Journal of Inorganic Materials ›› 2025, Vol. 40 ›› Issue (1): 23-30.DOI: 10.15541/jim20240289

• RESEARCH ARTICLE • Previous Articles Next Articles

ZHANG Li1( ), GUAN Haoyang1, ZHENG Qining1, HONG Zhiliang2, WANG Jiaxuan1, XING Ning1, LI Mei1, LIU Yongsheng1, ZHANG Chengyu1(

), GUAN Haoyang1, ZHENG Qining1, HONG Zhiliang2, WANG Jiaxuan1, XING Ning1, LI Mei1, LIU Yongsheng1, ZHANG Chengyu1( )

)

Received:2024-06-13

Revised:2024-09-02

Published:2025-01-20

Online:2024-09-02

Contact:

ZHANG Chengyu, professor. E-mail: cyzhang@nwpu.edu.cnAbout author:ZHANG Li (1999-), male, Master candidate. E-mail: li.zhang0606@mail.nwpu.edu.cn

Supported by:CLC Number:

ZHANG Li, GUAN Haoyang, ZHENG Qining, HONG Zhiliang, WANG Jiaxuan, XING Ning, LI Mei, LIU Yongsheng, ZHANG Chengyu. Creep Properties and Damage Mechanisms of SiCf/SiC-SiYBC Prepared by Melt Infiltration[J]. Journal of Inorganic Materials, 2025, 40(1): 23-30.

| Material | Process | Fiber | Temperature/℃ | Stress/MPa | Creep rupture time/h | Source |

|---|---|---|---|---|---|---|

| SiCf/SiC-SiYBC | MI | Cansas3300 | 1300 | 100 | >1000 | This work |

| 1300 | 120 | 52.70 | ||||

| 1350 | 70 | >500 | ||||

| 1350 | 85 | >500 | ||||

| 1350 | 100 | 24.18 | ||||

| 1400 | 60 | >1000 | ||||

| 1400 | 70 | 195.12 | ||||

| 1400 | 85 | 1.32 | ||||

| 1400 | 100 | 3.78 | ||||

| SiCf/SiC[ | CVI | Cansas-II | 1200 | 110 | >560 | Northwestern Polytechnical University, China |

| 1300 | 100 | 70 | ||||

| 1400 | 100 | 1.60 | ||||

| SiCf/SiC[ | CVI | Cansas3300 | 1300 | 100 | >800 | |

| 1350 | 80 | >1000 | ||||

| 1400 | 100 | 82 | ||||

| SiCf/SiC[ | CVI | Hi-Nicalon | 1300 | 75 | 111.10 | DuPont Lanxide Composites, America |

| 1300 | 120 | 0.83 | ||||

| Enhanced SiCf/SiC[ | CVI | Hi-Nicalon | 1300 | 90 | 5.28 | |

| 1300 | 150 | 0.23 | ||||

| SiCf/SiC[ | MI | Hi-Nicalon Type S | 1315 | 69 | 315 | GE |

| 1315 | 103 | 190 | ||||

| 1400 | 69 | 150 | ||||

| 1400 | 103 | 38 | ||||

| SiCf/SiC[ | MI | Sylramic-iBN | 1204 | 165 | 1269 | |

| 1315 | 103 | 500 | ||||

| CVI | Sylramic-iBN | 1450 | 86 | >300 | ||

| SiCf/SiC[ | CVI | Hi-Nicalon Type S | 1400 | 120 | >200 | SNECMA, France |

Table 1 Comparison of creep rupture time of MI SiCf/SiC-SiYBC and related materials in air at home and abroad

| Material | Process | Fiber | Temperature/℃ | Stress/MPa | Creep rupture time/h | Source |

|---|---|---|---|---|---|---|

| SiCf/SiC-SiYBC | MI | Cansas3300 | 1300 | 100 | >1000 | This work |

| 1300 | 120 | 52.70 | ||||

| 1350 | 70 | >500 | ||||

| 1350 | 85 | >500 | ||||

| 1350 | 100 | 24.18 | ||||

| 1400 | 60 | >1000 | ||||

| 1400 | 70 | 195.12 | ||||

| 1400 | 85 | 1.32 | ||||

| 1400 | 100 | 3.78 | ||||

| SiCf/SiC[ | CVI | Cansas-II | 1200 | 110 | >560 | Northwestern Polytechnical University, China |

| 1300 | 100 | 70 | ||||

| 1400 | 100 | 1.60 | ||||

| SiCf/SiC[ | CVI | Cansas3300 | 1300 | 100 | >800 | |

| 1350 | 80 | >1000 | ||||

| 1400 | 100 | 82 | ||||

| SiCf/SiC[ | CVI | Hi-Nicalon | 1300 | 75 | 111.10 | DuPont Lanxide Composites, America |

| 1300 | 120 | 0.83 | ||||

| Enhanced SiCf/SiC[ | CVI | Hi-Nicalon | 1300 | 90 | 5.28 | |

| 1300 | 150 | 0.23 | ||||

| SiCf/SiC[ | MI | Hi-Nicalon Type S | 1315 | 69 | 315 | GE |

| 1315 | 103 | 190 | ||||

| 1400 | 69 | 150 | ||||

| 1400 | 103 | 38 | ||||

| SiCf/SiC[ | MI | Sylramic-iBN | 1204 | 165 | 1269 | |

| 1315 | 103 | 500 | ||||

| CVI | Sylramic-iBN | 1450 | 86 | >300 | ||

| SiCf/SiC[ | CVI | Hi-Nicalon Type S | 1400 | 120 | >200 | SNECMA, France |

Fig. 4 Creep fractures and crack distributions of MI SiCf/SiC-SiYBC at different creep conditions Creep fractures: (a) 1400 ℃/70 MPa, 195.12 h; (b) 1400 ℃/100 MPa, 3.78 h; (c) 1350 ℃/100 MPa, 24.18 h Crack distributions: (d) 1400 ℃/70 MPa, 195.12 h; (e) 1400 ℃/100 MPa, 3.78 h; (f) 1350 ℃/100 MPa, 24.18 h

Fig. 5 Oxidative damages of MI SiCf/SiC-SiYBC at different creep conditions (a) 1300 ℃/100 MPa, 1000 h; (b) 1350 ℃/100 MPa, 24.18 h; (c) 1400 ℃/70 MPa, 195.12 h; (d) 1400 ℃/100 MPa, 3.78 h

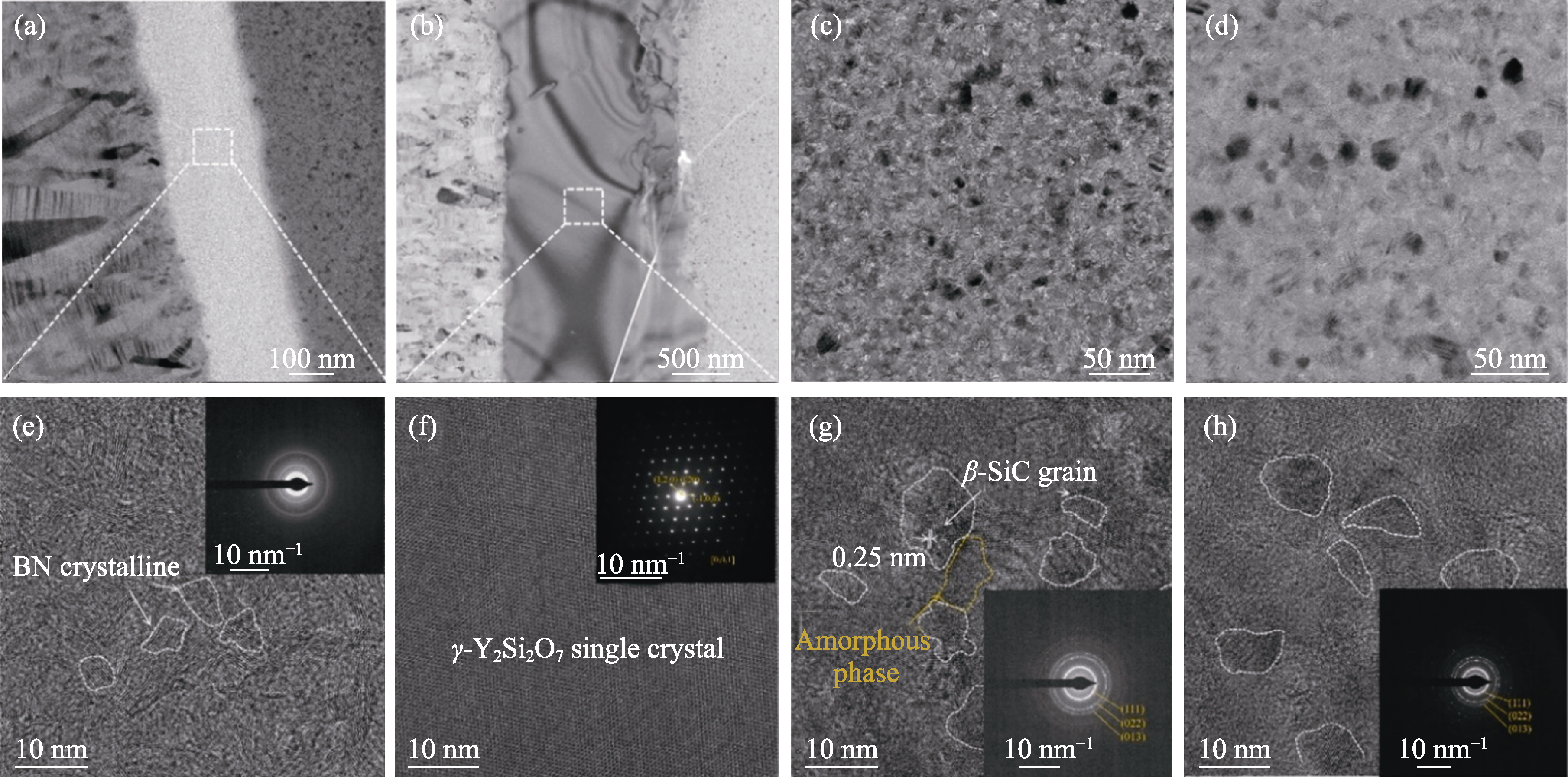

Fig. 7 TEM images of the interface and fiber in the oxidation zone before and after creep As-received: (a, c) TEM, (e, g) HRTEM images and SAED patterns of (a, e) interface and (c, g) fiber Creep at 1400 ℃/70 MPa: (b, d) TEM, (f, h) HRTEM images and SAED pattern of (b, f) interface and (d, h) fiber

| [1] |

刘巧沐, 黄顺洲, 何爱杰. 碳化硅陶瓷基复合材料在航空发动机上的应用需求及挑战. 材料工程, 2019, 47(2): 1.

DOI |

| [2] | 李崇俊. SiC/SiC复合材料及其应用. 高科技纤维与应用, 2013, 38(3): 1. |

| [3] | ALMANSOUR A. Characterizing ceramic-matrix composites to improve durability. American Ceramic Society Bulletin, 2016, 95(5): 35. |

| [4] | KOWBEL W, BRUCE C A, TSOU K L, et al. High thermal conductivity SiC/SiC composites for fusion applications. Journal of Nuclear Materials, 2000, 283: 570. |

| [5] | BHATT R T, HALBIG M C. Creep properties of melt infiltrated SiC/SiC composites with Sylramic™-iBN and Hi-Nicalon™-S fibers. International Journal of Applied Ceramic Technology, 2022, 19(2): 1074. |

| [6] | DICARLO J A, ROODE M V. Ceramic composite development for gas turbine engine hot section components. ASME Turbo Expo 2006: Power for Land, Sea, and Air, Barcelona, 2006: 221. |

| [7] | BHATT R T, KISER J D. Creep behavior and failure mechanisms of CVI and PIP SiC/SiC composites at temperatures to 1650 ℃ in air. Journal of the European Ceramic Society, 2021, 41(13): 6196. |

| [8] | CHRISTENSEN V L, ZOK F W. Insights into internal oxidation of SiC/BN/SiC composites. Journal of the American Ceramic Society, 2023, 106(2): 1561. |

| [9] | VAUGHN W L, MAAHS H G. Active-to-passive transition in the oxidation of silicon carbide and silicon nitride in air. Journal of the American Ceramic Society, 1990, 73(6): 1540. |

| [10] | 黄璇璇, 郭双全, 姚改成, 等. 航空发动机SiC/SiC复合材料环境障碍涂层研究进展. 航空维修与工程, 2017(2): 28. |

| [11] | TEJERO-MARTIN D, BENNETT C, HUSSAIN T. A review on environmental barrier coatings: history, current state of the art and future developments. Journal of the European Ceramic Society, 2021, 41(3): 1747. |

| [12] | HE F, CAO Y J, LIU Y S, et al. Self-healing and failure behavior of yttrium silicate coated SiCf/SiC composites in air at elevated temperatures. Ceramics International, 2023, 49(3): 5335. |

| [13] | LI J X, LIU Y S, HE F, et al. Preparation and properties of SiC/SiC-SiYC with excellent water-oxygen corrosion resistance. Journal of the European Ceramic Society, 2023, 43(14): 6606. |

| [14] | ZHANG B H, LIU Y S, GAO Y Q, et al. Water and oxygen corrosion resistance of SiCf/SiC-SiYBC composites prepared by reactive melt infiltration at 1300 ℃-1500 ℃. International Journal of Applied Ceramic Technology, 2024, 21(2): 1094. |

| [15] | 高雨晴. 反应熔渗法制备抗水腐蚀Si-Y-C陶瓷基复合材料的工艺研究. 西安: 西北工业大学硕士学位论文, 2021. |

| [16] | ZHU S J, MIZUNO M, NAGANO Y, et al. Creep and fatigue behavior in an enhanced SiC/SiC composite at high temperature. Journal of the American Ceramic Society, 1998, 81(9): 2269. |

| [17] | JING K K, GUAN H Y, ZHU S Y, et al. Tensile creep behavior of Cansas-II SiCf/SiC composites at high temperatures. Journal of Inorganic Materials, 2023, 38(2): 177. |

| [18] | 管皞阳. 国产三代2D-SiCf/SiC的高温拉伸蠕变性能及损伤机理. 西安: 西北工业大学硕士学位论文, 2024. |

| [19] | ZHU S J, MIZUNO M, KAGAWA Y, et al. Monotonic tension, fatigue and creep behavior of SiC-fiber-reinforced SiC-matrix composites: a review. Composites Science and Technology, 1999, 59(6): 833. |

| [20] | LAMON J. Properties and characteristics of SiC and SiC/SiC composites//KONINGS R J M, STOLLER R E. Comprehensive nuclear materials. Second Edition. Amsterdam: Elsevier, 2020: 400. |

| [21] | MORSCHER G N. Tensile creep of melt-infiltrated SiC/SiC composites with unbalanced Sylramic-iBN fiber architectures. International Journal of Applied Ceramic Technology, 2011, 8(2): 239. |

| [22] | LACOMBE A, SPRIET P, HABAROU G, et al. Ceramic matrix composites to make breakthroughs in aircraft engine performance. 50th AIAA/ASME/ASCE/AHS/ASC Structures, Structural Dynamics, and Materials Conference, Palm Springs, 2009: 2675. |

| [23] | HE F, LIU Y S, LI J X, et al. The impact of water and oxygen contents on the corrosion performance of yttrium silicate modified SiCf/SiC composites under high temperature conditions. Journal of the European Ceramic Society, 2024, 44(4): 2065. |

| [24] | JACOBSON N S, MYERS D L. Active oxidation of SiC. Oxidation of Metals, 2011, 75(1): 1. |

| [25] | NARUSHIMA T, GOTO T, IGUCHI Y, et al. High-temperature oxidation of chemically vapor-deposited silicon carbide in wet oxygen at 1823 to 1923 K. Journal of the American Ceramic Society, 1990, 73(12): 3580. |

| [26] | PRESSER V, NICKEL K G. Silica on silicon carbide. Critical Reviews in Solid State and Materials Sciences, 2008, 33(1): 1. |

| [27] | 曲诚诚. 国产SiC纤维的性能表征及抗氧化行为研究. 西安: 西北工业大学硕士学位论文, 2021. |

| [1] | LIU Jiangping, GUAN Xin, TANG Zhenjie, ZHU Wenjie, LUO Yongming. Research Progress on Catalytic Oxidation of Nitrogen-containing Volatile Organic Compounds [J]. Journal of Inorganic Materials, 2025, 40(9): 933-943. |

| [2] | ZHU Wenjie, TANG Lu, LU Jichang, LIU Jiangping, LUO Yongming. Research Progress on Catalytic Oxidation of Volatile Organic Compounds by Perovskite Oxides [J]. Journal of Inorganic Materials, 2025, 40(7): 735-746. |

| [3] | LI Jianjun, CHEN Fangming, ZHANG Lili, WANG Lei, ZHANG Liting, CHEN Huiwen, XUE Changguo, XU Liangji. Peroxymonosulfate Activation by CoFe2O4/MgAl-LDH Catalyst for the Boosted Degradation of Antibiotic [J]. Journal of Inorganic Materials, 2025, 40(4): 440-448. |

| [4] | MU Shuang, MA Qin, ZHANG Yu, SHEN Xu, YANG Jinshan, DONG Shaoming. Oxidation Behavior of Yb2Si2O7 Modified SiC/SiC Mini-composites [J]. Journal of Inorganic Materials, 2025, 40(3): 323-328. |

| [5] | LI Wei, XU Zhiming, GOU Yanzi, YIN Senhu, YU Yiping, WANG Song. Preparation and Performance of Sintered SiC Fiber-bonded Ceramics [J]. Journal of Inorganic Materials, 2025, 40(2): 177-183. |

| [6] | LI Xiaoxuan, FU Qiangang, WEN Zihao, YANG Jinshan, NI Dewei, ZHANG Jie, CHENG Yuan, LIU Yuxuan, CHU Yanhui, CAI Feiyan, WANG Jingyang, ZHANG Xinghong. Research Progress on Ultra-high Temperature Ceramic Structural Materials for Extreme Environments [J]. Journal of Inorganic Materials, 2025, 40(10): 1045-1078. |

| [7] | WANG Wenting, XU Jingjun, MA Ke, LI Meishuan, LI Xingchao, LI Tongqi. Oxidation Behavior at 1000-1300 ℃ in air of Ti2AlC-20TiB2 Synthesized by in-situ Reaction/Hot Pressing [J]. Journal of Inorganic Materials, 2025, 40(1): 31-38. |

| [8] | QUAN Wenxin, YU Yiping, FANG Bing, LI Wei, WANG Song. Oxidation Behavior and Meso-macro Model of Tubular C/SiC Composites in High-temperature Environment [J]. Journal of Inorganic Materials, 2024, 39(8): 920-928. |

| [9] | TAN Min, CHEN Xiaowu, YANG Jinshan, ZHANG Xiangyu, KAN Yanmei, ZHOU Haijun, XUE Yudong, DONG Shaoming. Microstructure and Oxidation Behavior of ZrB2-SiC Ceramics Fabricated by Tape Casting and Reactive Melt Infiltration [J]. Journal of Inorganic Materials, 2024, 39(8): 955-964. |

| [10] | JIANG Lingyi, PANG Shengyang, YANG Chao, ZHANG Yue, HU Chenglong, TANG Sufang. Preparation and Oxidation Behaviors of C/SiC-BN Composites [J]. Journal of Inorganic Materials, 2024, 39(7): 779-786. |

| [11] | CAI Feiyan, NI Dewei, DONG Shaoming. Research Progress of High-entropy Carbide Ultra-high Temperature Ceramics [J]. Journal of Inorganic Materials, 2024, 39(6): 591-608. |

| [12] | LIU Guoang, WANG Hailong, FANG Cheng, HUANG Feilong, YANG Huan. Effect of B4C Content on Mechanical Properties and Oxidation Resistance of (Ti0.25Zr0.25Hf0.25Ta0.25)B2-B4C Ceramics [J]. Journal of Inorganic Materials, 2024, 39(6): 697-706. |

| [13] | ZHENG Bin, KANG Kai, ZHANG Qing, YE Fang, XIE Jing, JIA Yan, SUN Guodong, CHENG Laifei. Preparation and Thermal Stability of Ti3SiC2 Ceramics by Polymer Derived Ceramics Method [J]. Journal of Inorganic Materials, 2024, 39(6): 733-740. |

| [14] | ZHANG Xinghong, WANG Yiming, CHENG Yuan, DONG Shun, HU Ping. Research Progress on Ultra-high Temperature Ceramic Composites [J]. Journal of Inorganic Materials, 2024, 39(6): 571-590. |

| [15] | ZHOU Yunkai, DIAO Yaqi, WANG Minglei, ZHANG Yanhui, WANG Limin. First-principles Calculation Study of the Oxidation Resistance of PANI Modified Ti3C2(OH)2 [J]. Journal of Inorganic Materials, 2024, 39(10): 1151-1158. |

| Viewed | ||||||

|

Full text |

|

|||||

|

Abstract |

|

|||||