无机材料学报 ›› 2020, Vol. 35 ›› Issue (1): 8-18.DOI: 10.15541/jim20190282 CSTR: 32189.14.10.15541/jim20190282

所属专题: MAX相和MXene材料; 二维材料; 功能陶瓷论文精选(二); MXene材料专辑(2020~2021); 【虚拟专辑】层状MAX,MXene及其他二维材料

收稿日期:2019-06-11

修回日期:2019-07-05

出版日期:2020-01-20

网络出版日期:2019-10-23

作者简介:杨以娜(1992-), 女, 博士研究生. E-mail: yangyina@student.sic.ac.cn

基金资助:

YANG Yi-Na1,2,WANG Ran-Ran1,SUN Jing1( )

)

Received:2019-06-11

Revised:2019-07-05

Published:2020-01-20

Online:2019-10-23

About author:YANG Yi-Na (1992-), female, PhD candidate. E-mail:yangyina@student.sic.ac.cn

Supported by:摘要:

随着可穿戴柔性电子技术的发展, 高灵敏度和宽感应范围的柔性力敏传感器的需求量逐渐增大, 如何选择兼具高导电性和良好柔性的材料作为传感器的敏感材料是获得高性能传感器的关键。近年来, MXene材料因其导电性好、柔韧性高、亲水性好以及合成可控等优点成为一种极具潜力的导电敏感材料。本文就MXene基柔性力敏传感器的类型、敏感材料的微结构设计方式、传感性能及传感机理等方面的研究进展进行了阐述和总结。

中图分类号:

杨以娜, 王冉冉, 孙静. MXenes在柔性力敏传感器中的应用研究进展[J]. 无机材料学报, 2020, 35(1): 8-18.

YANG Yi-Na, WANG Ran-Ran, SUN Jing. MXenes in Flexible Force Sensitive Sensors: a Review[J]. Journal of Inorganic Materials, 2020, 35(1): 8-18.

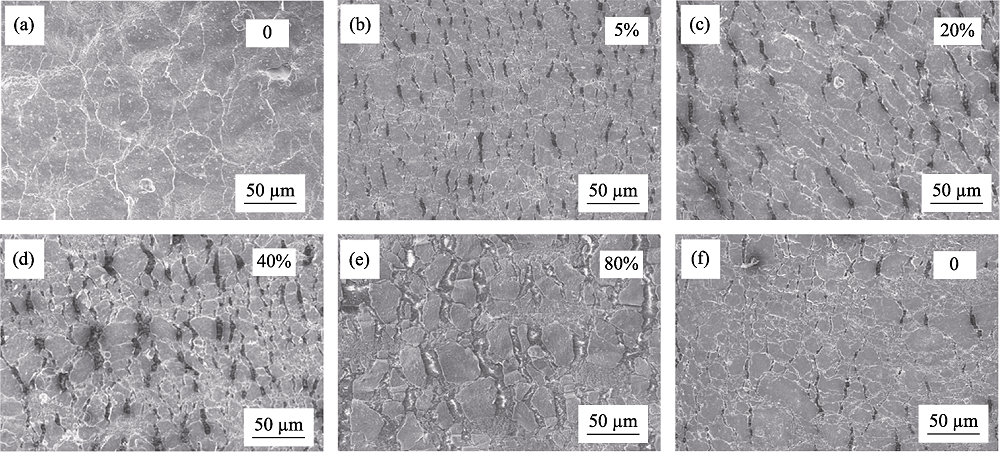

图2 Ti3C2Tx/CNT导电层在一个拉伸-释放循环中处于不同应变状态下的扫描电镜照片[55] (a) 0; (b) 5%; (c) 20%; (d) 40%; (e) 80%; (f) Back to 0

Fig. 2 Surface SEM images of the Ti3C2Tx/CNT film at various stretching states during the first strain-release cycle[55]

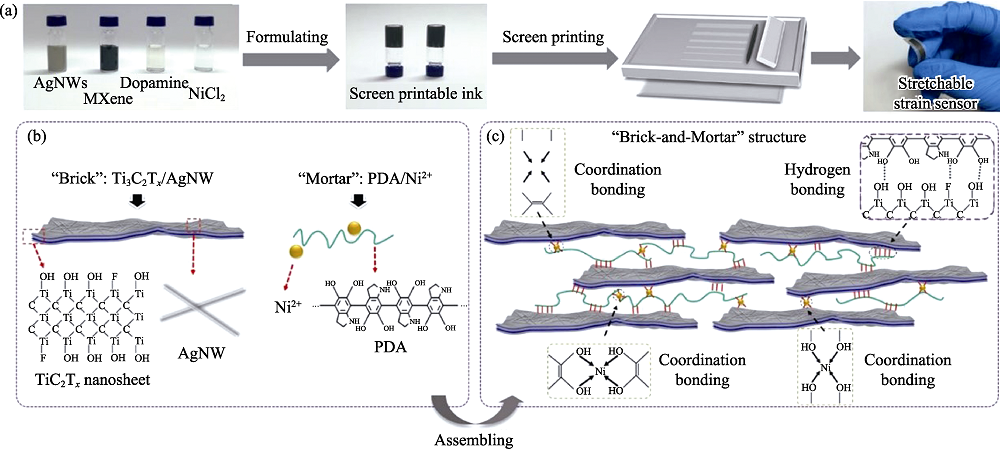

图3 (a)Ti3C2Tx-AgNW-PDA/Ni2+基柔性应变传感器的制作流程图; (b) “brick”材料(Ti3C2Tx和AgNWs)和 “mortar”材料(PDA/Ni2+)的结构示意图; (c)Ti3C2Tx-AgNW-PDA/Ni2+复合结构的示意图[56]

Fig. 3 (a) Schematic of the fabrication process for the bioinspired Ti3C2Tx-AgNW-PDA/Ni2+ sensor fabricated through the screen-printing method; (b) Schematic illustration of the structures for the “brick” materials (Ti3C2Tx and AgNWs) and “mortar” material (PDA/Ni2+); (c) Schematic illustration of the Ti3C2Tx-AgNW-PDA/Ni2+ sensor based on the “brick-and-mortar” architecture[56]

图4 MXene基水凝胶传感器在(a)拉伸应变和(b)压缩应变下的电学响应; (c)拉伸前和(d)拉伸后MXene基水凝胶表面的扫描电镜照片; (e~f)MXene基水凝胶的机电响应原理图[58]

Fig. 4 Electromechanical properties of M-hydrogel composite and mechanisms Electrical response of M-hydrogel to (a) tensile strain and (b) compressive strain, with insets showing the corresponding GFs; Scanning electron microscopy (SEM) images of M-hydrogel surface (c) before and (d) after stretching; (e-f) Schematic illustration for the mechanism of the electromechanical responses from M-hydrogel[58]

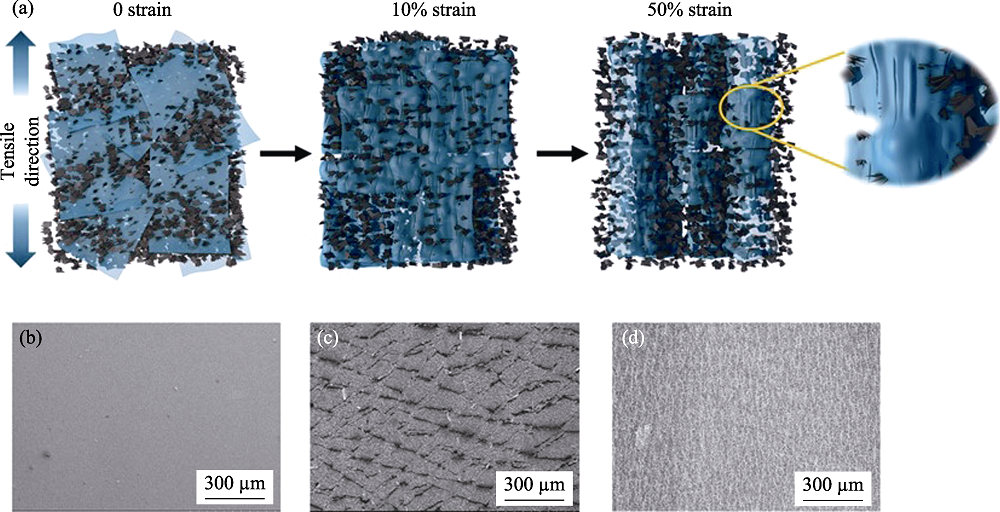

图5 (a)HF18 h-d20 min-Ti3C2Tx导电薄膜作用机理示意图; 基于(b)HF6 h-d3 h-Ti3C2Tx, (c)TMA-Ti3C2Tx和 (d)HF18 h-d20 min-Ti3C2Tx导电薄膜的传感器处于最大拉伸状态的SEM照片[15]

Fig. 5 (a) Schematic diagram of the HF18 h-d20 min-Ti3C2Tx conductive film at various stretching states during the first stretching-releasing cycle. Top-view SEM images of (b) HF6 h-d3 h-Ti3C2Tx-, (c) TMA-Ti3C2Tx-, and (d) HF18 h-d20 min-Ti3C2Tx-based strain sensors in the maximum tensile state[15]

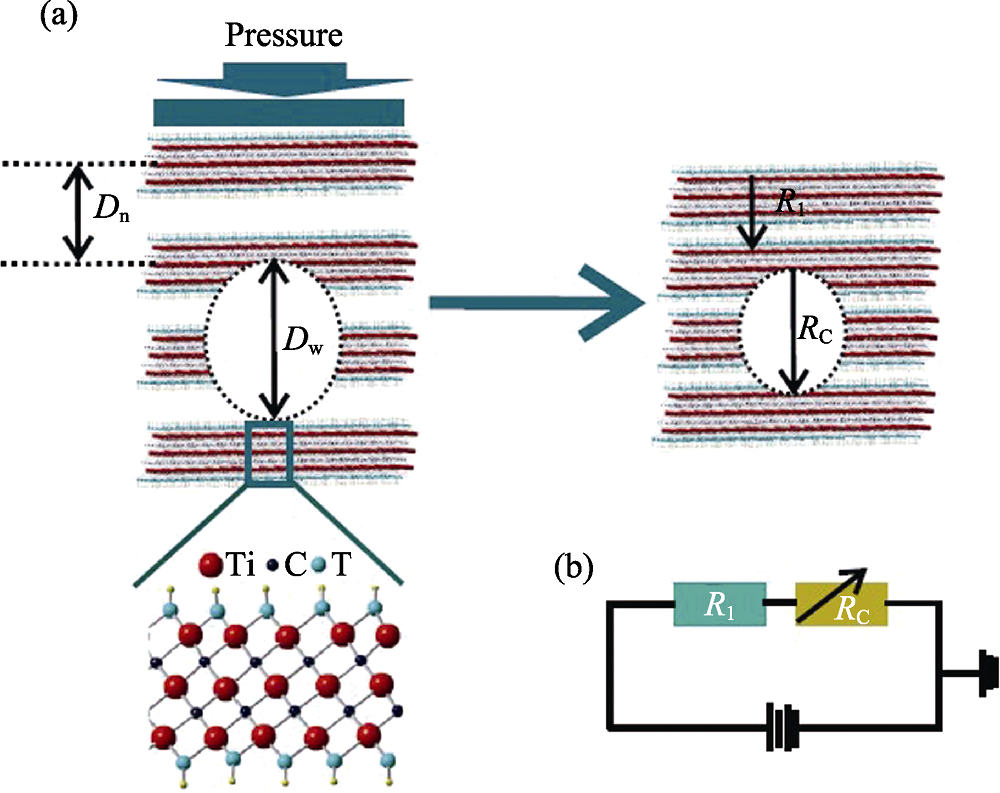

图6 MXene基压阻传感器的(a)传感器机理示意图和(b)等效电路图[59]

Fig. 6 (a) Working micromechanism and (b) the equivalent circuit diagram of MXene-material for piezoresistive sensor[59]

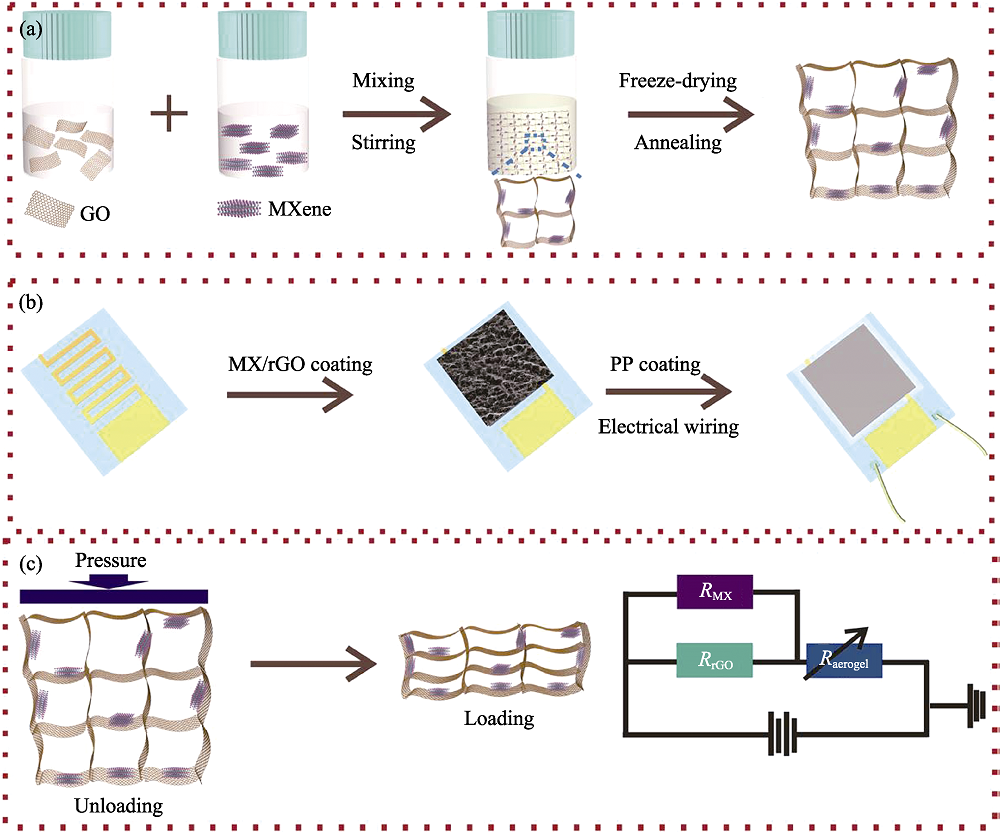

图7 (a)MX/rGO气凝胶的制备流程图; (b)基于MX/rGO气凝胶的传感器的制作流程图; (c)传感机理示意图[60]

Fig. 7 (a) Schematic illustration of fabrication of MX/rGO aerogel, (b) fabrication of MX/rGO aerogel-based sensor and (c) the sensing mechanism[60]

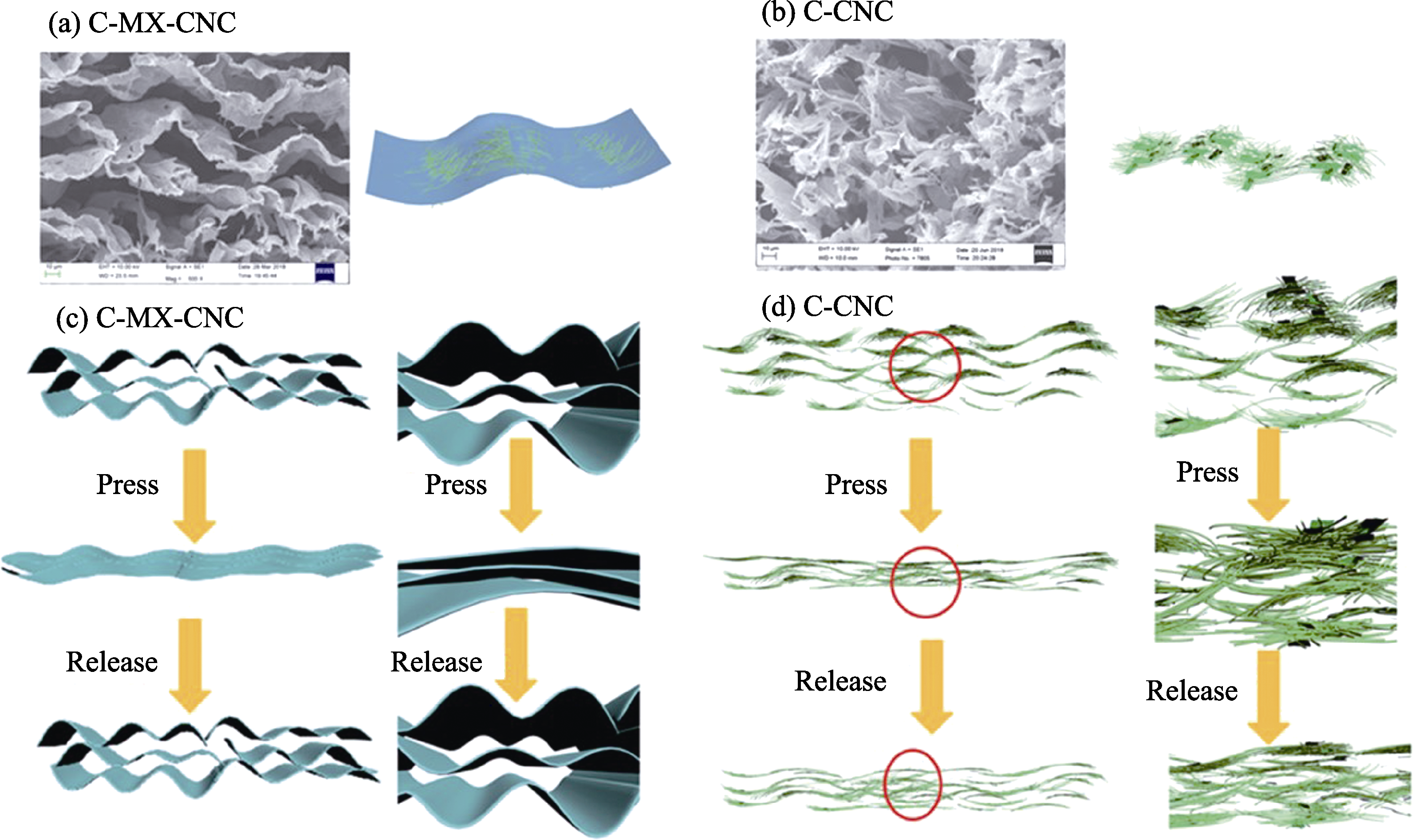

图8 (a)C-MX/CNC气凝胶, (b)C-CNC气凝胶的扫描电镜照片和结构示意图, (c)C-MX/CNC气凝胶, (d)C-CNC气凝胶的弹性机理[62]

Fig. 8 SEM images and schematic structures of (a) C-MX/CNC and (b) C-CNC; Schematic elasticity mechanisms of (c)C-MX/CNC and (d) C-CNC

图9 (a)MXene海绵和(b~c)MXene海绵/PVA纳米线传感器的制作流程图[64]

Fig. 9 Schematic illustrations of fabrication procedure of (a) MXene-sponge and (b-c) fabrication of MXene-Sponge/PVA NWs based sensor[64]

| [1] |

BARLION A A, PARK W T, MALLON J R , et al. Review: semiconductor piezoresistance for microsystems. Proc. IEEE Inst. Electr. Electron. Eng., 2009,97(3):513-552.

DOI URL PMID |

| [2] |

CHORTOS A, LIU J, BAO Z . Pursuing prosthetic electronic skin. Nat. Mater., 2016,15(9):937-950.

DOI URL PMID |

| [3] |

AMJADI M, KYUNG K U, PARK I , et al. Stretchable, skin- mountable, and wearable strain sensors and their potential applications: a review. Adv. Funct. Mater., 2016,26(11):1678-1698.

DOI URL |

| [4] |

NIE P, WANG R, XU X , et al. High-performance piezoresistive electronic skin with bionic hierarchical microstructure and microcracks. ACS Appl. Mater. Interfaces, 2017,9(17):14911-14919.

DOI URL PMID |

| [5] |

XU X, WANG R, NIE P , et al. Copper nanowire-based aerogel with tunable pore structure and its application as flexible pressure sensor. ACS Appl. Mater. Interfaces, 2017,9(16):14273-14280.

DOI URL PMID |

| [6] |

BAE G Y, PARK S, KIM D , et al. Linearly and highly pressure- sensitive electronic skin based on a bioinspired hierarchical structural array. Adv. Mater., 2016,28(26):5300-5306.

DOI URL PMID |

| [7] |

PAN L, CHORTOS A, YU G , et al. An ultra-sensitive resistive pressure sensor based on hollow-sphere microstructure induced elasticity in conducting polymer film. Nat. Commun., 2014,5:3002.

DOI URL PMID |

| [8] |

TRUNG T Q, LEE N E . Flexible and stretchable physical sensor integrated platforms for wearable human-activity monitoringand personal healthcare. Adv. Mater., 2016,28(22):4338-4372.

DOI URL PMID |

| [9] |

GONG S, SCHWALB W, WANG Y , et al. A wearable and highly sensitive pressure sensor with ultrathin gold nanowires. Nat. Commun., 2014,5:3132.

DOI URL PMID |

| [10] |

JIAN M, XIA K, WANG Q , et al. Flexible and highly sensitive pressure sensors based on bionic hierarchical structures. Adv. Funct. Mater., 2017,27(9):1606066.

DOI URL |

| [11] |

KIM D H, XIAO J, SONG J , et al. Stretchable, curvilinear electronics based on inorganic materials. Adv. Mater., 2010,22(19):2108-2124.

DOI URL PMID |

| [12] |

SHENG L, LIANG Y, JIANG L , et al . Bubble-decorated honeycomb-like graphene film as ultrahigh sensitivity pressure sensors. Adv. Funct. Mater., 2015,25(41):6545-6551.

DOI URL |

| [13] |

KIM J, LEE S W, KIM M H , et al. Zigzag-shaped silver nanoplates: synthesis via ostwald ripening and their application in highly sensitive strain sensors. ACS Appl. Mater. Interfaces, 2018,10(45):39134-39143.

DOI URL PMID |

| [14] |

BOLAND CONOR S, KHAN UMAR, BACKES CLAUDAI , et al. Sensitive, high-strain, high-rate bodily motion sensors based on graphene rubber composites. ACS Nano, 2014,8(9):8819-8830.

DOI URL PMID |

| [15] |

YANG Y, SHI L, CAO Z , et al. Strain sensors with a high sensitivity and a wide sensing range based on a Ti3C2Tx( MXene) nanoparticle- nanosheet hybrid network. Adv Funct. Mater., 2019,29(14):1807882.

DOI URL |

| [16] |

SHI X, LIU S, SUN Y , et al. Lowering internal friction of 0D-1D-2D ternary nanocomposite-based strain sensor by fullerene to boost the sensing performance. Adv. Funct. Mater., 2018,28(22):1800850.

DOI URL |

| [17] |

PARK J, LEE Y, HONG J , et al. Tactile-direction-sensitive and stretchable electronic skins based on human-skin-inspired interlocked microstructures. ACS Nano, 2014,8(12):12020-12029.

DOI URL PMID |

| [18] |

BOLAND C, KHAN U, RYAN G , et al. Sensitive electromechanical sensors using viscoelastic graphene-polymer nanocomposites. Science, 2016,354(6317):1257-1260.

DOI URL PMID |

| [19] |

PARK J, LEE Y, HONG J , et al. Giant tunneling piezoresistance of composite elastomers with interlocked microdome arrays for ultrasensitive and multimodal electronic skins. ACS Nano, 2014,8(5):4689-4697.

DOI URL PMID |

| [20] |

COHEN D J, MITRA D, PETERSON K , et al. A highly elastic, capacitive strain gauge based on percolating nanotube networks. Nano Lett., 2012,12(4):1821-1825.

DOI URL PMID |

| [21] |

PANG C, LEE G Y, KIM T I , et al. A flexible and highly sensitive strain-gauge sensor using reversible interlocking of nanofibres. Nat. Mater., 2012,11(9):795-801.

DOI URL PMID |

| [22] |

CHENG Y, WANG R, SUN J , et al. A stretchable and highly sensitive graphene-based fiber for sensing tensile strain, bending, and torsion. Adv. Mater., 2015,27(45):7365-7371.

DOI URL PMID |

| [23] |

MANNSFELD S C, TEE B C, STOLTENBERG R , et al. Highly sensitive flexible pressure sensors with microstructured rubber dielectric layers. Nat. Mater., 2010,9(10):859-864.

DOI URL PMID |

| [24] |

WANG X, GU Y, XIONG Z , et al. Silk-molded flexible, ultrasensitive, and highly stable electronic skin for monitoring human physiological signals. Adv. Mater., 2014,26(9):1336-1342.

DOI URL |

| [25] |

CAO Z, WANG R, HE T , et al. Interface-controlled conductive fibers for wearable strain sensors and stretchable conducting wires. ACS Appl. Mater. Interfaces, 2018,10(16):14087-14096.

DOI URL PMID |

| [26] |

LEE J, KIM S, LEE J , et al. A stretchable strain sensor based on a metal nanoparticle thin film for human motion detection. Nanoscale, 2014,6(20):11932-11939.

DOI URL |

| [27] |

BOLAND C S, KHAN U, BENAMUR H , et al. Surface coatings of silver nanowires lead to effective, high conductivity, high-strain, ultrathin sensors. Nanoscale, 2017,9(46):18507-18515.

DOI URL PMID |

| [28] |

NUR R, MATSUHISA N, JIANG Z , et al. A highly sensitive capacitive-type strain sensor using wrinkled ultrathin gold films. Nano Lett., 2018,18(9):5610-5617.

DOI URL PMID |

| [29] |

WANG Y, WANG Y, YANG Y . Graphene-polymer nanocomposite-based redox-induced electricity for flexible self-powered strain sensors. Adv. Energy Mater., 2018,8(22):1800961.

DOI URL |

| [30] |

LEE J, PYO S, KWON D S , et al. Ultrasensitive strain sensor based on separation of overlapped carbon nanotubes. Small, 2019,15(12):1805120.

DOI URL PMID |

| [31] |

ZHOU J, XU X, XIN Y , et al. Coaxial thermoplastic elastomer- wrapped carbon nanotube fibers for deformable and wearable strain sensors. Adv. Funct. Mater., 2018,28(16):1705591.

DOI URL PMID |

| [32] |

KIM KH, JANG NS, HA SH , et al. Highly sensitive and stretchable resistive strain sensors based on microstructured metal nanowire/elastomer composite films. Small, 2018,14(14):1704232.

DOI URL PMID |

| [33] |

OH J, YANG J, KIM J , et al. Pressure insensitive strain sensor with facile solution-based process for tactile sensing applications. ACS Nano, 2018,12(8):7546-7553.

DOI URL PMID |

| [34] |

LI X, ZHANG R, YU W , et al. Stretchable and highly sensitive graphene-on-polymer strain sensors. Sci. Rep., 2012,2:870.

DOI URL PMID |

| [35] |

NAGUIB M, KURTOGLU M, PRESSER V , et al. Two-dimensional nanocrystals produced by exfoliation of Ti3AlC2. Adv. Mater., 2011,23(37):4248-4253.

DOI URL PMID |

| [36] |

NAGUIB M, JOSHUA C, PRESSER V , et al. Two-dimensional transition metal carbides. ACS Nano, 2012,6(2):1322-1331.

DOI URL PMID |

| [37] |

NAGUIB M, MOCHALIN V N, BARSOUM M W , et al. 25th anniversary article: MXenes: a new family of two-dimensional materials. Adv Mater, 2014,26(7):992-1005.

DOI URL |

| [38] |

LEI J, ZHANG X, ZHOU Z . Recent advances in MXene: preparation, properties, and applications. Frontiers of Physics, 2015,10(3):276-286.

DOI URL PMID |

| [39] |

WANG H, CAO H, ZHANG J . Research progress of novel two-dimensional material MXene. Journal of Inorganic Materials, 2017,32(6):561-570.

DOI URL |

| [40] |

XIU L, WANG Z, YU M , et al. Aggregation-resistant 3D MXene-based architecture as efficient bifunctional electrocatalyst for overall water splitting. ACS Nano, 2018,12(8):8017-8028.

DOI URL PMID |

| [41] |

NAGUIB M, GOGOTSI Y . Synthesis of two-dimensional materials by selective extraction. ACC Chem. Res., 2015,48(1):128-135.

DOI URL PMID |

| [42] |

NAGUIB M, UNOCIC R R, ARMSTRONG B L , et al. Large-scale delamination of multi-layers transition metal carbides and carbonitrides "MXenes". Dalton Trans., 2015,44(20):9353-9358.

DOI URL PMID |

| [43] |

GHIDIU M, LUKATSKAYA M R, ZHAO M Q , et al. Conductive two-dimensional titanium carbide 'clay' with high volumetric capacitance. Nature, 2014,516(7529):78-81.

DOI URL |

| [44] |

MASHTALIR O, NAGUIB M, DYATKIN B , et al. Kinetics of aluminum extraction from Ti3AlC2 in hydrofluoric acid. Mater. Chem. Phys., 2013,139(1):147-152.

DOI URL |

| [45] |

ENYASHIN A N, IVANOVSKII A L . Atomic structure, comparative stability and electronic properties of hydroxylated Ti2C and Ti3C2 nanotubes. Comput. Theor. Chem., 2012,989:27-32.

DOI URL |

| [46] |

ANASARI B, XIE Y, BEDAGHI M , et al. Two-dimensional, ordered, double transition metals carbides (MXenes). ACS Nano, 2015,9(10):9507-9516.

DOI URL PMID |

| [47] |

KHAZAEI M, ARAI M, SASAKI T , et al. Novel electronic and magnetic properties of two-dimensional transition metal carbides and nitrides. Adv. Funct. Mater., 2013,23(17):2185-2192.

DOI URL |

| [48] |

WU F, JIANG Y, YE Z , et al. A 3D flower-like VO2/MXene hybrid architecture with superior anode performance for sodium ion batteries. J. Mater. Chem. A, 2019,7(3):1315-1322.

DOI URL |

| [49] |

XIAO Z, YANG Z, LI Z , et al. Synchronous gains of areal and volumetric capacities in lithium-sulfur batteries promised by flower-like porous Ti3C2Tx matrix. ACS Nano, 2019,13(3):3404-3412.

DOI URL PMID |

| [50] |

LUO J, WANG C, WANG H , et al. Pillared MXene with ultralarge iInterlayer spacing as a stable matrix for high performance sodium metal anodes. Adv. Funct. Mater., 2019,29:1805946.

DOI URL |

| [51] |

PENG Y, AKUZUM B, KURRA N , et al. All-MXene (2D titanium carbide) solid-state microsupercapacitors for on-chip energy storage. Energy Environ. Sci., 2016,9(9):2847-2854.

DOI URL |

| [52] |

PERSSON I, HALIM J, LIND H , et al. 2D Transition metal carbides (MXenes) for carbon capture. Adv. Mater., 2019,31(2):1805472.

DOI URL PMID |

| [53] |

LIU J, ZHANG H, SUN R , et al. Hydrophobic, flexible, and lightweight MXene foams for high-performance electromagnetic- interference shielding. Adv Mater, 2017,29(38):1702367.

DOI URL PMID |

| [54] |

FAISAL S, CHRISTINE B, ANASORI B , et al. Electromagnetic interference shielding with 2D transition metal carbides (MXenes). Science, 2016,353(6304):1137-1140.

DOI URL PMID |

| [55] |

CAI Y, SHEN J, GE G , et al. Stretchable Ti3C2Tx MXene/carbon nanotube composite based strain sensor with ultrahigh sensitivity and tunable sensing range. ACS Nano, 2018,12(1):56-62.

DOI URL PMID |

| [56] |

SHI X, WANG H, XIE X , et al. Bioinspired ultrasensitive and stretchable MXene-based strain sensor via nacre-mimetic microscale "brick-and-mortar" architecture. ACS Nano, 2019,13(1):649-659.

DOI URL PMID |

| [57] |

HYOSUNG AN, TOUSEEF HABIB, SMIT SHAH , et al. Surface- agnostic highly stretchable Surface- agnostic highly stretchable and bendable conductive MXene multilayers. Sci. Adv. 2018, 4(3): eaaq0118

DOI URL PMID |

| [58] |

ZHANG Y, LEE K, ANJUM D , et al. MXenes stretch hydrogel sensor performance to new limits. Sci. Adv., 2018, 4(6): eaat0098.

DOI URL PMID |

| [59] |

MA Y, LIU N, LI L , et al. A highly flexible and sensitive piezoresistive sensor based on MXene with greatly changed interlayer distances. Nat. Commun., 2017,8:1207.

DOI URL PMID |

| [60] |

MA Y, YUE Y, ZHANG H , et al. 3D Synergistical MXene/reduced graphene oxide aerogel for a piezoresistive sensor. ACS Nano, 2018,12(4):3209-3216.

DOI URL PMID |

| [61] |

LIU J, ZHANG H, XIE X , et al. Multifunctional, superelastic, and lightweight MXene/polyimide aerogels. Small, 2018,14(45):1802479.

DOI URL PMID |

| [62] |

ZHUO H, HU Y, CHEN Z , et al. A carbon aerogel with super mechanical and sensing performances for wearable piezoresistive sensors. J. Mater. Chem. A, 2019,7(14):8092-8100.

DOI URL |

| [63] |

CHEN Z, HU Y, ZHUO H , et al. Compressible, elastic, and pressure- sensitive carbon aerogels derived from 2D titanium carbide nanosheets and bacterial cellulose for wearable sensors. Chem. Mater., 2019,31(9):3301-3312.

DOI URL |

| [64] |

YUE Y, LIU N, LIU W , et al. 3D hybrid porous MXene-sponge network and its application in piezoresistive sensor. Nano Energy, 2018,50:79-87.

DOI URL |

| [65] |

LI X, LI Y, LI X , et al. Highly sensitive, reliable and flexible piezoresistive pressure sensors featuring polyurethane sponge coated with MXene sheets. J. Colloid Interface Sci., 2019,542:54-62.

DOI URL PMID |

| [66] |

GUO Y, ZHONG M, FANG Z , et al. A wearable transient pressure sensor made with MXene nanosheets for sensitive broad-range human-machine interfacing. Nano Lett., 2019,19(2):1143-1150.

DOI URL PMID |

| [1] | 朱文杰, 唐璐, 陆继长, 刘江平, 罗永明. 钙钛矿型氧化物催化氧化挥发性有机化合物的研究进展[J]. 无机材料学报, 2025, 40(7): 735-746. |

| [2] | 胡智超, 杨鸿宇, 杨鸿程, 孙成礼, 杨俊, 李恩竹. P-V-L键理论在微波介质陶瓷性能调控中的应用[J]. 无机材料学报, 2025, 40(6): 609-626. |

| [3] | 吴琼, 沈炳林, 张茂华, 姚方周, 邢志鹏, 王轲. 铅基织构压电陶瓷研究进展[J]. 无机材料学报, 2025, 40(6): 563-574. |

| [4] | 张碧辉, 刘小强, 陈湘明. Ruddlesden-Popper结构杂化非常规铁电体的研究进展[J]. 无机材料学报, 2025, 40(6): 587-608. |

| [5] | 吴杰, 杨帅, 王明文, 李景雷, 李纯纯, 李飞. 铅基织构压电陶瓷的发展历程、现状与挑战[J]. 无机材料学报, 2025, 40(6): 575-586. |

| [6] | 姜昆, 李乐天, 郑木鹏, 胡永明, 潘勤学, 吴超峰, 王轲. PZT陶瓷的低温烧结研究进展[J]. 无机材料学报, 2025, 40(6): 627-638. |

| [7] | 田睿智, 兰正义, 殷杰, 郝南京, 陈航榕, 马明. 基于微流控技术的纳米无机生物材料制备: 原理及其研究进展[J]. 无机材料学报, 2025, 40(4): 337-347. |

| [8] | 张继国, 吴田, 赵旭, 杨钒, 夏天, 孙士恩. 钠离子电池正极材料循环稳定性提升策略及产业化进程[J]. 无机材料学报, 2025, 40(4): 348-362. |

| [9] | 殷杰, 耿佳毅, 王康龙, 陈忠明, 刘学建, 黄政仁. SiC陶瓷的3D打印成形与致密化新进展[J]. 无机材料学报, 2025, 40(3): 245-255. |

| [10] | 谌广昌, 段小明, 朱金荣, 龚情, 蔡德龙, 李宇航, 杨东雷, 陈彪, 李新民, 邓旭东, 余瑾, 刘博雅, 何培刚, 贾德昌, 周玉. 直升机特定结构先进陶瓷材料研究进展与应用展望[J]. 无机材料学报, 2025, 40(3): 225-244. |

| [11] | 范晓波, 祖梅, 杨向飞, 宋策, 陈晨, 王子, 罗文华, 程海峰. 质子调控型电化学离子突触研究进展[J]. 无机材料学报, 2025, 40(3): 256-270. |

| [12] | 海热古·吐逊, 郭乐, 丁嘉仪, 周嘉琪, 张学良, 努尔尼沙·阿力甫. 上转换荧光探针辅助的光学成像技术在肿瘤显影中的应用研究进展[J]. 无机材料学报, 2025, 40(2): 145-158. |

| [13] | 孙树娟, 郑南南, 潘昊坤, 马猛, 陈俊, 黄秀兵. 单原子催化剂制备方法的研究进展[J]. 无机材料学报, 2025, 40(2): 113-127. |

| [14] | 陶桂龙, 支国伟, 罗添友, 欧阳佩东, 衣新燕, 李国强. 空腔型薄膜体声波滤波器的关键技术进展[J]. 无机材料学报, 2025, 40(2): 128-144. |

| [15] | 周帆, 田志林, 李斌. 热防护系统用碳化物超高温陶瓷抗烧蚀涂层研究进展[J]. 无机材料学报, 2025, 40(1): 1-16. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||