无机材料学报 ›› 2021, Vol. 36 ›› Issue (7): 773-778.DOI: 10.15541/jim20200529 CSTR: 32189.14.10.15541/jim20200529

所属专题: MXene材料专辑(2020~2021); 【虚拟专辑】层状MAX,MXene及其他二维材料

李友兵1,2( ), 秦彦卿1,2, 陈科1,2, 陈露1,2, 张霄1,2, 丁浩明1,2, 李勉1,2, 张一鸣1,2, 都时禹1,2, 柴之芳1,2, 黄庆1,2(

), 秦彦卿1,2, 陈科1,2, 陈露1,2, 张霄1,2, 丁浩明1,2, 李勉1,2, 张一鸣1,2, 都时禹1,2, 柴之芳1,2, 黄庆1,2( )

)

收稿日期:2020-09-09

修回日期:2020-10-22

出版日期:2021-07-20

网络出版日期:2020-11-05

通讯作者:

黄庆, 研究员. E-mail:huangqing@nimte.ac.cn

作者简介:李友兵(1990-), 男, 博士. E-mail:liyoubing@nimte.ac.cn

LI Youbing1,2( ), QIN Yanqing1,2, CHEN Ke1,2, CHEN Lu1,2, ZHANG Xiao1,2, DING Haoming1,2, LI Mian1,2, ZHANG Yiming1,2, DU Shiyu1,2, CHAI Zhifang1,2, HUANG Qing1,2(

), QIN Yanqing1,2, CHEN Ke1,2, CHEN Lu1,2, ZHANG Xiao1,2, DING Haoming1,2, LI Mian1,2, ZHANG Yiming1,2, DU Shiyu1,2, CHAI Zhifang1,2, HUANG Qing1,2( )

)

Received:2020-09-09

Revised:2020-10-22

Published:2021-07-20

Online:2020-11-05

Contact:

HUANG Qing, Professor. E-mail:huangqing@nimte.ac.cn

About author:LI Youbing(1990-), male, PhD. E-mail:liyoubing@nimte.ac.cn

Supported by:摘要:

MAX相是一类兼具金属和陶瓷特性的三元层状材料, 也是合成二维MXenes的前驱体材料。理论预测稳定的三元层状MAX相材料约有600余种, 目前实验合成的三元层状MAX相材料已有80余种, 但M位主要为前过渡族金属, 而对M为稀土元素的三元MAX相鲜有报道。本研究以Sc、Sn, 和C元素粉为原料, 通过熔盐法合成了M位为稀土元素Sc的全新Sc2SnC MAX相材料。结合X射线衍射、扫描电子显微镜和X射线能谱等分析手段, 确认Sc2SnC MAX的相组成和微观结构。并通过密度泛函理论计算了Sc2SnC MAX相的结构稳定性、晶格参数、力学和电子性质, 理论计算结果表明Sc2SnC热力学稳定, Sc-3d电子在费米能级上占主导地位, MAX相呈金属性质。

中图分类号:

李友兵, 秦彦卿, 陈科, 陈露, 张霄, 丁浩明, 李勉, 张一鸣, 都时禹, 柴之芳, 黄庆. 熔盐法合成纳米层状Sc2SnC MAX相[J]. 无机材料学报, 2021, 36(7): 773-778.

LI Youbing, QIN Yanqing, CHEN Ke, CHEN Lu, ZHANG Xiao, DING Haoming, LI Mian, ZHANG Yiming, DU Shiyu, CHAI Zhifang, HUANG Qing. Molten Salt Synthesis of Nanolaminated Sc2SnC MAX Phase[J]. Journal of Inorganic Materials, 2021, 36(7): 773-778.

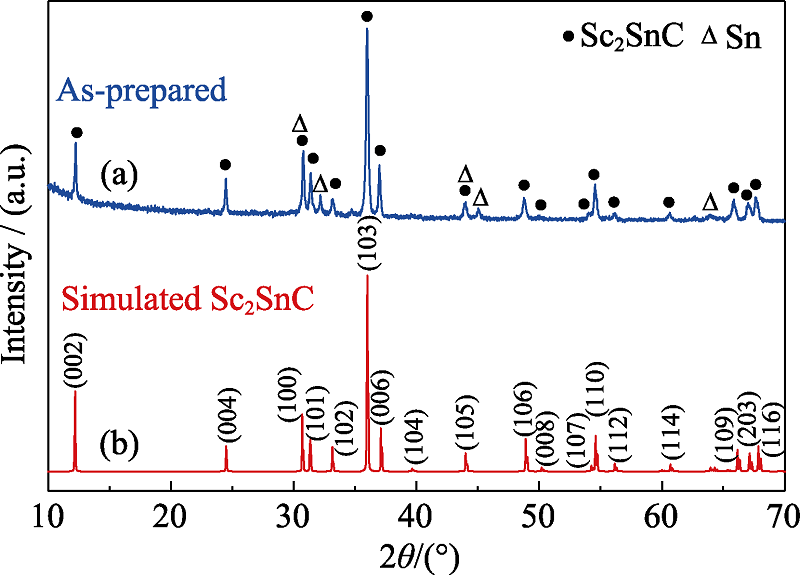

Fig. 1 Comparison of XRD patterns between (a) powders synthesized through the reaction between Sc, Sn, and C mixtures, and (b) the simulated one of Sc2SnC

| Site | Element | x | y | z | Symmetry | Wyckoff symbol |

|---|---|---|---|---|---|---|

| M | Sc | 1/3 | 2/3 | 0.5786 | 3m | 4f |

| A | Sn | 1/3 | 2/3 | 0.2500 | m2 | 2d |

| X | C | 0 | 0 | 0 | m | 2a |

Table 1 Atomic positions in Sc2SnC determined from the Rietveld refinement

| Site | Element | x | y | z | Symmetry | Wyckoff symbol |

|---|---|---|---|---|---|---|

| M | Sc | 1/3 | 2/3 | 0.5786 | 3m | 4f |

| A | Sn | 1/3 | 2/3 | 0.2500 | m2 | 2d |

| X | C | 0 | 0 | 0 | m | 2a |

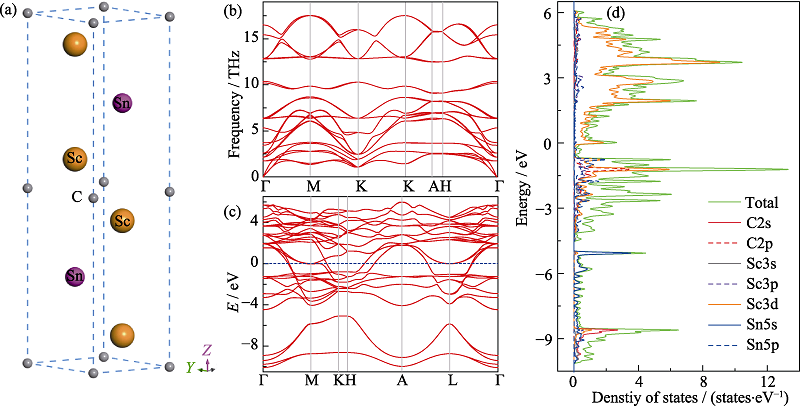

Fig. 4 (a) Crystal structure , (b) calculated phonon dispersion and (c) band structure of Sc2SnC, and (d) projected density of Sc, Sn, and C atom states in the Sc2SnC

| Compound | a/nm | c/nm | C11 | C12 | C13 | C33 | C44 | C66 | B | G | E | G/B | v | Ref. |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Sc2SnC | 0.3368 | 1.4653 | 197 | 63 | 47 | 182 | 67 | 53 | 100 | 63 | 157 | 0.630 | 0.238 | This work |

| V2SnC | 0.3134 | 1.2943 | 336 | 126 | 122 | 304 | 85 | 105 | 190 | 95 | 244 | 0.500 | 0.286 | [35] |

| Ti2SnC | 0.3136 | 1.3641 | 337 | 86 | 102 | 329 | 169 | 126 | 176 | 138 | 328 | 0.784 | 0.188 | [39] |

| Zr2SnC | 0.3352 | 1.4681 | 269 | 80 | 107 | 290 | 148 | 94 | 157 | 110 | 368 | 0.700 | 0.215 | [39] |

| Hf2SnC | 0.3308 | 1.4450 | 330 | 54 | 126 | 292 | 167 | 138 | 173 | 132 | 316 | 0.763 | 0.195 | [39] |

| Nb2SnC | 0.3244 | 1.3754 | 341 | 106 | 169 | 321 | 183 | 118 | 209 | 126 | 314 | 0.603 | 0.250 | [39] |

Table 2 Theoretically predicted Lattice parameters (nm), calculated elastic constants, Cij (GPa), bulk modulus, B (GPa), shear modulus, G (GPa), and Young’s modulus, E (GPa), Pugh ratio, G/B, and Poisson ratio, v, of different compounds

| Compound | a/nm | c/nm | C11 | C12 | C13 | C33 | C44 | C66 | B | G | E | G/B | v | Ref. |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Sc2SnC | 0.3368 | 1.4653 | 197 | 63 | 47 | 182 | 67 | 53 | 100 | 63 | 157 | 0.630 | 0.238 | This work |

| V2SnC | 0.3134 | 1.2943 | 336 | 126 | 122 | 304 | 85 | 105 | 190 | 95 | 244 | 0.500 | 0.286 | [35] |

| Ti2SnC | 0.3136 | 1.3641 | 337 | 86 | 102 | 329 | 169 | 126 | 176 | 138 | 328 | 0.784 | 0.188 | [39] |

| Zr2SnC | 0.3352 | 1.4681 | 269 | 80 | 107 | 290 | 148 | 94 | 157 | 110 | 368 | 0.700 | 0.215 | [39] |

| Hf2SnC | 0.3308 | 1.4450 | 330 | 54 | 126 | 292 | 167 | 138 | 173 | 132 | 316 | 0.763 | 0.195 | [39] |

| Nb2SnC | 0.3244 | 1.3754 | 341 | 106 | 169 | 321 | 183 | 118 | 209 | 126 | 314 | 0.603 | 0.250 | [39] |

| [1] |

BARSOUM M W. The MN+1AXN phases: a new class of solids; thermodynamically stable nanolaminates. Progress in Solid State Chemistry, 2000,28(1):201-281.

DOI URL |

| [2] |

SOKOL M, NATU V, KOTA S, et al. On the chemical diversity of the MAX phases. Trends in Chemistry, 2009,1(2):210-223.

DOI URL |

| [3] |

EKLUND P, BECKERS M, JANSSON U, et al. The Mn+1AXn phases: materials science and thin-film processing. Thin Solid Films, 2010,518(8):1851-1878.

DOI URL |

| [4] |

WHITTLE K R, BLACKFORD M, AUGHTERSON M R, et al. Radiation tolerance of Mn+1AXn phases, Ti3AlC2 and Ti3SiC2. Acta Materialia, 2010,58(13):4362-4368.

DOI URL |

| [5] |

FASHANDI H, DAHLQVIST M, LU J, et al. Synthesis of Ti3AuC2, Ti3Au2C2 and Ti3IrC2 by noble metal substitution reaction in Ti3SiC2 for high-temperature-stable Ohmic contacts to SiC. Nature Materials, 2017,16(8):814-818.

DOI URL |

| [6] | WARD J, BOWDEN D, PRESTAT E, et al. Corrosion performance of Ti3SiC2, Ti3AlC2, Ti2AlC and Cr2AlC MAX phases in simulated primary water conditions. Corrosion Science, 2018,39:444-453. |

| [7] |

ZHU Y, ZHOU A, JI Y, et al. Tribological properties of Ti3SiC2 coupled with different counterfaces. Ceramics International, 2012,41(5):6950-6955.

DOI URL |

| [8] |

NAGUIB M, KURTOGLU M, PRESSER V, et al. Two-dimensional nanocrystals produced by exfoliation of Ti3AlC2. Advanced Materials, 2011,23(37):4248-4253.

DOI URL |

| [9] |

LUKATSKAYA M R, MASHTALIR O, REN C E, et al. Cation intercalation and high volumetric capacitance of two-dimensional titanium carbide. Science, 2013,341(6153):1502-1505.

DOI URL |

| [10] |

ANASORI B, LUKATSKAYA M R, GOGOTSI Y. 2D metal carbides and nitrides (MXenes) for energy storage. Nature Reviews Materials, 2017,2(2):16098.

DOI URL |

| [11] |

LI Y B, SHAO H, LIN Z F, et al. A general Lewis acidic etching route for preparing MXenes with enhanced electrochemical performance in non-aqueous electrolyte. Nature Materials, 2020,19(8):894-899.

DOI URL |

| [12] |

NECHICHE M, GAUTHIER-BRUNET V, MAUCHAMP V, et al. Synthesis and characterization of a new (Ti1-ε,Cuε)3(Al,Cu)C2 MAX phase solid solution. Journal of the European Ceramic Society, 2019,37(2):459-466.

DOI URL |

| [13] |

LI M, LU J, LUO K, et al. Element replacement approach by reaction with Lewis acidic molten salts to synthesize nanolaminated MAX phases and MXenes. Journal of the American Chemical Society, 2019,141(11):4730-4737.

DOI URL |

| [14] |

LI Y, LI M, LU J, et al. Single-atom-thick active layers realized in nanolaminated Ti3(AlxCu1-x)C2 and its artificial enzyme behavior. ACS Nano, 2019,13(8):9198-9205.

DOI URL |

| [15] |

DING H, LI Y B, LU J, et al. Synthesis of MAX phases Nb2CuC and Ti2(Al0.1Cu0.9)N by A-site replacement reaction in molten salts. Materials Research Letters, 2019,7(12):510-516.

DOI URL |

| [16] | LI Y B, LU J, LI M, et al. Multielemental single-atom-thick A layers in nanolaminated V2(Sn,A)C (A=Fe, Co, Ni, Mn) for tailoring magnetic properties. Proceedings of the National Academy of Sciences of the United States of America, 2020,117(2):820-825. |

| [17] |

ARYAL S, SAKIDJA R, BARSOUM M W, et al. A genomic approach to the stability, elastic, and electronic properties of the MAX phases. Physical Status Solidi, 2014,251(8):1480-1497.

DOI URL |

| [18] |

BOUHEMADOU A, KHENATA R, KHAROUBI M, et al. First-principles study of structural and elastic properties of Sc2AC (A=Al, Ga, In, Tl). Solid State Communications, 2008,146(3/4):175-180.

DOI URL |

| [19] |

COVER M F, WARSCHKOW O, BILEK M M, et al. A comprehensive survey of MAX phase elastic properties. Journal of Physics: Condensed Matter, 2009,21(30):305403.

DOI URL |

| [20] |

CHOWDHURY A, ALI M A, HOSSAIN M M, et al. Predicted MAX phase Sc2InC: dynamical stability, vibrational and optical properties. Physical Status Solidi, 2018,255(3):1700235.

DOI URL |

| [21] |

ZHA X H, REN J C, FENG L, et al. Bipolar magnetic semiconductors among intermediate states during the conversion from Sc2C(OH)2 to Sc2CO2 MXene. Nanoscale, 2018,10(18):8763-8771.

DOI URL |

| [22] |

KUCHIDA S, MURANAKA T, KAWASHIMA K, et al. Superconductivity in Lu2SnC. Physica C: Superconductivity, 2013,494:77-79.

DOI URL |

| [23] |

LIU X, FECHLER N, ANTONIETTI M. Salt melt synthesis of ceramics, semiconductors and carbon nanostructures. Chemical Society Reviews, 2013,42(21):8237-8265.

DOI URL |

| [24] |

WANG B, ZHOU A, HU Q, et al. Synthesis and oxidation resistance of V2AlC powders by molten salt method. International Journal of Applied Ceramic Technology, 2017,14(5):873-879.

DOI URL |

| [25] |

TIAN W B, WANG P L, KAN Y M, et al. Cr2AlC powders prepared by molten salt method. Journal of Alloys and Compounds, 2008,461(1/2):L5-L10.

DOI URL |

| [26] |

GALVIN T, HYATT N C, RAINFORTH W M, et al. Molten salt synthesis of MAX phases in the Ti-Al-C system. Journal of the European Ceramic Society, 2018,38(14):4585-4589.

DOI URL |

| [27] |

GUO X, WANG J, YANG S, et al. Preparation of Ti3SiC2 powders by the molten salt method. Materials Letters, 2013,111:211-213.

DOI URL |

| [28] |

ROY C, BANERJEE P, BHATTACHARYYAh S. Molten salt shielded synthesis (MS3) of Ti2AlN and V2AlC MAX phase powders in open air. Journal of the European Ceramic Society, 2020,40(3):923-929.

DOI URL |

| [29] |

CLARK S J, SEGALL M D, PICKARD C J, et al. First principles methods using CASTEP. Zeitschrift für Kristallographie-Crystalline Materials, 2005,220:567-570.

DOI URL |

| [30] |

SEGALL M, LINDAN P J, PROBERT M J, et al. First-principles simulation: ideas, illustrations and the CASTEP code. Journal of Physics: Condensed Matter, 2002,14:2717-2744.

DOI URL |

| [31] |

PERDEW J P, BURKE K, ERMZERHOF M. Generalized gradient approximation made simple. Physical Review Letters, 1996,77(18):3865-3868.

DOI URL |

| [32] |

VANDERBILT D. Soft self-consistent pseudopotentials in a generalized eigenvalue formalism. Physical Review B, 1990,41(11):7892-7895.

DOI URL |

| [33] |

FRANK W, ELSASSER C, FAHNLE M. Ab initio force-constant method for phonon dispersions in alkali metals. Physical Review Letters, 1995,74(10):1791-1794.

DOI URL |

| [34] |

PARLINSKI K, LI Z Q, KAWAZOE Y. First-principles determination of the soft mode in cubic ZrO2. Physical Review Letters, 1997,78(21):4063-4066.

DOI URL |

| [35] | XU Q, ZHOU Y, ZHANG H, et al. Theoretical prediction, synthesis, and crystal structure determination of new MAX phase compound V2SnC. Journal of Advanced Ceramics, 2020,29(4):481-492. |

| [36] | BORN M, MISRA R D. On the stability of crystal lattices. Mathematical Proceedings of the Cambridge Philosophical Society, 1940,36(4):466-478. |

| [37] |

KOC H, OZISIK H, DELIGOZ E, et al. Mechanical, electronic, and optical properties of Bi2S3 and Bi2Se3 compounds: first principle investigations. Journal of Molecular Modeling, 2014,20(4):2180.

DOI URL |

| [38] |

PUGH S F. Relations between the elastic moduli and the plastic properties of polycrystalline pure metals. The London, Edinburgh, and Dublin Philosophical Magazine and Journal of Science. 1954,45(367):823-843

DOI URL |

| [39] |

KANOUN M B, GOUMRI-SAID S, RESHAK A H. Theoretical study of mechanical, electronic, chemical bonding and optical properties of Ti2SnC, Zr2SnC, Hf2SnC and Nb2SnC. Computational Materials Science, 2009,47(2):491-500.

DOI URL |

| [1] | 刘艳艳, 谢曦, 刘增乾, 张哲峰. MAX相陶瓷增强金属基复合材料: 制备、性能与仿生设计[J]. 无机材料学报, 2024, 39(2): 145-152. |

| [2] | 张宇晨, 陆知遥, 赫晓东, 宋广平, 朱春城, 郑永挺, 柏跃磊. 硫族MAX相硼化物的物相稳定性和性能预测[J]. 无机材料学报, 2024, 39(2): 225-232. |

| [3] | 丁浩明, 李勉, 李友兵, 陈科, 肖昱琨, 周洁, 陶泉争, 尹航, 柏跃磊, 张毕堃, 孙志梅, 王俊杰, 张一鸣, 黄振莺, 张培根, 孙正明, 韩美康, 赵双, 王晨旭, 黄庆. 三元层状材料结构调控及性能研究进展[J]. 无机材料学报, 2023, 38(8): 845-884. |

| [4] | 丁健翔, 张凯歌, 柳东明, 郑伟, 张培根, 孙正明. Ti3AlC2陶瓷及其衍生物Ti3C2Tx增强的Ag基电接触材料[J]. 无机材料学报, 2022, 37(5): 567-573. |

| [5] | 张霄, 李友兵, 陈科, 丁浩明, 陈露, 李勉, 史蓉蓉, 柴之芳, 黄庆. M位与A位双固溶MAX相的磁学性能研究[J]. 无机材料学报, 2021, 36(12): 1247-1255. |

| [6] | 李勉, 黄庆. 三元层状碳氮化合物(MAX相)及其衍生二维纳米材料(MXene)研究趋势与展望[J]. 无机材料学报, 2020, 35(1): 1-7. |

| [7] | 党潇琳, 范晓孟, 殷小玮, 马昱昭, 马晓康. 多功能一体化MAX相改性连续纤维增韧陶瓷基复合材料的研究进展[J]. 无机材料学报, 2020, 35(1): 29-34. |

| [8] | 金森, 王作通, 杜亚琼, 胡前库, 禹建功, 周爱国. 双A层MAX相Mo2Ga2C的热压烧结研究[J]. 无机材料学报, 2020, 35(1): 41-45. |

| [9] | 陈雷雷, 邓子旋, 李勉, 李朋, 常可可, 黄峰, 都时禹, 黄庆. 新型MAX相的相图热力学研究[J]. 无机材料学报, 2020, 35(1): 35-40. |

| [10] | 李勉, 李友兵, 罗侃, LU Jun, EKLUND Per, PERSSON Per, ROSEN Johanna, HULTMAN Lars, 都时禹, 黄政仁, 黄庆. 基于A位元素置换策略合成新型MAX相材料Ti3ZnC2[J]. 无机材料学报, 2019, 34(1): 60-64. |

| [11] | 张志萍, 刘红飞, 潘坤旻, 陈小兵, 曾祥华. Sc2W3O12薄膜制备及其负热膨胀性能[J]. 无机材料学报, 2015, 30(12): 1278-1282. |

| [12] | 梅兴志, 罗永春, 张国庆, 康 龙. 稀土系A2B7型La1-xScxNi2.6Co0.3Mn0.5Al0.1(x = 0~0.5)储氢合金相结构和电化学性能研究[J]. 无机材料学报, 2015, 30(10): 1049-1055. |

| [13] | 崔云涛, 王金淑, 刘 伟, 王 茜, 王凯风 . 含钪扩散阴极用铝酸盐的制备及发射性能研究[J]. 无机材料学报, 2012, 27(5): 480-484. |

| [14] | 冯 涛,蔡 虹,漆云凤,蒋丹宇,周 军,楼祺洪,施剑林. Nd:Y3Sc1.5Al3.5O12透明陶瓷的光谱性能以及激光输出[J]. 无机材料学报, 2008, 23(5): 1041-1044. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||