无机材料学报 ›› 2023, Vol. 38 ›› Issue (8): 845-884.DOI: 10.15541/jim20230123 CSTR: 32189.14.10.15541/jim20230123

所属专题: 【材料计算】材料模拟计算(202506); 【信息功能】MAX、MXene及其他二维材料(202506); 【结构材料】核用陶瓷(202506)

• 特邀综述 • 下一篇

丁浩明1,2,3( ), 李勉1,3, 李友兵1,3, 陈科1,3, 肖昱琨1,3, 周洁4, 陶泉争4, 尹航5, 柏跃磊5, 张毕堃6, 孙志梅6, 王俊杰7, 张一鸣1,3, 黄振莺8, 张培根9, 孙正明9, 韩美康10, 赵双11, 王晨旭11, 黄庆1,3(

), 李勉1,3, 李友兵1,3, 陈科1,3, 肖昱琨1,3, 周洁4, 陶泉争4, 尹航5, 柏跃磊5, 张毕堃6, 孙志梅6, 王俊杰7, 张一鸣1,3, 黄振莺8, 张培根9, 孙正明9, 韩美康10, 赵双11, 王晨旭11, 黄庆1,3( )

)

收稿日期:2023-03-09

修回日期:2023-04-19

出版日期:2023-08-20

网络出版日期:2023-05-04

通讯作者:

黄 庆, 研究员. E-mail: huangqing@nimte.ac.cn作者简介:丁浩明(1994-), 男, 博士研究生. E-mail: dinghaoming@nimte.ac.cn

基金资助:

DING Haoming1,2,3( ), LI Mian1,3, LI Youbing1,3, CHEN Ke1,3, XIAO Yukun1,3, ZHOU Jie4, TAO Quanzheng4, Johanna Rosen4, YIN Hang5, BAI Yuelei5, ZHANG Bikun6, SUN Zhimei6, WANG Junjie7, ZHANG Yiming1,3, HUANG Zhenying8, ZHANG Peigen9, SUN Zhengming9, HAN Meikang10, ZHAO Shuang11, WANG Chenxu11, HUANG Qing1,3(

), LI Mian1,3, LI Youbing1,3, CHEN Ke1,3, XIAO Yukun1,3, ZHOU Jie4, TAO Quanzheng4, Johanna Rosen4, YIN Hang5, BAI Yuelei5, ZHANG Bikun6, SUN Zhimei6, WANG Junjie7, ZHANG Yiming1,3, HUANG Zhenying8, ZHANG Peigen9, SUN Zhengming9, HAN Meikang10, ZHAO Shuang11, WANG Chenxu11, HUANG Qing1,3( )

)

Received:2023-03-09

Revised:2023-04-19

Published:2023-08-20

Online:2023-05-04

Contact:

HUANG Qing, professor. E-mail: huangqing@nimte.ac.cnAbout author:DING Haoming (1994-), male, PhD candidate. E-mail: dinghaoming@nimte.ac.cn

Supported by:摘要:

MAX/MAB相是一类非范德华三元层状材料, 具有丰富的元素组成和晶体结构, 兼具陶瓷和金属的物理性质, 在高温、强腐蚀、辐照等极端环境中极具应用潜力。近年来, 由MAX/MAB相衍生的二维(2D)材料(MXene和MBene)在材料物理与材料化学领域引起了广泛兴趣, 已经成为继石墨烯和过渡金属硫族化合物之后最受关注的二维范德华材料。MAX/MAB相材料结构调控不仅对这类非范德华层状材料本征性能产生重要影响, 而且对其衍生的二维范德华材料结构功能特性研究也具有重要价值。本文归纳和总结了MAX/MAB相层状材料在结构调控、理论计算和应用基础研究等方向的最新科研进展, 并展望了该类层状材料未来发展方向。

中图分类号:

丁浩明, 李勉, 李友兵, 陈科, 肖昱琨, 周洁, 陶泉争, 尹航, 柏跃磊, 张毕堃, 孙志梅, 王俊杰, 张一鸣, 黄振莺, 张培根, 孙正明, 韩美康, 赵双, 王晨旭, 黄庆. 三元层状材料结构调控及性能研究进展[J]. 无机材料学报, 2023, 38(8): 845-884.

DING Haoming, LI Mian, LI Youbing, CHEN Ke, XIAO Yukun, ZHOU Jie, TAO Quanzheng, Johanna Rosen, YIN Hang, BAI Yuelei, ZHANG Bikun, SUN Zhimei, WANG Junjie, ZHANG Yiming, HUANG Zhenying, ZHANG Peigen, SUN Zhengming, HAN Meikang, ZHAO Shuang, WANG Chenxu, HUANG Qing. Progress in Structural Tailoring and Properties of Ternary Layered Ceramics[J]. Journal of Inorganic Materials, 2023, 38(8): 845-884.

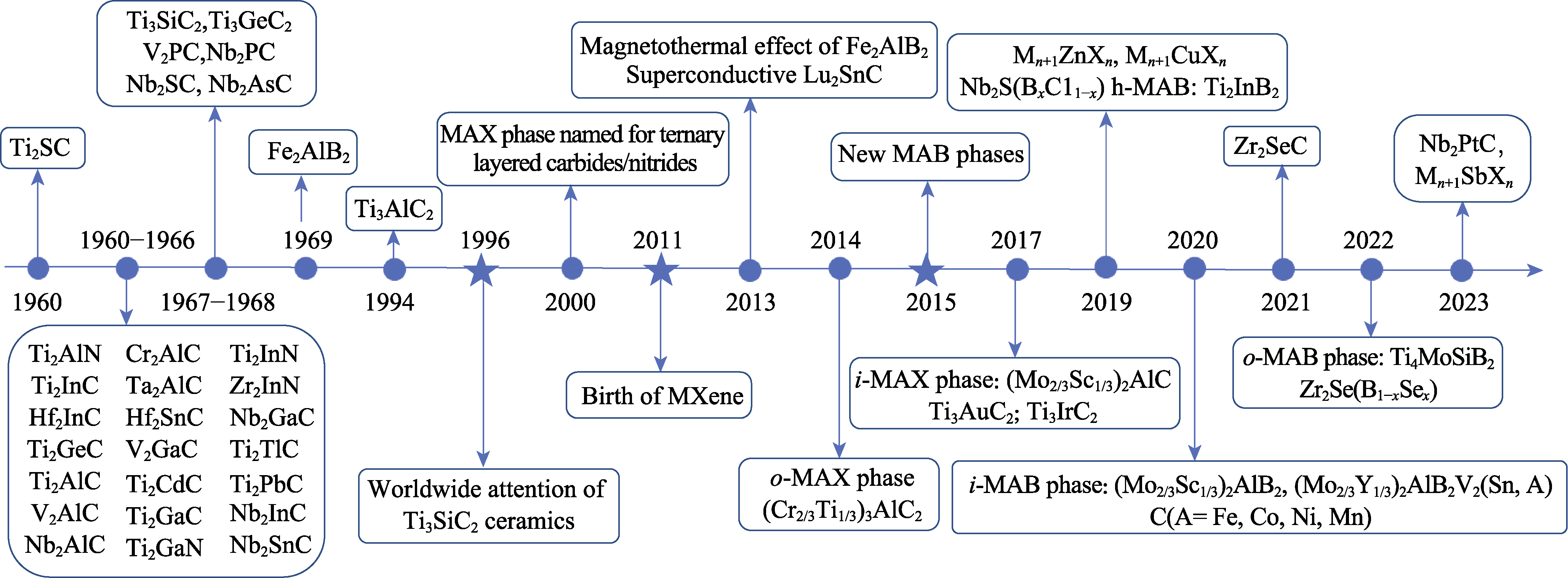

图1 三元层状材料的发现时间轴(非完全统计)

Fig. 1 Non-exhaustive chronicle of ternary layered materials In 1960, Ti2SC was synthesized[40]; From 1960 to 1966, a large number of ternary layered carbides/nitrides (H-phases) with an M2AX formula (211 type) were synthesized[41-42]; From 1967 to 1968, Ti3SiC2 (312 type) and a set of 312 and 211 types H-phases were produced[41,43-44]; In 1969, a typical ternary layered boride Fe2AlB2 was synthesized[7]; In 1994, Ti3AlC2 was discovered[45]; In 1996, the high purity Ti3SiC2 was produced and exhibited excellent properties, thus triggering the research upsurge to these materials[46]; In 2000, Barsoum[1] renamed H-phases as Mn+1AXn phases, short for MAX phases; In 2011, the first MXene Ti3C2Tx was discovered[28]; In 2013, the discovery of magnetocaloric effect of Fe2AlB2 raised research upsurge on ternary layered borides[9]. Also, Lu2SnC was synthesized and found to be superconducting[47]; In 2014, an o-MAX (Cr2/3Ti1/3)3AlC2 was synthesized[48]; In 2015, ternary layered borides were named as MAB phases. In addition, the first Zr-based MAX phase was discovered[10,49]; In 2017, an i-MAX (Mo2/3Sc1/3)2AlC and two noble-metal MAX phases Ti3AuC2 and Ti3IrC2 were synthesized[22,50]; In 2019, a series of MAX phases containing Cu and Zn, and a hexagonal MAB phase Ti2InB2, as well as Nb2SBxC1-x (x=0-1) were synthesized[24⇓-26,51,52]; In 2020, two i-MAB phases (Mo2/3Sc1/3)2AlB2 and (Mo2/3Y1/3)2AlB2, as well as a variety of MAX phases containing Fe, Co, Ni, and Mn were synthesized[16,19]; In 2021, MAX phases having Se atoms at the A-site were produced[53]; In 2022, o-MAX phase Ti4MoSiB2, the first MBene, and Zr2Se(B1-xSex) were synthesized[20,54-55]; In 2023, a chemical scissor-mediated structural editing strategy was proposed, which extremely expands the diversity of MAX phases and MXene[56]

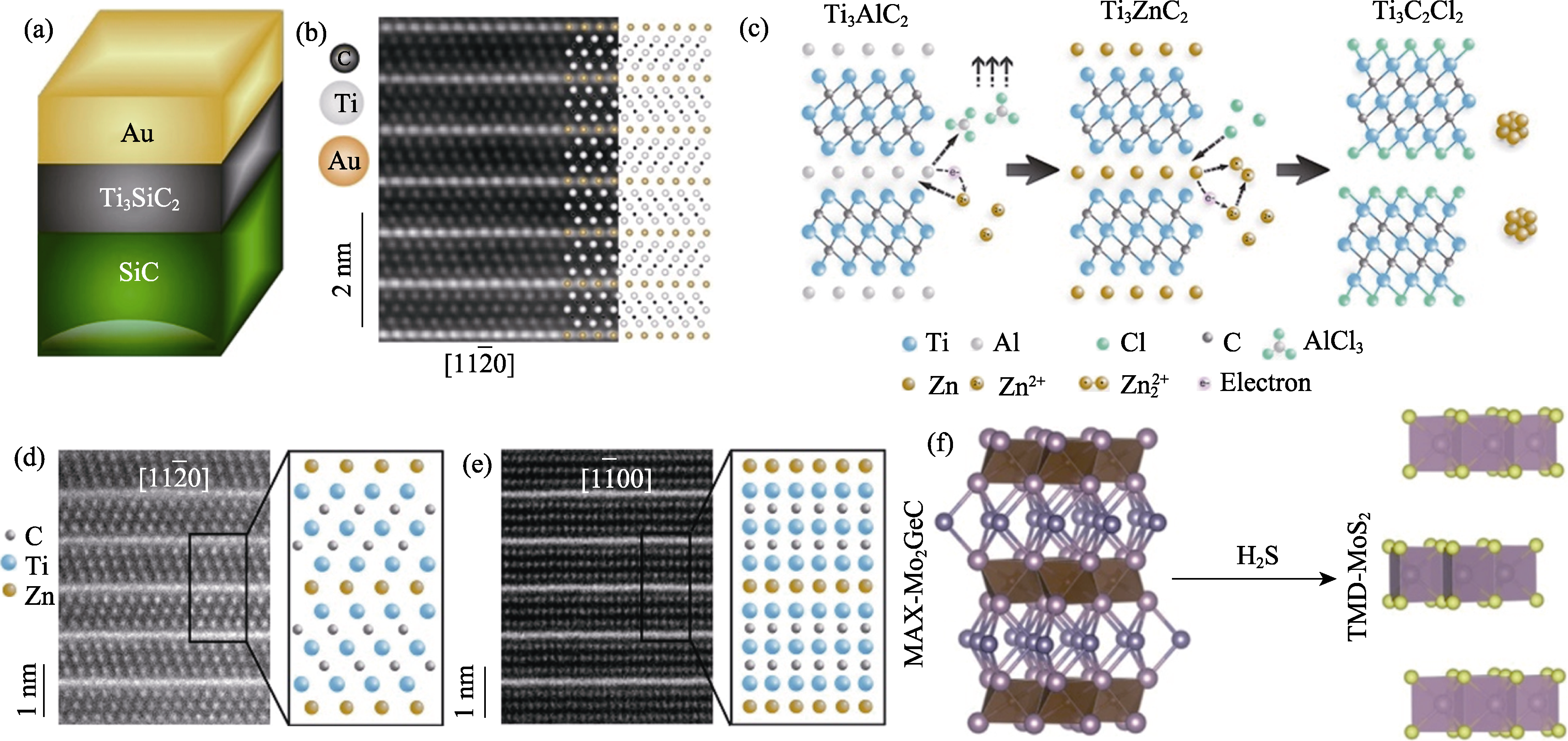

图2 MAX相的元素及结构调控

Fig. 2 Atomic and structural regulation of MAX phases (a) Schematic illustration of Ti3SiC2 film covered by Au film on the SiC substrate[22]; (b) STEM image of Ti3SiC2 and its corresponding atomic model[22]; (c) Schematic illustration of preparing novel MAX phases and MXene based on a Lewis-acidic-molten-salt route[24]; (d) STEM image of Ti3ZnC2 and its corresponding atomic model[24]; (e) STEM image of Ti3C2Cl2 and its corresponding atomic model[24]; (f) Schematic illustration of the conversion from non-van der Waals solids to 2D transition-metal chalcogenides[57]

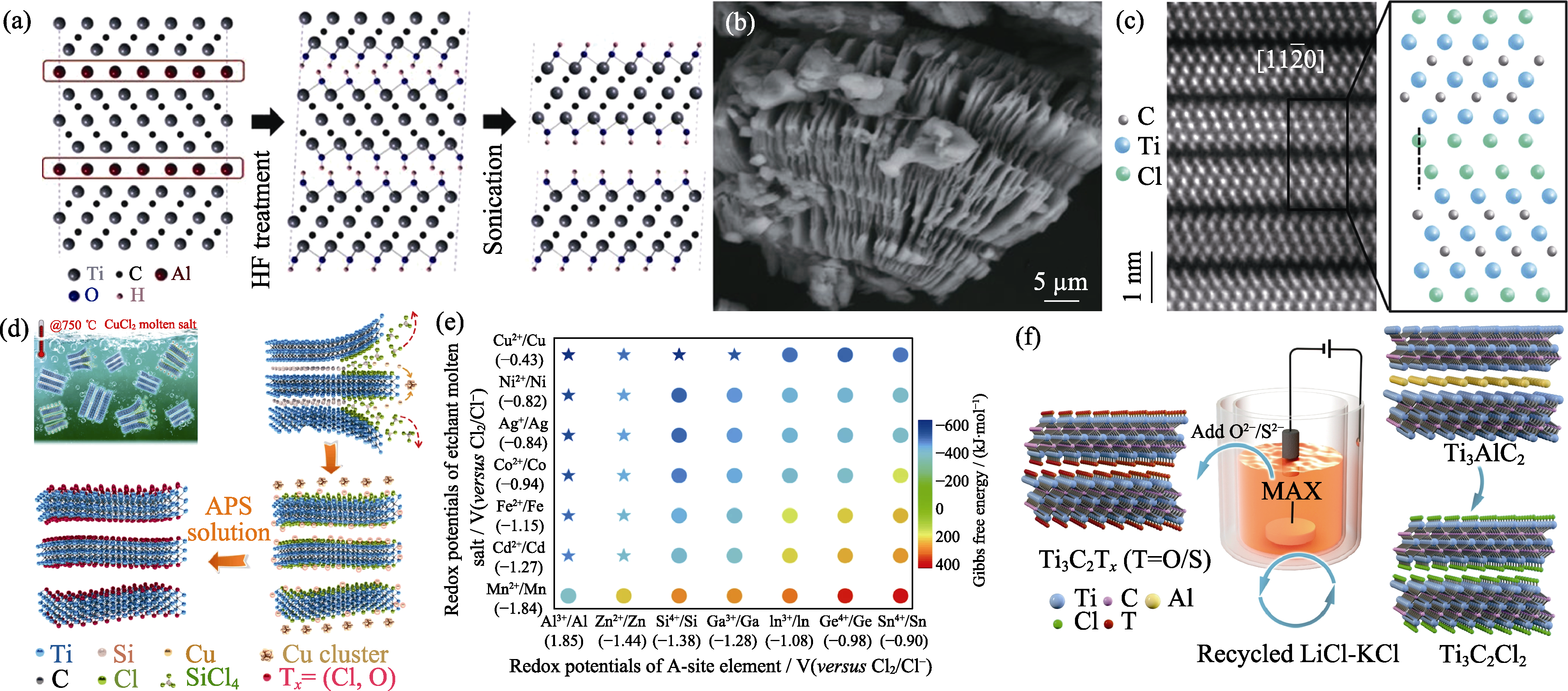

图3 不同的MXene的制备方法

Fig. 3 Different methods for the synthesis of MXene (a) Schematic illustration of preparing MXene using HF solution as etchant[28]; (b) SEM image of Ti3C2Tx prepared by HF solution, showing the typical accordion-like morpholorgy of MXene particle[28]; (c) STEM image of Ti3C2Cl2 prepared by Lewis-acidic-molten-salt route, and its corresponding atomic model[24]; (d) Schematic illustration of preparing Ti3C2Tx MXene via a reaction between Ti3SiC2 and CuCl2; (e) Redox potential/Gibbs free energy between Lewis acid cations and A-site atoms in molten salts[30]; (f) Schematic illustration of the electrochemistry etching strategy for the preparation of MXene in molten salt[72]

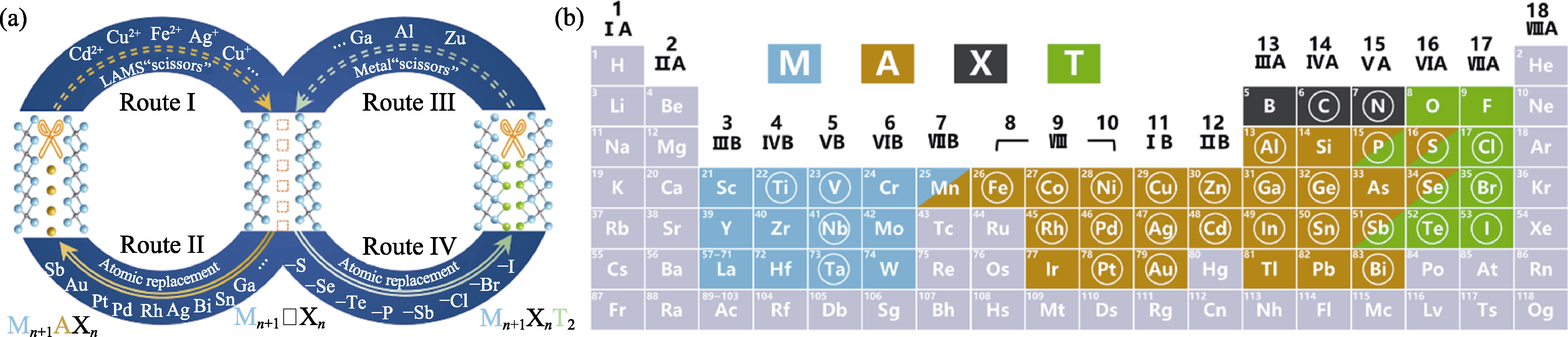

图4 “化学剪刀”辅助的MAX相和MXene的结构编辑

Fig. 4 Structural editing of MAX phases and MXene aided by chemical scissors (a) Schematic illustration of chemical intercalation strategy aided by chemical scissors[56]; (b) Periodic table showing elements involved in the formation of MAX phases and MXenes. Light blue: M elements; Brown: A elements; Black: X elements; Green: ligand (T) elements; Circled: elements studied in the present work[56]

图5 新型硫属MAX相的晶体结构及其典型的物理性能

Fig. 5 Crystal structure and physical properties of novel chalcogenide MAX phases (a-d) First synthesized Se-containing MAX phase, Zr2SeC[53]; (e, f) First synthesized Te-containing MAX phase, Hf2TeB[93]; (h-j) First synthesized MAX phase with chalcogen at X site, Zr2Se(B1-xSex) with x at 0 (h), 0.60 (i), and 0.97 (j), respectively[20]

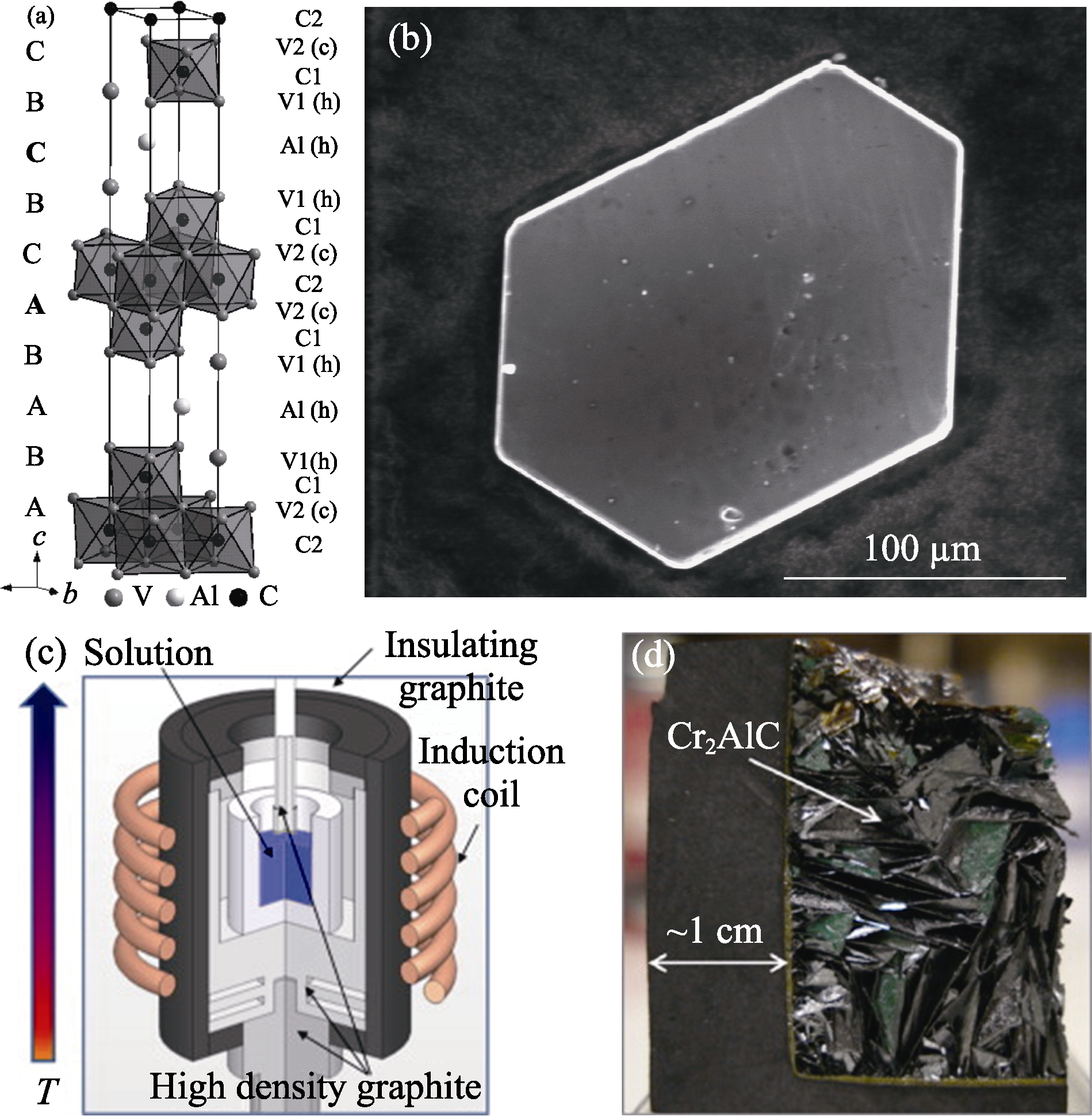

图6 单晶MAX相的制备

Fig. 6 Preparation of single crystal MAX phases (a) Crystal structure of V4AlC3-x[106]; (b) SEM image of single MAX phase V4AlC3-x[106]; (c) Schematic of the experimental set-up used for high temperature solution growth[107]; (d) Photograph of part of the crucible cut after growth and dipping into dilute HCl, the Cr2AlC platelets are coalescing due to an unusually long growth time[107]

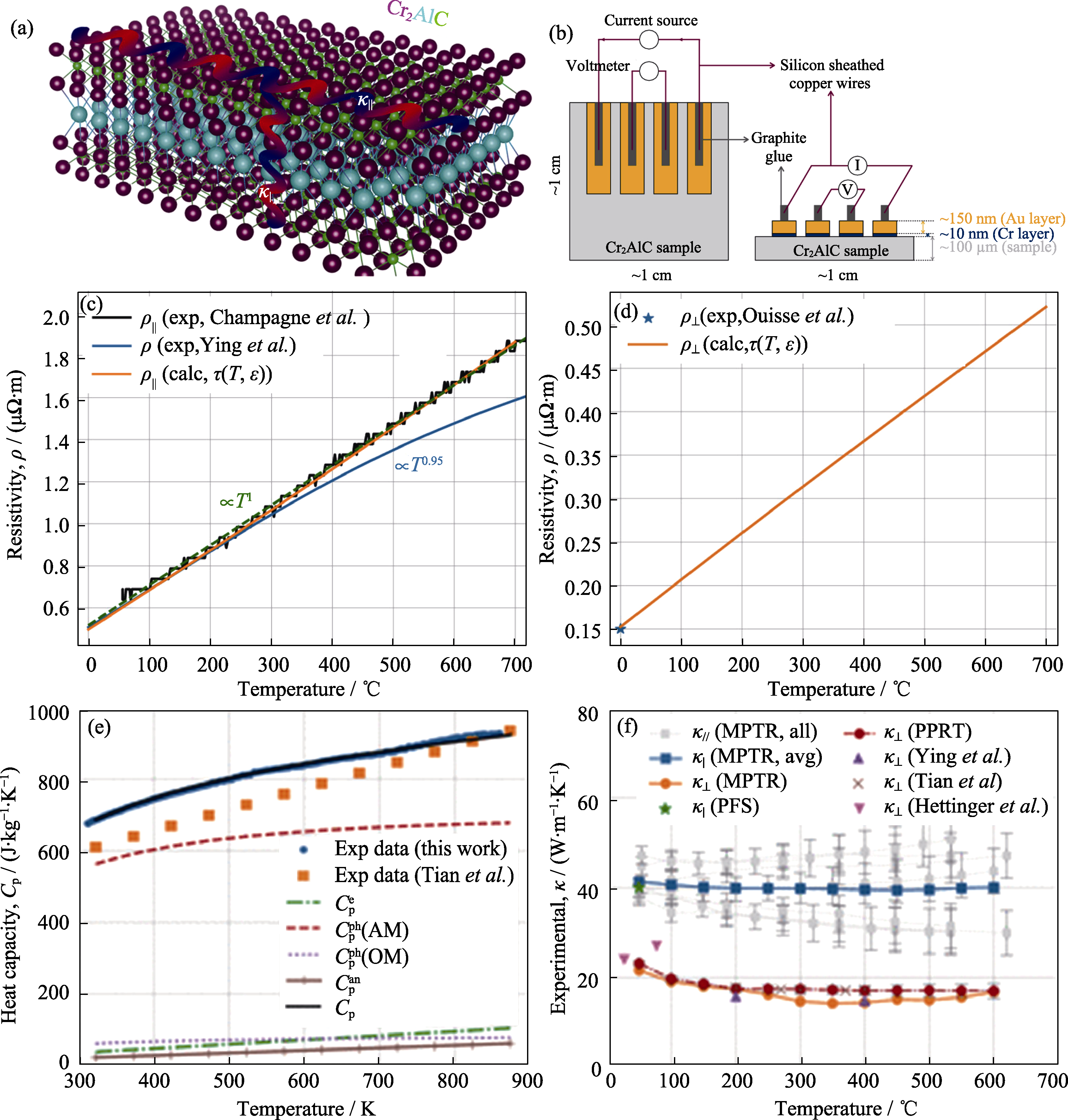

图7 Cr2AlC单晶的热容和各向异性的热导率[110]

Fig. 7 Heat capacity and anisotropic thermal conductivity in Cr2AlC single crystals at high temperatures[110] (a) Atomic structure model of Cr2AlC; (b) Schematic of the in-plane resistivity measurements in Cr2AlC using a four-probe configuration with equidistant and parallel pads; (c) Temperature-dependence measurements of the in-plane resistivity for Cr2AlC single crystals (black line); (d) Predicted out-of-plane resistivity (orange line); (e) Heat capacity measurements of Cr2AlC single crystals measured experimentally (blue dots); (f) Measured in-plane (κ∥) and out-of-plane (κ⊥) thermal conductivities using various techniques

图8 i-MAX相及其衍生的二维结构i-MXene[50]

Fig. 8 i-MAX phases and its derived two-dimensional product of i-MXene[50] (a-c) i-MAX with in-plane chemical order, viewed from [100], [010] and [110] zone axes, respectively; (d) Schematic of the conversion from i-MAX to i-MXene; (e) Low-magnification STEM image of single flake of Mo1.33C i-MXene; (f) Higher magnification STEM image with the FFT result of Mo1.33C i-MXene; (g) Atomically resolved STEM image of Mo1.33C i-MXene; (h) Atomic structure model corresponding to (g)

| M′4/3 | M″2/3 | A | X | Ref. |

|---|---|---|---|---|

| Mo4/3 | Sc2/3/Y2/3 | Al | C | [ |

| W4/3 | Sc2/3/Y2/3 | Al | C | [ |

| Mn4/3 | Sc2/3 | Ga | C | [ |

| Cr4/3 | Sc2/3/Y2/3/Zr2/3 | Al | C | [ |

| Cr4/3 | Sc2/3 | Ga | C | [ |

| V4/3 | Sc2/3/Zr2/3 | Al | C | [ |

| Mo4/3 | Sc2/3/Y2/3 | Ga | C | [ |

| Mo4/3 | Ce2/3/Pr2/3/Nd2/3/Sm2/3/Gd2/3/Tb2/3/Dy2/3/Ho2/3/Er2/3/Tm2/3/Lu2/3 | Al | C | [ |

| Mo4/3 | Gd2/3/Tb2/3/Dy2/3/Ho2/3/Er2/3/Tm2/3/Yb2/3/Lu2/3 | Ga | C | [ |

| W4/3 | Gd2/3/Tb2/3/Dy2/3/Ho2/3/Er2/3/Tm2/3/Lu2/3 | Al | C | [ |

| Cr4/3 | Gd2/3/Tb2/3/Dy2/3/Ho2/3/Er2/3/Tm2/3/Lu2/3 | Al | C | [ |

表1 实验上已经合成的i-MAX相

Table 1 List of synthesized i-MAX phases

| M′4/3 | M″2/3 | A | X | Ref. |

|---|---|---|---|---|

| Mo4/3 | Sc2/3/Y2/3 | Al | C | [ |

| W4/3 | Sc2/3/Y2/3 | Al | C | [ |

| Mn4/3 | Sc2/3 | Ga | C | [ |

| Cr4/3 | Sc2/3/Y2/3/Zr2/3 | Al | C | [ |

| Cr4/3 | Sc2/3 | Ga | C | [ |

| V4/3 | Sc2/3/Zr2/3 | Al | C | [ |

| Mo4/3 | Sc2/3/Y2/3 | Ga | C | [ |

| Mo4/3 | Ce2/3/Pr2/3/Nd2/3/Sm2/3/Gd2/3/Tb2/3/Dy2/3/Ho2/3/Er2/3/Tm2/3/Lu2/3 | Al | C | [ |

| Mo4/3 | Gd2/3/Tb2/3/Dy2/3/Ho2/3/Er2/3/Tm2/3/Yb2/3/Lu2/3 | Ga | C | [ |

| W4/3 | Gd2/3/Tb2/3/Dy2/3/Ho2/3/Er2/3/Tm2/3/Lu2/3 | Al | C | [ |

| Cr4/3 | Gd2/3/Tb2/3/Dy2/3/Ho2/3/Er2/3/Tm2/3/Lu2/3 | Al | C | [ |

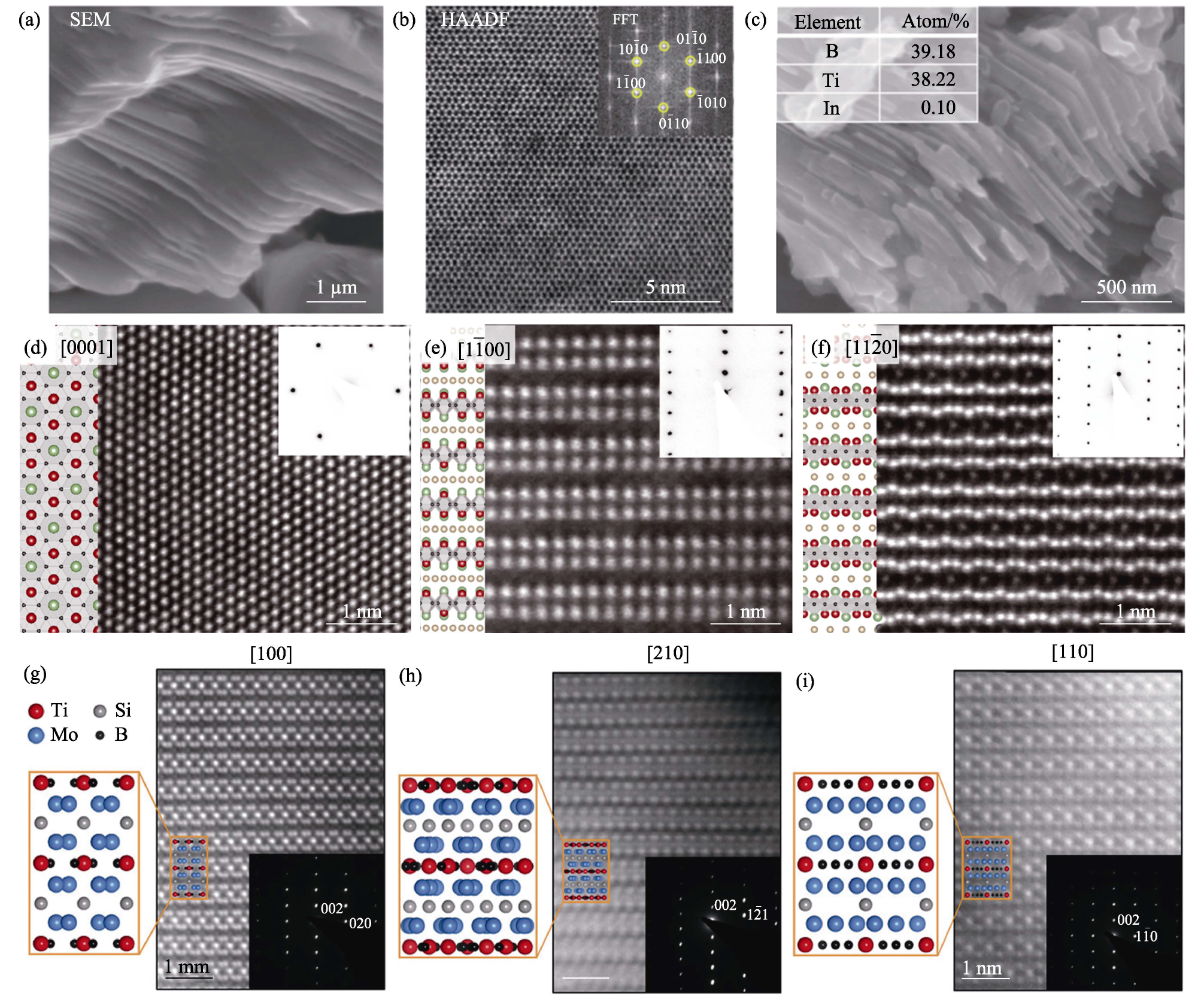

图9 MAB相、i-MAB相和o-MAB相

Fig. 9 MAB phases, i-MAB phases and o-MAB phases (a) SEM image of layered Ti2InB2; (b) STEM image of Ti2InB2 along the direction of [001] and corresponding FFT result in the inset image; (c) SEM image of 2D-TiB and its corresponding EDS semi-quantitative resultin inset table[52]; (d-f) STEM images of i-MAB phase (Mo2/3A1/3)2AlB2 and corresponding atomic model along the direction [0001], [$1\bar{1}00$] and [$11\bar{2}0$], respectively, and their corresponding FFT images[55]; (g-i) STEM images of o-MAB phase Ti4MoSiB2 and corresponding atomic model along the direction [100], [210] and [110], respectivly, and their corresponding FFT images[54]

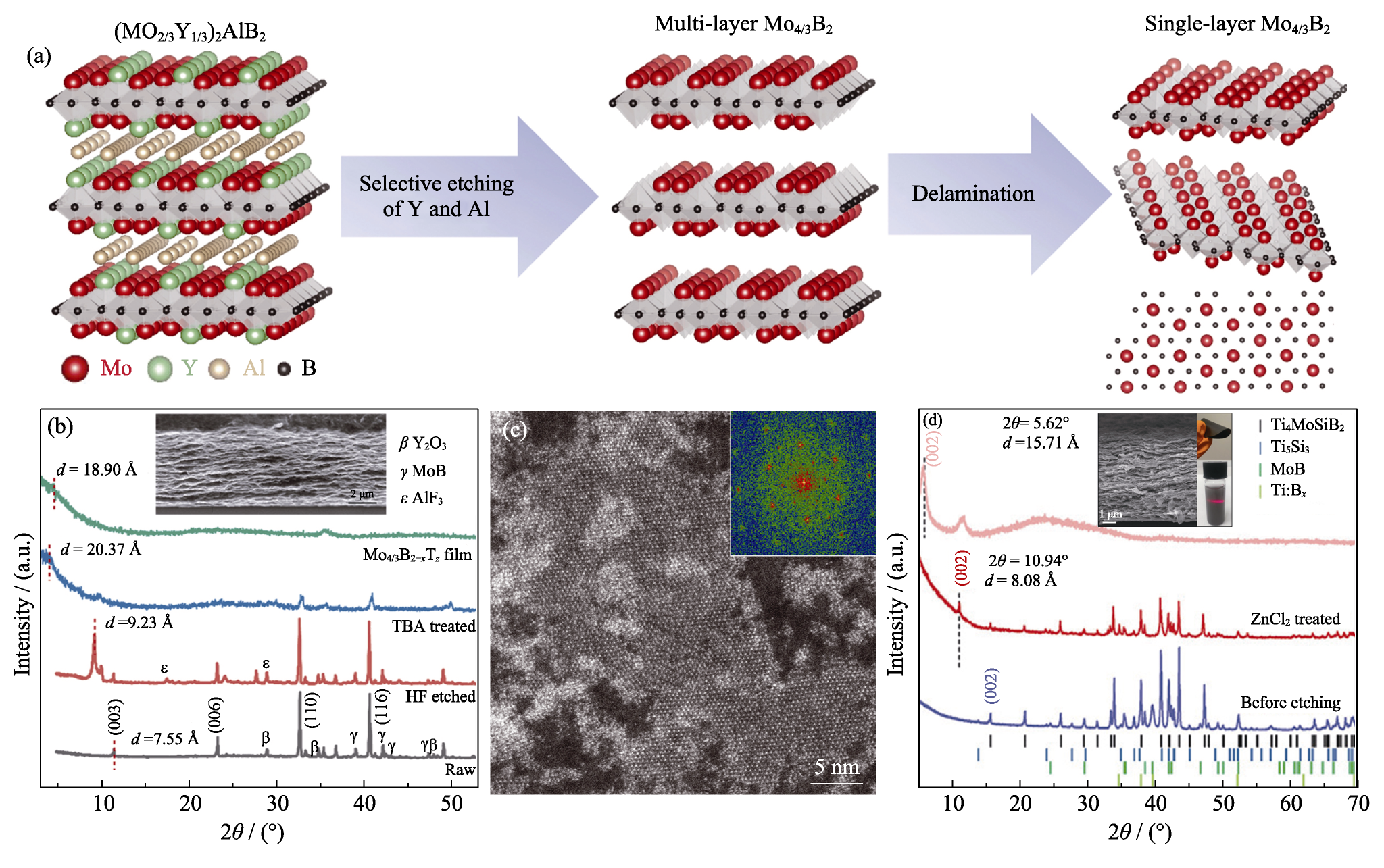

图10 通过化学刻蚀得到的MAB相衍生的二维产物

Fig. 10 Two-dimensional products derived from MAB phases through chemical etching (a) Schematic of chemical etching i-MAB phase to prepare two-dimensional derivative[55]; (b) XRD patterns of prestine i-MAX (Mo2/3Y1/3)2AlB2, etched product Mo4/3B2-xTz, TBAOH intercalation product, and delamination film with SEM image (inset) showing the cross-sectional morphology of Mo4/3B2-xTz film [55]; (c) STEM image of monolayer Mo4/3B2-xTz and its FFT image (inset) [55]; (d) XRD patterns of o-MAX Ti4MoSiB2, product etched by ZnCl2 and two-dimensional TiOxCly after delamination and filtering with SEM image (inset) of cross-sectional morphology of a TiOxCly film[54]

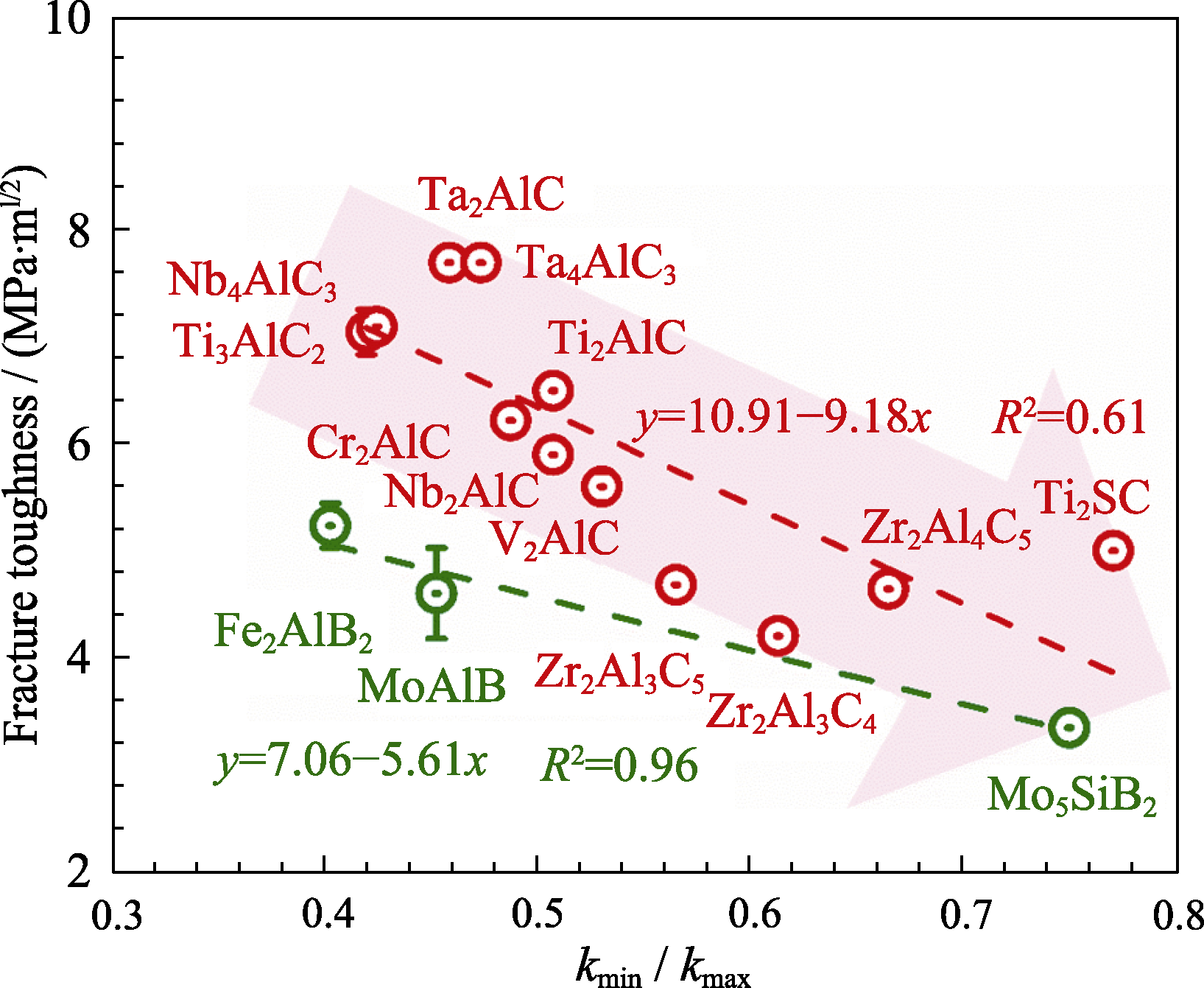

图11 实验测量的单边缺口梁断裂韧性随部分典型三元层状化合物(MAX和MAB相)的最弱与最强化学键刚度比kmin/kmax的变化[138]

Fig. 11 Experimentally measured unilateral notched beam fracture toughness as a function of the weakest to strongest chemical bond stiffness ratio kmin/kmax for some typical ternary layered compounds (MAX and MAB phases)[138]

| MAB phase | M type | A type | Ref. | MAB phase | M type | A type | Ref. |

|---|---|---|---|---|---|---|---|

| Orthorhombic M2A2B2 | Ti | Al | [ | Orthorhombic M3AB4 | Sc | Al | [ |

| Hf | Ti | ||||||

| V | Zr | ||||||

| Nb | Hf | ||||||

| Ta | V | ||||||

| Tc | Nb | ||||||

| Cr | Ta | ||||||

| Mn | Mo | ||||||

| Orthorhombic M2AB2 | Sc | Al | [ | W | |||

| Ti | Mn | ||||||

| Zr | Fe | ||||||

| Hf | Orthorhombic M4AB6 | Sc | Al | [ | |||

| V | Ti | ||||||

| Nb | Zr | ||||||

| W | Hf | ||||||

| Tc | V | ||||||

| Rh | Nb | ||||||

| Ni | Ta | ||||||

| Co | Mo | ||||||

| Orthorhombic M3A2B2 | Sc | Al | [ | Hexagonal M2AB2 | Ti | Sn | [ |

| Ti | Hf | In | [ | ||||

| Zr | Sn | ||||||

| Hf | Zr | In | |||||

| Cr | Pb | ||||||

| Mn | Tl | ||||||

| Tc | Hexagonal M3AB4 | Hf | In | [ | |||

| Fe | Sn | ||||||

| Ni | P | ||||||

| Zr | Cd | ||||||

| Pb |

表2 理论预测可稳定存在的MAB相种类

Table 2 Stable MAB phases by theoretical prediction

| MAB phase | M type | A type | Ref. | MAB phase | M type | A type | Ref. |

|---|---|---|---|---|---|---|---|

| Orthorhombic M2A2B2 | Ti | Al | [ | Orthorhombic M3AB4 | Sc | Al | [ |

| Hf | Ti | ||||||

| V | Zr | ||||||

| Nb | Hf | ||||||

| Ta | V | ||||||

| Tc | Nb | ||||||

| Cr | Ta | ||||||

| Mn | Mo | ||||||

| Orthorhombic M2AB2 | Sc | Al | [ | W | |||

| Ti | Mn | ||||||

| Zr | Fe | ||||||

| Hf | Orthorhombic M4AB6 | Sc | Al | [ | |||

| V | Ti | ||||||

| Nb | Zr | ||||||

| W | Hf | ||||||

| Tc | V | ||||||

| Rh | Nb | ||||||

| Ni | Ta | ||||||

| Co | Mo | ||||||

| Orthorhombic M3A2B2 | Sc | Al | [ | Hexagonal M2AB2 | Ti | Sn | [ |

| Ti | Hf | In | [ | ||||

| Zr | Sn | ||||||

| Hf | Zr | In | |||||

| Cr | Pb | ||||||

| Mn | Tl | ||||||

| Tc | Hexagonal M3AB4 | Hf | In | [ | |||

| Fe | Sn | ||||||

| Ni | P | ||||||

| Zr | Cd | ||||||

| Pb |

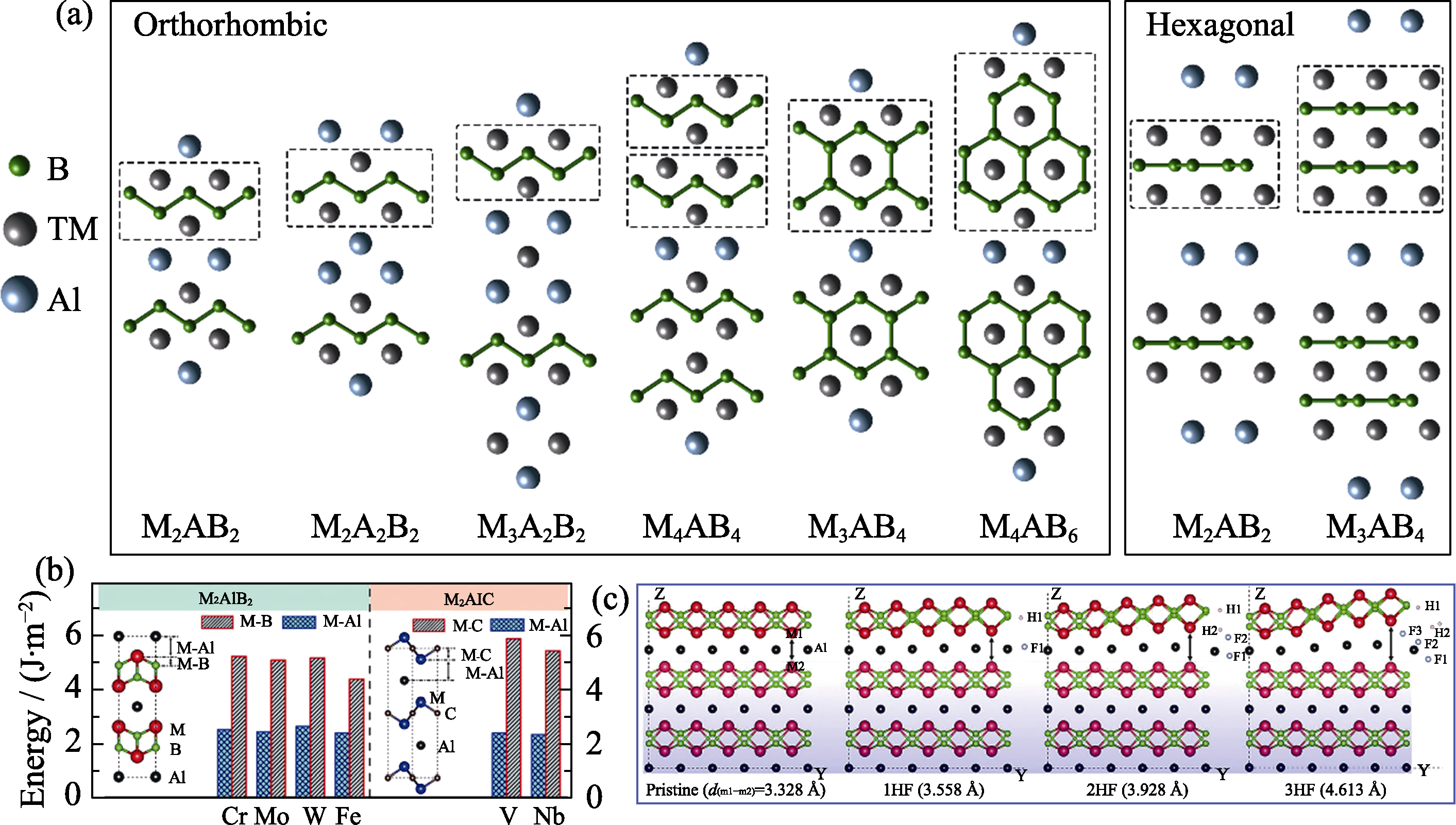

图12 MAB相的理论计算

Fig. 12 Theoretical calculation of MAB phases (a) Structures of orthorhombic and hexagonal MAB phases[163]; (b) Bonding energy of M2AlB2-type orthorhombic MAB and M2AlC-type MAX phases; (c) Simulated exfoliation process of orthorhombic M2AlB2 using HF, where the red, green, black, cyan, and pink balls represent Mo, B, Al, F, and H atoms, respectively[146]

| MAB phase | B/GPa | G/GPa | E/GPa | ¯ν/GPa | Ref. |

|---|---|---|---|---|---|

| Mn2AlB2 | 239 | 169 | 411 | 0.21 | [ |

| Fe2AlB2 | 209 | 133 | 329 | 0.24 | |

| Co2AlB2 | 216 | 92 | 242 | 0.31 | |

| TiAlB | 145 | 116 | 274 | 0.18 | |

| VAlB | 173 | 133 | 317 | 0.19 | |

| NbAlB | 180 | 130 | 315 | 0.21 | |

| TaAlB | 192 | 138 | 333 | 0.21 | |

| CrAlB | 189 | 140 | 338 | 0.20 | |

| MnAlB | 167 | 101 | 252 | 0.25 | |

| TcAlB | 220 | 114 | 292 | 0.28 | |

| Sc2AlB2 | 238 | 142 | 356 | 0.25 | |

| Ti2AlB2 | 170 | 150 | 347 | 0.16 | |

| Zr2AlB2 | 152 | 112 | 270 | 0.20 | |

| Hf2AlB2 | 168 | 132 | 314 | 0.19 | |

| V2AlB2 | 195 | 129 | 317 | 0.23 | |

| Nb2AlB2 | 199 | 110 | 279 | 0.27 | |

| Cr2AlB2 | 229 | 177 | 422 | 0.19 | |

| Mo2AlB2 | 238 | 142 | 356 | 0.25 | |

| W2AlB2 | 262 | 139 | 354 | 0.28 | |

| Tc2AlB2 | 260 | 132 | 339 | 0.28 | |

| Ni2AlB2 | 200 | 91 | 237 | 0.30 | |

| MoAlB | 213 | 146 | 357 | 0.22 | [ |

| WAlB | 232 | 146 | 362 | 0.24 | |

| Mn2AlB2 | 222 | 161 | 388 | 0.21 | [ |

| Fe2AlB2 | 210 | 132 | 329 | 0.24 | [ |

| Co2AlB2 | 241 | 101 | 266 | 0.31 | [ |

| Zr3CdB4 | — | 82 | 202 | 0.37 | [ |

| Hf3PB4 | — | 180 | 407 | 0.19 | [ |

表3 部分MAB相的理论体积模量(B)、剪切模量(G)、杨氏模量(E)和泊松比(ν)

Table 3 Theoretical mechanical properties of several MAB-phases, including bulk modulus (B), shear modulus (G), Young’s modulus (E), and Poisson ratio (ν)

| MAB phase | B/GPa | G/GPa | E/GPa | ¯ν/GPa | Ref. |

|---|---|---|---|---|---|

| Mn2AlB2 | 239 | 169 | 411 | 0.21 | [ |

| Fe2AlB2 | 209 | 133 | 329 | 0.24 | |

| Co2AlB2 | 216 | 92 | 242 | 0.31 | |

| TiAlB | 145 | 116 | 274 | 0.18 | |

| VAlB | 173 | 133 | 317 | 0.19 | |

| NbAlB | 180 | 130 | 315 | 0.21 | |

| TaAlB | 192 | 138 | 333 | 0.21 | |

| CrAlB | 189 | 140 | 338 | 0.20 | |

| MnAlB | 167 | 101 | 252 | 0.25 | |

| TcAlB | 220 | 114 | 292 | 0.28 | |

| Sc2AlB2 | 238 | 142 | 356 | 0.25 | |

| Ti2AlB2 | 170 | 150 | 347 | 0.16 | |

| Zr2AlB2 | 152 | 112 | 270 | 0.20 | |

| Hf2AlB2 | 168 | 132 | 314 | 0.19 | |

| V2AlB2 | 195 | 129 | 317 | 0.23 | |

| Nb2AlB2 | 199 | 110 | 279 | 0.27 | |

| Cr2AlB2 | 229 | 177 | 422 | 0.19 | |

| Mo2AlB2 | 238 | 142 | 356 | 0.25 | |

| W2AlB2 | 262 | 139 | 354 | 0.28 | |

| Tc2AlB2 | 260 | 132 | 339 | 0.28 | |

| Ni2AlB2 | 200 | 91 | 237 | 0.30 | |

| MoAlB | 213 | 146 | 357 | 0.22 | [ |

| WAlB | 232 | 146 | 362 | 0.24 | |

| Mn2AlB2 | 222 | 161 | 388 | 0.21 | [ |

| Fe2AlB2 | 210 | 132 | 329 | 0.24 | [ |

| Co2AlB2 | 241 | 101 | 266 | 0.31 | [ |

| Zr3CdB4 | — | 82 | 202 | 0.37 | [ |

| Hf3PB4 | — | 180 | 407 | 0.19 | [ |

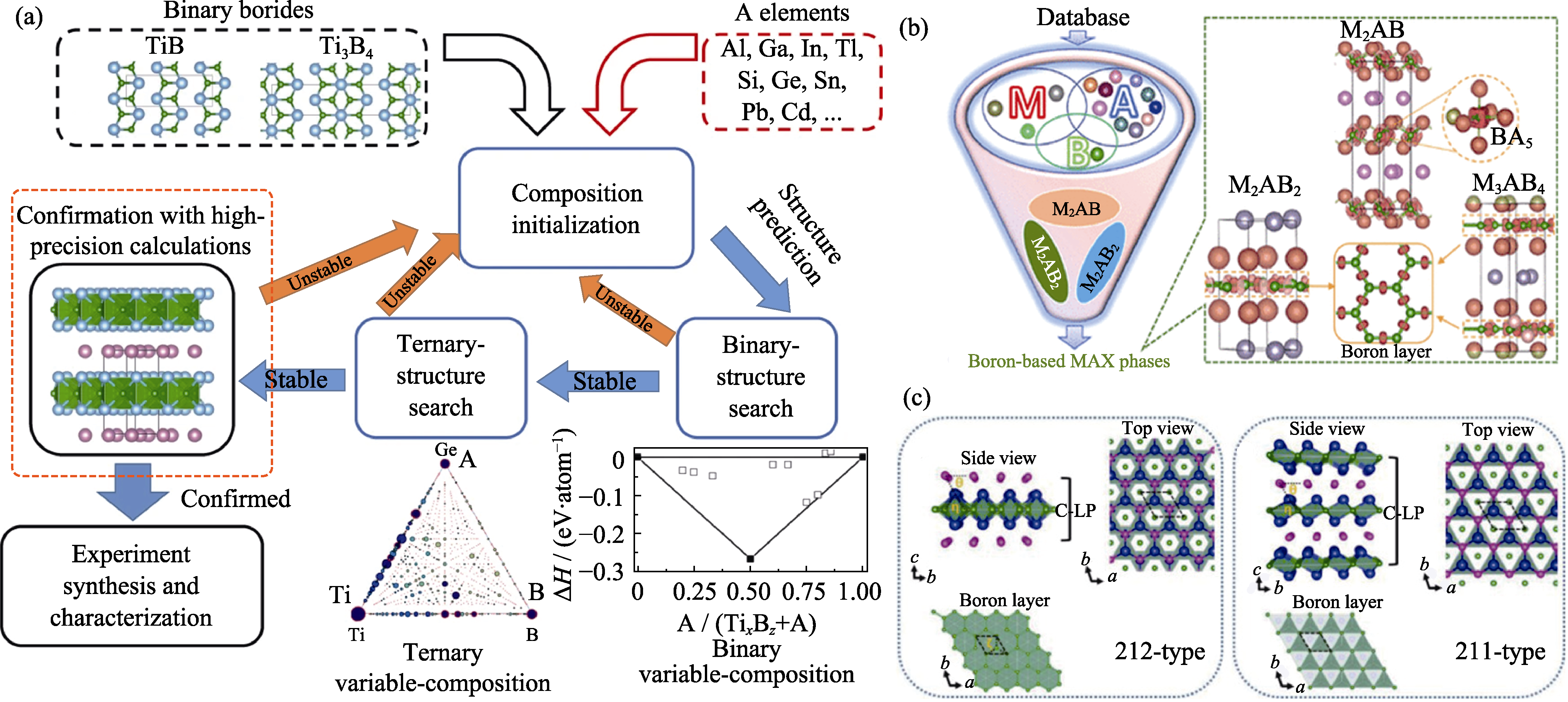

图14 三元MAX相的发现

Fig. 14 Discovery of ternary MAX phases (a) Calculation-based approach to discovery of novel ternary phases Ti2InB2[52]; (b) High-throughput prediction of MAB phases[162]; (c) Crystal structures for the stable Nb2AB2 and Nb2AB (A: P or S)[183]

图15 四元MAB相的理论预测

Fig. 15 Theoretical study of quaternary MAB phases (a) Crystal structure of Cr3AlB4, ordered M2M'AlB4, and disordered M2M'AlB4[186]; (b) Prediction and synthesis of i-MAB phases Mo4/3Sc2/3AlB2 and Mo4/3Y2/3AlB2[16]; (c) Elemental mapping involved in this computational work; (d) Schematic illustration of the evolution of structure and electronic structure of h-MAB during the introduction of the fourth element M″[187]

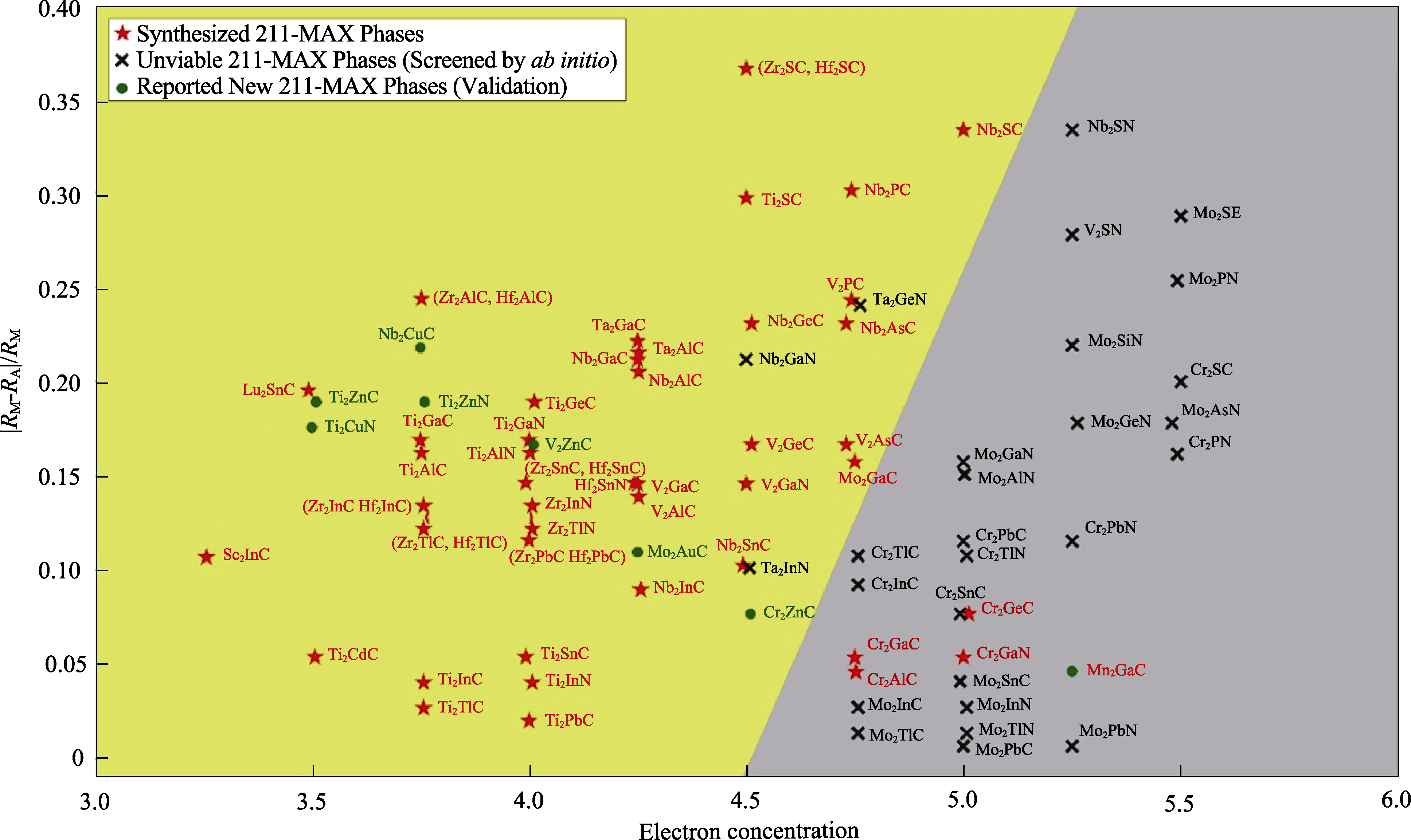

图16 选取特征量为电子浓度和尺寸因素所绘制的结构映射图[36]

Fig. 16 Structure mapping based on the selected characteristic quantities of electron concentration and atomic sizes[36]

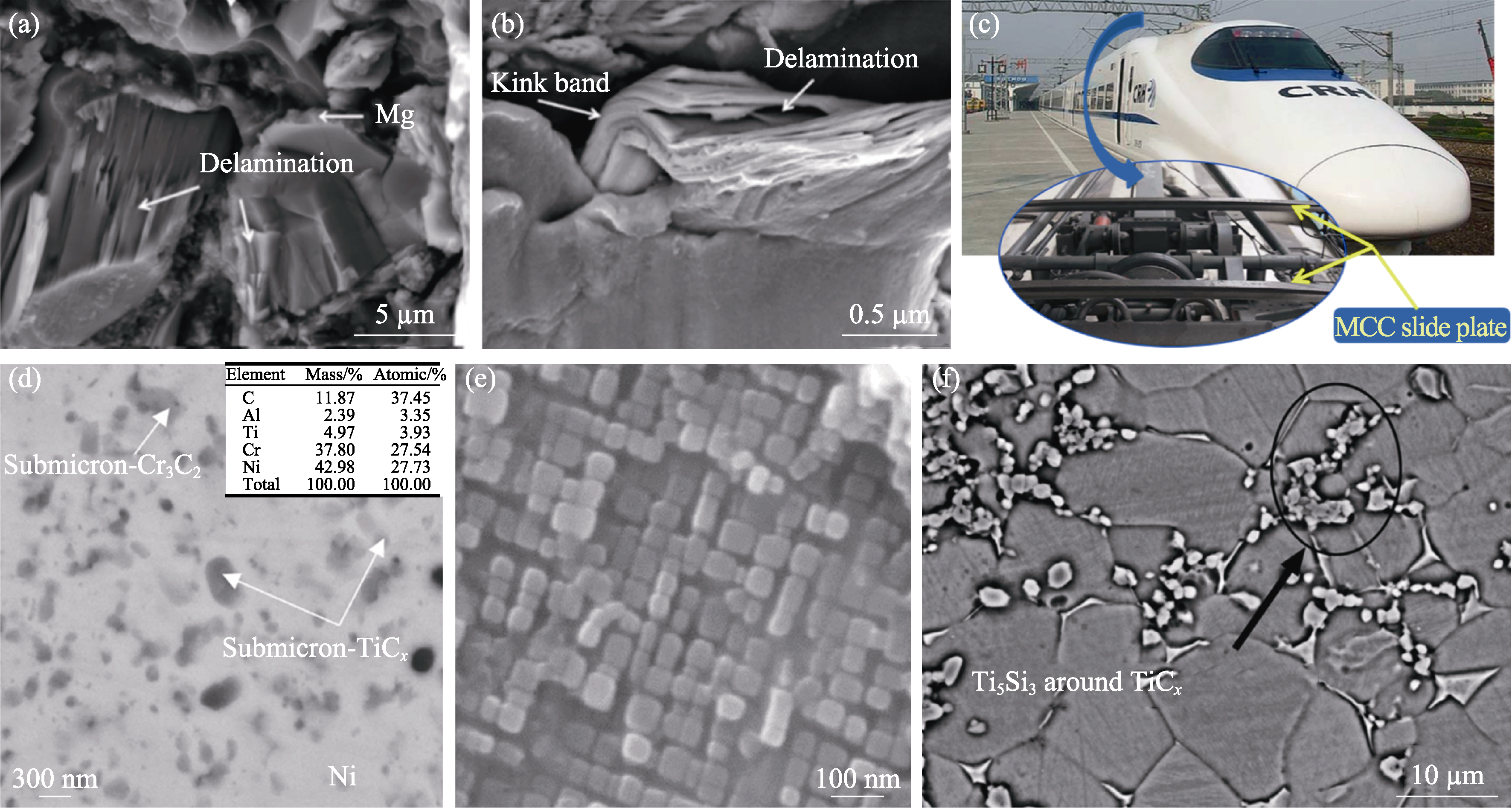

图17 MAX增强金属基复合材料

Fig. 17 MAX-reinforced metal matrix composites (a-b) Fracture morphology of MAX in Mg matrix composites undergoing microplastic deformation[213]; (c) MAX/Cu matrix composite MCC pantograph slide plate[215]; (d, e) Transformation of MAX to TiCx and Cr3C2 in Ni matrix composites and morphology of in situ authentic γ'[224]; (f) Morphology of the MAX transformation to TiCx and Ti5Si3 in Ti matrix composites[225]

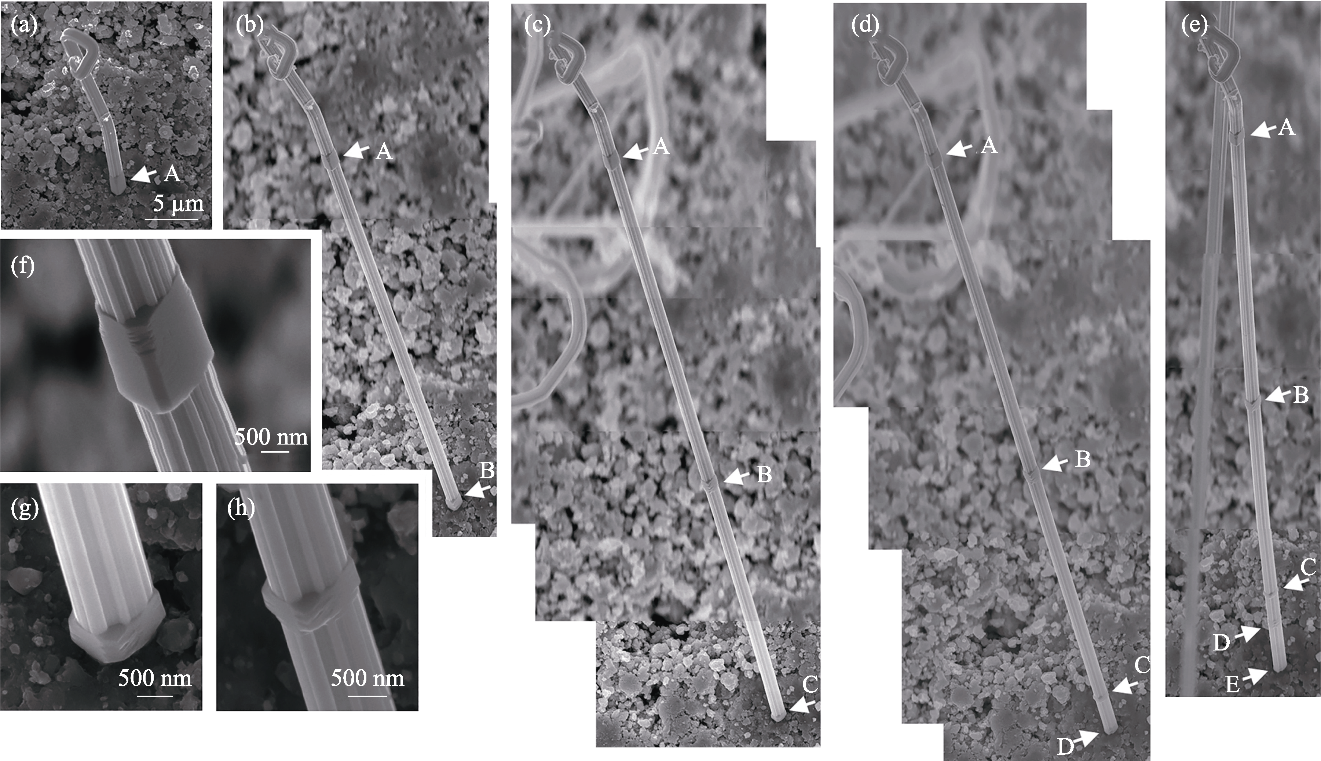

图18 在空气与真空中交替生长的Sn晶须的SEM图片[259]

Fig. 18 SEM images of a Sn whisker alternately cultivated in air and vacuum[259] (a-e) For once, twice, 3 times, 4 times, and 5 times, respectively with faceted segments formed in vacuum being pointed by white arrows; (f-h) High magnification SEM images of the faceted segments indicated by arrow A in (b), arrow C in (c), and arrow C in (d), respectively

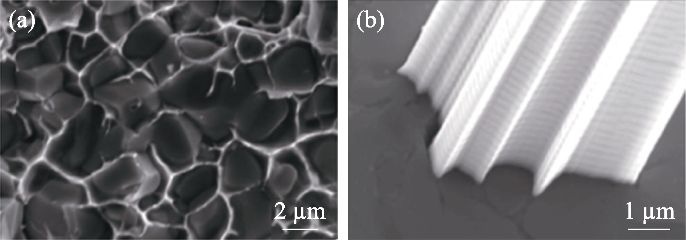

图19 Zr2InC样品端口及其表面生长的In晶须的SEM照片[243]

Fig. 19 SEM images of fractured Zr2InC surface and an In whisker[243] (a) Fractured Zr2InC surface showing In at grain boundaries (this surface being covered with thin In film); (b) An In whisker whose cross-sectional shape is determined by grain boundary geometry at the In/Zr2InC interface

图20 Sn晶须/Ti2SnC界面的微观结构[266]

Fig. 20 Microstructure of Sn whiskers/Ti2SnC interface[266] (a) TEM image of the interface; (b) Magnified view of the white rectangle area in (a); (c, d) HRTEM images of the interface

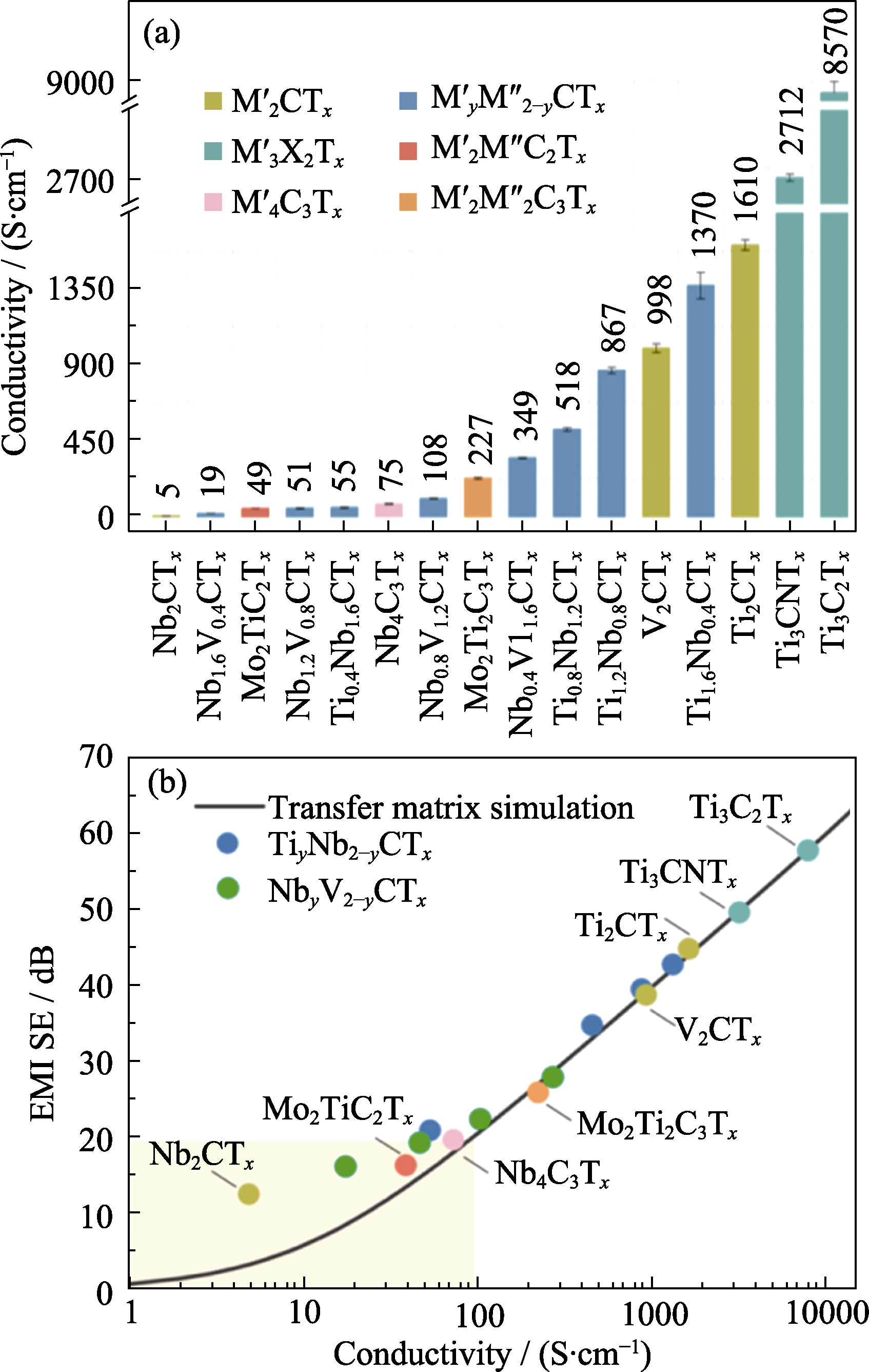

图21 不同MXene薄膜的电导率(a)及其电磁屏蔽效能与电导率间的关系(b)[282]

Fig. 21 (a) Electrical conductivity of different MXene films and (b) conductivity-dependent electromagnetic interference shielding effectiveness of different MXenes[282]

图22 辐照环境下MAX相材料中的缺陷产生和微观结构转变

Fig. 22 Defect generation and microstructural transformation in MAX phase materials under irradiation (a) STEM HAADF (high-angle annular dark-field) image along [11¯20] of Ti3AlC2 irradiated with 1 MeV Au ions, showing direct evidence of cation antisite defects. The white arrows indicate the initial Al layers, whose image contrast is altered when compared with the initial hexagonal structure[295]; (b, c) Contrast profiles along line 1 and line 2 in (a), respectively, which directly show the variation of contrast arising from the formation of TiAl-AlTi antisite defects produced by ion irradiation[295]; (d) TEM image of Ti3(Si,Al)C2 being irradiated at 0.2 dpa indicating a cluster of point defects (black dots)[296]; (e-g) Phase transformation (hcp to γ to fcc solid solution) processes with chemical disorder induced by ion irradiation in a typical MAX phase, Ti3AlC2 (hcp: hexagonal close packing; fcc: face-centered cubic)[295]

图23 MAX相的辐照温度效应

Fig. 23 MAX phase irradiation temperature effect (a) Ti3AlC2 is completely recovered to initial phase (a dose of 2×1016 cm-2) or partially recovered to initial phase and γ-Ti3AlC2 phase (a dose of 4×1016 cm-2) after irradiation with 1 MeV Au ions and then annealed at 800 ℃ for 1 h[303]; (b) Cr2AlC films showing completely amorphous after irradiation with 320 keV Xe ions up to 3.3 dpa at 300 K, but not completely amorphized after irradiation up to 90 dpa at 623 K[306]

图24 高熵MAX相的辐照相变及非晶化[302]

Fig. 24 Phase transformation and amorphization caused by irradiation of MAX phases[302] (a) Schematic of atomic structure models of Ti2SnC and (TiVNbZrHf)2SnC; (b) In-situ selective area electron diffraction (SAED) micrographs of Ti2SnC and five-component (TiVNbZrHf)2SnC recorded during 800 keV Kr2+ irradiation, showing different phase transformation process and amorphization resistance; (c) M-Sn antisite defect formation energies calculated via DFT in the corresponding single-component M2SnC and the five-component (TiVNbZrHf)2SnC supercell

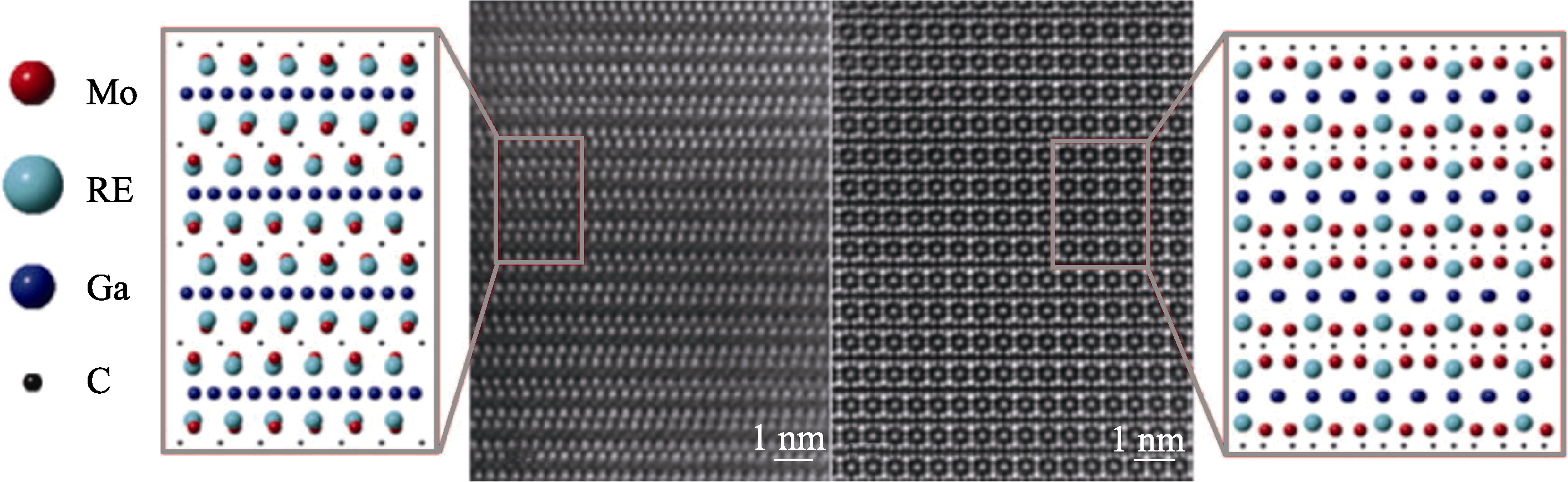

图25 (Mo2/3RE1/3)2GaC i-MAX相沿 (a) [100]和 (b) [010] 方向的扫描透射电镜(STEM)图像[120]

Fig. 25 STEM micrographs of (Mo2/3RE1/3)2GaC i-MAX phase along (a) [100] and (b) [010] zone axis[120]

| [1] |

BARSOUM M W. The MN+1AXN phases: a new class of solids: thermodynamically stable nanolaminates. Progress in Solid State Chemistry, 2000, 28: 201.

DOI URL |

| [2] |

DEYSHER G, SHUCK C E, HANTANASIRISAKUL K, et al. Synthesis of Mo4VAlC4 MAX phase and two-dimensional Mo4VC4 MXene with five atomic layers of transition metals. ACS Nano, 2019, 14(1): 204.

DOI URL |

| [3] | BARSOUM M W. MAX phases: properties of machinable ternary carbides and nitrides: John Wiley & Sons, 2013. |

| [4] |

SUN Z. Progress in research and development on MAX phases: a family of layered ternary compounds. International Materials Reviews, 2011, 56(3): 143.

DOI URL |

| [5] | 柏跃磊, 尹航, 宋广平, 等. 高韧性三元层状陶瓷: 从MAX相到MAB相. 材料工程, 2021, 49(5): 1. |

| [6] | KOTA S, SOKOL M, BARSOUM M W. A progress report on the MAB phases: atomically laminated, ternary transition metal borides. International Materials Reviews, 2020, 65(4): 226. |

| [7] | JEITSCHKO W. The crystal structure of Fe2AlB2. Acta Crystallographica Section B: Structural Crystallography and Crystal Chemistry, 1969, 25(1): 163. |

| [8] | NOWOTNY H, ROGL P. Ternary metal borides. In. Boron and refractory borides. Springer, 1977: 413. |

| [9] |

TAN X, CHAI P, THOMPSON C M, et al. Magnetocaloric effect in AlFe2B2: toward magnetic refrigerants from earth-abundant elements. Journal of the American Chemical Society, 2013, 135(25): 9553.

DOI URL |

| [10] |

ADE M, HILLEBRECHT H. Ternary borides Cr2AlB2, Cr3AlB4, and Cr4AlB6: the first members of the series (CrB2)nCrAl with n= 1, 2, 3 and a unifying concept for ternary borides as MAB-phases. Inorganic Chemistry, 2015, 54(13): 6122.

DOI URL |

| [11] |

SOKOL M, NATU V, KOTA S, et al. On the chemical diversity of the MAX phases. Trends in Chemistry, 2019, 1(2): 210.

DOI URL |

| [12] |

YU W, MAUCHAMP V, CABIOC’H T, et al. Solid solution effects in the Ti2Al(CxNy) MAX phases: synthesis, microstructure, electronic structure and transport properties. Acta Materialia, 2014, 80: 421.

DOI URL |

| [13] |

NAGUIB M, BENTZEL G, SHAH J, et al. New solid solution MAX phases: (Ti0.5,V0.5)3AlC2, (Nb0.5,V0.5)2AlC, (Nb0.5,V0.5)4AlC3 and (Nb0.8,Zr0.2)2AlC. Materials Research Letters, 2014, 2(4): 233.

DOI URL |

| [14] | TALAPATRA A, DUONG T, SON W, et al. High-throughput combinatorial study of the effect of M site alloying on the solid solution behavior of M2AlC MAX phases. Physical Review B, 2016, 94(10): 104106. |

| [15] | CHAMPAGNE A, RICCI F, BARBIER M, et al. Insights into the elastic properties of RE-i-MAX phases and their potential exfoliation into two-dimensional RE-i-MXenes. Physical Review Materials, 2020, 4(1): 013604. |

| [16] |

DAHLQVIST M, TAO Q, ZHOU J, et al. Theoretical prediction and synthesis of a family of atomic laminate metal borides with in-plane chemical ordering. Journal of the American Chemical Society, 2020, 142(43): 18583.

DOI URL |

| [17] |

NEMANI S K, ZHANG B, WYATT B C, et al. High-entropy 2D carbide mxenes: TiVNbMoC3 and TiVCrMoC3. ACS Nano, 2021, 15(8): 12815.

DOI URL |

| [18] |

ZHANG X, LI Y B, CHEN K, et al. Tailoring MAX phase magnetic property based on M-site and A-site double solid solution. Journal of Inorganic Materials, 2021, 36(12): 1247.

DOI URL |

| [19] |

LI Y, LU J, LI M, et al. Multielemental single-atom-thick A layers in nanolaminated V2(Sn,A)C (A=Fe, Co, Ni, Mn) for tailoring magnetic properties. Proceedings of the National Academy of Sciences, 2020, 117(2): 820.

DOI URL |

| [20] | LI Z, WU E, CHEN K, et al. Chalcogenide MAX phases Zr2Se(B1-xSex)(x=0-0.97) and their conduction behaviors. Acta Materialia, 2022, 237: 118183. |

| [21] | RADOVIC M, BARSOUM M W. MAX phases: bridging the gap between metals and ceramics. American Ceramics Society Bulletin, 2013, 92(3): 20. |

| [22] |

FASHANDI H, DAHLQVIST M, LU J, et al. Synthesis of Ti3AuC2, Ti3Au2C2 and Ti3IrC2 by noble metal substitution reaction in Ti3SiC2 for high-temperature-stable Ohmic contacts to SiC. Nature Materials, 2017, 16(8): 814.

DOI URL |

| [23] |

LI M, LI Y B, LUO K, et al. Synthesis of novel MAX Phase Ti3ZnC2 via A-site-element-substitution approach. Journal of Inorganic Materials, 2019, 34(1): 60.

DOI URL |

| [24] |

LI M, LU J, LUO K, et al. Element replacement approach by reaction with Lewis acidic molten salts to synthesize nanolaminated MAX phases and MXenes. Journal of the American Chemical Society, 2019, 141(11): 4730.

DOI URL |

| [25] |

LI Y, LI M, LU J, et al. Single-atom-thick active layers realized in nanolaminated Ti3(AlxCu1-x)C2 and its artificial enzyme behavior. ACS Nano, 2019, 13(8): 9198.

DOI URL |

| [26] |

DING H, LI Y, LU J, et al. Synthesis of MAX phases Nb2CuC and Ti2(Al0.1Cu0.9)N by A-site replacement reaction in molten salts. Materials Research Letters, 2019, 7(12): 510.

DOI URL |

| [27] | LI Y, LIANG J, DING H, et al. Near-room temperature ferromagnetic behavior of single-atom-thick 2D iron in nanolaminated ternary MAX phases. Applied Physics Reviews, 2021, 8(3): 031418. |

| [28] |

NAGUIB M, KURTOGLU M, PRESSER V, et al. Two-dimensional nanocrystals produced by exfoliation of Ti3AlC2. Advanced Materials, 2011, 23(37): 4248.

DOI URL |

| [29] | VAHIDMOHAMMADI A, ROSEN J, GOGOTSI Y. The world of two-dimensional carbides and nitrides (MXenes). Science, 2021, 372(6547): eabf1581. |

| [30] |

LI Y, SHAO H, LIN Z, et al. A general Lewis acidic etching route for preparing MXenes with enhanced electrochemical performance in non-aqueous electrolyte. Nature Materials, 2020, 19(8): 894.

DOI |

| [31] |

LI M, LI X, QIN G, et al. Halogenated Ti3C2 MXenes with electrochemically active terminals for high-performance zinc ion batteries. ACS Nano, 2021, 15(1): 1077.

DOI URL |

| [32] |

MEDVEDEVA N, NOVIKOV D, IVANOVSKY A, et al. Electronic properties of Ti3SiC2-based solid solutions. Physical Review B, 1998, 58(24): 16042.

DOI URL |

| [33] |

WANG J, ZHOU Y. Recent progress in theoretical prediction, preparation, and characterization of layered ternary transition-metal carbides. Annual Review of Materials Research, 2009, 39(1): 415.

DOI URL |

| [34] | HUG G, FRIES E. Full-potential electronic structure of Ti2AlC and Ti2AlN. Physical Review B, 2002, 65(11): 113104. |

| [35] | MUSIC D, HOUBEN A, DRONSKOWSKI R, et al. Ab initio study of ductility in M2AlC (M=Ti, V, Cr). Physical Review B, 2007, 75(17): 174102. |

| [36] | ZHANG Y, MAO Z, HAN Q, et al. The role of Hume-Rothery’s rules play in the MAX phases formability. Materialia, 2020, 12: 100810. |

| [37] | WANG G, PENG L, LI K, et al. ALKEMIE: an intelligent computational platform for accelerating materials discovery and design. Computational Materials Science, 2021, 186: 110064. |

| [38] |

FREY N C, WANG J, VEGA BELLIDO G I N, et al. Prediction of synthesis of 2D metal carbides and nitrides (MXenes) and their precursors with positive and unlabeled machine learning. ACS Nano, 2019, 13(3): 3031.

DOI URL |

| [39] | SIRIWARDANE E M, JOSHI R P, KUMAR N, et al. Revealing the formation energy-exfoliation energy-structure correlation of MAB phases using machine learning and DFT. ACS Applied Materials & Interfaces, 2020, 12(26): 29424. |

| [40] |

ROHDE H, KUDIELKA H. Strukturuntersuchungen an carbosulfiden von titan und zirkon. Zeitschrift für Kristallographie-Crystalline Materials, 1960, 114: 447.

DOI URL |

| [41] |

NOWOTNY V H. Strukturchemie einiger verbindungen der übergangsmetalle mit den elementen C, Si, Ge, Sn. Progress in Solid State Chemistry, 1971, 5: 27.

DOI URL |

| [42] |

JEITSCHKO W, NOWOTNY H, BENESOVSKY F. Die h-phasen: Ti2CdC, Ti2GaC, Ti2GaN, Ti2InN, Zr2InN und Nb2GaC. Monatshefte für Chemie und verwandte Teile anderer Wissenschaften, 1964, 95: 178.

DOI URL |

| [43] |

JEITSCHKO W, NOWOTNY H. Die kristallstruktur von Ti3SiC2- einneuerkom plexcarbid-typ. Monatshefte für Chemie-Chemical Monthly, 1967, 98: 329.

DOI URL |

| [44] |

WOLFSGRUBER H, NOWOTNY H, BENESOVSKY F. Die Kristallstruktur von Ti3GeC2: Kurze Mitteilung. Monatshefte für Chemie und verwandte Teile anderer Wissenschaften, 1967, 98: 2403.

DOI URL |

| [45] |

PIETZKA M, SCHUSTER J. Summary of constitutional data on the aluminum-carbon-titanium system. Journal of Phase Equilibria, 1994, 15: 392.

DOI URL |

| [46] |

BARSOUM M W, EL-RAGHY T. Synthesis and characterization of a remarkable ceramic: Ti3SiC2. Journal of the American Ceramic Society, 1996, 79(7): 1953.

DOI URL |

| [47] |

KUCHIDA S, MURANAKA T, KAWASHIMA K, et al. Superconductivity in Lu2SnC. Physica C: Superconductivity, 2013, 494: 77.

DOI URL |

| [48] |

LIU Z, WU E, WANG J, et al. Crystal structure and formation mechanism of (Cr2/3Ti1/3)3AlC2 MAX phase. Acta Materialia, 2014, 73: 186.

DOI URL |

| [49] |

LAPAUW T, HALIM J, LU J, et al. Synthesis of the novel Zr3AlC2 MAX phase. Journal of the European Ceramic Society, 2016, 36(3): 943.

DOI URL |

| [50] |

TAO Q, DAHLQVIST M, LU J, et al. Two-dimensional Mo1.33C MXene with divacancy ordering prepared from parent 3D laminate with in-plane chemical ordering. Nature Communications, 2017, 8(1): 14949.

DOI URL |

| [51] | RACKL T, EISENBURGER L, NIKLAUS R, et al. Syntheses and physical properties of the MAX phase boride Nb2SB and the solid solutions Nb2SBxC-x (x=0-1). Physical Review Materials, 2019, 3(5): 054001. |

| [52] |

WANG J, YE T N, GONG Y, et al. Discovery of hexagonal ternary phase Ti2InB2 and its evolution to layered boride TiB. Nature Communications, 2019, 10(1): 2284.

DOI |

| [53] |

CHEN K, BAI X, MU X, et al. MAX phase Zr2SeC and its thermal conduction behavior. Journal of the European Ceramic Society, 2021, 41(8): 4447.

DOI URL |

| [54] | DAHLQVIST M, ZHOU J, PERSSON I, et al. Out-of-plane ordered laminate borides and their 2D Ti-based derivative from chemical exfoliation. Advanced Materials, 2021, 33(38): 2008361. |

| [55] |

ZHOU J, PALISAITIS J, HALIM J, et al. Boridene: two-dimensional Mo4/3B2-x with ordered metal vacancies obtained by chemical exfoliation. Science, 2021, 373(6556): 801.

DOI URL |

| [56] |

DING H, LI Y, LI M, et al. Chemical scissor-mediated structural editing of layered transition metal carbides. Science, 2023, 379(6637): 1130.

DOI URL |

| [57] |

DU Z, YANG S, LI S, et al. Conversion of non-van der Waals solids to 2D transition-metal chalcogenides. Nature, 2020, 577(7791): 492.

DOI |

| [58] |

WANG S, CHENG J, ZHU S, et al. A novel route to prepare a Ti3SnC2/Al2O3 composite. Scripta Materialia, 2017, 131: 80.

DOI URL |

| [59] |

LI Y, ZHU S, WU E, et al. Nanolaminated ternary transition metal carbide (MAX phase)-derived core-shell structure electrocatalysts for hydrogen evolution and oxygen evolution reactions in alkaline electrolytes. The Journal of Physical Chemistry Letters, 2023, 14: 481.

DOI URL |

| [60] |

LU Y, KHAZAEI M, HU X, et al. Facile synthesis of Ti2AC (A=Zn, Al, In, and Ga) MAX phases by hydrogen incorporation into crystallographic voids. The Journal of Physical Chemistry Letters, 2021, 12(46): 11245.

DOI URL |

| [61] |

LAPAUW T, LAMBRINOU K, CABIOC’H T, et al. Synthesis of the new MAX phase Zr2AlC. Journal of the European Ceramic Society, 2016, 36(8): 1847.

DOI URL |

| [62] |

GOGOTSI Y, ANASORI B. The rise of MXenes. ACS Nano, 13(8): 8491.

DOI URL |

| [63] |

HALIM J, LUKATSKAYA M R, COOK K M, et al. Transparent conductive two-dimensional titanium carbide epitaxial thin films. Chemistry of Materials, 2014, 26(7): 2374.

DOI URL |

| [64] |

WANG L, ZHANG H, WANG B, et al. Synthesis and electrochemical performance of Ti3C2Tx with hydrothermal process. Electronic Materials Letters, 2016, 12(5): 702.

DOI URL |

| [65] |

GHIDIU M, LUKATSKAYA M R, ZHAO M Q, et al. Conductive two-dimensional titanium carbide ‘clay’ with high volumetric capacitance. Nature, 2014, 516(7529): 78.

DOI |

| [66] |

URBANKOWSKI P, ANASORI B, MAKARYAN T, et al. Synthesis of two-dimensional titanium nitride Ti4N3(MXene). Nanoscale, 2016, 8(22): 11385.

DOI URL |

| [67] |

LI T, YAO L, LIU Q, et al. Fluorine-free synthesis of high-purity Ti3C2Tx (T=OH, O) via alkali treatment. Angewandte Chemie International Edition, 2018, 57(21): 6115.

DOI URL |

| [68] |

NAGUIB M, UNOCIC R R, ARMSTRONG B L, et al. Large-scale delamination of multi-layers transition metal carbides and carbonitrides “MXenes”. Dalton Transactions, 2015, 44(20): 9353.

DOI URL |

| [69] | XUAN J, WANG Z, CHEN Y, et al. Organic-base-driven intercalation and delamination for the production of functionalized titanium carbide nanosheets with superior photothermal therapeutic performance. Angewandte Chemie International Edition, 2016, 128(47): 14789. |

| [70] |

MA G, SHAO H, XU J, et al. Li-ion storage properties of two- dimensional titanium-carbide synthesized via fast one-pot method in air atmosphere. Nature Communications, 2021, 12(1): 5085.

DOI |

| [71] | CHEN J, JIN Q, LI Y, et al. Molten salt-shielded synthesis (MS3) of MXenes in air. Energy & Environmental Materials, 2023, 6(2): e12328. |

| [72] |

SHEN M, JIANG W, LIANG K, et al. One-pot green process to synthesize MXene with controllable surface terminations using molten salts. Angewandte Chemie, 2021, 133(52): 27219.

DOI URL |

| [73] | ZHOU J, LIN Z, REN H, et al. Layered intercalation materials. Advanced Materials, 2021, 33(25): e2004557. |

| [74] |

KAMYSBAYEV V, FILATOV A S, HU H, et al. Covalent surface modifications and superconductivity of two-dimensional metal carbide MXenes. Science, 2020, 369(6506): 979.

DOI URL |

| [75] |

CUI S, FENG W, HU H, et al. Hexagonal Ti2SC with high hardness and brittleness: a first-principles study. Scripta Materialia, 2009, 61(6): 576.

DOI URL |

| [76] |

CHEN K, YE Q, ZHOU J, et al. Synthesis of Ti2SC phase using iron disulfide or iron sulfide post-treated with acid. Journal of the American Ceramic Society, 2015, 98(4): 1074.

DOI URL |

| [77] | AMINI S, BARSOUM M W, EL RAGHY T. Synthesis and mechanical properties of fully dense Ti2SC. Journal of the American Ceramic Society, 2007, 90(12): 3953. |

| [78] | SCABAROZI T, AMINI S, FINKEL P, et al. Electrical, thermal, and elastic properties of the MAX-phase Ti2SC. Journal of Applied Physics, 2008, 104(3): 033502. |

| [79] |

WANG X, CHEN K, WU E, et al. Synthesis and thermal expansion of chalcogenide MAX phase Hf2SeC. Journal of the European Ceramic Society, 2022, 42(5): 2084.

DOI URL |

| [80] |

FU H, TENG M, LIU W, et al. The axial compressibility, thermal expansion and elastic anisotropy of Hf2SC under pressure. The European Physical Journal B, 2010, 78(1): 37.

DOI URL |

| [81] |

GONZALEZ-JULIAN J. Processing of MAX phases: from synthesis to applications. Journal of the American Ceramic Society, 2021, 104(2): 659.

DOI URL |

| [82] |

CHEN K, WANG X, ZHANG J, et al. Effect of A-site atom on static corrosion behavior and irradiation damage of Ti2SC phases. Journal of the American Ceramic Society, 2022, 105(2): 1386.

DOI URL |

| [83] |

WANG X, CHEN K, LI Z, et al. MAX phases Hf2(SexS1-x)C (x=0-1) and their thermal expansion behaviors. Journal of the European Ceramic Society, 2023, 43(5): 1874.

DOI URL |

| [84] | ALI M, QURESHI M W. DFT insights into the new Hf-based chalcogenide MAX phase Hf2SeC. Vacuum, 2022, 201: 111072. |

| [85] |

ALI M, QURESHI M W. Newly synthesized MAX phase Zr2SeC: DFT insights into physical properties towards possible applications. RSC Advances, 2021, 11(28): 16892.

DOI URL |

| [86] |

CHEN K, CHEN Y, ZHANG J, et al. Medium-entropy (Ti,Zr,Hf)2SC MAX phase. Ceramics International, 2021, 47(6): 7582.

DOI URL |

| [87] |

XIONG K, SUN Z, ZHANG S, et al. A comparative study the structural, mechanical, and electronic properties of medium- entropy MAX phase (TiZrHf)2SC with Ti2SC, Zr2SC, Hf2SC via first-principles. Journal of Materials Research and Technology, 2022, 19: 2717.

DOI URL |

| [88] | RACKL T, JOHRENDT D. The MAX phase borides Zr2SB and Hf2SB. Solid State Sciences, 2020, 106: 106316. |

| [89] |

ZHOU Y, XIANG H, HU C. Extension of MAX phases from ternary carbides and nitrides (X= C and N) to ternary borides (X= B, C, and N): a general guideline. International Journal of Applied Ceramic Technology, 2023, 20(2): 803.

DOI URL |

| [90] |

ZHANG Q, FU S, WAN D, et al. Rapidly synthesizing Hf2SB ceramics by thermal explosion. Journal of the European Ceramic Society, 2022, 42(9): 3780.

DOI URL |

| [91] |

ZHANG Q, FU S, WAN D, et al. Synthesis and property characterization of ternary laminar Zr2SB ceramic. Journal of Advanced Ceramics, 2022, 11(5): 825.

DOI |

| [92] | QIN Y, ZHOU Y, FAN L, et al. Synthesis and characterization of ternary layered Nb2SB ceramics fabricated by spark plasma sintering. Journal of Alloys and Compounds, 2021, 878: 160344. |

| [93] |

ZHANG Q, ZHOU Y, SAN X, et al. Thermal explosion synthesis of first Te-containing layered ternary Hf2TeB MAX phase. Journal of the European Ceramic Society, 2023, 43(1): 173.

DOI URL |

| [94] |

SUN Z M, GUPTA S, YE H, et al. Spontaneous growth of freestanding Ga nanoribbons from Cr2GaC surfaces. Journal of Materials Research, 2005, 20(10): 2618.

DOI URL |

| [95] | WANG X, ZHOU Y. Layered machinable and electrically conductive Ti2AlC and Ti3AlC2 ceramics: a review. Journal of Materials Science & Technology, 2010, 26(5): 385. |

| [96] |

EKLUND P, BECKERS M, JANSSON U, et al. The Mn+1AXn phases: materials science and thin-film processing. Thin Solid Films, 2010, 518(8): 1851.

DOI URL |

| [97] | HETTINGER J, LOFLAND S, FINKEL P, et al. Electrical transport, thermal transport, and elastic properties of M2AlC (M=Ti, Cr, Nb, and V). Physical Review B, 2005, 72(11): 115120. |

| [98] | SCABAROZI T, GANGULY A, HETTINGER J, et al. Electronic and thermal properties of Ti3Al(C0.5,N0.5)2, Ti2Al(C0.5,N0.5) and Ti2AlN. Journal of Applied Physics, 2008, 104(7): 073713. |

| [99] |

HU C, HE L, ZHANG J, et al. Microstructure and properties of bulk Ta2AlC ceramic synthesized by an in situ reaction/hot pressing method. Journal of the European Ceramic Society, 2008, 28(8): 1679.

DOI URL |

| [100] | HU C, HUANG Q, BAO Y, et al. Sintering of ceramics: new emerging techniques. Norderstedt: BoD-Books on Demand, 2012: 141. |

| [101] |

HU C, SAKKA Y, TANAKA H, et al. Low temperature thermal expansion, high temperature electrical conductivity, and mechanical properties of Nb4AlC3 ceramic synthesized by spark plasma sintering. Journal of Alloys and Compounds, 2009, 487(1/2): 675.

DOI URL |

| [102] |

EL-RAGHY T, CHAKRABORTY S, BARSOUM M. Synthesis and characterization of Hf2PbC, Zr2PbC and M2SnC (M=Ti, Hf, Nb or Zr). Journal of the European Ceramic Society, 2000, 20(14/15): 2619.

DOI URL |

| [103] |

BARSOUM M, EL-RAGHY T, ALI M. Processing and characterization of Ti2AlC, Ti2AlN, and Ti2AlC0.5N0.5. Metallurgical and Materials Transactions A, 2000, 31(7): 1857.

DOI URL |

| [104] |

BARSOUM M W, RADOVIC M. Mechanical properties of the MAX phases. Annual Review of Materials Research, 2011, 41(1): 195.

DOI URL |

| [105] | 吴希俊. 晶界结构及其对力学性质的影响(I). 力学进展, 1989, 19(4): 9. |

| [106] |

ETZKORN J, ADE M, HILLEBRECHT H. V2AlC, V4AlC3-x (x≈ 0.31), and V12Al3C8: synthesis, crystal growth, structure, and superstructure. Inorganic Chemistry, 2007, 46(18): 7646.

DOI URL |

| [107] |

OUISSE T, SARIGIANNIDOU E, CHAIX-PLUCHERY O, et al. High temperature solution growth and characterization of Cr2AlC single crystals. Journal of Crystal Growth, 2013, 384: 88.

DOI URL |

| [108] |

ETZKORN J, ADE M, HILLEBRECHT H. Ta3AlC2 and Ta4AlC3-single-crystal investigations of two new ternary carbides of tantalum synthesized by the molten metal technique. Inorganic Chemistry, 2007, 46(4): 1410.

DOI URL |

| [109] |

ETZKORN J, ADE M, KOTZOTT D, et al. Ti2GaC, Ti4GaC3 and Cr2GaC-synthesis, crystal growth and structure analysis of Ga-containing MAX-phases Mn+1GaCn with M=Ti, Cr and n=1, 3. Journal of Solid State Chemistry, 2009, 182(5): 995.

DOI URL |

| [110] |

CHAMPAGNE A, BATTAGLIA J L, OUISSE T, et al. Heat capacity and anisotropic thermal conductivity in Cr2AlC single crystals at high temperature. The Journal of Physical Chemistry C, 2020, 124(43): 24017.

DOI URL |

| [111] |

ZHANG S, SHI L, MERCIER F, et al. Conversion of MAX phase single crystals in highly porous carbides by high temperature chlorination. Ceramics International, 2017, 43(11): 8246.

DOI URL |

| [112] |

OUISSE T, PINEK D, BARSOUM M. Modelling in-plane magneto- transport in Cr2AlC. Ceramics International, 2019, 45(17): 22956.

DOI URL |

| [113] |

SHI L, OUISSE T, SARIGIANNIDOU E, et al. Synthesis of single crystals of V2AlC phase by high-temperature solution growth and slow cooling technique. Acta Materialia, 2015, 83: 304.

DOI URL |

| [114] | PINEK D, ITO T, IKEMOTO M, et al. Electronic structure of V2AlC. Physical Review B, 2018, 98(3): 035120. |

| [115] |

KIM Y, GKOUNTARAS A, CHAIX-PLUCHERY O, et al. Elementary processes governing V2AlC chemical etching in HF. RSC Advances, 2020, 10(42): 25266.

DOI URL |

| [116] |

WANG D, SI J, LIN S, et al. Achieving macroscopic V4C3Tx MXene by selectively etching Al from V4AlC3 single crystals. Inorganic Chemistry, 2020, 59(5): 3239.

DOI URL |

| [117] |

SHI O, XU L, JIANG A, et al. Synthesis and oxidation resistance of MoAlB single crystals. Ceramics International, 2019, 45(2): 2446.

DOI URL |

| [118] | DAHLQVIST M, LU J, MESHKIAN R, et al. Prediction and synthesis of a family of atomic laminate phases with Kagomé-like and in-plane chemical ordering. Science Advances, 2017, 3(7): e1700642. |

| [119] |

TAO Q, LU J, DAHLQVIST M, et al. Atomically layered and ordered rare-earth i-MAX phases: a new class of magnetic quaternary compounds. Chemistry of Materials, 2019, 31(7): 2476.

DOI URL |

| [120] |

PETRUHINS A, LU J, HULTMAN L, et al. Synthesis of atomically layered and chemically ordered rare-earth (RE) i-MAX phases; (Mo2/3RE1/3)2GaC with RE=Gd, Tb, Dy, Ho, Er, Tm, Yb, and Lu. Materials Research Letters, 2019, 7(11): 446.

DOI URL |

| [121] |

YANG J, LIU R, JIA N, et al. Novel W-based in-plane chemically ordered (W2/3R1/3)2AlC (R=Gd, Tb, Dy, Ho, Er, Tm and Lu) MAX phases and their 2D W1.33C MXene derivatives. Carbon, 2021, 183: 76.

DOI URL |

| [122] | SUN S, MA Z, CHEN Z, et al. The crystallographic structure and properties of novel quaternary nanolaminated rare-earth-Cr-based i-MAX phases. Acta Materialia, 2023, 242: 118479. |

| [123] | MESHKIAN R, DAHLQVIST M, LU J, et al. W-based atomic laminates and their 2D derivative W1.33C MXene with vacancy ordering. Advanced Materials, 2018, 30(21): 1706409. |

| [124] |

PETRUHINS A, DAHLQVIST M, LU J, et al. Theoretical prediction and experimental verification of the chemically ordered atomic-laminate i-MAX phases (Cr2/3Sc1/3)2GaC and (Mn2/3Sc1/3)2GaC. Crystal Growth & Design, 2019, 20(1): 55.

DOI URL |

| [125] |

LU J, THORE A, MESHKIAN R, et al. Theoretical and experimental exploration of a novel in-plane chemically ordered (Cr2/3M1/3)2AlC i-MAX phase with M= Sc and Y. Crystal Growth & Design, 2017, 17(11): 5704.

DOI URL |

| [126] |

CHEN L, DAHLQVIST M, LAPAUW T, et al. Theoretical prediction and synthesis of (Cr2/3Zr1/3)2AlC i-MAX phase. Inorganic Chemistry, 2018, 57(11): 6237.

DOI URL |

| [127] |

THÖRNBERG J, HALIM J, LU J, et al. Synthesis of (V2/3Sc1/3)2AlC i-MAX phase and V2-xC MXene scrolls. Nanoscale, 2019, 11(31): 14720.

DOI URL |

| [128] |

DAHLQVIST M, PETRUHINS A, LU J, et al. Origin of chemically ordered atomic laminates (i-MAX): expanding the elemental space by a theoretical/experimental approach. ACS Nano, 2018, 12(8): 7761.

DOI URL |

| [129] | QI X X, SONG G P, YIN W L, et al. Analysis on phase stability and mechanical property of newly-discovered ternary layered boride Cr4AlB4. Journal of Inorganic Materials, 2020, 35(1): 53. |

| [130] |

BAI Y, QI X, HE X, et al. Phase stability and weak metallic bonding within ternary-layered borides CrAlB, Cr2AlB2, Cr3AlB4, and Cr4AlB6. Journal of the American Ceramic Society, 2019, 102(6): 3715.

DOI URL |

| [131] |

BAI Y, QI X, DUFF A, et al. Density functional theory insights into ternary layered boride MoAlB. Acta Materialia, 2017, 132: 69.

DOI URL |

| [132] |

KOTA S, ZAPATA-SOLVAS E, LY A, et al. Synthesis and characterization of an alumina forming nanolaminated boride: MoAlB. Scientific Reports, 2016, 6(1): 26475.

DOI |

| [133] |

LI N, BAI Y, WANG S, et al. Rapid synthesis, electrical, and mechanical properties of polycrystalline Fe2AlB2 bulk from elemental powders. Journal of the American Ceramic Society, 2017, 100(10): 4407.

DOI URL |

| [134] | ZHANG H, DAI F Z, XIANG H, et al. Crystal structure of Cr4AlB4: a new MAB phase compound discovered in Cr-Al-B system. Journal of Materials Science & Technology, 2019, 35(4): 530. |

| [135] | MCGUIRE M A, PARKER D S. Magnetic and structural properties of ferromagnetic Fe5PB2 and Fe5SiB2 and effects of Co and Mn substitutions. Journal of Applied Physics, 2015, 118(16): 163903. |

| [136] | ELMELIGY T A, KOTA S, NATU V, et al. Synthesis, characterization, properties, first principles calculations, and X-ray photoelectron spectroscopy of bulk Mn5SiB2 and Fe5SiB2 ternary borides. Journal of Alloys and Compounds, 2021, 888: 161377. |

| [137] |

ZHANG Q, ZHOU Y, SAN X, et al. Zr2SeB and Hf2SeB: two new MAB phase compounds with the Cr2AlC-type MAX phase (211 phase) crystal structures. Journal of Advanced Ceramics, 2022, 11(11): 1764.

DOI |

| [138] |

QI X, HE X, YIN W, et al. Stability trend, weak bonding, and magnetic properties of the Al-and Si-containing ternary-layered borides MAB phases. Journal of the American Ceramic Society, 2022, 106(2): 1513.

DOI URL |

| [139] |

LU J, KOTA S, BARSOUM M W, et al. Atomic structure and lattice defects in nanolaminated ternary transition metal borides. Materials Research Letters, 2017, 5(4): 235.

DOI URL |

| [140] |

ZHANG H, KIM J Y, SU R, et al. Defect behavior and radiation tolerance of MAB phases (MoAlB and Fe2AlB2) with comparison to MAX phases. Acta Materialia, 2020, 196: 505.

DOI URL |

| [141] | SUN Y, YANG A, DUAN Y, et al. Electronic, elastic, and thermal properties, fracture toughness, and damage tolerance of TM5Si3B (TM=V and Nb) MAB phases. International Journal of Refractory Metals and Hard Materials, 2022, 103: 105781. |

| [142] |

OKADA S, IIZUMI K, KUDAKA K, et al. Single crystal growth of (MoxCr1-x)AlB and (MoxW1-x)AlB by metal Al solutions and properties of the crystals. Journal of Solid State Chemistry, 1997, 133(1): 36.

DOI URL |

| [143] | POTASHNIKOV D, CASPI E, PESACH A, et al. Magnetic properties of (Fe1-xMnx)2AlB2 and the impact of substitution on the magnetocaloric effect. Physical Review Materials, 2020, 4(8): 084404. |

| [144] |

HANNER L A, BADR H O, DAHLQVIST M, et al. Synthesis, characterization and first principle modelling of the MAB phase solid solutions: (Mn1-xCrx)2AlB2 and (Mn1-xCrx)3AlB4. Materials Research Letters, 2021, 9(2): 112.

DOI URL |

| [145] | YAO B, LI S, MA P, et al. Oxidation behavior of MoAl0.97Si0.03B solid solution at 1200-1400 ℃. Materials Today Communications, 2020, 22: 100846. |

| [146] |

GUO Z, ZHOU J, SUN Z. New two-dimensional transition metal borides for Li ion batteries and electrocatalysis. Journal of Materials Chemistry A, 2017, 5(45): 23530.

DOI URL |

| [147] | DAHLQVIST M, ALLING B, ROSÉN J. Stability trends of MAX phases from first principles. Physical Review B, 2010, 81(22): 220102. |

| [148] |

DAHLQVIST M, ROSEN J. Predictions of attainable compositions of layered quaternary i-MAB phases and solid solution MAB phases. Nanoscale, 2021, 13(43): 18311.

DOI URL |

| [149] |

BAI Y, HE X, SUN Y, et al. Chemical bonding and elastic properties of Ti3AC2 phases (A=Si, Ge, and Sn): a first-principle study. Solid State Sciences, 2010, 12(7): 1220.

DOI URL |

| [150] |

BAI Y, QI X, HE X, et al. Experimental and DFT insights into elastic, magnetic, electrical, and thermodynamic properties of MAB-phase Fe2AlB2. Journal of the American Ceramic Society, 2020, 103(10): 5837.

DOI URL |

| [151] |

LIN L C, BERGER A H, MARTIN R L, et al. In silico screening of carbon-capture materials. Nature Materials, 2012, 11(7): 633.

DOI |

| [152] | SU Y, FU H, BAI Y, et al. Progress in materials genome engineering in China. Acta Metallurgica Sinica, 2020, 56(10): 1313. |

| [153] |

YANG K, SETYAWAN W, WANG S, et al. A search model for topological insulators with high-throughput robustness descriptors. Nature Materials, 2012, 11(7): 614.

DOI |

| [154] | WANG G, LI K, PENG L, et al. High-throughput automatic integrated material calculations and data management intelligent platform and the application in novel alloys. Acta Metallurgica Sinica, 2021, 58(1): 75. |

| [155] |

PENG L, MIAO N, WANG G, et al. Novel metal oxides with promising high-temperature thermoelectric performance. Journal of Materials Chemistry C, 2021, 9(37): 12884.

DOI URL |

| [156] |

GAN Y, HUANG Y, MIAO N, et al. Novel IV-V-VI semiconductors with ultralow lattice thermal conductivity. Journal of Materials Chemistry C, 2021, 9(12): 4189.

DOI URL |

| [157] |

GAN Y, MIAO N, LAN P, et al. Robust design of high-performance optoelectronic chalcogenide crystals from high-throughput computation. Journal of the American Chemical Society, 2022, 144(13): 5878.

DOI URL |

| [158] |

GAN Y, WANG G, ZHOU J, et al. Prediction of thermoelectric performance for layered IV-V-VI semiconductors by high- throughput ab initio calculations and machine learning. npj Computational Materials, 2021, 7(1): 176.

DOI |

| [159] |

ALAMEDA L T, LORD R W, BARR J A, et al. Multi-step topochemical pathway to metastable Mo2AlB2 and related two- dimensional nanosheet heterostructures. Journal of the American Chemical Society, 2019, 141(27): 10852.

DOI URL |

| [160] |

LIU Y, JIANG Z, JIANG X, et al. New refractory MAB phases and their 2D derivatives: insight into the effects of valence electron concentration and chemical composition. RSC Advances, 2020, 10(43): 25836.

DOI URL |

| [161] |

KHAZAEI M, WANG J, ESTILI M, et al. Novel MAB phases and insights into their exfoliation into 2D MBenes. Nanoscale, 2019, 11(23): 11305.

DOI URL |

| [162] |

MIAO N, WANG J, GONG Y, et al. Computational prediction of boron-based MAX phases and MXene derivatives. Chemistry of Materials, 2020, 32(16): 6947.

DOI URL |

| [163] |

ZHANG B, ZHOU J, SUN Z. MBenes: progress, challenges and future. Journal of Materials Chemistry A, 2022, 10: 15865.

DOI URL |

| [164] |

XIANG H, FENG Z, LI Z, et al. Theoretical investigations on mechanical and dynamical properties of MAlB (M= Mo, W) nanolaminated borides at ground-states and elevated temperatures. Journal of Alloys and Compounds, 2018, 738: 461.

DOI URL |

| [165] | SURUCU G, YILDIZ B, ERKISI A, et al. The investigation of electronic, anisotropic elastic and lattice dynamical properties of MAB phase nanolaminated ternary borides: M2AlB2 (M=Mn, Fe and Co) under spin effects. Journal of Alloys and Compounds, 2020, 838: 155436. |

| [166] | KÁDAS K, IUŞAN D, HELLSVIK J, et al. AlM2B2 (M=Cr, Mn, Fe, Co, Ni): a group of nanolaminated materials. Journal of Physics: Condensed Matter, 2017, 29(15): 155402. |

| [167] | QURESHI M W, ALI M, MA X. Screen the thermomechanical and optical properties of the new ductile 314 MAX phase boride Zr3CdB4: a DFT insight. Journal of Alloys and Compounds, 2021, 877: 160248. |

| [168] | ALI M, HOSSAIN M, ISLAM A, et al. Ternary boride HF3PB4: insights into the physical properties of the hardest possible boride MAX phase. Journal of Alloys and Compounds, 2021, 857: 158264. |

| [169] | ZHANG H, XIANG H, DAI F Z, et al. First demonstration of possible two-dimensional MBene CrB derived from MAB phase Cr2AlB2. Journal of Materials Science & Technology, 2018, 34(11): 2022. |

| [170] |

ALAMEDA L T, MORADIFAR P, METZGER Z P, et al. Topochemical deintercalation of Al from MoAlB: stepwise etching pathway, layered intergrowth structures, and two-dimensional MBene. Journal of the American Chemical Society, 2018, 140(28): 8833.

DOI URL |

| [171] | KHALEDIALIDUSTI R, KHAZAEI M, WANG V, et al. Exploring structural, electronic, and mechanical properties of 2D hexagonal MBenes. Journal of Physics: Condensed Matter, 2021, 33(15): 155503. |

| [172] |

XING S, ZHOU J, ZHANG B, et al. Magnetic superexchange induced quantum phase transition in Cr2B2MBene. The Journal of Physical Chemistry C, 2022, 126(33): 14275.

DOI URL |

| [173] | ZHANG B, ZHOU J, GUO Z, et al. Two-dimensional chromium boride MBenes with high HER catalytic activity. Applied Surface Science, 2020, 500: 144248. |

| [174] |

JIANG Z, WANG P, JIANG X, et al. MBene (MnB): a new type of 2D metallic ferromagnet with high Curie temperature. Nanoscale Horizons, 2018, 3(3): 335.

DOI URL |

| [175] | LIU X, GE X, DONG Y, et al. First-principle calculations on the structure, electronic property and catalytic activity for hydrogen evolution reaction of 2D transition-metal borides. Materials Chemistry and Physics, 2020, 253: 123334. |

| [176] |

GORKAN T, VATANSEVER E, AKINCI U M, et al. Above room temperature ferromagnetism in Gd2B2 monolayer with high magnetic anisotropy. The Journal of Physical Chemistry C, 2020, 124(23): 12816.

DOI URL |

| [177] | GAO S, HAO J, ZHANG X, et al. Two dimension transition metal boride Y2B2 as a promising anode in Li-ion and Na-ion batteries. Computational Materials Science, 2021, 200: 110776. |

| [178] | LI R, LIU Y, DENG H, et al. A first-principles study of MBene as anode material for Mg-ion battery. Journal of Electrochemical Energy Conversion and Storage, 2020, 17(4): 041002. |

| [179] | XIAO Y, LI Y, GUO Z, et al. Functionalized Mo2B2 MBenes: promising anchoring and electrocatalysis materials for Lithium-sulfur battery. Applied Surface Science, 2021, 566: 150634. |

| [180] |

ZHANG T, ZHANG B, PENG Q, et al. Mo2B2 MBene-supported single-atom catalysts as bifunctional HER/OER and OER/ORR electrocatalysts. Journal of Materials Chemistry A, 2021, 9(1): 433.

DOI URL |

| [181] | GUO X, LIN S, GU J, et al. Establishing a theoretical landscape for identifying basal plane active 2D metal borides (MBenes) toward nitrogen electroreduction. Advanced Functional Materials, 2021, 31(6): 2008056. |

| [182] | SUN X, ZHENG J, GAO Y, et al. Machine-learning-accelerated screening of hydrogen evolution catalysts in MBenes materials. Applied Surface Science, 2020, 526: 146522. |

| [183] | LI S, SUN W, LUO Y, et al. Pushing the limit of thermal conductivity of MAX borides and MABs. Journal of Materials Science & Technology, 2022, 97: 79. |

| [184] | FENG S, MIAO N, WANG J. Hexagonal MBene (Hf2BO2): a promising platform for the electrocatalysis of hydrogen evolution reaction. ACS Applied Materials & Interfaces, 2021, 13(47): 56131. |

| [185] |

WANG S, MIAO N, SU K, et al. Discovery of intrinsic two-dimensional antiferromagnets from transition-metal borides. Nanoscale, 2021, 13(17): 8254.

DOI URL |

| [186] | DAI F-Z, XIANG H, SUN Y, et al. M2M'AlB4 (M=Mn, Fe, Co, M'= Cr, Mo, W): theoretical predicted ordered MAB phases with Cr3AlB4 crystal structure. Journal of Materials Science & Technology, 2019, 35(7): 1432. |

| [187] |

YAO Y, MIAO N, GONG Y, et al. Theoretical exploration of quaternary hexagonal MAB phases and two-dimensional derivatives. Nanoscale, 2021, 13(31): 13208.

DOI URL |

| [188] | NAIR V G, BIROWSKA M, BURY D, et al. 2D MBenes: a novel member in the flatland. Advanced Materials, 2022, 34: 2108840. |

| [189] | MORGAN D, CEDER G. Handbook of Materials Modeling:Methods. Berlin: Springer, Dordrecht, 2005: 395. |

| [190] |

FRIEDRICH W, KNIPPING P, LAUE M. Interferenzerscheinungen bei roentgenstrahlen. Annalen der Physik, 1913, 346(10): 971.

DOI URL |

| [191] | BRAGG W L. The structure of some crystals as indicated by their diffraction of X-rays. Proceedings of the Royal Society of London. Series A, 1913, 89(610): 248. |

| [192] |

WOLVERTON C, YAN X-Y, VIJAYARAGHAVAN R, et al. Incorporating first-principles energetics in computational thermodynamics approaches. Acta Materialia, 2002, 50(9): 2187.

DOI URL |

| [193] | ASTA M, OZOLINS V, WOODWARD C. A first-principles approach to modeling alloy phase equilibria. JOM, 2001, 53: 16. |

| [194] | BLUM V, ZUNGER A. Mixed-basis cluster expansion for thermodynamics of bcc alloys. Physical Review B, 2004, 70(15): 155108. |

| [195] |

CURTAROLO S, MORGAN D, CEDER G. Accuracy of ab initio methods in predicting the crystal structures of metals: a review of 80 binary alloys. Calphad, 2005, 29(3): 163.

DOI URL |

| [196] | CHELIKOWSKY J R. Digital Encyclopedia of Applied Physics: Cohesive Energy. Hoboken: Wiley Online Library, 2002: 572. |

| [197] | VILLARS P. Factors governing crystal structures. Principles, 1994: 227. |

| [198] | BURDETT J K, RODGERS J R. Structure & property maps for inorganic solids. John Wiley & Son. Ltd.: Encyclopedia of Inorganic Chemistry, 2006. |

| [199] | RAJAN K. Informatics for materials science and engineering. Amsterdam: Elsevier, 2013: 365. |

| [200] |

PETTIFOR D. Structure maps revisited. Journal of Physics: Condensed Matter, 2003, 15(25): V13.

DOI URL |

| [201] |

MOOSER E, PEARSON W. On the crystal chemistry of normal valence compounds. Acta Crystallographica, 1959, 12(12): 1015.

DOI URL |

| [202] |

ZUNGER A. Structural stability of 495 binary compounds. Physical Review Letters, 1980, 44(9): 582.

DOI URL |

| [203] |

VILLARS P. Three-dimensional structural stability diagrams for 648 binary AB3 and 389 binary A3B5 intermetallic compounds: III. Journal of the Less Common Metals, 1984, 102(2): 199.

DOI URL |

| [204] |

VILLARS P. A three-dimensional structural stability diagram for 1011 binary AB2 intermetallic compounds: II. Journal of the Less Common Metals, 1984, 99(1): 33.

DOI URL |

| [205] |

VILLARS P. A three-dimensional structural stability diagram for 998 binary AB intermetallic compounds. Journal of the Less Common Metals, 1983, 92(2): 215.

DOI URL |

| [206] |

PETTIFOR D G. A chemical scale for crystal-structure maps. Solid State Communications, 1984, 51(1): 31.

DOI URL |

| [207] |

PETTIFOR D. The structures of binary compounds. I. Phenomenological structure maps. Journal of Physics C: Solid State Physics, 1986, 19(3): 285.

DOI URL |

| [208] |

ZHOU A, BASU S, BARSOUM M. Kinking nonlinear elasticity, damping and microyielding of hexagonal close-packed metals. Acta Materialia, 2008, 56(1): 60.

DOI URL |

| [209] |

KONTSOS A, LOUTAS T, KOSTOPOULOS V, et al. Nanocrystalline Mg-MAX composites: mechanical behavior characterization via acoustic emission monitoring. Acta Materialia, 2011, 59(14): 5716.

DOI URL |

| [210] |

BARSOUM M, ZHEN T, KALIDINDI S, et al. Fully reversible, dislocation-based compressive deformation of Ti3SiC2 to 1 GPa. Nature Materials, 2003, 2(2): 107.

DOI |

| [211] |

AMINI S, NI C, BARSOUM M W. Processing, microstructural characterization and mechanical properties of a Ti2AlC/nanocrystalline Mg-matrix composite. Composites Science and Technology, 2009, 69(3/4): 414.

DOI URL |

| [212] |

ANASORI B, EL’AD N C, BARSOUM M W. Fabrication and mechanical properties of pressureless melt infiltrated magnesium alloy composites reinforced with TiC and Ti2AlC particles. Materials Science and Engineering: A, 2014, 618: 511.

DOI URL |

| [213] |

CHEN W, YU W, MA C, et al. A review of novel ternary nano-layered MAX phases reinforced AZ91D magnesium composite. Journal of Magnesium and Alloys, 2022, 10(6): 1457.

DOI URL |

| [214] |

GUPTA S, BARSOUM M. On the tribology of the MAX phases and their composites during dry sliding: a review. Wear, 2011, 271(9/10): 1878.

DOI URL |

| [215] | 刘文扬, 张建波, 陈婷婷, 等. MAX/金属基自润滑复合材料摩擦学研究. 有色金属科学与工程, 2017, 8(4): 61. |

| [216] | ZHAO H, FENG Y, ZHOU Z, et al. Effect of electrical current density, apparent contact pressure, and sliding velocity on the electrical sliding wear behavior of Cu-Ti3AlC2 composites. Wear, 2020, 444: 203156. |

| [217] | YANG K, MA H, ZHAO W, et al. Investigation of the preparation and tribological behavior of a frictional interface covered with sinusoidal microchannels containing SnAgCu and Ti3SiC2. Tribology International, 2020, 150: 106368. |

| [218] |

WANG D, TIAN W, MA A, et al. Anisotropic properties of Ag/Ti3AlC2 electrical contact materials prepared by equal channel angular pressing. Journal of Alloys and Compounds, 2019, 784: 431.

DOI URL |

| [219] | WANG D D, TIAN W B, DING J X, et al. Anisotropic arc erosion resistance of Ag/Ti3AlC2 composites induced by the alignment of Ti3AlC2. Corrosion Science, 2020, 171: 108633. |

| [220] | HUANG X, FENG Y, GE J, et al. Arc erosion mechanism of Ag-Ti3SiC2 material. Journal of Alloys and Compounds, 2020, 817: 152741. |

| [221] |

DING J, TIAN W, WANG D, et al. Corrosion and degradation mechanism of Ag/Ti3AlC2 composites under dynamic electric arc discharge. Corrosion Science, 2019, 156: 147.

DOI URL |

| [222] | LIU Y, JI C, SU X, et al. Electromagnetic and microwave absorption properties of Ti3SiC2 powders decorated with Ag particles. Journal of Alloys and Compounds, 2020, 820: 153154. |

| [223] | WANG D, TIAN W, DING J, et al. The beauty and the deed of silver during arc erosion of Ag/Ti3AlC2 contacts. Journal of Alloys and Compounds, 2020, 820: 153136. |

| [224] |

HU W, HUANG Z, CAI L, et al. In-situ TiC and γ′-Ni3(Al,Ti) triggered microstructural modification and strengthening of Ni matrix composite by reactive hot-press sintering pure Ni and Ti2AlC precursor. Journal of Alloys and Compounds, 2018, 747: 1043.

DOI URL |

| [225] |

HUANG X, GAO Y, WANG Z, et al. Microstructure, mechanical properties and strengthening mechanisms of in-situ prepared (Ti5Si3+TiC0.67)/TC4 composites. Journal of Alloys and Compounds, 2019, 792: 907.

DOI URL |

| [226] |

HUANG Z, BONNEVILLE J, ZHAI H, et al. Microstructural characterization and compression properties of TiC0.61/Cu(Al) composite synthesized from Cu and Ti3AlC2 powders. Journal of Alloys and Compounds, 2014, 602: 53.

DOI URL |

| [227] |

LI M, ZHAI H, HUANG Z, et al. Tensile behavior and strengthening mechanism in ultrafine TiC0.5 particle reinforced Cu-Al matrix composites. Journal of Alloys and Compounds, 2015, 628: 186.

DOI URL |

| [228] |

HU W, HUANG Z, CAI L, et al. Microstructural characterization and mechanical properties of a novel TiC-based cermet bonded with Ni3(Al,Ti) and NiAl duplexalloy. Materials Characterization, 2018, 135: 295.

DOI URL |

| [229] |

HU W, HUANG Z, CAI L, et al. Exploring the interfacial state and tensile behaviors in nickel matrix composite with in-situ TiC and γ′-Ni3(Al,Ti) reinforcements. Journal of Alloys and Compounds, 2018, 765: 987.

DOI URL |

| [230] |

HU W, HUANG Z, YU Q, et al. Investigation on high temperature mechanical behaviors of TiC-γ′ reinforced Ni composite. Metals and Materials International, 2021, 27(8): 3003.

DOI |

| [231] | JIAO Y, HUANG Z, HU W, et al. In-situ hybrid Cr3C2 and γ′-Ni3(Al,Cr) strengthened Ni matrix composites: microstructure and enhanced properties. Materials Science and Engineering: A, 2021, 820: 141524. |

| [232] | LI X, HUANG Z, WANG H, et al. Ni composites reinforced with ultrafine and uniform TiCx and Cr3C2 particles in situ: enhanced properties and a well-matched interface. Materials Science and Engineering: A, 2022, 857: 144081. |

| [233] |

YU Q, HUANG Z, ZHENG G, et al. Thermal shock behavior of a novel TiCx-Ni3(Al,Ti)/Ni functionally graded composite. Metals and Materials International, 2021, 27(12): 5133.

DOI |

| [234] | HU W, HUANG Z, YU Q, et al. Ti2AlC triggered in-situ ultrafine TiC/Inconel 718 composites: microstructure and enhanced properties. Journal of Materials Science & Technology, 2020, 51: 70. |

| [235] | YU Q, HUANG Z, HU W, et al. High strength and toughness of in-situ TiC/In718 functionally gradient material by using Ti3AlC2 as a precursor. Journal of Alloys and Compounds, 2022, 920: 165962. |

| [236] | CHIKER N, BENAMOR A, HADDAD A, et al. Pressureless sintering and tribological properties of in-situ TiC-Ni3(Al,Ti)/ Ni(Al,Ti) composites. International Journal of Refractory Metals and Hard Materials, 2021, 98: 105559. |

| [237] | ZHANG F, DU M, FAN K, et al. Fabrication and mechanical properties of network structured titanium alloy matrix composites reinforced with Ti2AlC particulates. Materials Science and Engineering: A, 2020, 776: 139065. |

| [238] | WANG H, HUANG Z, LI X, et al. Microstructure and properties of TiCx/TC4 composites with a quasi-network structure prepared by the decomposition of the Ti2AlC precursor. Journal of Alloys and Compounds, 2022, 920: 166011. |

| [239] | SUN Y, ZHOU C, ZHAO Z, et al. Microstructure and mechanical properties of Ti2AlC particle and in-situ TiAl3 reinforced pure Al composites. Materials Science and Engineering: A, 2020, 785: 139310. |

| [240] |

WANG Y, HUANG Z, HU W, et al. Microstructure and mechanical behaviors of Ti3AlC2 triggered in-situ Al3Ti and TiC reinforced 2024Al composite. Journal of Materials Research and Technology, 2022, 19: 289.

DOI URL |

| [241] | ZHUANG W, HUANG Z, HU W, et al. Microstructure characterization and enhanced mechanical properties of quasi- continuous network structured Ti3AlC2-Al3Ti/2024Al composite. Materials Characterization, 2022, 191: 112131. |

| [242] |

BARSOUM M, FARBER L. Room-temperature deintercalation and self-extrusion of Ga from Cr2GaN. Science, 1999, 284(5416): 937.

DOI URL |

| [243] | BARSOUM M W, HOFFMAN E N, DOHERTY R D, et al. Driving force and mechanism for spontaneous metal whisker formation. Physical Review Letters, 2004, 93(20): 206104. |

| [244] |

ZHANG P, LIU Y, DING J, et al. Controllable growth of Ga wires from Cr2GaC-Ga and its mechanism. Physica B: Condensed Matter, 2015, 475: 90.

DOI URL |

| [245] |

LIU Y, ZHANG P, LING C, et al. Spontaneous Sn whisker formation on Ti2SnC. Journal of Materials Science: Materials in Electronics, 2017, 28(8): 5788.

DOI URL |

| [246] | TANG J, ZHANG P, LIU Y, et al. Selective growth of tin whiskers from its alloys on Ti2SnC. Journal of Materials Science & Technology, 2020, 54: 206. |

| [247] |

ZHANG J, LIU B, WANG J, et al. Low-temperature instability of Ti2SnC: a combined transmission electron microscopy, differential scanning calorimetry, and X-ray diffraction investigations. Journal of Materials Research, 2009, 24(1): 39.

DOI URL |

| [248] | ZHANG P, ZHANG Y, SUN Z. Spontaneous growth of metal whiskers on surfaces of solids: a review. Journal of Materials Science & Technology, 2015, 31(7): 675. |

| [249] |

LIU Y, LU C, ZHANG P, et al. Mechanisms behind the spontaneous growth of tin whiskers on the Ti2SnC ceramics. Acta Materialia, 2020, 185: 433.

DOI URL |

| [250] |

LI C F, LIU Z Q. Microstructure and growth mechanism of tin whiskers on RESn3 compounds. Acta Materialia, 2013, 61(2): 589.

DOI URL |

| [251] |

PEI F, BUCHOVECKY E, BOWER A, et al. Stress evolution and whisker growth during thermal cycling of Sn films: a comparison of analytical modeling and experiments. Acta Materialia, 2017, 129: 462.

DOI URL |

| [252] |

DELHAISE A M, BAGHERI Z, MESCHTER S, et al. Tin whisker growth on electronic assemblies soldered with Bi-containing, Pb-free alloys. Journal of Electronic Materials, 2021, 50(3): 842.

DOI |

| [253] |

CHASON E, JADHAV N, PEI F, et al. Growth of whiskers from Sn surfaces: driving forces and growth mechanisms. Progress in Surface Science, 2013, 88(2): 103.

DOI URL |

| [254] | KIRSCH M, GONZALEZ O, AGUILAR M, et al. NASA engineering and safety center technical assessment report: national highway traffic safety administration Toyota unintended acceleration investigation. (2011-01-18) [2023-04-24]. https://static.nhtsa.gov/odi/inv/2014/INRP-DP14003-61483.pdf |

| [255] |

SMETANA J. Theory of tin whisker growth: “the end game”. IEEE Transactions on Electronics Packaging Manufacturing, 2007, 30(1): 11.

DOI URL |

| [256] | 田志华, 张培根, 刘玉爽, 等. MAX 相表面金属晶须自发生长现象的研究现状与展望. 金属学报, 2022, 58(3): 295. |

| [257] |

ZHANG P, SHEN L, OUYANG J, et al. Room temperature mushrooming of gallium wires and its growth mechanism. Journal of Alloys and Compounds, 2015, 619: 488.

DOI URL |

| [258] | ZHANG Q, TIAN Z, ZHANG P, et al. Rapid and massive growth of tin whisker on mechanochemically decomposed Ti2SnC. Materials Today Communications, 2022, 31: 103466. |

| [259] | LIU Y, ZHANG P, YU J, et al. Confining effect of oxide film on tin whisker growth. Journal of Materials Science & Technology, 2019, 35(8): 1735. |

| [260] | 赵子寿, 冼爱平. 锡晶须生长机理研究的现状与问题. 中国有色金属学报, 2012, 22(8): 2267. |

| [261] | TIAN Z, ZHANG P, ZHANG Y, et al. Tin whisker growth from titanium-tin intermetallic and the mechanism. Journal of Materials Science & Technology, 2022, 129: 79. |

| [262] |

LI S, LIU Y, ZHANG P, et al. Interface energy-driven indium whisker growth on ceramic substrates. Journal of Materials Science: Materials in Electronics, 2021, 32(12): 16881.

DOI |

| [263] | EL-RAGHY T, BARSOUM M. Growing metallic whiskers: alternative interpretation. Science, 1999, 285(5432): 1355. |

| [264] | LU C, LIU Y, FANG J, et al. Isotope study reveals atomic motion mechanism for the formation of metal whiskers in MAX phase. Acta Materialia, 2021, 203: 116475. |

| [265] | HOFFMAN E N, BARSOUM M W, WANG W, et al. On the spontaneous growth of soft metallic whiskers. Proceedings of the Fifty-First IEEE Holm Conference on Electrical Contacts, 2005, 2005: 121. |

| [266] | 刘玉爽. MAX相中A位金属晶须自发生长机理研究. 南京: 东南大学博士学位论文, 2020. |

| [267] |

ZHANG Q, TANG J, TANG H, et al. Method for inhibiting Sn whisker growth on Ti2SnC. Journal of Materials Science, 2022, 57(43): 20462.

DOI |

| [268] |

HAN M, GOGOTSI Y. Perspectives for electromagnetic radiation protection with MXenes. Carbon, 2023, 204: 17.

DOI URL |

| [269] |

BAI P, WANG S, ZHAO B, et al. Electrically conductive and corrosion resistant MAX phases with superior electromagnetic wave shielding performance. Journal of the European Ceramic Society, 2022, 42(16): 7414.

DOI URL |

| [270] | LI S, TAN Y, XUE J, et al. Electromagnetic interference shielding performance of nano-layered Ti3SiC2 ceramics at high-temperatures. AIP Advances, 2018, 8(1): 015027. |

| [271] |

TAN Y, LUO H, ZHOU X, et al. Dependences of microstructure on electromagnetic interference shielding properties of nano-layered Ti3AlC2 ceramics. Scientific Reports, 2018, 8(1): 7935.

DOI |

| [272] | TAN Y, LUO H, ZHANG H, et al. High-temperature electromagnetic interference shielding of layered Ti3AlC2 ceramics. Scripta Materialia, 2017, 134: 471. |

| [273] |

FAN X, YIN X, CHEN L, et al. Mechanical behavior and electromagnetic interference shielding properties of C/SiC-Ti3Si(Al)C2. Journal of the American Ceramic Society, 2016, 99(5): 1717.

DOI URL |

| [274] | ZHONG Z, ZHANG B, YE J, et al. Tailorable microwave absorption properties of macro-porous core@shell structured SiC@Ti3SiC2 via molten salt shielded synthesis (MS3) method in air. Journal of Alloys and Compounds, 2022, 927: 167046. |

| [275] | ZHANG Y, WEN J, ZHANG L, et al. High antioxidant lamellar structure Cr2AlC: dielectric and microwave absorption properties in X band. Journal of Alloys and Compounds, 2021, 860: 157896. |

| [276] |

YAO P, QIAN Y, LI W, et al. Exploration of dielectric and microwave absorption properties of quaternary MAX phase ceramic (Cr2/3Ti1/3)3AlC2. Ceramics International, 2020, 46(14): 22919.

DOI URL |

| [277] | LI J, XU T, BAI H, et al. Structural modifications and electromagnetic property regulations of Ti3AlC2 MAX for enhancing microwave absorption through the strategy of Fe doping. Advanced Materials Interfaces, 2022, 9(6): 2101510. |

| [278] |

ZHANG H, ZHAO B, XIANG H, et al. Electromagnetic wave absorbing properties of Cr2AlB2 powders and the effect of high- temperature oxidation. Journal of the American Ceramic Society, 2021, 104(5): 2213.

DOI URL |

| [279] | SHAHZAD F, IQBAL A, KIM H, et al. 2D transition metal carbides (MXenes): applications as an electrically conducting material. Advanced Materials, 2020, 32(51): 2002159. |

| [280] |

SHAHZAD F, ALHABEB M, HATTER C B, et al. Electromagnetic interference shielding with 2D transition metal carbides (MXenes). Science, 2016, 353(6304): 1137.

DOI URL |

| [281] | HAN M, YIN X, WU H, et al. Ti3C2 MXenes with modified surface for high-performance electromagnetic absorption and shielding in the X-band. ACS Applied Materials & Interfaces, 2016, 8(32): 21011. |

| [282] |

HAN M, SHUCK C E, RAKHMANOV R, et al. Beyond Ti3C2Tx: MXenes for electromagnetic interference shielding. ACS Nano, 2020, 14(4): 5008.

DOI URL |

| [283] | ZHANG J, KONG N, UZUN S, et al. Scalable manufacturing of free-standing, strong Ti3C2Tx MXene films with outstanding conductivity. Advanced Materials, 2020, 32(23): 2001093. |

| [284] | YUN T, KIM H, IQBAL A, et al. Electromagnetic shielding of monolayer MXene assemblies. Advanced Materials, 2020, 32(9): 1906769. |

| [285] |

MATHIS T S, MALESKI K, GOAD A, et al. Modified MAX phase synthesis for environmentally stable and highly conductive Ti3C2 MXene. ACS Nano, 2021, 15(4): 6420.

DOI URL |

| [286] | HAN M, SHUCK C E, SINGH A, et al. Efficient microwave absorption with Vn+1CnTx MXenes. Cell Reports Physical Science, 2022, 3(10): 101073. |

| [287] |

HAN M, ZHANG D, SHUCK C E, et al. Electrochemically modulated interaction of MXenes with microwaves. Nature Nanotechnology, 2023, 18: 373.

DOI |

| [288] | MIRKHANI S A, SHAYESTEH ZERAATI A, ALIABADIAN E, et al. High dielectric constant and low dielectric loss via poly (vinyl alcohol)/Ti3C2Tx MXene nanocomposites. ACS Applied Materials & Interfaces, 2019, 11(20): 18599. |

| [289] |

WEN C, LI X, ZHANG R, et al. High-density anisotropy magnetism enhanced microwave absorption performance in Ti3C2Tx MXene@Ni microspheres. ACS Nano, 2021, 16(1): 1150.

DOI URL |

| [290] | LI X, YIN X, SONG C, et al. Self-assembly core-shell graphene- bridged hollow MXenes spheres 3D foam with ultrahigh specific EM absorption performance. Advanced Functional Materials, 2018, 28(41): 1803938. |

| [291] | LI M, ZHU W, LI X, et al. Ti3C2Tx/MoS2 self-rolling rod-based foam boosts interfacial polarization for electromagnetic wave absorption. Advanced Science, 2022: 2201118. |

| [292] | LI M, HAN M, ZHOU J, et al. Novel scale-like structures of graphite/TiC/Ti3C2 hybrids for electromagnetic absorption. Advanced Electronic Materials, 2018, 4(5): 1700617. |

| [293] |

KNASTER J, MOESLANG A, MUROGA T. Materials research for fusion. Nature Physics, 2016, 12(5): 424.

DOI |

| [294] | ZINKLE S J, BUSBY J T. Structural materials for fission & fusion energy. Materials Today, 2009, 12(11): 12. |

| [295] |

WANG C, YANG T, TRACY C L, et al. Disorder in Mn+1AXn phases at the atomic scale. Nature Communications, 2019, 10(1): 622.

DOI |

| [296] |

LE FLEM M, LIU X, DORIOT S, et al. Irradiation damage in Ti3(Si,Al)C2: a TEM investigation. International Journal of Applied Ceramic Technology, 2010, 7(6): 766.

DOI URL |

| [297] |

YANG T, WANG C, TAYLOR C A, et al. The structural transitions of Ti3AlC2 induced by ion irradiation. Acta Materialia, 2014, 65: 351.

DOI URL |

| [298] |

WANG C, YANG T, XIAO J, et al. Structural transitions induced by ion irradiation in V2AlC and Cr2AlC. Journal of the American Ceramic Society, 2016, 99(5): 1769.

DOI URL |

| [299] |