无机材料学报 ›› 2021, Vol. 36 ›› Issue (12): 1247-1255.DOI: 10.15541/jim20210126 CSTR: 32189.14.10.15541/jim20210126

所属专题: MXene材料专辑(2020~2021)

张霄1,2,3( ), 李友兵2,3, 陈科2,3, 丁浩明2,3, 陈露2,3, 李勉2,3, 史蓉蓉1(

), 李友兵2,3, 陈科2,3, 丁浩明2,3, 陈露2,3, 李勉2,3, 史蓉蓉1( ), 柴之芳2,3, 黄庆2,3(

), 柴之芳2,3, 黄庆2,3( )

)

收稿日期:2021-03-03

修回日期:2021-03-24

出版日期:2021-12-20

网络出版日期:2021-06-01

通讯作者:

史蓉蓉, 副教授. E-mail: shirr@lzu.edu.cn;黄 庆, 研究员. E-mail: huangqing@nimte.ac.cn

作者简介:张 霄(1996-), 男, 硕士研究生. E-mail: zhangxiao18@lzu.edu.cn

基金资助:

ZHANG Xiao1,2,3( ), LI Youbing2,3, CHEN Ke2,3, DING Haoming2,3, CHEN Lu2,3, LI Mian2,3, SHI Rongrong1(

), LI Youbing2,3, CHEN Ke2,3, DING Haoming2,3, CHEN Lu2,3, LI Mian2,3, SHI Rongrong1( ), CHAI Zhifang2,3, HUANG Qing2,3(

), CHAI Zhifang2,3, HUANG Qing2,3( )

)

Received:2021-03-03

Revised:2021-03-24

Published:2021-12-20

Online:2021-06-01

Contact:

SHI Rongrong, associate professor. E-mail: shirr@lzu.edu.cn;HUANG Qing, professor. E-mail: huangqing@nimte.ac.cn

About author:ZHANG Xiao(1996-), male, Master candidate. E-mail: zhangxiao18@lzu.edu.cn

Supported by:摘要:

三元层状化合物MAX相兼具金属与陶瓷优良的力学性质, 通常被认为是一类高安全结构材料。有研究显示, 通过熔盐法可以将副族元素插入到MAX相A位层间, 获得具有铁磁性能的V2(Sn, A)C (A =Fe、Co、Ni和Mn)材料。因而, 如何构建新的MAX相结构并对实现其磁性调控备受关注。本研究通过MAX相M位和A位双固溶的方式设计了四种新型MAX相(V, Nb)2(Sn, A)C (A =Fe、Co、Ni和Mn)。XRD、SEM、EDS结合TEM分析证实了上述新相的合成。超导量子磁强计(Superconducting quantum interference device magnetometer, SQUID)测试磁学性能发现, M位固溶后的MAX相的居里温度与其四方率(c/a)、元素组成有关。(V, Nb)2(Sn, Fe)C、(V, Nb)2(Sn, Ni)C、(V, Nb)2(Sn, Mn)C相较于M位固溶Nb元素之前的V2(Sn, A)C相, 其矫顽力Hc和剩余磁化强度Mr减小, 饱和磁化强度Ms增大。而V2(Sn, Co)C在M位固溶Nb元素之后磁性变化均与前述MAX相相反。通过以上结果, 揭示了M/A位双固溶对MAX相磁性的影响规律, 为调控MAX相磁性提供了新的思路。

中图分类号:

张霄, 李友兵, 陈科, 丁浩明, 陈露, 李勉, 史蓉蓉, 柴之芳, 黄庆. M位与A位双固溶MAX相的磁学性能研究[J]. 无机材料学报, 2021, 36(12): 1247-1255.

ZHANG Xiao, LI Youbing, CHEN Ke, DING Haoming, CHEN Lu, LI Mian, SHI Rongrong, CHAI Zhifang, HUANG Qing. Tailoring MAX Phase Magnetic Property Based on M-site and A-site Double Solid Solution[J]. Journal of Inorganic Materials, 2021, 36(12): 1247-1255.

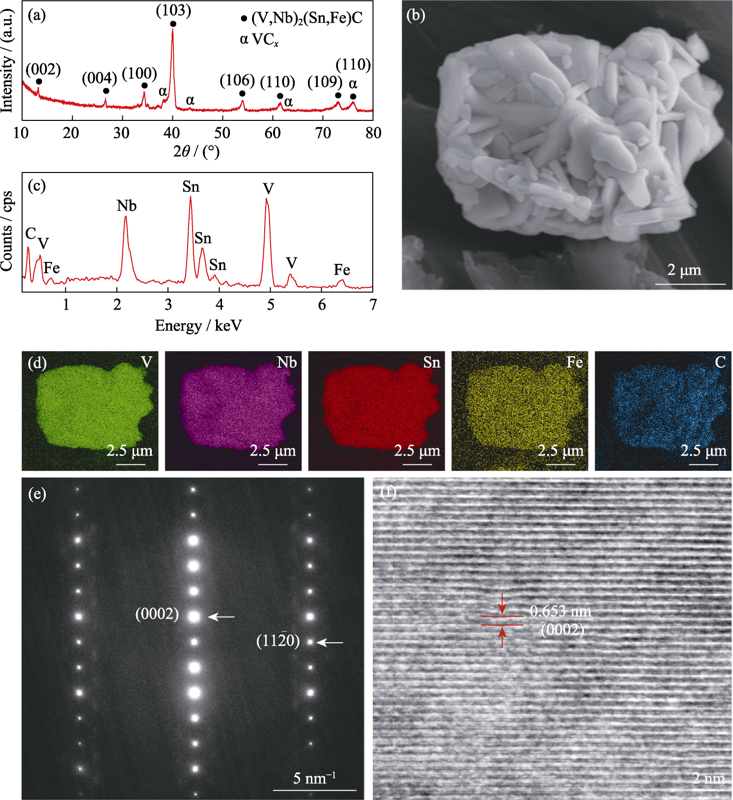

图1 酸处理后的(V, Nb)2(Sn, Fe)C表征结果

Fig. 1 Characterization results of (V, Nb)2(Sn, Fe)C after acid treatment (a) XRD pattern; (b) SEM image; (c) Corresponding energy-dispersive spectroscopy analysis; (d) Elemental mapping scanning on one particle; (e) Selected area electron diffraction pattern, showing the electron beam being paralleled to the [1$\bar{1}$00] direction; (f) HR-TEM image

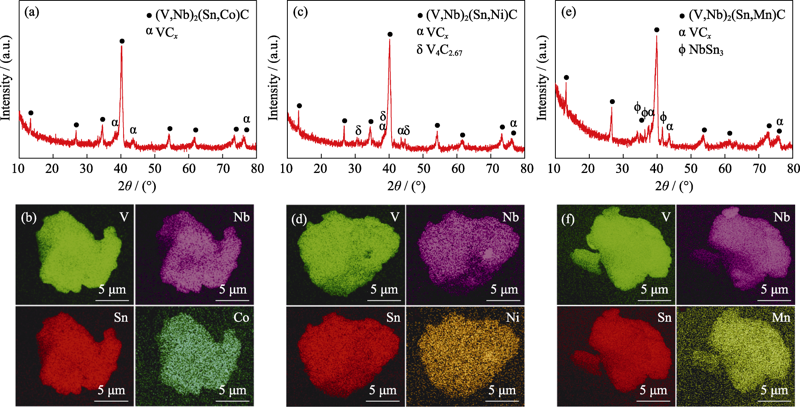

图2 (a) (V, Nb)2(Sn, Co)C、(c) (V, Nb)2(Sn, Ni)C和(e) (V, Nb)2(Sn, Mn)C酸处理后的XRD谱图;(b) (V, Nb)2(Sn, Co)C、(d) (V, Nb)2(Sn, Ni)C、(f) (V, Nb)2(Sn, Mn)C元素分布图

Fig. 2 XRD patterns of (a) (V, Nb)2(Sn, Co)C, (c) (V, Nb)2(Sn, Ni)C, and (e) (V, Nb)2(Sn, Mn)C after acid treatment; SEM-EDS elemental mappings of (b) (V, Nb)2(Sn, Co)C, (d) (V, Nb)2(Sn, Ni)C, and (f) (V, Nb)2(Sn, Mn)C after acid treatment

| MAX phase | Lattice parameter | Element percentage/% | Nb element in M site/% | Magnetic element in A site/% | |||||

|---|---|---|---|---|---|---|---|---|---|

| a/nm | c/nm | c/a | V | Nb | Sn | A | |||

| V2(Sn, Fe)C[ | 0.2984 | 1.3345 | 4.4718 | 66.84 | - | 22.05 | 11.11 | - | 33.50 |

| (V, Nb)2(Sn, Fe)C | 0.3014 | 1.3447 | 4.4622 | 54.32 | 13.38 | 25.03 | 7.27 | 19.76 | 22.51 |

| V2(Sn, Co)C[ | 0.2989 | 1.3409 | 4.4864 | 66.36 | - | 22.44 | 11.19 | - | 33.28 |

| (V, Nb)2(Sn, Co)C | 0.3016 | 1.3419 | 4.4493 | 56.41 | 11.23 | 24.60 | 7.76 | 16.60 | 23.98 |

| V2(Sn, Ni)C[ | 0.2985 | 1.3357 | 4.4751 | 67.47 | - | 24.36 | 8.16 | - | 25.10 |

| (V, Nb)2(Sn, Ni)C | 0.3021 | 1.3413 | 4.4402 | 56.87 | 13.00 | 21.66 | 8.47 | 18.61 | 28.10 |

| V2(Sn, Mn)C[ | 0.2982 | 1.3403 | 4.4941 | 66.19 | - | 23.07 | 10.74 | - | 31.76 |

| (V, Nb)2(Sn, Mn)C | 0.3026 | 1.3509 | 4.4646 | 57.10 | 10.84 | 23.50 | 8.56 | 15.96 | 26.70 |

表1 晶格参数和MAX相中元素的原子百分比

Table 1 Lattice parameters and atomic percentage of element in MAX phases

| MAX phase | Lattice parameter | Element percentage/% | Nb element in M site/% | Magnetic element in A site/% | |||||

|---|---|---|---|---|---|---|---|---|---|

| a/nm | c/nm | c/a | V | Nb | Sn | A | |||

| V2(Sn, Fe)C[ | 0.2984 | 1.3345 | 4.4718 | 66.84 | - | 22.05 | 11.11 | - | 33.50 |

| (V, Nb)2(Sn, Fe)C | 0.3014 | 1.3447 | 4.4622 | 54.32 | 13.38 | 25.03 | 7.27 | 19.76 | 22.51 |

| V2(Sn, Co)C[ | 0.2989 | 1.3409 | 4.4864 | 66.36 | - | 22.44 | 11.19 | - | 33.28 |

| (V, Nb)2(Sn, Co)C | 0.3016 | 1.3419 | 4.4493 | 56.41 | 11.23 | 24.60 | 7.76 | 16.60 | 23.98 |

| V2(Sn, Ni)C[ | 0.2985 | 1.3357 | 4.4751 | 67.47 | - | 24.36 | 8.16 | - | 25.10 |

| (V, Nb)2(Sn, Ni)C | 0.3021 | 1.3413 | 4.4402 | 56.87 | 13.00 | 21.66 | 8.47 | 18.61 | 28.10 |

| V2(Sn, Mn)C[ | 0.2982 | 1.3403 | 4.4941 | 66.19 | - | 23.07 | 10.74 | - | 31.76 |

| (V, Nb)2(Sn, Mn)C | 0.3026 | 1.3509 | 4.4646 | 57.10 | 10.84 | 23.50 | 8.56 | 15.96 | 26.70 |

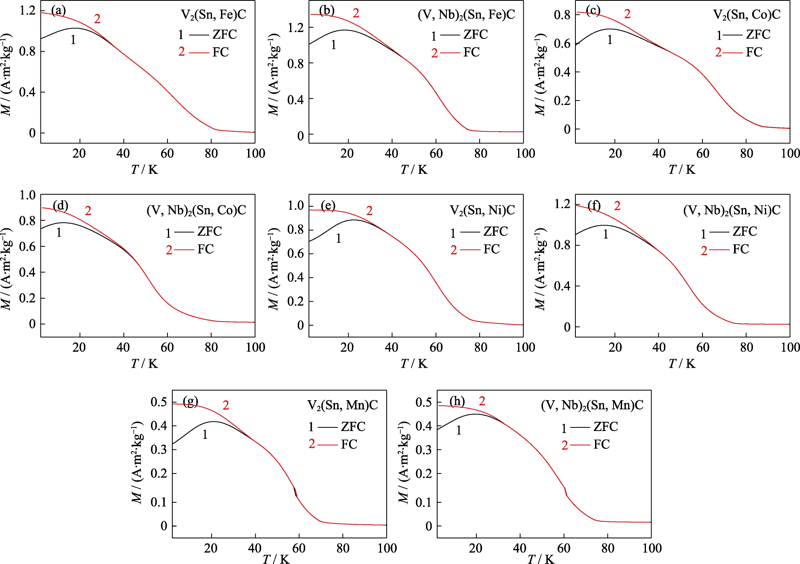

图3 在0.1 T下, V2(Sn, A)C和(V, Nb)2(Sn, A)C (A = Fe, Co, Ni和Mn)在2~100 K范围内随温度变化的磁化M-T曲线

Fig. 3 Temperature dependent magnetization M-T curves for (a) V2(Sn, A)C and (b) V2(Sn, A)C (A = Fe, Co, Ni and Mn) at 0.1 T in the range of 2-100 K

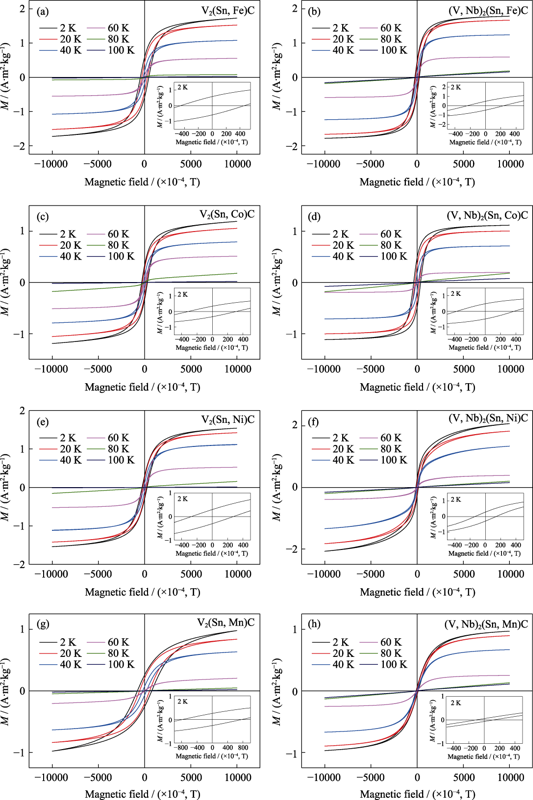

图4 V2(Sn, A)C和(V, Nb)2(Sn, A)C(A=Fe、Co、Ni和Mn)在-1~1 T范围内的磁滞回线

Fig. 4 Magnetic hysteresis loops of V2(Sn, A)C and V2(Sn, A)C (A=Fe, Co, Ni and Mn) at different temperatures in the range from -1 to 1 T, respectively Colourful figures are available on website

| MAX phase | TC | 2 K | 20 K | 40 K | ||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Hc | Mr | Ms | Hc | Mr | Ms | Hc | Mr | Ms | ||

| V2(Sn, Fe)C | 63 | 458 | 0.59 | 1.73 | 305 | 0.42 | 1.53 | 152 | 0.18 | 1.08 |

| (V, Nb)2(Sn, Fe)C | 63 | 238 | 0.48 | 1.79 | 174 | 0.37 | 1.67 | 73 | 0.14 | 1.24 |

| V2(Sn, Co)C | 66 | 314 | 0.34 | 1.19 | 224 | 0.26 | 1.05 | 113 | 0.12 | 0.79 |

| (V, Nb)2(Sn, Co)C | 53 | 378 | 0.49 | 1.11 | 240 | 0.33 | 1.00 | 134 | 0.17 | 0.71 |

| V2(Sn, Ni)C | 60 | 276 | 0.30 | 1.54 | 191 | 0.23 | 1.42 | 94 | 0.10 | 1.12 |

| (V, Nb)2(Sn, Ni)C | 53 | 140 | 0.29 | 2.07 | 96 | 0.19 | 1.83 | 45 | 0.07 | 1.34 |

| V2(Sn, Mn)C | 56 | 780 | 0.26 | 0.98 | 545 | 0.21 | 0.84 | 206 | 0.07 | 0.63 |

| (V, Nb)2(Sn, Mn)C | 57 | 117 | 0.06 | 0.97 | 75 | 0.04 | 0.90 | 32 | 0.01 | 0.67 |

表2 V2(Sn, A)C与(V, Nb)2(Sn, A)C(A = Fe、Co、Ni和Mn)的磁性参数

Table 2 Magnetic parameters of V2(Sn, A)C and (V, Nb)2(Sn, A)C (A = Fe, Co, Ni and Mn)

| MAX phase | TC | 2 K | 20 K | 40 K | ||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Hc | Mr | Ms | Hc | Mr | Ms | Hc | Mr | Ms | ||

| V2(Sn, Fe)C | 63 | 458 | 0.59 | 1.73 | 305 | 0.42 | 1.53 | 152 | 0.18 | 1.08 |

| (V, Nb)2(Sn, Fe)C | 63 | 238 | 0.48 | 1.79 | 174 | 0.37 | 1.67 | 73 | 0.14 | 1.24 |

| V2(Sn, Co)C | 66 | 314 | 0.34 | 1.19 | 224 | 0.26 | 1.05 | 113 | 0.12 | 0.79 |

| (V, Nb)2(Sn, Co)C | 53 | 378 | 0.49 | 1.11 | 240 | 0.33 | 1.00 | 134 | 0.17 | 0.71 |

| V2(Sn, Ni)C | 60 | 276 | 0.30 | 1.54 | 191 | 0.23 | 1.42 | 94 | 0.10 | 1.12 |

| (V, Nb)2(Sn, Ni)C | 53 | 140 | 0.29 | 2.07 | 96 | 0.19 | 1.83 | 45 | 0.07 | 1.34 |

| V2(Sn, Mn)C | 56 | 780 | 0.26 | 0.98 | 545 | 0.21 | 0.84 | 206 | 0.07 | 0.63 |

| (V, Nb)2(Sn, Mn)C | 57 | 117 | 0.06 | 0.97 | 75 | 0.04 | 0.90 | 32 | 0.01 | 0.67 |

| [1] |

JEITSCHKO W, NOWOTNY H, BENESOVSKY F. Kohlenstoffhaltige ternäre Verbindungen (H-Phase). Monatshefte für Chemie und verwandte Teile anderer Wissenschaften, 1963, 94(4): 672-676.

DOI URL |

| [2] |

JEITSCHKO W, NOWOTNY H, BENESOVSKY F. Die H-phasen Ti2TlC, Ti2PbC, Nb2InC, Nb2SnC und Ta2GaC. Monatshefte für Chemie und verwandte Teile anderer Wissenschaften, 1964, 95(2): 431-435.

DOI URL |

| [3] |

BARSOUM M W. The MN+1AXN phases: a new class of solids; Thermodynamically stable nanolaminates. Progress in Solid State Chemistry, 2000, 28(1-4): 201-281.

DOI URL |

| [4] |

BARSOUM M W, RADOVIC M. Elastic and mechanical properties of the MAX phases. Annual Review of Materials Research, 2011, 41(1): 195-227.

DOI URL |

| [5] |

SUN Z M. Progress in research and development on MAX phases: a family of layered ternary compounds. International Materials Reviews, 2013, 56(3): 143-166.

DOI URL |

| [6] | RADOVIC M, BARSOUM M W. MAX phases: bridging the gap between metals and ceramics. American Ceramics Society Bulletin, 2013, 92(3): 20-27. |

| [7] |

SHI S, ZHANG L, LI J. Ti3SiC2 material: an application for electromagnetic interference shielding. Applied Physics Letters, 2008, 93(17): 172903.

DOI URL |

| [8] |

NG W H K, GNANAKUMAR E S, BATYREV E, et al. The Ti3AlC2 MAX phase as an efficient catalyst for oxidative dehydrogenation of n-butane. Angewandte Chemie International Edition, 2018, 57(6): 1485-1490.

DOI URL |

| [9] |

ZHAO S, DALL’AGNESE Y, CHU, et al. Electrochemical interaction of Sn-containing MAX phase (Nb2SnC) with Li-ions. ACS Energy Letters, 2019, 4(10): 2452-2457.

DOI URL |

| [10] |

INGASON A S, MOCKUTE A, DAHLQVIST M, et al. Magnetic self-organized atomic laminate from first principles and thin film synthesis. Physical Review Letters, 2013, 110(19): 195502.

DOI URL |

| [11] |

INGASON A S, PETRUHINS A, DAHLQVIST M, et al. A nanolaminated magnetic phase: Mn2GaC. Materials Research Letters, 2013, 2(2): 89-93.

DOI URL |

| [12] |

LIN S, TONG P, WANG B S, et al. Magnetic and electrical/ thermal transport properties of Mn-doped Mn+1AXn phase compounds Cr2-xMnxGaC (0≤x≤1). Journal of Applied Physics, 2013, 113(5): 053502.

DOI URL |

| [13] |

THORE A, DAHLQVIST M, ALLING B, et al. Magnetic exchange interactions and critical temperature of the nanolaminate Mn2GaC from first-principles supercell methods. Physical Review B, 2016, 93(5): 054432.

DOI URL |

| [14] |

INGASON A S, DAHLQVIST M, ROSÉN J. Magnetic MAX phases from theory and experiments; a review. Journal of Physics: Condensed Matter, 2016, 28(43): 433003.

DOI URL |

| [15] |

BEI G, PEDIMONTE B J, FEY T, et al. Oxidation behavior of MAX phase Ti2Al1-xSnxC solid solution. Journal of the American Ceramic Society, 2013, 96(5): 1359-1362.

DOI URL |

| [16] |

NECHICHE M, GAUTHIER-BRUNET V, MAUCHAMP V, et al. Synthesis and characterization of a new (Ti1-ε, Cuε)3(Al, Cu)C2 MAX phase solid solution. Journal of the European Ceramic Society, 2017, 37(2): 459-466.

DOI URL |

| [17] |

ZAPATA-SOLVAS E, HADI M A, HORLAIT D, et al. Synthesis and physical properties of (Zr1-x, Tix)3AlC2 MAX phases. Journal of the American Ceramic Society, 2017, 100(8): 3393-3401.

DOI URL |

| [18] |

QU L, BEI G, STELZER B, et al. Synthesis, crystal structure, microstructure and mechanical properties of (Ti1-xZrx)3SiC2 MAX phase solid solutions. Ceramics International, 2019, 45(1): 1400-1408.

DOI URL |

| [19] |

MENG F L, ZHOU Y C, WANG J Y. Strengthening of Ti2AlC by substituting Ti with V. Scripta Materialia, 2005, 53(12): 1369-1372.

DOI URL |

| [20] |

LI Y, LI M, LU J, et al. Single-atom-thick active layers realized in nanolaminated Ti3(AlxCu1-x)C2 and its artificial enzyme behavior. ACS Nano, 2019, 13(8): 9198-9205.

DOI URL |

| [21] |

HAMM C M, BOCARSLY J D, SEWARD G, et al. Non-conventional synthesis and magnetic properties of MAX phases (Cr/Mn)2AlC and (Cr/Fe)2AlC. Journal of Materials Chemistry C, 2017, 5(23): 5700-5708.

DOI URL |

| [22] |

FATHEEMA J, FATIMA M, MONIR N B, et al. A comprehensive computational and experimental analysis of stable ferromagnetism in layered 2D Nb-doped Ti3C2 MXene. Physica E: Low-dimensional Systems and Nanostructures, 2020, 124: 114253.

DOI URL |

| [23] |

LI Y, LU J, LI M, et al. Multielemental single-atom-thick A layers in nanolaminated V2(Sn, A) C (A = Fe, Co, Ni, Mn) for tailoring magnetic properties. Proceedings of the National Academy of Sciences, 2020, 117(2): 820-825.

DOI URL |

| [24] |

XU Q, ZHOU Y, ZHANG H, et al. Theoretical prediction, synthesis, and crystal structure determination of new MAX phase compound V2SnC. Journal of Advanced Ceramics, 2020, 9(4): 481-492.

DOI URL |

| [25] |

BARSOUM M W, YAROSCHUK G, TYAGI S. Fabrication and characterization of M2SnC (M=Ti, Zr, Hf and Nb). Scripta Materialia, 1997, 37(10): 1583-1591.

DOI URL |

| [26] |

TIAN W B, WANG P L, KAN Y M, et al. Cr2AlC powders prepared by molten salt method. Journal of Alloys and Compounds, 2008, 461(1/2): L5-L10.

DOI URL |

| [27] |

GUO X, WANG J, YANG S, et al. Preparation of Ti3SiC2 powders by the molten. salt method. Materials Letters, 2013, 111: 211-213.

DOI URL |

| [28] |

WANG B, ZHOU A, HU Q, et al. Synthesis and oxidation resistance of V2AlC powders by molten salt method. International Journal of Applied Ceramic Technology, 2017, 14(5): 873-879.

DOI URL |

| [29] |

MANOUN B, SAXENA S K, HUG G, et al. Synthesis and compressibility of Ti3(Al,Sn0.2)C2 and Ti3Al(C0.5,N0.5)2. Journal of Applied Physics, 2007, 101(11): 113523.

DOI URL |

| [30] |

SALIKHOV R, MESHKIAN R, WELLER D, et al. Magnetic properties of nanolaminated (Mo0.5Mn0.5)2GaC MAX phase. Journal of Applied Physics, 2017, 121(16): 163904.

DOI URL |

| [31] |

BEGG B D, VANCE E R, NOWOTNY J. Effect of particle size on the room-temperature crystal structure of barium titanate. Journal of the American Ceramic Society, 1994, 77(12): 3186-3192.

DOI URL |

| [32] |

GRIFFITHS R B. Nonanalytic behavior above the critical point in a random ising ferromagnet. Physical Review Letters, 1969, 23(1): 17-19.

DOI URL |

| [33] |

SHOEMAKER D P, RODRIGUEZ E E, SESHADRI R, et al. Intrinsic exchange bias in ZnxMn3-xO4 (x≤1) solid solutions. Physical Review B, 2009, 80(14): 144422.

DOI URL |

| [34] |

MEHDAOUI B, PENA O, BAHOUT M, et al. Magnetic properties of the spinel system MgxMn3-xO4(0≤x≤2). Boletín de la Sociedad Española de Cerámica y Vidrio, 2008, 47: 143-147.

DOI URL |

| [35] |

UCHINO K, SADANAGA E, HIROSE T, et al. Dependence of the crystal structure on particle size in barium titanate. Journal of the American Ceramic Society, 1989, 72(8): 1555-1558.

DOI URL |

| [36] |

ALI M A, HOSSAIN M M, HOSSAIN M A, et al. Recently synthesized (Zr1-xTix)2AlC (0 ≤x≤ 1) solid solutions: theoretical study of the effects of M mixing on physical properties. Journal of Alloys and Compounds, 2018, 743: 146-154.

DOI URL |

| [37] |

KRONIK L, JAIN M, CHELIKOWSKY J R. Electronic structure and spin polarization of MnxGa1-xN. Physical Review B, 2002, 66(4): 041203.

DOI URL |

| [38] |

KUMAR S, OJHA A K. Room temperature ferromagnetism in undoped and Mn doped t-ZrO2 nanostructures originated due to oxygen vacancy and effect of Mn doping on its optical properties. Materials Chemistry and Physics, 2016, 169: 13-20.

DOI URL |

| [39] |

KUMAR S, LAYEK S, YASHPAL M, et al. Room temperature ferromagnetism in undoped and Mn doped CdO nanostructures. Journal of Magnetism and Magnetic Materials, 2015, 393: 555-561.

DOI URL |

| [40] |

MERINO I L C, FIGUEIREDO L C, PASSAMANI E C, et al. Study of the influence of Nb buffer layer on the exchange coupling induced at the Co/IrMn interface. Journal of Magnetism and Magnetic Materials, 2017, 432: 494-500.

DOI URL |

| [41] |

DOSPIAL M, PLUSA D, ŚLUSAREK B. Study of the magnetic interaction in nanocrystalline Pr-Fe-Co-Nb-B permanent magnets. Journal of Magnetism and Magnetic Materials, 2012, 324(5): 843-848.

DOI URL |

| [42] |

STAMOPOULOS D, ARISTOMENOPOULOU E, LAGOGIANNIS A. Co/Nb/Co trilayers as efficient cryogenic spin valves and supercurrent switches: the relevance to the standard giant and tunnel magnetoresistance effects. Superconductor Science and Technology, 2014, 27(9): 095008.

DOI URL |

| [1] | 李建军, 陈芳明, 张梨梨, 王磊, 张丽亭, 陈慧雯, 薛长国, 徐良骥. CoFe2O4/MgAl-LDH催化剂活化过氧一硫酸盐促进抗生素降解[J]. 无机材料学报, 2025, 40(4): 440-448. |

| [2] | 王悦, 王欣, 于显利. 室温铁磁性还原氧化石墨烯基全碳膜[J]. 无机材料学报, 2025, 40(3): 305-313. |

| [3] | 黄洁, 汪刘应, 王滨, 刘顾, 王伟超, 葛超群. 基于微纳结构设计的电磁性能调控研究进展[J]. 无机材料学报, 2024, 39(8): 853-870. |

| [4] | 蔡和庆, 韩璐, 杨松松, 薛新玉, 张扣, 孙志成, 刘儒平, 胡堃, 危岩. 小粒径Fe3O4-DMSA-PEI磁性纳米颗粒的制备及其基因负载能力研究[J]. 无机材料学报, 2024, 39(5): 517-524. |

| [5] | 张宇晨, 陆知遥, 赫晓东, 宋广平, 朱春城, 郑永挺, 柏跃磊. 硫族MAX相硼化物的物相稳定性和性能预测[J]. 无机材料学报, 2024, 39(2): 225-232. |

| [6] | 刘艳艳, 谢曦, 刘增乾, 张哲峰. MAX相陶瓷增强金属基复合材料: 制备、性能与仿生设计[J]. 无机材料学报, 2024, 39(2): 145-152. |

| [7] | 丁浩明, 李勉, 李友兵, 陈科, 肖昱琨, 周洁, 陶泉争, 尹航, 柏跃磊, 张毕堃, 孙志梅, 王俊杰, 张一鸣, 黄振莺, 张培根, 孙正明, 韩美康, 赵双, 王晨旭, 黄庆. 三元层状材料结构调控及性能研究进展[J]. 无机材料学报, 2023, 38(8): 845-884. |

| [8] | 王磊, 李建军, 宁军, 胡天玉, 王洪阳, 张占群, 武琳馨. CoFe2O4@Zeolite催化剂活化过一硫酸盐对甲基橙的强化降解: 性能与机理[J]. 无机材料学报, 2023, 38(4): 469-476. |

| [9] | 丁健翔, 张凯歌, 柳东明, 郑伟, 张培根, 孙正明. Ti3AlC2陶瓷及其衍生物Ti3C2Tx增强的Ag基电接触材料[J]. 无机材料学报, 2022, 37(5): 567-573. |

| [10] | 胡靖三, 顾建飞, 章维益. 晶场劈裂序参量导致稀土-硼十二化合物中磁性和比热反常的理论研究[J]. 无机材料学报, 2021, 36(8): 865-870. |

| [11] | 李友兵, 秦彦卿, 陈科, 陈露, 张霄, 丁浩明, 李勉, 张一鸣, 都时禹, 柴之芳, 黄庆. 熔盐法合成纳米层状Sc2SnC MAX相[J]. 无机材料学报, 2021, 36(7): 773-778. |

| [12] | 朱正旺,冯锐,柳扬,张扬,谢文翰,董丽杰. 类鱼骨结构CoFe2O4纳米纤维的制备与性能[J]. 无机材料学报, 2020, 35(9): 1011-1016. |

| [13] | 李淑芳,赵爽,周潇,李满荣. Zn3-xMnxTeO6的晶体结构与吸收光谱和磁性研究[J]. 无机材料学报, 2020, 35(8): 895-901. |

| [14] | 赵占奎, 李涛, 鲁书含, 王明罡, 张京京, 程道文, 吴臣, 迟悦, 王虹力. SPS界面反应增强机制调控的软磁复合材料磁性能和电阻率[J]. 无机材料学报, 2020, 35(11): 1223-1226. |

| [15] | 陈雷雷, 邓子旋, 李勉, 李朋, 常可可, 黄峰, 都时禹, 黄庆. 新型MAX相的相图热力学研究[J]. 无机材料学报, 2020, 35(1): 35-40. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||