Journal of Inorganic Materials ›› 2021, Vol. 36 ›› Issue (4): 339-346.DOI: 10.15541/jim20200611

Previous Articles Next Articles

SUN Luchao1( ), REN Xiaomin1,2, DU Tiefeng1, LUO Yixiu1, ZHANG Jie1, WANG Jingyang1(

), REN Xiaomin1,2, DU Tiefeng1, LUO Yixiu1, ZHANG Jie1, WANG Jingyang1( )

)

Received:2020-10-27

Revised:2020-12-14

Published:2021-04-20

Online:2020-12-10

Contact:

WANG Jingyang, professor. E-mail: jywang@imr.ac.cn

About author:SUN Luchao(1984-), male, associate professor. E-mail: lcsun@imr.ac.cn

Supported by:CLC Number:

SUN Luchao, REN Xiaomin, DU Tiefeng, LUO Yixiu, ZHANG Jie, WANG Jingyang. High Entropy Engineering: New Strategy for the Critical Property Optimizations of Rare Earth Silicates[J]. Journal of Inorganic Materials, 2021, 36(4): 339-346.

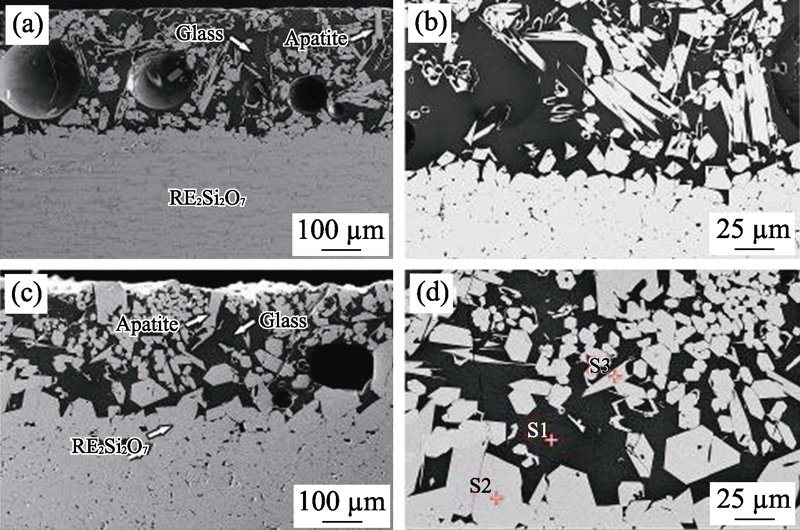

Fig. 4 Observations of the reaction front in the cross-sections of high entropy (Er1/4Tm1/4Yb1/4Lu1/4)2Si2O7 after CMAS corrosion at 1500 ℃ for 4 h (a,b) and 50 h (c,d)[48]

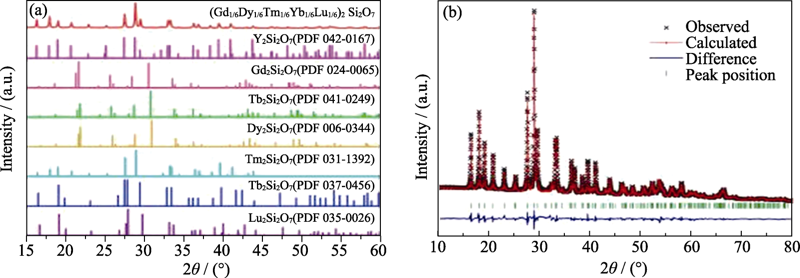

Fig. 5 (a) XRD patterns of (Gd1/6Tb1/6Dy1/6Tm1/6Yb1/4Lu1/6)2 Si2O7, along with the standard XRD patterns of RE2Si2O7 (RE = Y, Gd, Tb, Dy, Tm, Yb and Lu) and (b) Rietveld refinement of XRD pattern for (Gd1/6Tb1/6Dy1/6Tm1/6Yb1/4Lu1/6)2Si2O7[50]

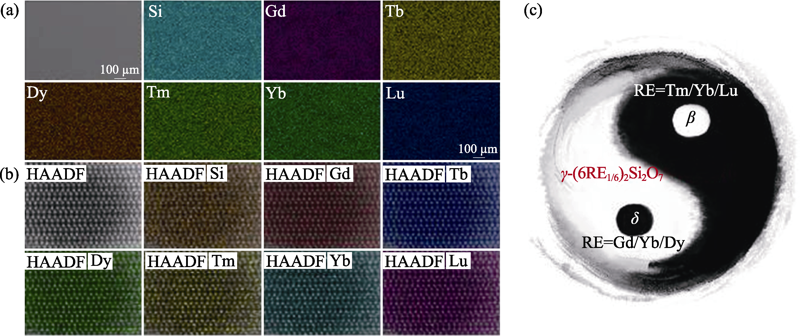

Fig. 6 (a) SEM image of (Gd1/6Tb1/6Dy1/6Tm1/6Yb1/4Lu1/6)2Si2O7 surface with EDS mappings of Si, Gd, Tb, Dy, Tm, Yb and Lu, (b) STEM high angle annular dark field (HAADF) image and corresponding selected compositional EDS maps of high entropy (Gd1/6Tb1/6Dy1/6Tm1/6Yb1/4Lu1/6)2Si2O7, and (c) schematic diagram of the phase formation of (6RE1/6)2Si2O7[50]

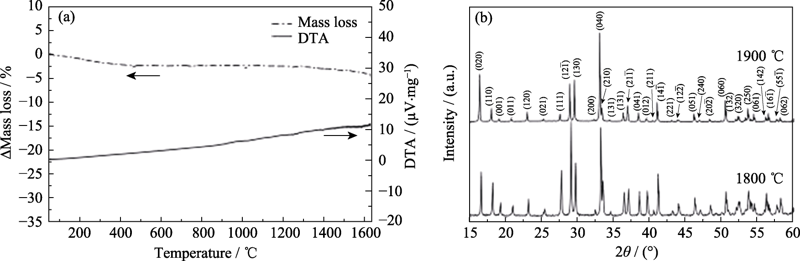

Fig. 7 (a)TG/DTA curves of (Gd1/6Tb1/6Dy1/6Tm1/6Yb1/4Lu1/6)2 Si2O7 and (b) XRD patterns of specimens after being heat-treated at 1800 and 1900 ℃ for 2 h[50]

| [1] |

TSAI M H, YEH J W. High-entropy alloys: a critical review. Materials Research Letters, 2014,2(3):107-123.

DOI URL |

| [2] |

MIRACLE D B, SENKOV O N. A critical review of high entropy alloys and related concepts. Acta Materialia, 2017,122:448-511.

DOI URL |

| [3] |

YEH J W, CHEN S K, LIN S J, et al. Nanostructured high-entropy alloys with multiple principal elements: novel alloy design concepts and outcomes. Advanced Engineering Materials, 2004,6(5):299-303.

DOI URL |

| [4] |

HUANG P K, YEH J W, SHUN T T, et al. Multi-principal-element alloys with improved oxidation and wear resistance for thermal spray coating. Advanced Engineering Materials, 2004,6(1/2):74-78.

DOI URL |

| [5] | TONG C J, CHEN Y L, CHEN S K, et al. Microstructure characterization of AlxCoCrCuFeNi high-entropy alloy system with multiprincipal elements. Metallurgical and Materials Transactions A, 2005,36(4):881-893. |

| [6] | ZHANG Y, ZUO T T, TANG Z, et al. Microstructures and properties of high-entropy alloys. Progress in Materials Science, 2014,61:1-93. |

| [7] | MURTY B S, YEH J W, RANGANATHAN S. High-entropy Alloys. London: Elsevier, 2014. |

| [8] | ZHANG Y, ZUO T T, CHENG Y Q, et al. High-entropy alloys with high saturation magnetization, electrical resistivity, and malleability. Scientific Reports, 2013,3:1-7. |

| [9] | CHUANG M H, TSAI M H, WANG W R, et al. Microstructure and wear behavior of AlxCo1.5CrFeNi1.5Tiy high entropy alloys. Acta Materialia, 2011,59(16):6308-6317. |

| [10] | JIANG S C, HU T, GILD J, et al. A new class of high-entropy perovskite oxides. Scripta Materialia, 2018,142:116-120. |

| [11] | TSAI M H. Physical properties of high entropy alloys. Entropy, 2013,15:5338-5345. |

| [12] | 顾俊峰, 邹冀, 张帆, 等. 高熵陶瓷材料研究进展. 中国材料进展, 2019,38(9):855-865. |

| [13] | YEH J W. Recent progress in high-entropy alloys. Annales De Chimie-Science des Materiaux, 2006,31:633-648. |

| [14] | MIRACLE D B. High-entropy alloys: a current evaluation of founding ideas and core effects and exploring “nonlinear alloys”. JOM, 2017,69(11):2130-2136. |

| [15] | ROST C M, SACHET E, BORMAN T, et al. Entropy-stabilized oxides. Nature Communications, 2015,6(1):8485. |

| [16] | CHELLALI M R, SARKAR A, NANDAM S H, et al. On the homogeneity of high entropy oxides: an investigation at the atomic scale. Scripta Materialia, 2019,166:58-63. |

| [17] | DJENADIC R, SARKAR A, CLEMENS O, et al. Multicomponent equiatomic rare earth oxides. Materials Research Letters, 2017,5(2):102-109. |

| [18] | DUPUY A D, WANG X, SCHOENUNG J M. Entropic phase transformation in nanocrystalline high entropy oxides. Materials Research Letters, 2019,7(2):60-67. |

| [19] |

GILD J, ZHANG Y Y, HARRINGTON T, et al. High-entropy metal diborides: a new class of high-entropy materials and a new type of ultrahigh temperature ceramics. Scientific Reports, 2016,6:37946.

URL PMID |

| [20] | YAN X L, CONSTANTIN L, LU Y F, et al. (Hf0.2Zr0.2Ta0.2Nb0.2Ti0.2)C high-entropy ceramics with low thermal conductivity. Journal of the American Ceramic Society, 2018,101(10):4486-4491. |

| [21] | CHEN H, XIANG H M, DAI F Z, et al. High porosity and low thermal conductivity high entropy (Zr0.2Hf0.2Ti0.2Nb0.2Ta0.2)C. Journal of Materials Science & Technology, 2019,35(8):1700-1705. |

| [22] | CASTLE E, CSANADI T, GRASSO S, et al. Processing and properties of high-entropy ultra-high temperature carbides. Scientific Reports, 2018,8(1):8609. |

| [23] |

SARKER P, HARRINGTON T, TOHER C, et al. High-entropy high-hardness metal carbides discovered by entropy descriptors. Nature Communications, 2018,9(1):4980.

URL PMID |

| [24] | YE B L, WEN T Q, NGUYEN M C, et al. First-principles study, fabrication and characterization of (Zr0.25Nb0.25Ti0.25V0.25)C high- entropy ceramics. Acta Materialia, 2019,170:15-23. |

| [25] | HARRINGTON T J, GILD J, SARKER P, et al. Phase stability and mechanical properties of novel high entropy transition metal carbides. Acta Materialia, 2019,166:271-280. |

| [26] | YE B L, WEN T Q, HUANG K H, et al. First-principles study, fabrication, and characterization of (Hf0.2Zr0.2Ta0.2Nb0.2Ti0.2)C high- entropy ceramic. Journal of the American Ceramic Society, 2019,102(7):4344-4352. |

| [27] | WANG K, CHEN L, XU C G, et al. Microstructure and mechanical properties of (TiZrNbTaMo)C high-entropy ceramic. Journal of Materials Science & Technology, 2020,39:99-105. |

| [28] | ZHANG W, CHEN L, XU C G, et al. Densification, microstructure and mechanical properties of multicomponent (TiZrHfNbTaMo)C ceramic prepared by pressureless sintering. Journal of Materials Science & Technology, 2021,72:23-28. |

| [29] | JIN T, SANG X H, UNOCIC R R, et al. Mechanochemical- assisted synthesis of high-entropy metal nitride via a soft urea strategy. Advanced Materials, 2018,30(23):1707512. |

| [30] |

GILD J, BRAUN J, KAUFMANN K, et al. A high-entropy silicide: (Mo0.2Nb0.2Ta0.2Ti0.2W0.2)Si2. Journal of Materiomics, 2019,5(3):337-343.

DOI URL |

| [31] | ZHAO Z F, XIANG H M, DAI F Z, et al. (TiZrHf)P2O7: an equimolar multicomponent or high entropy ceramic with good thermal stability and low thermal conductivity. Journal of Materials Science & Technology, 2019,35(10):2227-2231. |

| [32] | LIU Y C, JIA D C, ZHOU Y, et al. Zn0.1Ca0.1Sr0.4Ba0.4ZrO3: a non-equimolar multicomponent perovskite ceramic with low thermal conductivity. Journal of the European Ceramic Society, 2020,40:6272-6277. |

| [33] | ZHU D M. Advanced Environmental Barrier Coatings for SiC/SiC Ceramic Matrix Composite Turbine Components. Engineered Ceramics: Current Status and Future Prospects, Hoboken, New Jersey: John Wiley & Sons, Inc, 2016. |

| [34] | LEE K N, FOX D S, BANSAL N P. Rare earth silicate environmental barrier coatings for SiC/SiC composites and Si3N4 ceramics. Journal of the European Ceramic Society, 2005,25(10):1705-1715. |

| [35] | 田志林. 几种稀土硅酸盐陶瓷的预测、制备和性能研究. 北京: 中国科学院大学博士学位论文, 2016. |

| [36] | LUO Y X, SUN L C, WANG J M, et al. Tunable thermal properties in yttrium silicates switched by anharmonicity of low-frequency phonons. Journal of the European Ceramic Society, 2018,38:2043-2052. |

| [37] | POERSCHKE D L, HASS D D, EUSTIS S, et al. Stability and CMAS resistance of ytterbium-silicate/hafnate EBCs/TBC for SiC composites. Journal of the American Ceramic Society, 2015,98(1):278-286. |

| [38] | DONG Y, REN K, LU Y H, et al. High-entropy environmental barrier coating for the ceramic matrix composites. Journal of the European Ceramic Society, 2019,39:2574-2579. |

| [39] | CHEN H, XIANG H M, DAI F Z, et al. High entropy (Yb0.25Y0.25Lu0.25Er0.25)2SiO5 with strong anisotropy in thermal expansion. Journal of Materials Science & Technology, 2020,36:134-139. |

| [40] | REN X M, TIAN Z L, ZHANG J, et al. Equiatomic quaternary (Y1/4Ho1/4Er1/4Yb1/4)2SiO5 silicate: a perspective multifunctional thermal and environmental barrier coating material. Scripta Materialia, 2019,168:47-50. |

| [41] | RIDLEY M, GASKINS J, HOPKINS P, et al. Tailoring thermal properties of multi-component rare earth monosilicates. Acta Materialia, 2020,195:698-707. |

| [42] | TURCER L R, SENGUPTA A, PADTURE N P. Low thermal conductivity in high-entropy rare-earth pyrosilicate solid-solutions for thermal environmental barrier coatings. Scripta Materialia, 2021,191:40-45. |

| [43] | POERSCHKE D L, JACKSON R W, LEVI C G. Silicate deposit degradation of engineered coatings in gas turbines: progress toward models and materials solutions. Annual Review of Materials Research, 2017,47:297-330. |

| [44] | LIU J, ZHANG L T, LIU Q M, et al. Calcium-magnesium- aluminosilicate corrosion behaviors of rare-earth disilicates at 1400 ℃. Journal of the European Ceramic Society, 2013,33:3419-3428. |

| [45] | TIAN Z L, REN X M, LEI Y M, et al. Corrosion of RE2Si2O7 (RE=Y, Yb, and Lu) environmental barrier coating materials by molten calcium-magnesium-alumino-silicate glass at high temperatures. Journal of the European Ceramic Society, 2019,39:4245-4254. |

| [46] | TURCER L R, KRAUSE A R, GARCES H F, et al. Environmental-barrier coating ceramics for resistance against attack by molten calcia-magnesia-aluminosilicate (CMAS) glass: Part I, YAlO3 and γ-Y2Si2O7. Journal of the European Ceramic Society, 2018,38:3905-3913. |

| [47] | TURCER L R, KRAUSE A R, GARCES H F, et al. Environmental-barrier coating ceramics for resistance against attack by molten calcia-magnesia-aluminosilicate (CMAS) glass: Part II, β-Yb2Si2O7 and β-Sc2Si2O7. Journal of the European Ceramic Society, 2018,38:3914-3924. |

| [48] | SUN L C, LUO Y X, TIAN Z L, et al. High temperature corrosion of (Er0.25Tm0.25Yb0.25Lu0.25)2Si2O7 environmental barrier coating material subjected to water vapor and molten calcium-magnesium- aluminosilicate (CMAS). Corrosion Science, 2020,175:108881. |

| [49] | FELSCHE J. The Crystal Chemistry of the Rare-earth Silicates. Rare Earths. Structure and Bonding, Vol 13. Berlin, Heidelberg: Springer, 1973. |

| [50] | SUN L C, LUO Y X, REN X M, et al. A multicomponent γ-type (Gd1/6Tb1/6Dy1/6Tm1/6Yb1/6Lu1/6)2Si2O7 disilicate with outstanding thermal stability. Materials Research Letters, 2020,8(11):424-430. |

| [1] | ZHU Wenjie, TANG Lu, LU Jichang, LIU Jiangping, LUO Yongming. Research Progress on Catalytic Oxidation of Volatile Organic Compounds by Perovskite Oxides [J]. Journal of Inorganic Materials, 2025, 40(7): 735-746. |

| [2] | HU Zhichao, YANG Hongyu, YANG Hongcheng, SUN Chengli, YANG Jun, LI Enzhu. Usage of the P-V-L Bond Theory in Regulating Properties of Microwave Dielectric Ceramics [J]. Journal of Inorganic Materials, 2025, 40(6): 609-626. |

| [3] | WU Qiong, SHEN Binglin, ZHANG Maohua, YAO Fangzhou, XING Zhipeng, WANG Ke. Research Progress on Lead-based Textured Piezoelectric Ceramics [J]. Journal of Inorganic Materials, 2025, 40(6): 563-574. |

| [4] | ZHANG Bihui, LIU Xiaoqiang, CHEN Xiangming. Recent Progress of Hybrid Improper Ferroelectrics with Ruddlesden-Popper Structure [J]. Journal of Inorganic Materials, 2025, 40(6): 587-608. |

| [5] | WU Jie, YANG Shuai, WANG Mingwen, LI Jinglei, LI Chunchun, LI Fei. Textured PT-based Piezoelectric Ceramics: Development, Status and Challenge [J]. Journal of Inorganic Materials, 2025, 40(6): 575-586. |

| [6] | JIANG Kun, LI Letian, ZHENG Mupeng, HU Yongming, PAN Qinxue, WU Chaofeng, WANG Ke. Research Progress on Low-temperature Sintering of PZT Ceramics [J]. Journal of Inorganic Materials, 2025, 40(6): 627-638. |

| [7] | TIAN Ruizhi, LAN Zhengyi, YIN Jie, HAO Nanjing, CHEN Hangrong, MA Ming. Microfluidic Technology Based Synthesis of Inorganic Nano-biomaterials: Principles and Progress [J]. Journal of Inorganic Materials, 2025, 40(4): 337-347. |

| [8] | ZHANG Jiguo, WU Tian, ZHAO Xu, YANG Fan, XIA Tian, SUN Shien. Improvement of Cycling Stability of Cathode Materials and Industrialization Process for Sodium-ion Batteries [J]. Journal of Inorganic Materials, 2025, 40(4): 348-362. |

| [9] | YIN Jie, GENG Jiayi, WANG Kanglong, CHEN Zhongming, LIU Xuejian, HUANG Zhengren. Recent Advances in 3D Printing and Densification of SiC Ceramics [J]. Journal of Inorganic Materials, 2025, 40(3): 245-255. |

| [10] | CHEN Guangchang, DUAN Xiaoming, ZHU Jinrong, GONG Qing, CAI Delong, LI Yuhang, YANG Donglei, CHEN Biao, LI Xinmin, DENG Xudong, YU Jin, LIU Boya, HE Peigang, JIA Dechang, ZHOU Yu. Advanced Ceramic Materials in Helicopter Special Structures: Research Progress and Application Prospect [J]. Journal of Inorganic Materials, 2025, 40(3): 225-244. |

| [11] | FAN Xiaobo, ZU Mei, YANG Xiangfei, SONG Ce, CHEN Chen, WANG Zi, LUO Wenhua, CHENG Haifeng. Research Progress on Proton-regulated Electrochemical Ionic Synapses [J]. Journal of Inorganic Materials, 2025, 40(3): 256-270. |

| [12] | HAIREGU Tuxun, GUO Le, DING Jiayi, ZHOU Jiaqi, ZHANG Xueliang, NUERNISHA Alifu. Research Progress of Optical Bioimaging Technology Assisted by Upconversion Fluorescence Probes in Tumor Imaging [J]. Journal of Inorganic Materials, 2025, 40(2): 145-158. |

| [13] | SUN Shujuan, ZHENG Nannan, PAN Haokun, MA Meng, CHEN Jun, HUANG Xiubing. Research Progress on Preparation Methods of Single-atom Catalysts [J]. Journal of Inorganic Materials, 2025, 40(2): 113-127. |

| [14] | TAO Guilong, ZHI Guowei, LUO Tianyou, OUYANG Peidong, YI Xinyan, LI Guoqiang. Progress on Key Technologies of Cavity-structured Thin Film Bulk Acoustic Wave Filter [J]. Journal of Inorganic Materials, 2025, 40(2): 128-144. |

| [15] | ZHOU Fan, TIAN Zhilin, LI Bin. Research Progress on Carbide Ultra-high Temperature Ceramic Anti-ablation Coatings for Thermal Protection System [J]. Journal of Inorganic Materials, 2025, 40(1): 1-16. |

| Viewed | ||||||

|

Full text |

|

|||||

|

Abstract |

|

|||||