无机材料学报 ›› 2021, Vol. 36 ›› Issue (2): 128-139.DOI: 10.15541/jim20200488 CSTR: 32189.14.10.15541/jim20200488

所属专题: 封面文章; 电致变色材料与器件; 功能材料论文精选(2021); 【虚拟专辑】电致变色与热致变色材料; 电致变色专栏2021

• 专栏: 电致变色材料与器件(特邀编辑:刁训刚, 王金敏) • 上一篇 下一篇

收稿日期:2020-08-24

修回日期:2020-09-23

出版日期:2021-02-20

网络出版日期:2020-11-05

通讯作者:

刁训刚, 教授. E-mail: diaoxg@buaa.edu.cn作者简介:钟晓岚(1986-), 女, 副教授. Email: zhongxl@buaa.edu.cn

基金资助:

ZHONG Xiaolan1( ), LIU Xueqing1, DIAO Xungang2(

), LIU Xueqing1, DIAO Xungang2( )

)

Received:2020-08-24

Revised:2020-09-23

Published:2021-02-20

Online:2020-11-05

About author:ZHONG Xiaolan(1986-), female, associate professor. E-mail: zhongxl@buaa.edu.cn

Supported by:摘要:

电致变色器件(Electrochromic Devices, ECDs)是一种颜色变化受电压调控的智能装置, 具有工作温度范围宽、光学对比度高、可逆双稳态性能好、驱动电压低和能耗低等优点, 在智能动态调光窗、全彩色电子显示屏、防眩光护目镜、自适应双隐身伪装以及可视化储能等领域展现出了巨大的应用潜力。阴极着色材料氧化钨(WO3)和阳极着色材料氧化镍(NiO)是两种被广泛研究的无机电致变色材料, 由WO3和NiO薄膜组成的互补型电致变色器件在大规模智能窗的应用中具有极高的商业价值。改善电致变色器件的综合性能如光学调制范围、响应速度、循环寿命和耐候性等问题一直备受关注。本文围绕互补型电致变色器件的结构组成, 综述了基于WO3和NiO的电致变色全器件的近期研究进展。首先分别阐述了WO3和NiO薄膜的电致变色机理和衰退机制, 讨论了改进制备工艺、元素掺杂改性、设计纳米结构和引入复合材料这四种薄膜性能优化策略的作用和最新研究进展, 其次, 按照器件的组成成分和结构设计介绍了互补型电致变色全器件的分类体系, 总结了各组分材料的选择和器件结构对器件综合性能的影响, 最后对电致变色器件的应用前景和发展趋势进行了展望。

中图分类号:

钟晓岚, 刘雪晴, 刁训刚. 基于氧化钨和氧化镍的电致变色器件研究进展[J]. 无机材料学报, 2021, 36(2): 128-139.

ZHONG Xiaolan, LIU Xueqing, DIAO Xungang. Electrochromic Devices Based on Tungsten Oxide and Nickel Oxide: a Review[J]. Journal of Inorganic Materials, 2021, 36(2): 128-139.

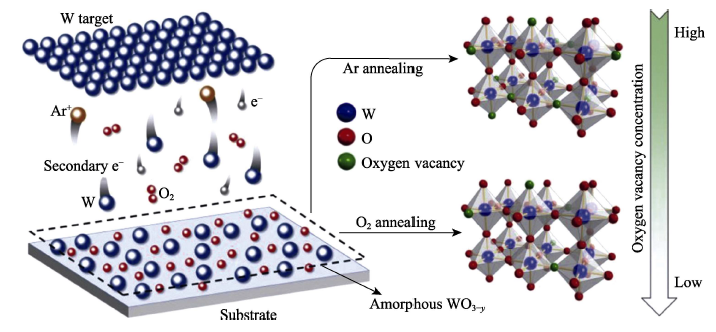

图2 WO3薄膜的制备过程、晶体结构和氩/氧气氛退火引起的氧空位变化[18]

Fig. 2 Illustration of WO3 thin films fabrication process, crystal structure and oxygen vacancy change induced by Ar/O2 atmosphere annealing[18]

| Year | Device structure | tc/s | tb/s | CE/(cm2·C-1) | ΔT/% | Cycles | Ref. |

|---|---|---|---|---|---|---|---|

| 2016 | ITO/NiOx/ZrO2:H/WO3/ITO | 116 | 108 | - | 65.2 | 2000 | [72] |

| 2016 | ITO/NiOx/Ta2O5:H/WO3/ITO | - | - | - | 60 | - | [76] |

| 2016 | ITO/WO3/LiClO4-PC-PMMA/NiOx/ITO | 4.5 | 1.7 | - | 51.7 | 50000 | [77] |

| 2016 | Glass/ITO/WO3/LiNbO3/NiOx/ITO | 45 | 25 | - | 65 | - | [78] |

| 2016 | ITO/NiOx:Ti/PVB(Li+)/WO3/ITO | 4.4 | 3.2 | 96 | 60 | - | [79] |

| 2017 | Glass/ITO/WO3/PVB-GPEF/Ni1-xO/ITO/Glass | 9.5 | 16 | 175.34 | 65.8 | 3000 | [80] |

| 2017 | Glass /ITO/NiOx/electrolyte/WO3/ITO | 7 | 2 | - | 70 | 300 | [81] |

| 2017 | Glass /ITO/NiO/Si3N4/LiNbO3/Si3N4/WO3/ITO | - | - | - | 43 | - | [82] |

| 2017 | ITO/NiO/Ta2O5/LiNbO3/WO3/ITO | - | - | - | 34 | - | [83] |

| 2018 | Glass/ITO/NiO/Si3N4/LixMgyN/WO3/ITO | - | - | 77 | 40 | 1000 | [84] |

| 2018 | Glass/ITO/WO3/Li2.5TaOx/NiO/ITO | 30 | 30 | 63 | 40 | 300 | [71] |

| 2018 | FTO/WO3/gel polymer electrolyte/NiO/FTO | 1.2 | 2.6 | - | 43.81 | 20000 | [85] |

| 2018 | Glass/ITO/WO3:H/Ta2O5/NiOx/ITO | - | - | 24.3 | 42 | 300 | [86] |

| 2018 | Glass/ITO/WO3/LiPON/NiO/ITO | - | - | - | 40 | - | [74] |

| 2018 | Glass/ITO/LixNiOy/LiTaO3/WO3/ITO | 13 | 3.5 | 42 | 40 | 7000 | [87] |

| 2018 | ITO/NiOx/Ta2O5/LiNbO3/Ta2O5/WO3/ITO | - | - | 98 | 52.5 | 10000 | [88] |

| 2018 | ITO/NiO/ZrO2/LiNbO3/WO3/ITO | - | - | 24.3 | 53 | - | [89] |

| 2018 | ITO/NiO/Ta2O5/LiNbO3/WO3/ITO/Glass | 10 | 7 | - | 71.7 | - | [90] |

| 2019 | Glass/IAI/NiOx/LiClO4-PC-PMMA/WO3/IAI/Glass | 2.25 | 2.02 | 31.7 | 55 | - | [62] |

| 2019 | ITO/NiOx/LixAlOz/WO3/ITO | 5.7 | 2.2 | 76.45 | 74.4 | 10000 | [75] |

| 2019 | ITO/WO3-Nb2O5/Nb2O5/NiVOx/ITO | 7 | 0.7 | - | 33 | 30000 | [91] |

| 2019 | ITO/WO3/LiClO4-PC-PMMA/NiO/ITO | 3.2 | 1.1 | 130.8 | 45 | 1000 | [92] |

| 2019 | ITO/NiOx/Ta2O5/LiNbO3/Ta2O5/WO3/ITO | 18.4 | 9.5 | - | 55.2 | 2500 | [93] |

| 2019 | ITO/NiOx/Ta2O5/WO3/ITO | 13 | 2 | - | 70.9 | - | [94] |

| 2020 | Glass /ITO/WO3/LiF/NiO/ITO | 9.6 | 4 | 88.5 | 58.9 | 450 | [73] |

| 2020 | ITO/WO3/Gelatin/NiO/ITO | 10 | 50 | 60.38 | 43.35 | - | [70] |

| 2020 | ITO/Li-NiO/Li-WO3/ITO | 8.6 | 1.7 | 87.5 | 32 | 1000 | [95] |

| 2020 | ITO/WO3/LiClO4-PC-PMMA-ACN/NiO/ITO | 1.2 | 1.5 | 243 | 51.27 | 20000 | [96] |

| 2020 | ITO/WO3/LiNbO3/Al-LiNiOx/ITO | 17.9 | 4.1 | - | 44 | 5000 | [97] |

表1 2016~2020年基于WO3和NiO薄膜的电致变色器件结构与性能对比

Table 1 Comparison of structure and performance of ECDs based on WO3 and NiO films researched from 2016 to 2020

| Year | Device structure | tc/s | tb/s | CE/(cm2·C-1) | ΔT/% | Cycles | Ref. |

|---|---|---|---|---|---|---|---|

| 2016 | ITO/NiOx/ZrO2:H/WO3/ITO | 116 | 108 | - | 65.2 | 2000 | [72] |

| 2016 | ITO/NiOx/Ta2O5:H/WO3/ITO | - | - | - | 60 | - | [76] |

| 2016 | ITO/WO3/LiClO4-PC-PMMA/NiOx/ITO | 4.5 | 1.7 | - | 51.7 | 50000 | [77] |

| 2016 | Glass/ITO/WO3/LiNbO3/NiOx/ITO | 45 | 25 | - | 65 | - | [78] |

| 2016 | ITO/NiOx:Ti/PVB(Li+)/WO3/ITO | 4.4 | 3.2 | 96 | 60 | - | [79] |

| 2017 | Glass/ITO/WO3/PVB-GPEF/Ni1-xO/ITO/Glass | 9.5 | 16 | 175.34 | 65.8 | 3000 | [80] |

| 2017 | Glass /ITO/NiOx/electrolyte/WO3/ITO | 7 | 2 | - | 70 | 300 | [81] |

| 2017 | Glass /ITO/NiO/Si3N4/LiNbO3/Si3N4/WO3/ITO | - | - | - | 43 | - | [82] |

| 2017 | ITO/NiO/Ta2O5/LiNbO3/WO3/ITO | - | - | - | 34 | - | [83] |

| 2018 | Glass/ITO/NiO/Si3N4/LixMgyN/WO3/ITO | - | - | 77 | 40 | 1000 | [84] |

| 2018 | Glass/ITO/WO3/Li2.5TaOx/NiO/ITO | 30 | 30 | 63 | 40 | 300 | [71] |

| 2018 | FTO/WO3/gel polymer electrolyte/NiO/FTO | 1.2 | 2.6 | - | 43.81 | 20000 | [85] |

| 2018 | Glass/ITO/WO3:H/Ta2O5/NiOx/ITO | - | - | 24.3 | 42 | 300 | [86] |

| 2018 | Glass/ITO/WO3/LiPON/NiO/ITO | - | - | - | 40 | - | [74] |

| 2018 | Glass/ITO/LixNiOy/LiTaO3/WO3/ITO | 13 | 3.5 | 42 | 40 | 7000 | [87] |

| 2018 | ITO/NiOx/Ta2O5/LiNbO3/Ta2O5/WO3/ITO | - | - | 98 | 52.5 | 10000 | [88] |

| 2018 | ITO/NiO/ZrO2/LiNbO3/WO3/ITO | - | - | 24.3 | 53 | - | [89] |

| 2018 | ITO/NiO/Ta2O5/LiNbO3/WO3/ITO/Glass | 10 | 7 | - | 71.7 | - | [90] |

| 2019 | Glass/IAI/NiOx/LiClO4-PC-PMMA/WO3/IAI/Glass | 2.25 | 2.02 | 31.7 | 55 | - | [62] |

| 2019 | ITO/NiOx/LixAlOz/WO3/ITO | 5.7 | 2.2 | 76.45 | 74.4 | 10000 | [75] |

| 2019 | ITO/WO3-Nb2O5/Nb2O5/NiVOx/ITO | 7 | 0.7 | - | 33 | 30000 | [91] |

| 2019 | ITO/WO3/LiClO4-PC-PMMA/NiO/ITO | 3.2 | 1.1 | 130.8 | 45 | 1000 | [92] |

| 2019 | ITO/NiOx/Ta2O5/LiNbO3/Ta2O5/WO3/ITO | 18.4 | 9.5 | - | 55.2 | 2500 | [93] |

| 2019 | ITO/NiOx/Ta2O5/WO3/ITO | 13 | 2 | - | 70.9 | - | [94] |

| 2020 | Glass /ITO/WO3/LiF/NiO/ITO | 9.6 | 4 | 88.5 | 58.9 | 450 | [73] |

| 2020 | ITO/WO3/Gelatin/NiO/ITO | 10 | 50 | 60.38 | 43.35 | - | [70] |

| 2020 | ITO/Li-NiO/Li-WO3/ITO | 8.6 | 1.7 | 87.5 | 32 | 1000 | [95] |

| 2020 | ITO/WO3/LiClO4-PC-PMMA-ACN/NiO/ITO | 1.2 | 1.5 | 243 | 51.27 | 20000 | [96] |

| 2020 | ITO/WO3/LiNbO3/Al-LiNiOx/ITO | 17.9 | 4.1 | - | 44 | 5000 | [97] |

| [1] | DEB S K. A novel electrophotographic system. Applied Optics, 1969,8(S1):192-195. |

| [2] | PATEL K J, BHATT G G, RAY J R, et al. All-inorganic solid-state electrochromic devices: a review. Journal of Solid State Electrochemistry, 2017,21(2):337-347. |

| [3] | JIA H X, CAO X, JIN P S. Advances in inorganic all-solid-state electrochromic materials and devices. Journal of Inorganic Materials, 2020,35(5):511-524. |

| [4] | GRANQVIST C G. Handbook of Inorganic Electrochromic Materials. Amsterdam: Elsevier, 1995: 4-5. |

| [5] | MCINTYRE J D E, BASU S, PECK W F, et al. Cation insertion reactions of electrochromic tungsten and iridium oxide-films. Physical Review B, 1982,25(12):7242-7254. |

| [6] | EREN E, ALVER C, KARACA G Y, et al. High-performance flexible complementary electrochromic device based on plasma modified WO3 nano hybrids and V2O5 nanofilm with low operation voltages. Electroanalysis, 2018,30(9):2099-2109. |

| [7] | HUANG H, TIAN J, ZHANG W K, et al. Electrochromic properties of porous NiO thin film as a counter electrode for NiO/WO3 complementary electrochromic window. Electrochimica Acta, 2011,56(11):4281-4286. |

| [8] | DEB S K. Optical and photoelectric properties and color centers in thin-films of tungsten oxide. Philosophical Magazine, 1973,27(4):801-822. |

| [9] | FAUGHNAN B W, CRANDALL R S, HEYMAN P M. Electrochromism in WO3 amorphous films. Rca Review, 1975,36(1):177-197. |

| [10] | SCHIRMER O F, WITTWER V, BAUR G, et al. Dependence of WO3 electrochromic absorption on crystallinity. Journal of the Electrochemical Society, 1977,124(5):749-753. |

| [11] | ZHOU K L, WANG H, LIU J B, et al. The mechanism of trapped ions eroding the electrochromic performances of WO3 thin films. International Journal of Electrochemical Science, 2018,13(8):7335-7346. |

| [12] | ZHOU K L, WANG H, LIU J B, et al. Ions transport control in electrochromic WO3 film for the cyclic stability study. Journal of the Electrochemical Society, 2020,167(10):106502. |

| [13] | PAN J B, WANG Y, ZHENG R Z, et al. Directly grown high- performance WO3 films by a novel one-step hydrothermal method with significantly improved stability for electrochromic applications. Journal of Materials Chemistry A, 2019,7(23):13956-13967. |

| [14] | CAI G F, TU J P, ZHOU D, et al. Growth of vertically aligned hierarchical WO3 nano-architecture arrays on transparent conducting substrates with outstanding electrochromic performance. Solar Energy Materials and Solar Cells, 2014,124:103-110. |

| [15] |

COSTA C, PINHEIRO C, HENRIQUES I, et al. Inkjet printing of Sol-Gel synthesized hydrated tungsten oxide nanoparticles for flexible electrochromic devices. ACS Applied Materials & Interfaces, 2012,4(3):1330-1340.

URL PMID |

| [16] | CAI G F, CUI M Q, KUMAR V, et al. Ultra-large optical modulation of electrochromic porous WO3 film and the local monitoring of redox activity. Chemical Science, 2016,7(2):1373-1382. |

| [17] | CAI G F, DARMAWAN P, CHENG X, et al. Inkjet printed large area multifunctional smart windows. Advanced Energy Materials, 2017,7(14):1602598. |

| [18] | YU H, GUO J J, WANG C, et al. Essential role of oxygen vacancy in electrochromic performance and stability for WO3-y films induced by atmosphere annealing. Electrochimica Acta, 2020,332:135504. |

| [19] | SHEN K, SHENG K, WANG Z T, et al. Cobalt ions doped tungsten oxide nanowires achieved vertically aligned nanostructure with enhanced electrochromic properties. Applied Surface Science, 2020,501:144003. |

| [20] | ZHOU J L, WEI Y X, LUO G, et al. Electrochromic properties of vertically aligned Ni-doped WO3 nanostructure films and their application in complementary electrochromic devices. Journal of Materials Chemistry C, 2016,4(8):1613-1622. |

| [21] | WANG B, MAN W K, YU H Y, et al. Fabrication of Mo-doped WO3 nanorod arrays on FTO substrate with enhanced electrochromic properties. Materials, 2018,11(9):1627. |

| [22] | XIE S J, BI Z J, CHEN Y B, et al. Electrodeposited Mo-doped WO3 film with large optical modulation and high areal capacitance toward electrochromic energy-storage applications. Applied Surface Science, 2018,459:774-781. |

| [23] | WANG W Q, YAO Z J, WANG X L, et al. Niobium doped tungsten oxide mesoporous film with enhanced electrochromic and electrochemical energy storage properties. Journal of Colloid and Interface Science, 2019,535:300-307. |

| [24] | ZHAN Y, TAN M R J, CHENG X, et al. Ti-doped WO3 synthesized by a facile wet bath method for improved electrochromism. Journal of Materials Chemistry C, 2017,5(38):9995-10000. |

| [25] | SONG Y, ZHANG Z Y, YAN L M, et al. Electrodeposition of Ti-doped hierarchically mesoporous silica microspheres/tungsten oxide nanocrystallines hybrid films and their electrochromic performance. Nanomaterials, 2019,9(12):1795. |

| [26] | BATHE S R, PATIL P S. WO3 thin films doped with Ru by facile chemical method with enhanced electrochromic properties for electrochromic window application. Materials Science and Engineering B-Advanced Functional Solid-State Materials, 2020,257:114542. |

| [27] | HASANI A, LE Q V, NGUYEN T P, et al. A thorough study on electrochromic properties of metal doped tungsten trioxide film prepared by a facile solution process. Electrochimica Acta, 2018,283:1195-1202. |

| [28] | CHANG J Y, CHEN Y C, WANG C M, et al. Electrochromic properties of lithium-doped tungsten oxide prepared by electron beam evaporation. Coatings, 2019,9(3):191. |

| [29] | KIM K H, KOO B R, AHN H J. Effects of Sb-doped SnO2-WO3 nanocomposite on electrochromic performance. Ceramics International, 2019,45(13):15990-15995. |

| [30] | LUO G, SHEN L Y, ZHENG J M, et al. A europium ion doped WO3 film with the bi-functionality of enhanced electrochromic switching and tunable red emission. Journal of Materials Chemistry C, 2017,5(14):3488-3494. |

| [31] | SHEN L Y, LUO G, ZHENG J M, et al. Effect of pH on the electrochromic and photoluminescent properties of Eu doped WO3 film. Electrochimica Acta, 2018,278:263-270. |

| [32] | YIN Y, LAN C Y, HU S M, et al. Effect of Gd-doping on electrochromic properties of sputter deposited WO3 films. Journal of Alloys and Compounds, 2018,739:623-631. |

| [33] |

SHEN L Y, ZHENG J M, XU C Y. Enhanced electrochromic switches and tunable green fluorescence based on terbium ion doped WO3 films. Nanoscale, 2019,11(47):23049-23057.

DOI URL PMID |

| [34] |

KUNYAPAT T, XU F, NEATE N, et al. Ce-doped bundled ultrafine diameter tungsten oxide nanowires with enhanced electrochromic performance. Nanoscale, 2018,10(10):4718-4726.

URL PMID |

| [35] | YAO Y J, ZHAO Q, WEI W, et al. WO3 quantum-dots electrochromism. Nano Energy, 2020,68:104350. |

| [36] | XIE Z, ZHANG Q, LIU Q, et al. Enhanced electrochromic performance of 2D grid-structured WO3 thin films. Thin Solid Films, 2018,653:188-193. |

| [37] | YUAN G Z, HUA C Z, KHAN S, et al. Improved electrochromic performance of WO3 films with size controlled nanorods. Electrochimica Acta, 2018,260:274-280. |

| [38] | ZHANG K, LI N, WANG Y, et al. Bifunctional urchin-like WO3@PANI electrodes for superior electrochromic behavior and lithium-ion battery. Journal of Materials Science-Materials in Electronics, 2018,29(17):14803-14812. |

| [39] | GUO Q F, ZHAO X Q, LI Z Y, et al. A novel solid-state electrochromic supercapacitor with high energy storage capacity and cycle stability based on poly(5-formylindole)/WO3 honeycombed porous nanocomposites. Chemical Engineering Journal, 2020,384:123370. |

| [40] | BODE H, DEHMELT K, WITTE J. Zur kenntnis der nickelhydroxidelektrode—I. Über das nickel (II)-hydroxidhydrat. Electrochimica Acta, 1966,11:1079-1087. |

| [41] | PASSERINI S, SCROSATI B. Electrochromism of thin-film nickel-oxide electrodes. Solid State Ionics, 1992,53:520-524. |

| [42] | BOUESSAYA I, ROUGIER A, POIZOT P, et al. Electrochromic degradation in nickel oxide thin film: a self-discharge and dissolution phenomenon. Electrochimica Acta, 2005,50(18):3737-3745. |

| [43] | DONG D M, WANG W W, ROUGIER A, et al. Life-cycling and uncovering cation-trapping evidence of a monolithic inorganic electrochromic device: glass/ITO/WO3/LiTaO3/NiO/ITO. Nanoscale, 2018,10(35):16521-16530. |

| [44] | AMIRZHANOVA A, KARAKAYA I, UZUNDAL C B, et al. Synthesis and water oxidation electrocatalytic and electrochromic behaviours of mesoporous nickel oxide thin film electrodes. Journal of Materials Chemistry A, 2019,7(38):22012-22020. |

| [45] | PAN J B, ZHENG R Z, WANG Y, et al. A high-performance electrochromic device assembled with hexagonal WO3 and NiO/PB composite nanosheet electrodes towards energy storage smart window. Solar Energy Materials and Solar Cells, 2020,207:110337. |

| [46] | YUE Y F, LI H Z, LI K R, et al. Preparation and properties of NiO/PB hybrid electrochromic film. Journal of Inorganic Materials, 2017,32(9):949-954. |

| [47] | ZRIKEM K, SONG G, AGHZZAF A A, et al. UV treatment for enhanced electrochromic properties of spin coated NiO thin films. Superlattices and Microstructures, 2019,127:35-42. |

| [48] | SAADEDDIN I, SULEIMAN M, SALMAN H, et al. Optimization of low value electrodeposition parameters of nano-structured NiO electrochromic thin films. Solid State Ionics, 2019,343:115129. |

| [49] | WANG M, THIMONT Y, PRESMANES L, et al. The effect of the oxygen ratio control of DC reactive magnetron sputtering on as-deposited non stoichiometric NiO thin films. Applied Surface Science, 2017,419:795-801. |

| [50] | ZHOU K L, QI Z C, ZHAO B W, et al. The influence of crystallinity on the electrochromic properties and durability of NiO thin films. Surfaces and Interfaces, 2017,6:91-97. |

| [51] | HOU S, GAVRILYUK A I, ZHAO J P, et al. Controllable crystallinity of nickel oxide film with enhanced electrochromic properties. Applied Surface Science, 2018,451:104-111. |

| [52] | FIRAT Y E, PEKSOZ A. Efficiency enhancement of electrochromic performance in NiO thin film via Cu doping for energy- saving potential. Electrochimica Acta, 2019,295:645-654. |

| [53] | HE Y, LI T, ZHONG X, et al. Lattice and electronic structure variations in critical lithium doped nickel oxide thin film for superior anode electrochromism. Electrochimica Acta, 2019,316:143-151. |

| [54] | LEE S J, LEE T G, NAHM S, et al. Investigation of all-solid-state electrochromic devices with durability enhanced tungsten-doped nickel oxide as a counter electrode. Journal of Alloys and Compounds, 2020,815:152399. |

| [55] | DONG D, WANG W, BARNABE A, et al. Enhanced electrochromism in short wavelengths for NiO:(Li, Mg) films in full inorganic device ITO/NiO:(Li, Mg)/Ta2O5/WO3/ITO. Electrochimica Acta, 2018,263:277-285. |

| [56] | HUANG Q, ZHANG Q, XIAO Y, et al. Improved electrochromic performance of NiO-based thin films by lithium and tantalum co-doping. Journal of Alloys and Compounds, 2018,747:416-422. |

| [57] | WU Z S, LI M Y, WANG X Q, et al. Room-temperature fabrication of NiO films for electrochromic application by electrophoretic deposition (EPD): from single layers to devices. ECS Journal of Solid State Science and Technology, 2019,8(9):Q171-Q177. |

| [58] | TIAN Y L, LI Z Y, DOU S L, et al. Facile preparation of aligned NiO nanotube arrays for electrochromic application. Surface & Coatings Technology, 2018,337:63-67. |

| [59] | REN Y, ZHOU X G, ZHANG H, et al. Preparation of a porous NiO array-patterned film and its enhanced electrochromic performance. Journal of Materials Chemistry C, 2018,6(18):4952-4958. |

| [60] | DONG W J, LV Y, ZHANG N, et al. Trifunctional NiO-Ag-NiO electrodes for ITO-free electrochromic supercapacitors. Journal of Materials Chemistry C, 2017,5(33):8408-8414. |

| [61] | LIANG H, LI R, LI C, et al. Regulation of carbon content in MOF-derived hierarchical-porous NiO@C films for high- performance electrochromism. Materials Horizons, 2019,6(3):571-579. |

| [62] | WANG M Y, BARNABE A, THIMONT Y, et al. Optimized properties of innovative ElectroChromic Device using ITO/Ag/ITO electrodes. Electrochimica Acta, 2019,301:200-208. |

| [63] | WANG M Y, LIU Q R, DONG G B, et al. Influence of thickness on the structure, electrical, optical and electrochromic properties of AZO thin films and their inorganic all-solid-state devices. Electrochimica Acta, 2017,258:1336-1347. |

| [64] | LIU Q, DONG G, XIAO Y, et al. An all-thin-film inorganic electrochromic device monolithically fabricated on flexible PET/ITO substrate by magnetron sputtering. Materials Letters, 2015,142:232-234. |

| [65] | LEE H B, JIN W Y, OVHAL M M, et al. Flexible transparent conducting electrodes based on metal meshes for organic optoelectronic device applications: a review. Journal of Materials Chemistry C, 2019,7(5):1087-1110. |

| [66] | CAI G F, CHENG X, LAYANI M, et al. Direct inkjet-patterning of energy efficient flexible electrochromics. Nano Energy, 2018,49:147-154. |

| [67] | CAI G F, DARMAWAN P, CUI M Q, et al. Highly stable transparent conductive silver grid/PEDOT:PSS electrodes for integrated bifunctional flexible electrochromic supercapacitors. Advanced Energy Materials, 2016,6(4):1501882. |

| [68] | WEI Y X, CHEN M, LIU W M, et al. Electrochemical investigation of electrochromic devices based on NiO and WO3 films using different lithium salts electrolytes. Electrochimica Acta, 2017,247:107-115. |

| [69] | YANG X W, CONG S, LI J, et al. An aramid nanofibers-based gel polymer electrolyte with high mechanical and heat endurance for all-solid-state NIR electrochromic devices. Solar Energy Materials and Solar Cells, 2019,200:109952. |

| [70] | WOOTTHIKANOKKHAN J, JARUPHAN P, AZARIAN M H, et al. Effects of ethylene-acrylic acid ionomer on thermomechanical and electrochromic properties of electrochromic devices using gelatin-based electrolytes. Journal of Applied Polymer Science, 2020,137(44):e49362. |

| [71] | XIAO Y, DONG G B, GUO J J, et al. Thickness dependent surface roughness of sputtered Li2.5TaOx ion conductor and its effect on electro-optical performance of inorganic monolithic electrochromic device. Solar Energy Materials and Solar Cells, 2018,179:319-327. |

| [72] | ZHOU Y L, DIAO X G, DONG G B, et al. Enhanced transmittance modulation of ITO/NiOx/ZrO2:H/WO3/ITO electrochromic devices. Ionics, 2016,22(1):25-32. |

| [73] | CHEN X, DOU S L, LI W J, et al. All solid state electrochromic devices based on the LiF electrolyte. Chemical Communications, 2020,56(37):5018-5021. |

| [74] | XIAO Y, ZHONG X, GUO J, et al. The role of interface between LiPON solid electrolyte and electrode in inorganic monolithic electrochromic devices. Electrochimica Acta, 2018,260:254-263. |

| [75] | XIE L L, ZHAO S W, ZHU Y, et al. High performance and excellent stability of all-solid-state electrochromic devices based on a Li1.85AlOz ion conducting layer. ACS Sustainable Chemistry & Engineering, 2019,7(20):17390-17396. |

| [76] | DONG D, WANG W, DONG G, et al. Electrochromic properties and performance of NiOx films and their corresponding all-thin- film flexible devices preparedby reactive DC magnetron sputtering. Applied Surface Science, 2016,383:49-56. |

| [77] | LIU Q, DONG G, XIAO Y, et al. Electrolytes-relevant cyclic durability of nickel oxide thin films as an ion-storage layer in an all-solid-state complementary electrochromic device. Solar Energy Materials and Solar Cells, 2016,157:844-852. |

| [78] | WU Z H, DIAO X G, DONG G B. Preparation and Properties of All-solid-state Inorganic Thin Film Glass/ITO/WO3/LiNbO3/NiOx/ITO Electrochromic Device. Selected Papers of the Photoelectronic Technology Committee Conferences Held November 2015. International Society for Optics and Photonics, 2016,9796:979612. |

| [79] | DONG D, WANG W, DONG G, et al. Improved performance of co-sputtered Ni-Ti oxide films for all-solid-state electrochromic devices. RSC Advances, 2016,6(112):111148-111160. |

| [80] | ZHANG F, DONG G B, LIU J, et al. Polyvinyl butyral-based gel polymer electrolyte films for solid-state laminated electrochromic devices. Ionics, 2017,23(7):1879-1888. |

| [81] | WANG M, DIAO X, DONG G, et al. Optical, electrical, and electrochemical properties of indium tin oxide thin films studied in different layer-structures and their corresponding inorganic all-thin-film solid-state electrochromic devices. Journal of Vacuum Science & Technology A, 2017,35(2):021512. |

| [82] | HUANG Q, DONG G, XIAO Y, et al. Electrochemical studies of silicon nitride electron blocking layer for all-solid-state inorganic electrochromic device. Electrochimica Acta, 2017,252:331-337. |

| [83] | ATAK G, COSKUN O D. Annealing effects of NiO thin films for all-solid-state electrochromic devices. Solid State Ionics, 2017,305:43-51. |

| [84] | XIAO Y, DONG G, HUANG Q, et al. Electro-optical performance of inorganic monolithic electrochromic device with a pulsed DC sputtered LixMgyN ion conductor. Journal of Solid State Electrochemistry, 2018,22(1):275-283. |

| [85] | WANG W J, GUAN S, LI M, et al. A novel hybrid quasi-solid polymer electrolyte based on porous PVB and modified PEG for electrochromic application. Organic Electronics, 2018,56:268-275. |

| [86] | CHE X Q, WU Z H, DONG G B, et al. Properties of all-thin-film glass/ITO/WO3:H/Ta2O5/NiOx/ITO electrochromic devices prepared by magnetron sputtering. Thin Solid Films, 2018,662:6-12. |

| [87] | ZHU Y, XIE L L, CHANG T C, et al. High performance all-solid-state electrochromic device based on LixNiOy layer with gradient Li distribution. Electrochimica Acta, 2019,317:10-16. |

| [88] | LIU Q R, DONG G B, CHEN Q Q, et al. Charge-transfer kinetics and cyclic properties of inorganic all-solid-state electrochromic device with remarkably improved optical memory. Solar Energy Materials and Solar Cells, 2018,174:545-553. |

| [89] | ATAK G, COSKUN O D. Fabrication of an all solid-state electrochromic device using zirconium dioxide as an ion-conducting layer. Thin Solid Films, 2018,664:70-78. |

| [90] | COSKUN O D, ATAK G. The effects of lithiation process on the performance of all-solid-state electrochromic devices. Thin Solid Films, 2018,662:13-20. |

| [91] | TANG C J, HE J L, JAING C C, et al. An all-solid-state electrochromic device based on WO3-Nb2O5 composite films prepared by fast-alternating bipolar-pulsed reactive magnetron sputtering. Coatings, 2019,9(1):9-15. |

| [92] | XIE Z Q, LIU Q Q, ZHANG Q Q, et al. Fast-switching quasi-solid state electrochromic full device based on mesoporous WO3 and NiO thin films. Solar Energy Materials and Solar Cells, 2019,200:110017. |

| [93] | LIU L, DU K, HE Z, et al. High-temperature adaptive and robust ultra-thin inorganic all-solid-state smart electrochromic energy storage devices. Nano Energy, 2019,62:46-54. |

| [94] | PAN L J, HAN Q N, DONG Z L, et al. Reactively sputtered WO3 thin films for the application in all thin film electrochromic devices. Electrochimica Acta, 2019,328:135107. |

| [95] | LI W J, ZHANG X, CHEN X, et al. Preparation and performance of fast-response ITO/Li-NiO/Li-WO3/ITO all-solid-state electrochromic devices by evaporation method. Materials Letters, 2020,265:127464. |

| [96] | KADAM A V. Electrochromic properties of ITO/WO3/LiClO4- PC-PMMA-ACN/NiO/ITO framework. Materials Today-Proceedings, 2020,23:352-358. |

| [97] | WANG C P, DONG G B, ZHAO Y Y, et al. Enhanced electrochromic performance on anodic nickel oxide inorganic device via lithium and aluminum co-doping. Journal of Alloys and Compounds, 2020,821:153365. |

| [98] | DING Y, DONG G, ZHOU Y, et al. Improved performance of all-thin-film electrochromic devices with two ZrO2 protective layers. Ionics, 2018,24(8):2427-2434. |

| [1] | 朱文杰, 唐璐, 陆继长, 刘江平, 罗永明. 钙钛矿型氧化物催化氧化挥发性有机化合物的研究进展[J]. 无机材料学报, 2025, 40(7): 735-746. |

| [2] | 胡智超, 杨鸿宇, 杨鸿程, 孙成礼, 杨俊, 李恩竹. P-V-L键理论在微波介质陶瓷性能调控中的应用[J]. 无机材料学报, 2025, 40(6): 609-626. |

| [3] | 吴琼, 沈炳林, 张茂华, 姚方周, 邢志鹏, 王轲. 铅基织构压电陶瓷研究进展[J]. 无机材料学报, 2025, 40(6): 563-574. |

| [4] | 张碧辉, 刘小强, 陈湘明. Ruddlesden-Popper结构杂化非常规铁电体的研究进展[J]. 无机材料学报, 2025, 40(6): 587-608. |

| [5] | 吴杰, 杨帅, 王明文, 李景雷, 李纯纯, 李飞. 铅基织构压电陶瓷的发展历程、现状与挑战[J]. 无机材料学报, 2025, 40(6): 575-586. |

| [6] | 姜昆, 李乐天, 郑木鹏, 胡永明, 潘勤学, 吴超峰, 王轲. PZT陶瓷的低温烧结研究进展[J]. 无机材料学报, 2025, 40(6): 627-638. |

| [7] | 田睿智, 兰正义, 殷杰, 郝南京, 陈航榕, 马明. 基于微流控技术的纳米无机生物材料制备: 原理及其研究进展[J]. 无机材料学报, 2025, 40(4): 337-347. |

| [8] | 张继国, 吴田, 赵旭, 杨钒, 夏天, 孙士恩. 钠离子电池正极材料循环稳定性提升策略及产业化进程[J]. 无机材料学报, 2025, 40(4): 348-362. |

| [9] | 殷杰, 耿佳毅, 王康龙, 陈忠明, 刘学建, 黄政仁. SiC陶瓷的3D打印成形与致密化新进展[J]. 无机材料学报, 2025, 40(3): 245-255. |

| [10] | 谌广昌, 段小明, 朱金荣, 龚情, 蔡德龙, 李宇航, 杨东雷, 陈彪, 李新民, 邓旭东, 余瑾, 刘博雅, 何培刚, 贾德昌, 周玉. 直升机特定结构先进陶瓷材料研究进展与应用展望[J]. 无机材料学报, 2025, 40(3): 225-244. |

| [11] | 范晓波, 祖梅, 杨向飞, 宋策, 陈晨, 王子, 罗文华, 程海峰. 质子调控型电化学离子突触研究进展[J]. 无机材料学报, 2025, 40(3): 256-270. |

| [12] | 海热古·吐逊, 郭乐, 丁嘉仪, 周嘉琪, 张学良, 努尔尼沙·阿力甫. 上转换荧光探针辅助的光学成像技术在肿瘤显影中的应用研究进展[J]. 无机材料学报, 2025, 40(2): 145-158. |

| [13] | 孙树娟, 郑南南, 潘昊坤, 马猛, 陈俊, 黄秀兵. 单原子催化剂制备方法的研究进展[J]. 无机材料学报, 2025, 40(2): 113-127. |

| [14] | 陶桂龙, 支国伟, 罗添友, 欧阳佩东, 衣新燕, 李国强. 空腔型薄膜体声波滤波器的关键技术进展[J]. 无机材料学报, 2025, 40(2): 128-144. |

| [15] | 周帆, 田志林, 李斌. 热防护系统用碳化物超高温陶瓷抗烧蚀涂层研究进展[J]. 无机材料学报, 2025, 40(1): 1-16. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||