Journal of Inorganic Materials ›› 2025, Vol. 40 ›› Issue (1): 31-38.DOI: 10.15541/jim20240352

Special Issue: 【信息功能】MAX、MXene及其他二维材料(202506)

• RESEARCH ARTICLE • Previous Articles Next Articles

WANG Wenting1,2( ), XU Jingjun1(

), XU Jingjun1( ), MA Ke1, LI Meishuan1, LI Xingchao3, LI Tongqi3

), MA Ke1, LI Meishuan1, LI Xingchao3, LI Tongqi3

Received:2024-07-27

Revised:2024-09-23

Published:2025-01-20

Online:2024-09-27

Contact:

XU Jingjun, associate professor. E-mail: jjxu@imr.ac.cnAbout author:WANG Wenting (1992-), female, PhD candidate. E-mail: wtwang16s@imr.ac.cn

Supported by:CLC Number:

WANG Wenting, XU Jingjun, MA Ke, LI Meishuan, LI Xingchao, LI Tongqi. Oxidation Behavior at 1000-1300 ℃ in air of Ti2AlC-20TiB2 Synthesized by in-situ Reaction/Hot Pressing[J]. Journal of Inorganic Materials, 2025, 40(1): 31-38.

| Temperature | 1000 ℃ | 1100 ℃ | 1200 ℃ | 1300 ℃ | |

|---|---|---|---|---|---|

| Ti2AlC- 20TiB2 | k | 0.0656 | 0.1355 | 0.0920 | 0.2849 |

| t0 | 0.0918 | 0.0488 | 0.1313 | 0.6860 | |

| R2 | 99.50 | 99.47 | 99.72 | 99.77 | |

| Ti2AlC | kc | 2.38×10-12 | 1.54×10-11 | 1.12×10-10 | 2.13×10-10 |

Table 1 k, t0, R2 by fitting the oxidation kinetics curves in Fig. 3(a) and kc of Ti2AlC[8]

| Temperature | 1000 ℃ | 1100 ℃ | 1200 ℃ | 1300 ℃ | |

|---|---|---|---|---|---|

| Ti2AlC- 20TiB2 | k | 0.0656 | 0.1355 | 0.0920 | 0.2849 |

| t0 | 0.0918 | 0.0488 | 0.1313 | 0.6860 | |

| R2 | 99.50 | 99.47 | 99.72 | 99.77 | |

| Ti2AlC | kc | 2.38×10-12 | 1.54×10-11 | 1.12×10-10 | 2.13×10-10 |

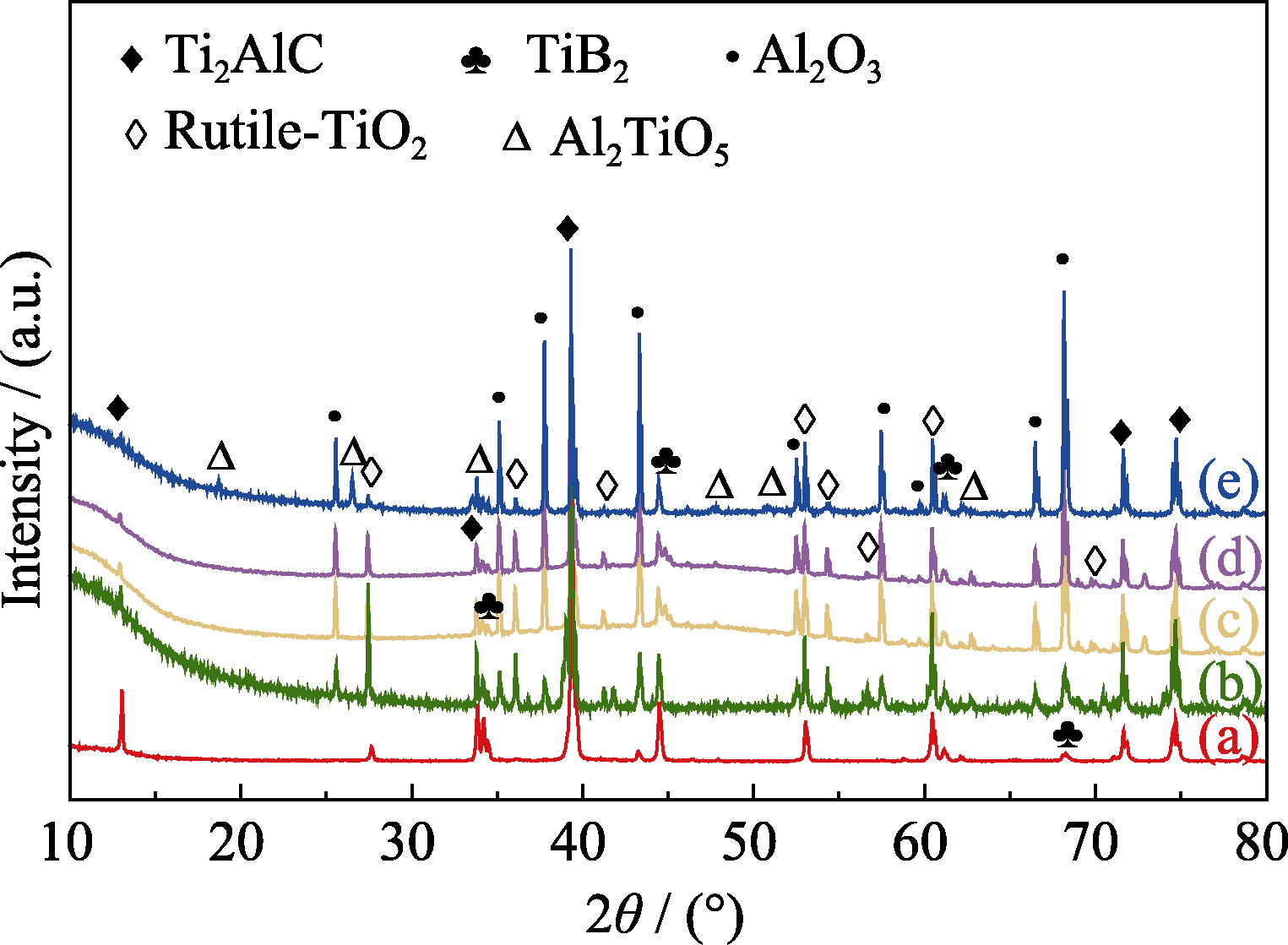

Fig. 4 XRD patterns of Ti2AlC-20TiB2 composite before and after oxidation at 1000-1300 ℃ in air for 10 h (a) Before oxidation; (b) 1000 ℃; (c) 1100 ℃; (d) 1200 ℃; (e) 1300 ℃

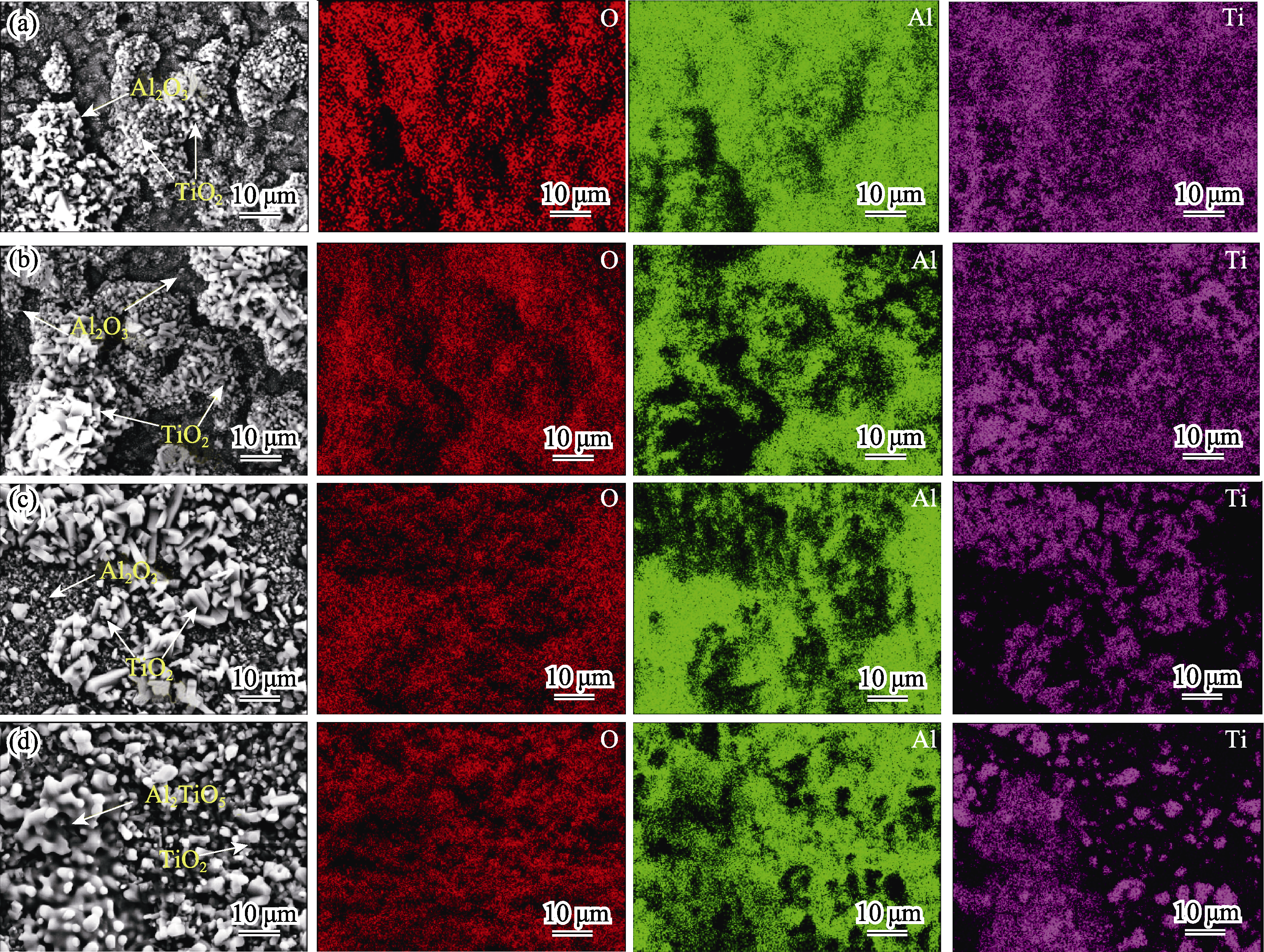

Fig. 5 Surface morphologies of Ti2AlC-20TiB2 composite oxidized at 1000-1300 ℃ in air for 10 h and EDS element mappings of O, Al, and Ti (a) 1000 ℃; (b) 1100 ℃; (c) 1200 ℃; (d) 1300 ℃

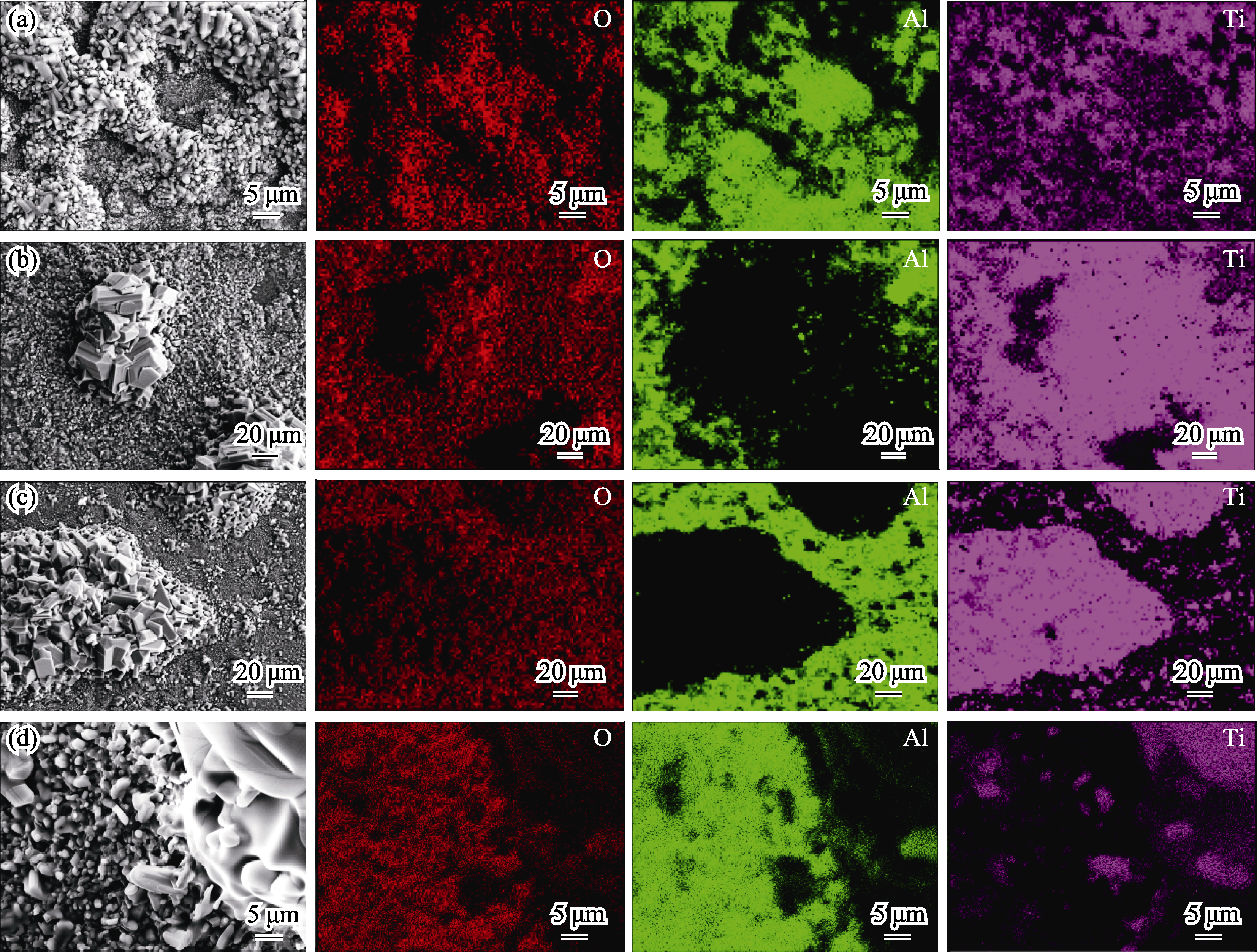

Fig. 6 Surface morphologies of Ti2AlC oxidized at 1000-1300 ℃ in air for 10 h and EDS element mappings of O, Al, and Ti (a) 1000 ℃; (b) 1100 ℃; (c) 1200 ℃; (d) 1300 ℃

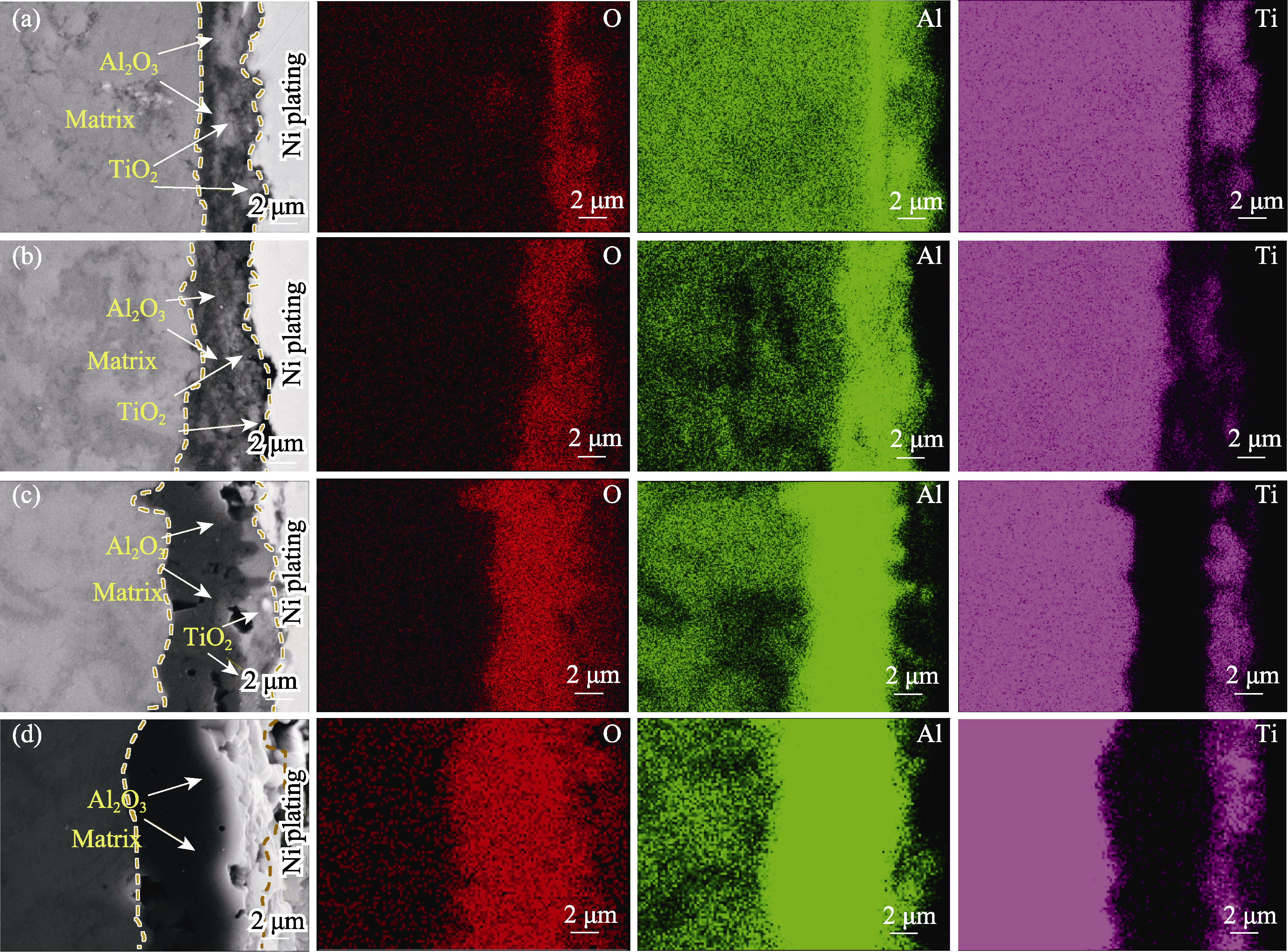

Fig. 7 Cross-sectional morphologies of Ti2AlC-20TiB2 composite oxidized at 1000-1300 ℃ in air for 10 h and EDS element mappings of O, Al, and Ti (a) 1000 ℃; (b) 1100 ℃; (c) 1200 ℃; (d) 1300 ℃

Fig. 8 Cross-sectional morphologies of Ti2AlC oxidized at 1000-1300 ℃ in air for 10 h and EDS element mappings of O, Al, and Ti (a) 1000 ℃; (b) 1100 ℃; (c) 1200 ℃; (d) 1300 ℃

| [1] | BARSOUM M W. The Mn+1AXn phases: a new class of solids: thermodynamically stable nanolaminates. Progress in Solid State Chemistry, 2000, 28: 201. |

| [2] | LIN Z J, ZHUO M J, ZHOU Y C, et al. Microstructural characterization of layered ternary Ti2AlC. Acta Materialia, 2006, 54(4): 1009. |

| [3] | WANG X H, ZHOU Y C. Layered machinable and electrically conductive Ti2AlC and Ti3AlC2 ceramics: a review. Journal of Materials Science & Technology, 2010, 26(5): 385. |

| [4] | ZHOU Y C, SUN Z M. Electronic structure and bonding properties of layered machinable Ti2AlC and Ti2AlN ceramics. Physical Review B, 2000, 61(19): 12570. |

| [5] |

PADTURE N P, GELL M, JORDAN E H. Thermal barrier coatings for gas-turbine engine applications. Science, 2002, 296(5566): 280.

PMID |

| [6] | FRODELIUS J, SONESTED M, BJORKLUND S, et al. Ti2AlC coatings deposited by high velocity oxy-fuel spraying. Surface and Coatings Technology, 2008, 202(24): 5976. |

| [7] | TALLMAN D J, ANASORI B, BARSOUM M W. A critical review of the oxidation of Ti2AlC, Ti3AlC2 and Cr2AlC in air. Materials Research Letters, 2013, 115(3): 115. |

| [8] | WANG X H, ZHOU Y C. High-temperature oxidation behavior of Ti2AlC in air. Oxidation of Metals, 2002, 59(3): 303. |

| [9] | ZHANG X H, WANG Y M, CHENG Y, et al. Research progress on ultra-high temperature ceramic composites. Journal of Inorganic Materials, 2024, 39(6): 571. |

| [10] | LI C, QIAN Y H, MA C L, et al. Suppressing the anomalous rapid oxidation of Ti3AlC2 by incorporating TiB2. Journal of Materials Science & Technology, 2019, 35(3): 432. |

| [11] | LI C, LI M S, ZHOU Y C, et al. In situ synthesis and properties of Ti3AlC2/TiB2 composites. Journal of the American Ceramic Society, 2007, 90(11): 3615. |

| [12] | LI M S, LI C, LI J J, et al. Oxidation behavior of a Ti3AlC2/TiB2 composite at 1000-1400 ℃ in air. Journal of the American Ceramic Society, 2010, 93(2): 554. |

| [13] | 赵芳, 王明远, 唐香珺, 等. Ti2AlC/TiB2/TiC复相陶瓷的制备及性能研究. 宇航材料工艺, 2016, 46(5): 4. |

| [14] | WANG W T, XU J J, ZUO J, et al. Oxidation resistance of in situ reaction/hot pressing synthesized Ti2AlC-20%TiB2 composite at 600-900 ℃ in air. Acta Metallurgica Sinica (English Letters), 2024, 37(4): 739. |

| [15] | SUNDBERG M, MALMQVIST G, MAGNUSSON A. Alumina forming high temperature silicides and carbides. Ceramics International, 2004, 30(7): 1899. |

| [16] | FU G D, GUI J, WANG Z G, et al. High temperature cyclic oxidation behavior of Ti2AlC/Al2O3 composites at 1100-1300 ℃ in air. China Ceramics, 2014, 50(3): 16. |

| [17] | WANG X H, ZHOU Y C. Oxidation behavior of Ti3AlC2 at 1000- 1400 ℃ in air. Corrosion Science, 2003, 45(5): 891. |

| [18] | SHEN Y, RUAN Y Z, YU Y. Study on the in-situ synthesis of aluminum titanate sintered by waste aluminum slag. Chinese Journal of Structural Chemistry, 2009, 28(1): 61. |

| [19] | LI X Q, XIE X, GONZALEZ-JULIAN J, et al. Mechanical and oxidation behavior of textured Ti2AlC and Ti3AlC2 MAX phase materials. Journal of the European Ceramic Society, 2020, 40(15): 5258. |

| [20] | WAGNER C. Beitrag zur theorie des anlaufvorgangs. Zeitschrift für Physikalische Chemie, 1933, 21B(1): 25. |

| [21] | LANGENSIEPEN R A, TRESSLER R E, HOWELL P R. A preliminary study of precipitation in Ti4+-doped polycrystalline alumina. Journal of Materials Science, 1983, 18(9): 2771. |

| [22] | WANG J Y, ZHOU Y C, LIAO T, et al. A first-principles investigation of the phase stability of Ti2AlC with Al vacancies. Scripta Materialia, 2008, 58(3): 227. |

| [23] | LEE D B, PARK S W. High-temperature oxidation of Ti3AlC2 between 1173 and 1473 K in air. Materials Science and Engineering: A, 2006, 434(1/2): 147. |

| [24] | SONG Q, ZHANG Z H. Microstructure and self-healing mechanism of B4C-TiB2-SiC composite ceramic after pre-oxidation behaviour. Ceramics International, 2022, 48(17): 25458. |

| [25] | YU W B, VALLET M, LEVRAUT B, et al. Oxidation mechanisms in bulk Ti2AlC: influence of the grain size. Journal of the European Ceramic Society, 2004, 40(5): 1820. |

| [26] | XU L D, ZHU D G, LIU Y L, et al. Effect of texture on oxidation resistance of Ti3AlC2. Journal of the European Ceramic Society, 2018, 38(10): 3417. |

| [1] | LI Xiaoxuan, FU Qiangang, WEN Zihao, YANG Jinshan, NI Dewei, ZHANG Jie, CHENG Yuan, LIU Yuxuan, CHU Yanhui, CAI Feiyan, WANG Jingyang, ZHANG Xinghong. Research Progress on Ultra-high Temperature Ceramic Structural Materials for Extreme Environments [J]. Journal of Inorganic Materials, 2025, 40(10): 1045-1078. |

| [2] | CHEN Bin, REN Ke, WANG Yiguang. Evolution of Mechanical Properties of Mini-SiCf/SiC Composites at High Temperatures over a Long Period of Time [J]. Journal of Inorganic Materials, 2025, 40(9): 971-980. |

| [3] | WEI Zhifan, CHEN Guoqing, ZU Yufei, LIU Yuan, LI Minghao, FU Xuesong, ZHOU Wenlong. ZrB2-HfSi2 Ceramics: Microstructure and Formation Mechanism of Core-rim Structure [J]. Journal of Inorganic Materials, 2025, 40(7): 817-825. |

| [4] | HONG Peiping, LIANG Long, WU Lian, MA Yingkang, PANG Hao. Structure Regulation of ZIF-67 and Adsorption Properties for Chlortetracycline Hydrochloride [J]. Journal of Inorganic Materials, 2025, 40(4): 388-396. |

| [5] | LI Jianjun, CHEN Fangming, ZHANG Lili, WANG Lei, ZHANG Liting, CHEN Huiwen, XUE Changguo, XU Liangji. Peroxymonosulfate Activation by CoFe2O4/MgAl-LDH Catalyst for the Boosted Degradation of Antibiotic [J]. Journal of Inorganic Materials, 2025, 40(4): 440-448. |

| [6] | HOU Jiaqi, CHEN Ruicong, ZENG Yaoying, ZHOU Lei, ZHANG Jiaping, FU Qiangang. Thermal Shock and Ablation Resistance of SiC Coating Repaired by Gaseous Silicon Infiltration [J]. Journal of Inorganic Materials, 2025, 40(2): 168-176. |

| [7] | LUAN Xingang, HE Dianwei, TU Jianyong, CHENG Laifei. 2D Plain and 3D Needle-punched C/SiC Composites: Low-velocity Impact Damage Behavior and Failure Mechanism [J]. Journal of Inorganic Materials, 2025, 40(2): 205-214. |

| [8] | ZHANG Li, GUAN Haoyang, ZHENG Qining, HONG Zhiliang, WANG Jiaxuan, XING Ning, LI Mei, LIU Yongsheng, ZHANG Chengyu. Creep Properties and Damage Mechanisms of SiCf/SiC-SiYBC Prepared by Melt Infiltration [J]. Journal of Inorganic Materials, 2025, 40(1): 23-30. |

| [9] | WEN Zhipeng, WEI Yi, HOU Xianghua, GUO Jiawen, LI Qu, ZHU Manqing, ZHANG Jiahao, PAN Kai, WU Lian. Research Progress of Bentonite-based Functional Materials in Electrochemical Energy Storage [J]. Journal of Inorganic Materials, 2024, 39(12): 1301-1315. |

| [10] | MA Yongjie, LIU Yongsheng, GUAN Kang, ZENG Qingfeng. Gas-phase Kinetic Study of Pyrolysis in the System of CH4+C2H5OH+Ar [J]. Journal of Inorganic Materials, 2024, 39(11): 1235-1244. |

| [11] | DING Ningning, SUN Jianhua, WEI Xu, SUN Lixia. Monitoring Ammonia at Room Temperature of p-Aminobenzene Sulfonic Acid Modified MoO3/PPy Composites [J]. Journal of Inorganic Materials, 2024, 39(11): 1245-1253. |

| [12] | ZHOU Yunkai, DIAO Yaqi, WANG Minglei, ZHANG Yanhui, WANG Limin. First-principles Calculation Study of the Oxidation Resistance of PANI Modified Ti3C2(OH)2 [J]. Journal of Inorganic Materials, 2024, 39(10): 1151-1158. |

| [13] | WEI Xiangxia, ZHANG Xiaofei, XU Kailong, CHEN Zhangwei. Current Status and Prospects of Additive Manufacturing of Flexible Piezoelectric Materials [J]. Journal of Inorganic Materials, 2024, 39(9): 965-978. |

| [14] | QUAN Wenxin, YU Yiping, FANG Bing, LI Wei, WANG Song. Oxidation Behavior and Meso-macro Model of Tubular C/SiC Composites in High-temperature Environment [J]. Journal of Inorganic Materials, 2024, 39(8): 920-928. |

| [15] | MA Binbin, ZHONG Wanling, HAN Jian, CHEN Liangyu, SUN Jingjing, LEI Caixia. ZIF-8/TiO2 Composite Mesocrystals: Preparation and Photocatalytic Activity [J]. Journal of Inorganic Materials, 2024, 39(8): 937-944. |

| Viewed | ||||||

|

Full text |

|

|||||

|

Abstract |

|

|||||