无机材料学报 ›› 2015, Vol. 30 ›› Issue (6): 581-587.DOI: 10.15541/jim20140621 CSTR: 32189.14.10.15541/jim20140621

刘 婧1, 2, 刘 军1, 李 江2, 林 丽1, 2, 潘裕柏2, 程晓农1, 郭景坤2

收稿日期:2014-12-01

修回日期:2015-02-13

出版日期:2015-06-04

网络出版日期:2015-05-22

作者简介:刘 婧(1986-), 女, 博士研究生. E-mail: liujing53302@163.com

基金资助:LIU Jing1, 2, LIU Jun1, LI Jiang2, LIN Li1, 2, PAN Yu-Bai2, CHENG Xiao-Nong1, GUO Jing-Kun2

Received:2014-12-01

Revised:2015-02-13

Published:2015-06-04

Online:2015-05-22

About author:LIU Jing. E-mail: liujing53302@163.com

Supported by:摘要:

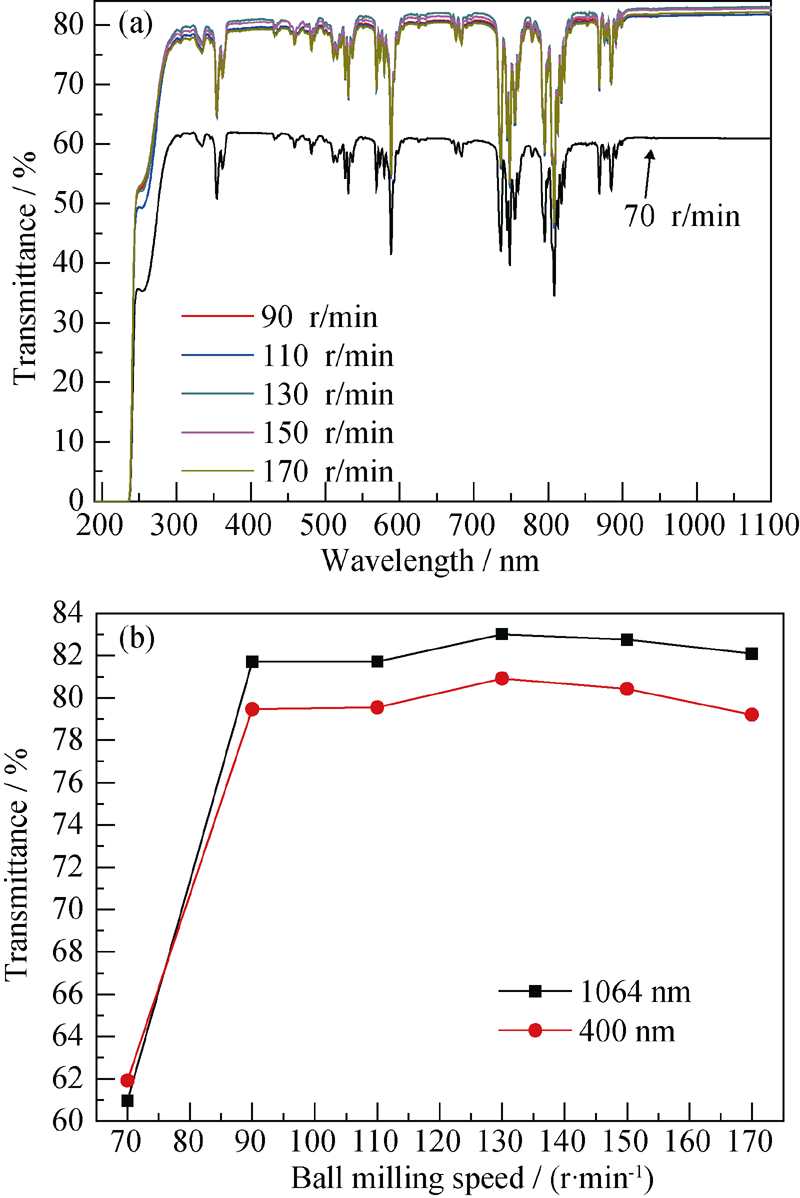

以高纯商业Y2O3、α-Al2O3和Nd2O3粉体为原料, 以TEOS(正硅酸乙酯)和MgO为烧结助剂, 采用固相反应和真空烧结技术制备了1.0at%Nd:YAG透明陶瓷。系统研究了球磨转速(球磨时间10 h)对混合粉体的尺寸以及对陶瓷样品致密化行为、显微结构和光学性能的影响。结果表明: 通过球磨过程可以充分细化原料粉体的颗粒; 随着球磨转速的提高, 陶瓷烧结时样品中的气孔能更好地排除。但是球磨转速过高时, 陶瓷烧结体中存在少量的富铝第二相会降低样品的光学透过率。当球磨转速为130 r/min时, 真空烧结(1760℃×50 h)所得Nd:YAG透明陶瓷的微结构均匀致密, 几乎没有晶界和晶内气孔存在, 样品在1064 nm处的直线透过率高达83%。

中图分类号:

刘 婧, 刘 军, 李 江, 林 丽, 潘裕柏, 程晓农, 郭景坤. 球磨转速对Nd:YAG透明陶瓷的显微结构及光学性能的影响[J]. 无机材料学报, 2015, 30(6): 581-587.

LIU Jing, LIU Jun, LI Jiang, LIN Li, PAN Yu-Bai, CHENG Xiao-Nong, GUO Jing-Kun. Influence of Ball Milling Speed on Microstructure and Optical Transparency of Nd:YAG Ceramics[J]. Journal of Inorganic Materials, 2015, 30(6): 581-587.

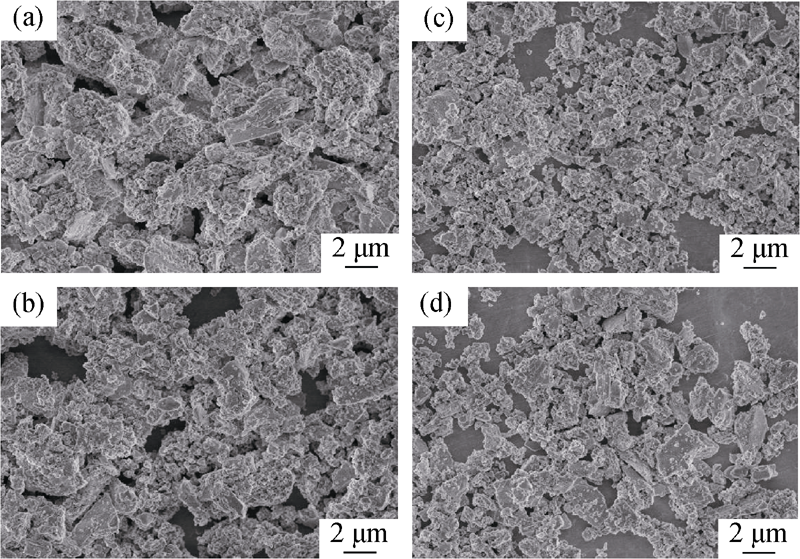

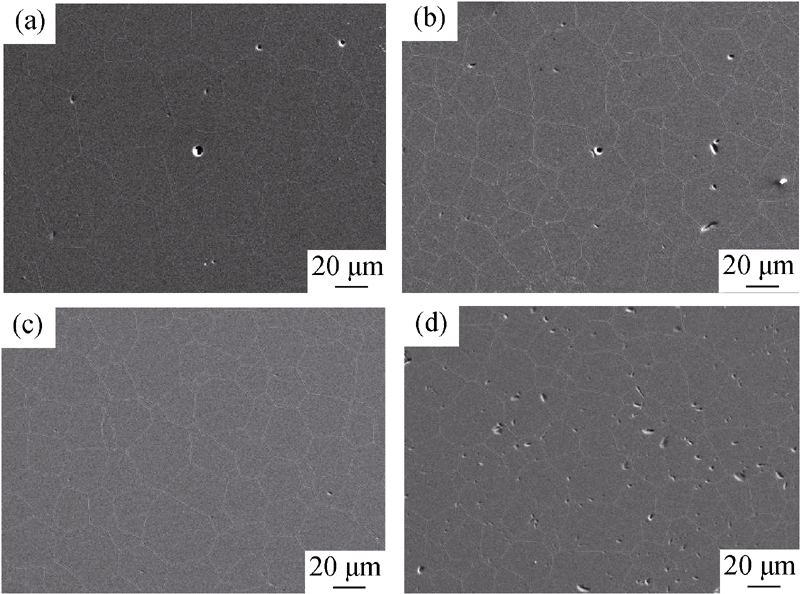

图2 经不同转速球磨(球磨10 h)后的混合粉体的FESEM形貌照片

Fig. 2 FESEM micrographs of the powder mixtures ball milled at different speeds for 10 h (a) 70 r/min; (b) 90 r/min; (c) 130 r/min; (d) 170 r/min

| Ball milling speed/(r·min-1) | 70 | 90 | 110 | 130 | 150 | 170 |

|---|---|---|---|---|---|---|

| SBET /(m2·g-1) | 5.833 | 6.275 | 6.985 | 7.295 | 7.370 | 7.412 |

表1 经不同转速球磨后混合粉体的比表面积

Table 1 Specific surface areas (SBET) of powder mixtures ball milled at different speeds for 10 h

| Ball milling speed/(r·min-1) | 70 | 90 | 110 | 130 | 150 | 170 |

|---|---|---|---|---|---|---|

| SBET /(m2·g-1) | 5.833 | 6.275 | 6.985 | 7.295 | 7.370 | 7.412 |

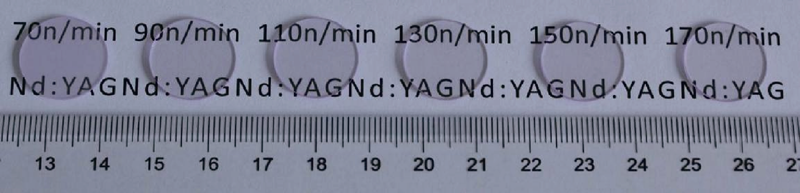

图3 不同转速球磨的混合粉体经1760 ℃×50 h真空烧结所得Nd:YAG陶瓷的实物照片

Fig. 3 Photographs of Nd:YAG ceramics sintered at 1760℃ for 50 h from the powder mixtures ball milled at different speeds

图4 不同转速球磨的混合粉体经1760℃×50 h真空烧结所得Nd:YAG陶瓷的透过率曲线

Fig. 4 In-line transmittances of Nd:YAG ceramics sintered at 1760℃ for 50 h from powder mixtures ball milled at different speeds (a) 190-1100 nm; (b) 1064 and 400 nm

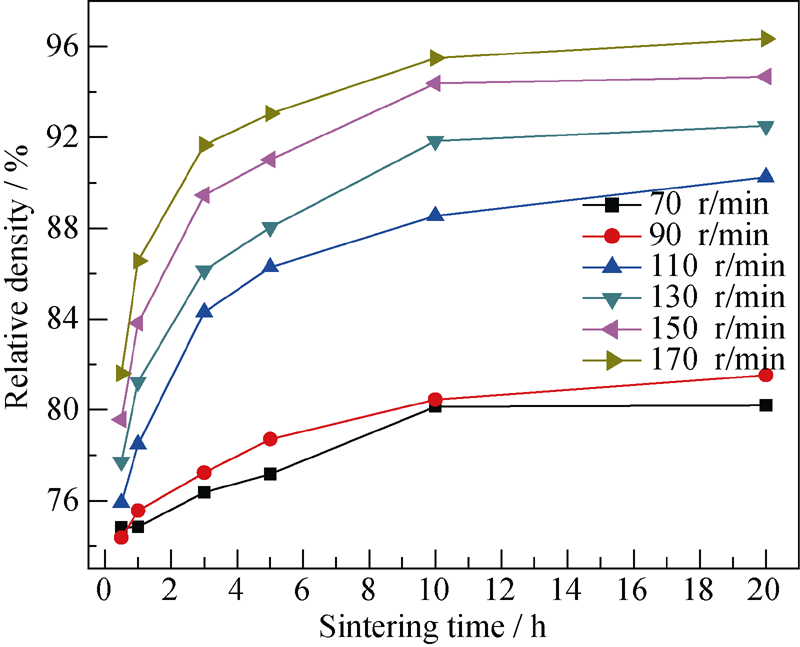

图5 不同转速球磨的混合粉体在1550℃烧结不同时间所得Nd:YAG陶瓷的致密化曲线

Fig. 5 Relative density versus sintering time at 1550 ℃ for Nd:YAG ceramics from powder mixtures ball milled at different speeds

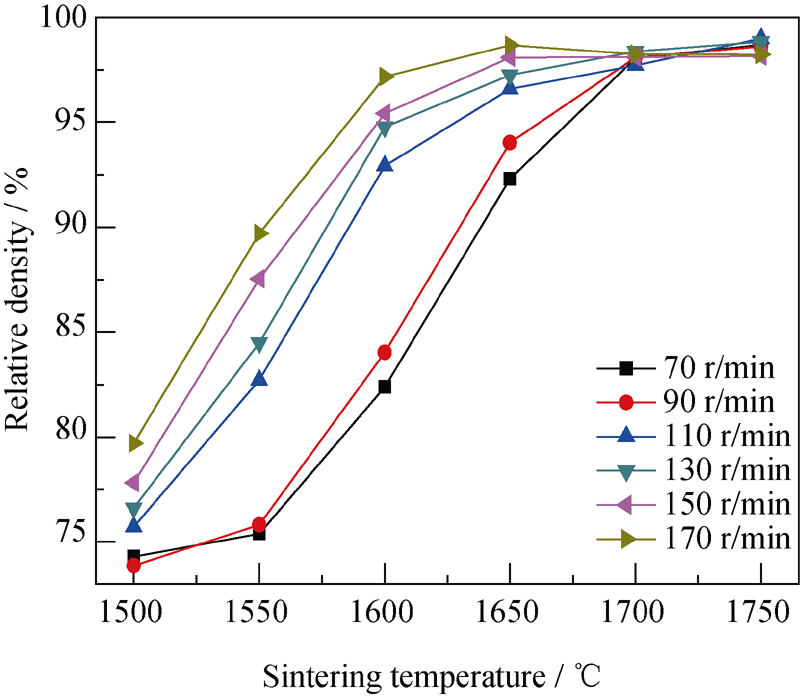

图 6 不同转速球磨的混合粉体在不同温度烧结2 h后Nd: YAG陶瓷样品的致密化曲线

Fig. 6 Relative density versus sintering temperature for Nd: YAG ceramics from powder mixtures ball milled at different speeds for 2 h

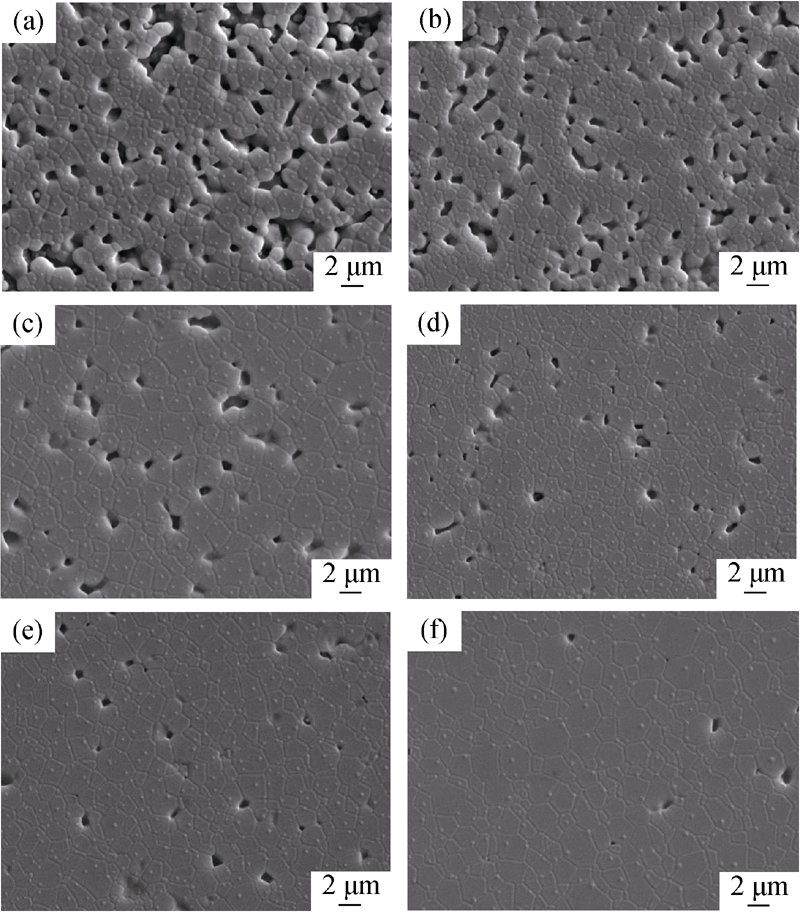

图7 不同转速球磨(球磨10 h)的混合粉体在1600℃×2 h真空烧结后所得陶瓷样品的热腐蚀表面形貌

Fig. 7 SEM micrographs of ceramics sintered at 1600℃ for 2 h from powder mixtures ball milled at different speeds for 10 h (a) 70 r/min; (b) 90 r/min; (c) 110 r/min; (d) 130 r/min; (e) 150 r/min; (f) 170 r/min

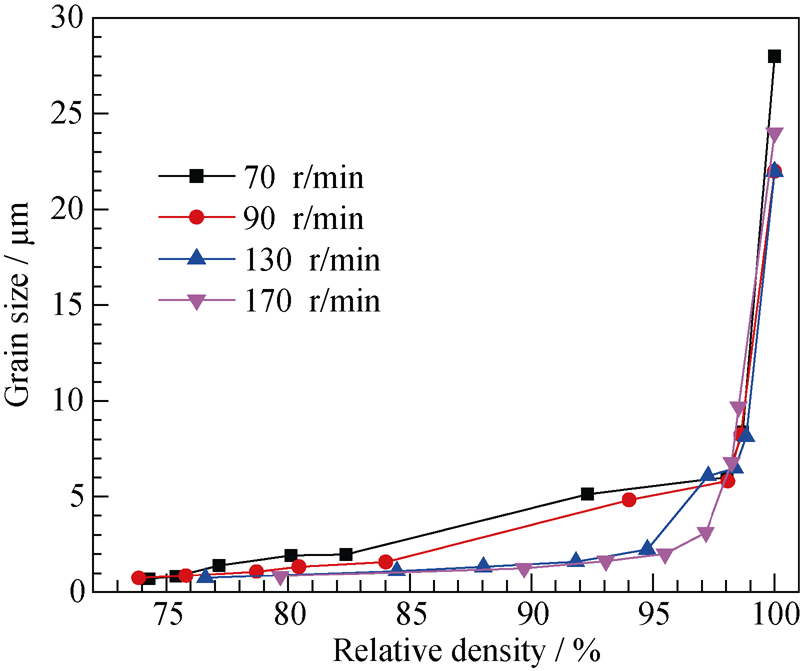

图8 不同转速球磨混合粉体在1500~1750℃之间烧结Nd: YAG陶瓷的轨线图

Fig. 8 Sintering trajectory for Nd:YAG ceramics sintered between 1500℃ and 1750℃ from powder mixtures ball milled at different speeds

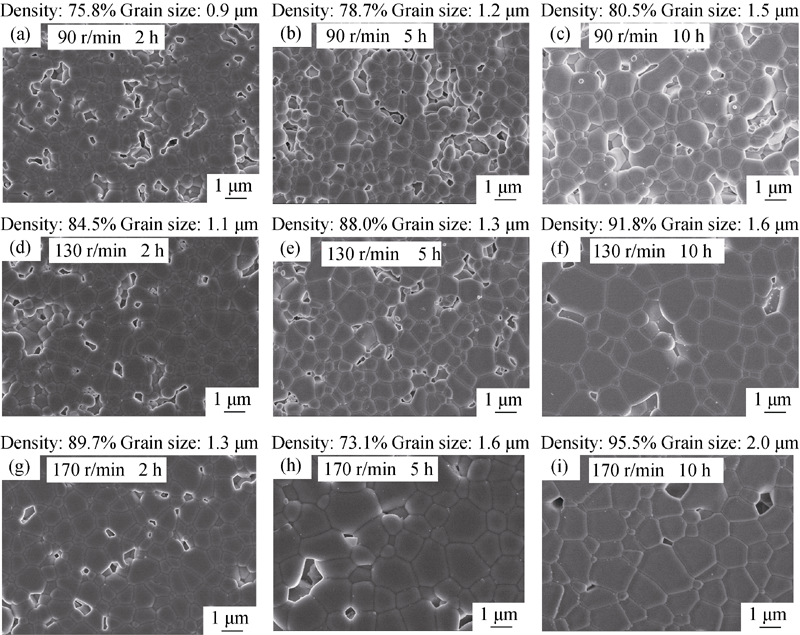

图9 不同球磨转速所得混合粉体在1550℃真空烧结不同时间所得陶瓷样品的表面形貌

Fig. 9 SEM micrographs of ceramics sintered at 1550℃ for different time from powder mixtures ball milled at different speeds

图10 不同转速球磨所得混合粉体在1760℃×50 h真空烧结后陶瓷样品腐蚀后表面形貌

Fig. 10 EPMA micrographs of ceramics sintered at 1760℃ for 50 h from powder mixtures ball milled at different speeds (a) 70 r/min; (b) 90 r/min; (c) 130 r/min; (d) 170 r/min

| [1] | IKESUE A, AUNG Y L, TAIRA T, et al.Progress in ceramic lasers.Annu. Rev. Mater. Res., 2006, 36: 397-429. |

| [2] | IKESUE A, AUNG Y L.Ceramic laser materials.Nat. Photonics, 2008, 2(12): 721-727. |

| [3] | LI J, PAN Y B, ZENG Y P, et al.The history, development, and future prospects for laser ceramics: a review.Int. J. Refract. Met. Hard Mater., 2013, 39: 44-52. |

| [4] | YAGI H, YANAGITANI T, TAKAICHI K, et al.Characterizations and laser performances of highly transparent Nd3+: Y3Al5O12 laser ceramics.Opt. Mater., 2007, 29(10): 1258-1262. |

| [5] | IKESUE A, FURUSATO I, KAMATA K.Fabrication of polycrystalline, transparent YAG ceramics by a solid-state reaction method.J. Am. Ceram. Soc., 1995, 78(1): 225-228. |

| [6] | LU J R, UEDA K, YAGI H, et al.Neodymium doped yttrium aluminum garnet(Y3Al5O12)nano-crystalline ceramics—a new generation of solid state laser and optical materials.J. Alloys Compd., 2002, 341(1-2): 220-225. |

| [7] | BOULON G.Fifty years of advances in solid-state laser materials.Opt. Mater., 2012, 34(3): 499-512. |

| [8] | LI X D, LI J G, XIU Z M, et al.Transparent Nd: YAG ceramics fabricated using nanosized γ-alumina and yttria powders.J. Am. Ceram. Soc., 2009, 92(1): 241-244. |

| [9] | TANG F, CAO Y G, HUANG J Q, et al.Fabrication and laser behavior of composite Yb:YAG ceramic.J. Am. Ceram. Soc., 2012, 95(1): 56-59. |

| [10] | ZHANG W, LU T, MA B, et al.Improvement of optical properties of Nd: YAG transparent ceramics by post-annealing and post hot isostatic pressing.Opt. Mater., 2013, 35(12): 2405-2410. |

| [11] | CHEN J C, LI J, XU J L, et al.4350 W quasi-continuous-wave operation of a diode face-pumped ceramic Nd: YAG slab laser.Opt. Laser Technol., 2014, 63: 50-53. |

| [12] | LEE S H, KOCHAWATTANA S, MESSING G L, et al.Solid-state reactive sintering of transparent polycrystalline Nd: YAG.J. Am. Ceram. Soc., 2006, 89(6): 1945-1950. |

| [13] | LI J, WU Y S, PAN Y B, et al.Fabrication, microstructure and properties of highly transparent Nd:YAG laser ceramics.Opt. Mater., 2008, 31(1): 6-17. |

| [14] | SERANONI M, PIANCASTELLI A, COSTA A L, et al.Improvements in the production of Yb:YAG transparent ceramic materials: spray drying optimization. Opt. Mater., 2012, 34(6): 995-1001. |

| [15] | LIU W B, ZHANG W X, LI J, et al.Synthesis of Nd: YAG powders leading to transparent ceramics: the effect of MgO dopant.J. Eur. Ceram. Soc., 2011, 31(4): 653-657. |

| [16] | LI J, CHEN F, LIU W B, et al.Co-precipitation synthesis route to yttrium aluminum garnet (YAG) transparent ceramics.J. Eur. Ceram. Soc., 2012, 32(11): 2971-2979. |

| [17] | LV Y H, ZHANG W, LIU H, et al.Synthesis of nano-sized and highly sinterable Nd: YAG powders by the urea homogeneous precipitation method.Powder Technol., 2012, 217: 140-147. |

| [18] | CHEN X T, LU T C, WEI N, et al.Effect of ball-milling granulation with PVB adhesive on the sinterability of co-precipitated Yb: YAG nanopowders.J. Alloys Compd., 2014, 589: 448-454. |

| [19] | LI J, LIU W B, JIANG B X, et al.Synthesis of nanocrystalline yttria powder and fabrication of Cr, Nd:YAG transparent ceramics.J. Alloys Compd., 2012, 515: 49-56. |

| [20] | LIU B L, LI J, IVANOV M, et al.Solid-state reactive sintering of Nd:YAG transparent ceramics: the effect of Y2O3 powders pretreatment.Opt. Mater., 2014, 36(9): 1591-1597. |

| [21] | LI J, LIU J, LIU B L, et al.Influence of heat treatment of powder mixture on the microstructure and optical transmission of Nd:YAG transparent ceramics.J. Eur. Ceram. Soc., 2014, 34(10): 2497-2507. |

| [22] | EPICIER T, BOULON G, ZHAO W, et al.Spatial distribution of the Yb3+ rare earth ions in Y3Al5O12 and Y2O3 optical ceramics as analyzed by TEM.J. Mater. Chem., 2012, 22: 18221-18229. |

| [23] | STEVENSON A J, KUPP E R, MESSING G L.Low temperature, transient liquid phase sintering of B2O3-SiO2-doped Nd:YAG transparent ceramics.J. Mater. Res., 2011, 26(09): 1151-1158. |

| [24] | YANG H, QIN X P, ZHANG J, et al.Fabrication of Nd:YAG transparent ceramics with both TEOS and MgO additives.J. Alloys Compd., 2011, 509(17): 5274-5279. |

| [25] | GUO W, CAO Y G, HUANG Q F, et al.Fabrication and laser behaviors of Nd:YAG ceramic microchips. J. Eur. Ceram. Soc., 2011, 31(13): 2241-2246. |

| [26] | BA X W, LI J, ZENG Y P, et al.Transparent Y3Al5O12 ceramics produced by an aqueous tape casting method.Ceram. Int., 2013, 39(4): 4639-4643. |

| [27] | GE L, LI J, ZHOU Z W, et al.Fabrication of composite YAG/Nd: YAG/YAG transparent ceramic for planar waveguide laser.Opt. Mater. Express, 2014, 4(5): 1042-1049. |

| [28] | FU Y L, LI J, LIU Y, et al.Effect of air annealing on the optical properties and laser behavior of Nd:YAG transparent ceramics.Opt. Mater. Express, 2014, 4(10): 2108-2115. |

| [29] | LIU J, LIN L, LI J, et al.Effects of ball milling time on microstructure evolution and optical transparency of Nd:YAG ceramics.Ceram. Int., 2014, 40: 9841-9851. |

| [30] | STEVENSON A J, LI X, MARTINEZ M A, et al.Effect of SiO2 on densification and microstructure development in Nd:YAG transparent ceramics.J. Am. Ceram. Soc., 2011, 94(5): 1380-1387. |

| [31] | BOULESTEIX R, MAîTRE A, BAUMARD J F, et al. The Effect of silica doping on neodymium diffusion in yttrium aluminum garnet ceramics: implications for sintering mechanisms.J. Eur. Ceram. Soc., 2009, 29(12): 2517-2526. |

| [32] | KOCHAWATTANA S, STEVENSON A, LEE S H, et al.Sintering and grain growth in SiO2 doped Nd:YAG.J. Eur. Ceram. Soc., 2008, 28(7): 1527-1534. |

| [1] | 叶君豪, 周真真, 胡辰, 王雁斌, 荆延秋, 李廷松, 程梓秋, 吴俊林, IVANOV Maxim, HRENIAK Dariusz, 李江. 共沉淀纳米粉体制备Yb:Sc2O3透明陶瓷的微结构与光学性能[J]. 无机材料学报, 2025, 40(2): 215-224. |

| [2] | 吕朝阳, 徐勇, 杨久延, 涂广升, 涂兵田, 王皓. MgF2助剂对MgAl1.9Ga0.1O4透明陶瓷的制备与光学性能的影响[J]. 无机材料学报, 2024, 39(5): 531-538. |

| [3] | 顾军毅, 范武刚, 张兆泉, 姚琴, 展红全. 还原制备Pr2O3粉体及其结构和光学性能研究[J]. 无机材料学报, 2023, 38(7): 771-777. |

| [4] | 李悦, 张旭良, 景芳丽, 胡章贵, 吴以成. 铈掺杂硼酸钙镧晶体的生长与性能研究[J]. 无机材料学报, 2023, 38(5): 583-588. |

| [5] | 王海东, 王燕, 朱昭捷, 李坚富, LAKSHMINARAYANA Gandham, 涂朝阳. Dy3+掺杂SrGdGa3O7晶体的晶体生长, 结构、光学和可见光荧光特性[J]. 无机材料学报, 2023, 38(12): 1475-1482. |

| [6] | 李文俊, 王皓, 涂兵田, 谌强国, 郑凯平, 王为民, 傅正义. 宽光谱透过Mg0.9Al2.08O3.97N0.03透明陶瓷的制备与性能研究[J]. 无机材料学报, 2022, 37(9): 969-975. |

| [7] | 刘强, 王倩, 陈鹏辉, 李晓英, 章立轩, 谢腾飞, 李江. 两步烧结法制备红色Ce:8YSZ透明陶瓷及其性能研究[J]. 无机材料学报, 2022, 37(8): 911-917. |

| [8] | 洪督, 牛亚然, 李红, 钟鑫, 郑学斌. 等离子喷涂TiC-Graphite复合涂层摩擦磨损性能[J]. 无机材料学报, 2022, 37(6): 643-650. |

| [9] | 孙鲁超, 周翠, 杜铁锋, 吴贞, 雷一明, 李家麟, 苏海军, 王京阳. 光悬浮区熔定向凝固Al2O3/Er3Al5O12和Al2O3/Yb3Al5O12共晶陶瓷的制备与性能研究[J]. 无机材料学报, 2021, 36(6): 652-658. |

| [10] | 刘子玉, TOCI Guido, PIRRI Angela, PATRIZI Barbara, 冯亚刚, 陈肖朴, 胡殿君, 田丰, 吴乐翔, VANNINIMatteo, 李江. 固体激光用Nd:Lu2O3透明陶瓷的制备和光学性能研究[J]. 无机材料学报, 2021, 36(2): 210-216. |

| [11] | 黄新友, 刘玉敏, 刘洋, 李晓英, 冯亚刚, 陈肖朴, 陈鹏辉, 刘欣, 谢腾飞, 李江. 醇水共沉淀法制备Yb:YAG透明陶瓷及其性能研究[J]. 无机材料学报, 2021, 36(2): 217-224. |

| [12] | 韦家蓓, TOCIGuido, PIRRIAngela, PATRIZIBarbara, 冯亚刚, VANNINIMatteo, 李江. 共沉淀纳米粉体制备Yb:CaF2激光陶瓷及其性能研究[J]. 无机材料学报, 2019, 34(12): 1341-1348. |

| [13] | 刘小元, 刘宝丹, 姜亚南, 王柯, 周洋, 杨兵, 张兴来, 姜辛. 形貌可控及光学吸收性能可调的钙钛矿型SrTiO3纳米结构的原位生长[J]. 无机材料学报, 2019, 34(1): 65-71. |

| [14] | 杨锁龙, 王晓方, 蒋春丽, 赵雅文, 曾荣光, 王怀胜, 赖新春. InP量子点的掺杂及其光学性能[J]. 无机材料学报, 2016, 31(10): 1051-1057. |

| [15] | 周 鼎, 施 鹰, 范灵聪, 林德宝, 孙泽清, 徐家跃. Ce, Pr离子双掺LuAG透明陶瓷制备及光学性能[J]. 无机材料学报, 2016, 31(10): 1099-1102. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||