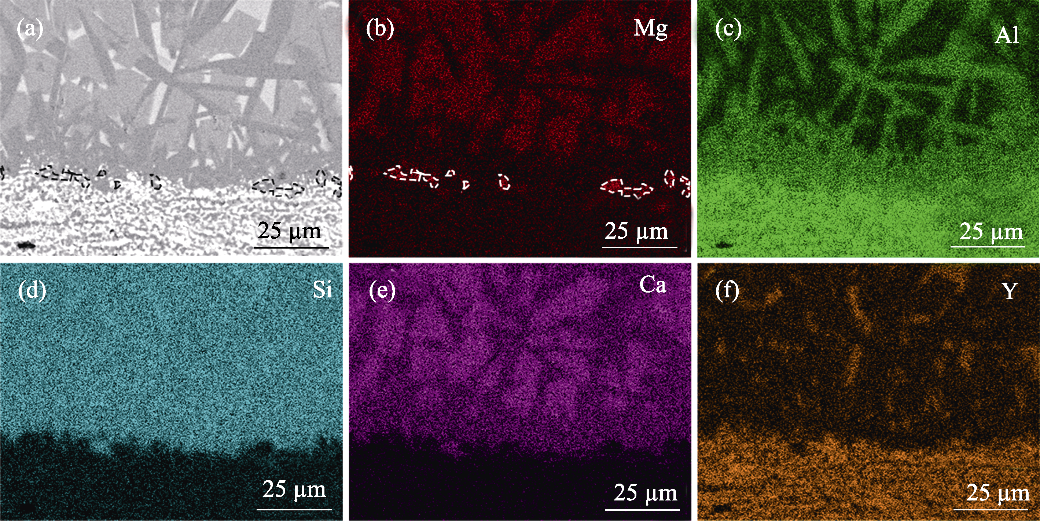

图6 1100 ℃热处理YAG/Al2O3涂层经CMAS腐蚀1 h后截面的EDS面扫描结果

Fig. 6 EDS mappings of the cross-section of YAG/Al2O3 coating annealed at 1100 ℃ after CMAS corrosion for 1 h

图7 1500 ℃热处理YAG/Al2O3涂层经CMAS腐蚀1 h后截面的EDS面扫描结果

Fig. 7 EDS mappings of the cross-section of YAG/Al2O3 coating annealed at 1500 ℃ after CMAS corrosion for 1 h

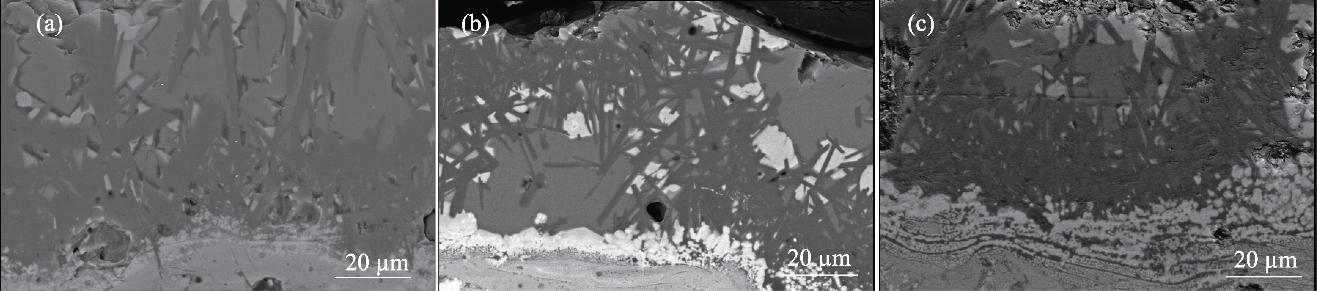

图S1 1300 ℃热处理YAG/Al2O3涂层经CMAS腐蚀(a) 1, (b) 4和(c) 25 h后样品截面形貌的高倍照片

Fig. S1 High-magnification cross-section observations of YAG/Al2O3 coatings annealed at 1300 ℃ after CMAS corrosion for (a) 1, (b) 4, and (c) 25 h

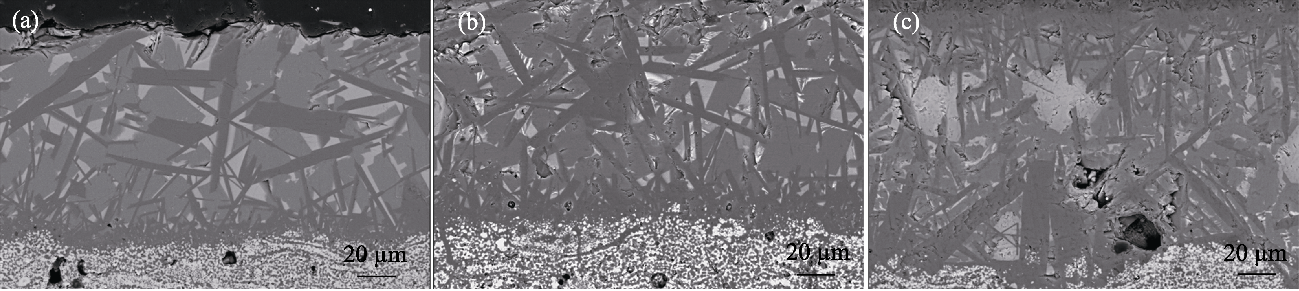

图S2 1500 ℃热处理YAG/Al2O3涂层经CMAS腐蚀(a) 1, (b) 4和(c) 25 h后样品截面形貌的高倍照片

Fig. S2 High-magnification cross-section observations of YAG/Al2O3 coatings annealed at 1500 ℃ after CMAS corrosion for (a) 1, (b) 4, and (c) 25 h

图S3 (a)制备态YAG/Al2O3涂层和分别经(b)1100、(c)1300和(d)1500 ℃热处理的截面形貌

Fig. S3 Cross-section observations of (a) as-deposited YAG/Al2O3 coating and coatings annealed at (b) 1100, (c) 1300, and (d) 1500 ℃

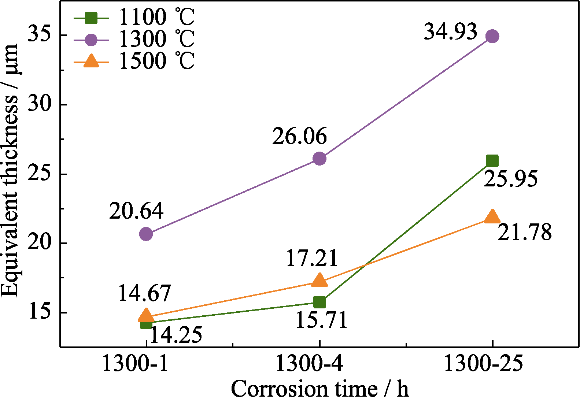

图S4 不同温度热处理后涂层析出YAG石榴石固溶体相的“等效”厚度统计

Fig. S4 Equivalent thickness statistics of precipitation YAG garnet-structure solid solution of coatings annealed at different temperatures

| Region | O | Mg | Al | Si | Ca | Y | Phase |

|---|---|---|---|---|---|---|---|

| E | 43.12±4.00 | 6.84±0.22 | 3.49±0.30 | 21.96±1.32 | 24.59±2.26 | Ca2MgSi2O7 | |

| F | 50.79±0.93 | 5.61±0.19 | 6.51±0.27 | 17.50±0.82 | 11.34±0.49 | 8.25±0.42 | YAG |

| G | 59.33±2.03 | 0.54±0.14 | 4.95±0.26 | 19.53±0.73 | 13.38±0.89 | 2.27±0.14 | CMAS |

表S1 图5(c)中区域E、F和G的TEM-EDS结果(%, 原子分数)

Table S1 TEM-EDS results of the regions marked with letters E, F, and G in Fig. 5(c)(%, in atom)

| Region | O | Mg | Al | Si | Ca | Y | Phase |

|---|---|---|---|---|---|---|---|

| E | 43.12±4.00 | 6.84±0.22 | 3.49±0.30 | 21.96±1.32 | 24.59±2.26 | Ca2MgSi2O7 | |

| F | 50.79±0.93 | 5.61±0.19 | 6.51±0.27 | 17.50±0.82 | 11.34±0.49 | 8.25±0.42 | YAG |

| G | 59.33±2.03 | 0.54±0.14 | 4.95±0.26 | 19.53±0.73 | 13.38±0.89 | 2.27±0.14 | CMAS |

| [1] | PADTURE N P. Advanced structural ceramics in aerospace propulsion. Nature Materials, 2016, 15: 804. |

| [2] | MANUEL B. Advanced ceramic materials for high temperature applications. Advanced Engineering Materials, 2006, 8(8):693. |

| [3] | JACOBSON N S, OPILA E J, LEE K N. Oxidation and corrosion of ceramics and ceramic matrix composites. Current Opinion in Solid State & Materials Science, 2001, 5(4):301. |

| [4] | EATON H E, LINSEY G D. Accelerated oxidation of SiC CMC’s by water vapor and protection via environmental barrier coating approach. Journal of the European Ceramic Society, 2002, 22(14/15):2741. |

| [5] | POERSCHKE D L, VAN SLUYTMAN J S, WONG K B, et al. Thermochemical compatibility of ytterbia-(hafnia/silica) multilayers for environment barrier coatings. Acta Materialia, 2013, 61(18):6743. |

| [6] | BAKAN E, MARCANO D, ZHOU D P, et al. Yb2Si2O7 environmental barrier coatings deposited by various thermal spray techniques: a preliminary comparative study. Journal of Thermal Spray Technology, 2017, 26(6):1011. |

| [7] | TIAN Z L, ZHENG L Y, WNAG J M, et al. Theoretical and experimental determination of the major thermo-mechanical properties of RE2SiO5 (RE=Tb, Dy, Ho, Er, Tm, Yb, Lu, and Y) for environmental and thermal barrier coating applications. Journal of the European Ceramic Society, 2015, 36: 189. |

| [8] |

王京阳, 孙鲁超, 罗颐秀, 等. 以抗CMAS腐蚀为目标的稀土硅酸盐环境障涂层高熵化设计与性能提升. 金属学报, 2023, 59(4):523.

DOI |

| [9] |

SUN L C, REN X M, DU T F, et al. High entropy engineering: new strategy for the critical property optimizations of rare earth silicates. Journal of Inorganic Materials, 2021, 36(4):339.

DOI |

| [10] | TIAN Z L, REN X M, LEI Y M, et al. Corrosion of RE2Si2O7 (RE=Y, Yb, and Lu) environmental barrier coating materials by molten calcium-magnesium-alumino-silicate glass at high temperatures. Journal of the European Ceramic Society, 2019, 39: 4245. |

| [11] | WEBSTER R I, OPILA E J. Mixed phase ytterbium silicate environmental-barrier coating materials for improved calcium- magnesium-alumino-silicate resistance. Journal of Materials Research, 2020, 35(17):2358. |

| [12] | WANG H Y, LUO Z X, SUN L C, et al. Comprehensive microstructural characterization and CMAS infiltration resistance of ytterbium disilicate coatings with lamellar and quasi-columnar structures. Corrosion Science, 2023, 221: 11316. |

| [13] | SUN H F, SUN L C, REN X M, et al. Outstanding molten calcium-magnesium-aluminosilicate (CMAS) corrosion resistance of directionally solidified Al2O3/Y3Al5O12 eutectic ceramic at 1500 ℃. Corrosion Science, 2023, 220: 111289. |

| [14] | ZHOU C, SUN L C, DU T F, et al. Excellent calcium- magnesium-luminosilicate corrosion resistance of high-entropy garnet/alumina directionally solidified eutectic at 1500 ℃. Journal of the American Ceramic Society, 2024, 107(3):1748. |

| [15] | STOLZENBURG F, JOHNSON M T, LEE K N, et al. The interaction of calcium-magnesium-aluminosilicate with ytterbium silicate environmental barrier materials. Surface & Coating Technology, 2015, 284: 44. |

| [16] | GODBOLE E, KARTHIKEYAN N, POERSCHKE D, et al. Garnet stability in the Al-Ca-Mg-Si-Y-O system with implications for reactions between TBCs, EBCs, and silicate deposits. Journal of the American Ceramic Society, 2020, 103(9):5270. |

| [17] | SATOSHI K, MAKOTO T, NAOKI K, et al. CMAS degradation of ytterbium aluminum garnets. Journal of the American Ceramic Society, 2023, 106: 4863. |

| [18] | THOMAS M S, PETE R D. Forces between aluminum oxide grains in a silicate melt and their effect on grain boundary wetting. Journal of the American Ceramic Society, 1991, 74(10):2495. |

| [19] | PHILIP L F, JOSEPH A P. Penetration of polycrystalline alumina by glass at high temperature. Journal of the American Ceramic Society, 1987, 70(7):449. |

| [20] | ZHAO H B, RICHARDE B T, LEVI C G, et al. Molten silicate reactions with plasma sprayed ytterbium silicate coatings. Surface & Coating Technology, 2016, 288: 151. |

| [1] | 梁锐辉, 钟鑫, 洪督, 黄利平, 牛亚然, 郑学斌. Yb2O3改性硅黏结层的环境障涂层体系耐高温水氧腐蚀行为研究[J]. 无机材料学报, 2025, 40(4): 425-432. |

| [2] | 范栋, 钟鑫, 王亚文, 张振忠, 牛亚然, 李其连, 张乐, 郑学斌. 富铝CMAS对稀土硅酸盐环境障涂层的腐蚀行为与机制研究[J]. 无机材料学报, 2023, 38(5): 544-552. |

| [3] | 洪督, 牛亚然, 李红, 钟鑫, 郑学斌. 等离子喷涂TiC-Graphite复合涂层摩擦磨损性能[J]. 无机材料学报, 2022, 37(6): 643-650. |

| [4] | 刘平平, 钟鑫, 张乐, 李红, 牛亚然, 张翔宇, 李其连, 郑学斌. 硅酸镱环境障涂层抗熔盐腐蚀行为与机制研究[J]. 无机材料学报, 2022, 37(12): 1267-1274. |

| [5] | 孙鲁超, 任孝旻, 杜铁锋, 罗颐秀, 张洁, 王京阳. 高熵化设计: 稀土硅酸盐材料关键性能优化新策略[J]. 无机材料学报, 2021, 36(4): 339-346. |

| [6] | 张小锋, 周克崧, 刘敏, 邓春明, 牛少鹏, 许世鸣. 等离子喷涂-物理气相沉积Si/莫来石/Yb2SiO5环境障涂层[J]. 无机材料学报, 2018, 33(3): 325-330. |

| [7] | 刘朝辉, 侯根良, 苏勋家, 郭 锋, 肖 舟, 贾海鹏. 热处理温度对TiO2/SiO2复合气凝胶光催化性能的影响[J]. 无机材料学报, 2012, 27(10): 1079-1083. |

| [8] | 颜建辉, 唐思文, 张厚安. 二硅化钼喷涂粉末的制备及其涂层组织结构[J]. 无机材料学报, 2011, 26(2): 203-208. |

| [9] | 刘文刚,许云华,杨 蓉,HOJAMBERDIEV Mirabbos,周志斌. 热处理温度对多元醇合成Li2MnSiO4/C电化学性能的影响[J]. 无机材料学报, 2010, 25(3): 327-331. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||