Journal of Inorganic Materials ›› 2024, Vol. 39 ›› Issue (8): 920-928.DOI: 10.15541/jim20240002

• RESEARCH ARTICLE • Previous Articles Next Articles

QUAN Wenxin( ), YU Yiping, FANG Bing, LI Wei, WANG Song(

), YU Yiping, FANG Bing, LI Wei, WANG Song( )

)

Received:2024-01-02

Revised:2024-03-13

Published:2024-08-20

Online:2024-03-30

Contact:

WANG Song, professor. E-mail: wangs0731@163.comAbout author:QUAN Wenxin (2000-), male, Master candidate. E-mail: quanwenxin18@nudt.edu.cn

Supported by:CLC Number:

QUAN Wenxin, YU Yiping, FANG Bing, LI Wei, WANG Song. Oxidation Behavior and Meso-macro Model of Tubular C/SiC Composites in High-temperature Environment[J]. Journal of Inorganic Materials, 2024, 39(8): 920-928.

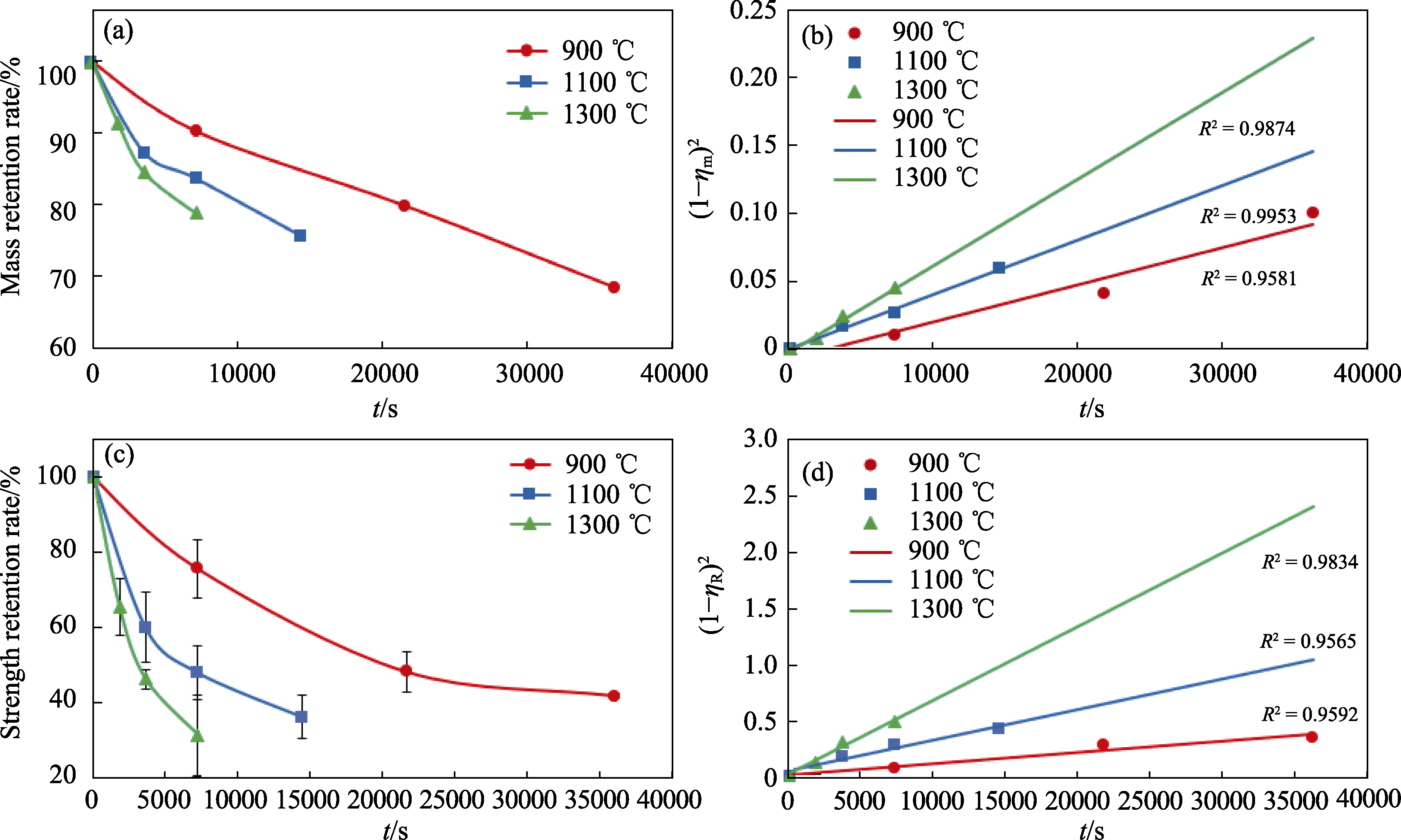

Fig. 6 Mass retention rate (a), function fitting of $ \left(1-\eta_{\mathrm{m}}\right)^{2}$ with t (b), strength retention rate (c), and function fitting of $ \left(1-\eta_{\mathrm{R}}\right)^{2}$ with t (d) for tubular C/SiC composites after high-temperature air oxidation

Fig. 11 EDS distributions of oxygen contents at cross sections of tubular C/SiC composites after 1100 ℃-1 h (a), 1300 ℃-0.5 h (b) and 1300 ℃-1 h (c) high-temperature air oxidation

| Parameter | 900 ℃ | 1000 ℃ | 1100 ℃ | 1200 ℃ | 1300 ℃ |

|---|---|---|---|---|---|

| B/(nm2∙min-1) | 1.05 | 10.29 | 39.48 | 84.84 | 163.17 |

Table 1 Parabolic rate constant of SiC in air oxidation

| Parameter | 900 ℃ | 1000 ℃ | 1100 ℃ | 1200 ℃ | 1300 ℃ |

|---|---|---|---|---|---|

| B/(nm2∙min-1) | 1.05 | 10.29 | 39.48 | 84.84 | 163.17 |

| Parameter | 900 ℃ | 1100 ℃ | 1300 ℃ |

|---|---|---|---|

| 3.18×10-5 | 3.53×10-5 | 3.86×10-5 | |

| B/(nm2∙s-1) | 0.0175 | 0.658 | 2.720 |

| Z/μm | 0.0251 | 0.1539 | 0.3129 |

| e/μm | 1.980 | 1.835 | 1.658 |

| 1.937×10-2 | 1.128×10-2 | 2.880×10-1 |

Table 2 Parameters of oxidation for 10 h

| Parameter | 900 ℃ | 1100 ℃ | 1300 ℃ |

|---|---|---|---|

| 3.18×10-5 | 3.53×10-5 | 3.86×10-5 | |

| B/(nm2∙s-1) | 0.0175 | 0.658 | 2.720 |

| Z/μm | 0.0251 | 0.1539 | 0.3129 |

| e/μm | 1.980 | 1.835 | 1.658 |

| 1.937×10-2 | 1.128×10-2 | 2.880×10-1 |

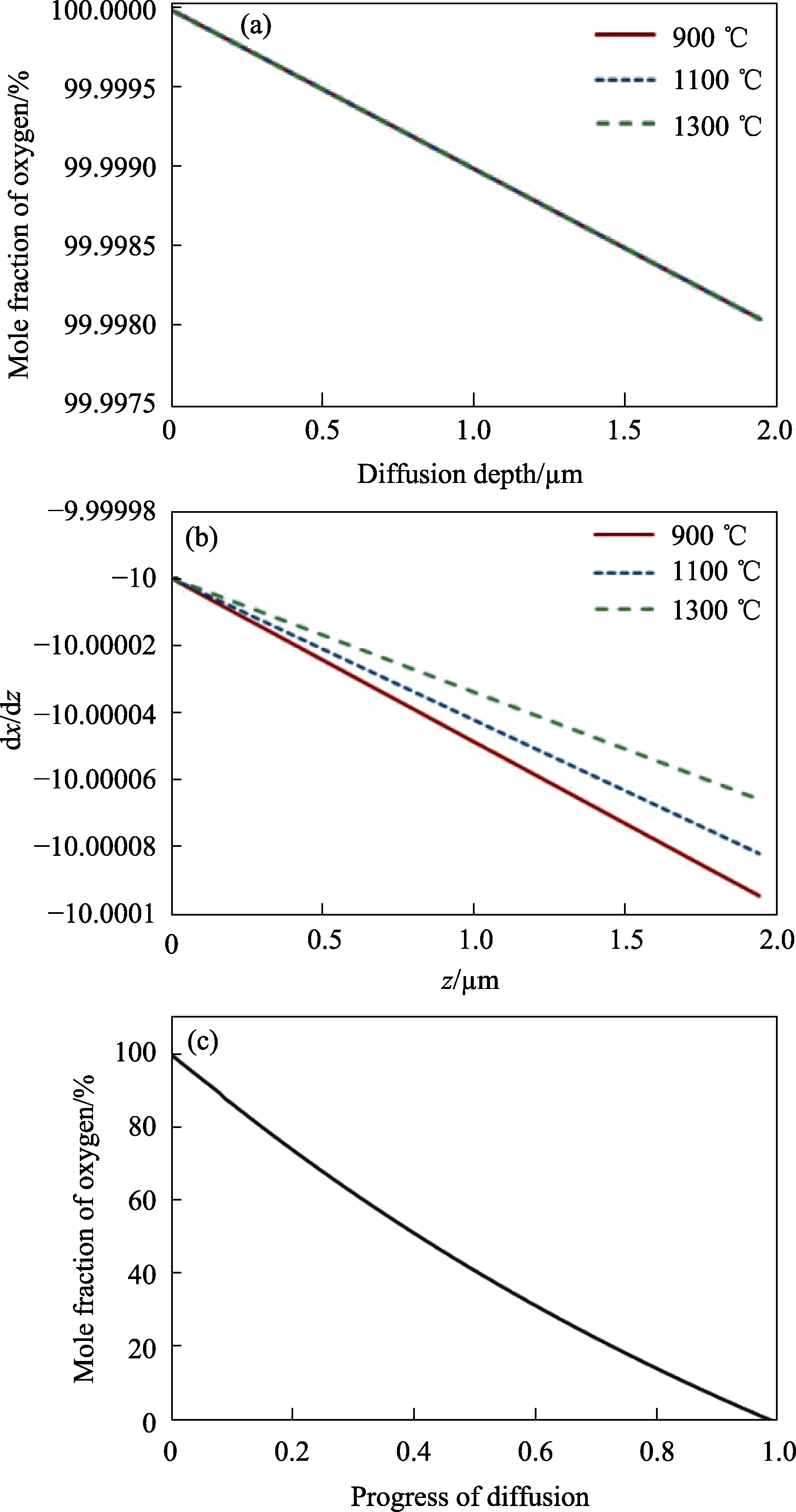

Fig. 12 Distributions of mole fraction of oxygen (a), gradient of mole fraction (b) and mole fraction with diffusion progress (c) in microcracks of SiC matrix

| Modifying factor | 900 ℃ | 1100 ℃ | 1300 ℃ |

|---|---|---|---|

| 1.2×10-5 | 3.1×10-5 | 6.0×10-5 |

Table 3 Modifying factor of equivalent oxidation depth

| Modifying factor | 900 ℃ | 1100 ℃ | 1300 ℃ |

|---|---|---|---|

| 1.2×10-5 | 3.1×10-5 | 6.0×10-5 |

| [1] | 栾新刚. 3D C/SiC在复杂耦合环境中的损伤机理与寿命预测. 西安: 西北工业大学博士学位论文, 2007. |

| [2] | 张紫煜. 陶瓷基复合材料应用. 中国科技投资, 2016, 18: 308. |

| [3] | XU Y, ZHANG W. Numerical modelling of oxidized microstructure and degraded properties of 2D C/SiC composites in air oxidizing environments below 800 ℃. Materials Science and Engineering, 2011, 528(27): 7974. |

| [4] | LACOMBE A, PICHON T, LACOSTE M. High temperature composite nozzle extensions: a mature and efficient technology to improve upper stage liquid rocket engine performance. 43rd AIAA/ASME/SAE/ASEE Joint Propulsion Conference & Exhibit, Cincinnati, 2007: 5471. |

| [5] | 张立同, 成来飞, 梅辉, 等. 陶瓷基复合材料. 北京: 中国铁道出版社, 2020: 12- 42. |

| [6] | 张立同, 成来飞. 连续纤维增韧陶瓷基复合材料可持续发展战略探讨. 复合材料学报, 2007, 2: 1. |

| [7] | HALBIG M C, MCGUFFIN-CAWLEY J D, ECKEL A J, et al. Oxidation kinetics and stress effects for the oxidation of continuous carbon fibers within a microcracked C/SiC ceramic matrix composite. Journal of the American Ceramic Society, 2008, 2: 519. |

| [8] | 成来飞, 栾新刚, 张立同, 等. 超高温结构复合材料服役行为模拟:理论与方法. 北京: 化学工业出版社, 2020: 174-237. |

| [9] | CHEN X, SUN Z, CHEN P, et al. Modeling thermal expansion behavior of 2.5D C/SiC composites in air oxidizing environments between 400 ℃ and 800 ℃. Applied Composite Materials, 2020, 6: 861. |

| [10] | MEI H, TAN Y, CHANG P, et al. Simplified approach to study oxidative damage of C/SiC composites induced from notch defects. Ceramics International, 2019, 45(17): 22464. |

| [11] | LAMOUROUX F, CAMUS G, THEBAULT J. Kinetics and mechanisms of oxidation of 2D woven C/SiC composites: I. experimental approach. Journal of the American Ceramic Society, 1994, 8: 2049. |

| [12] | LAMOUROUX F, NASLAIN R, JOUIN J. Kinetics and mechanisms of oxidation of 2D woven C/SiC composites: II, theoretical approach. Journal of the American Ceramic Society, 1994, 8: 2058. |

| [13] | SULLIVAN R M. A model for the oxidation of carbon silicon carbide composite structures. Carbon, 2005, 43(2): 275. |

| [14] | ZHAO C, TU Z, MAO J. The dynamic thermophysical properties evolution and multi-scale heat transport mechanisms of 2.5D C/SiC composite under high-temperature air oxidation environment. Composites Part B, 2023, 263: 110831. |

| [15] | DING J, SUN Z, CHEN X, et al. A progressive oxidative damage model of C/SiC composites under stressed oxidation environments. Applied Composite Materials, 2021, 28(5): 1609. |

| [16] | 颜淮. C/SiC复合材料微细观氧化损伤分析. 哈尔滨: 哈尔滨工业大学硕士学位论文, 2021. |

| [17] | CHEN P, NIU X, CHEN X, et al. Modeling the failure time and residual strength of C/SiC composites under stress-oxidation environment. Transactions of the Indian Ceramic Society, 2020, 4: 212. |

| [18] | ZHAO C, TU Z, MAO J. Thermal-oxidation coupled analysis method for unidirectional fiber-reinforced C/SiC composites in air oxidizing environments below 1000 ℃. International Communications in Heat and Mass Transfer, 2023, 143: 106678. |

| [19] | ECKEL A J, CAWLEY J D, PARTHASARATHY T A. Oxidation kinetics of a continuous carbon phase in a nonreactive matrix. Journal of the American Ceramic Society, 1995, 4: 972. |

| [20] | OPILA E J, SERRA J L. Oxidation of carbon fiber-reinforced silicon carbide matrix composites at reduced oxygen partial pressures. Journal of the American Ceramic Society, 2011, 7: 2185. |

| [21] | XIANG Y, CAO F, PENG Z, et al. Evolution of microstructure and mechanical properties of PIP-C/SiC composites after high- temperature oxidation. Journal of Asian Ceramic Societies, 2017, 3: 370. |

| [22] | SU F, HUANG P, WU J, et al. Creep behavior of C/SiC composite in hot oxidizing atmosphere and its mechanism. Ceramics International, 2017, 12: 9355. |

| [23] | DRAWIN S, BACOS M, DORVAUX J, et al. Oxidation model for carbon-carbon composites. 4th Symposium on Multidisciplinary Analysis and Optimization, Cleveland, 1992: 5016. |

| [24] | 国义军, 石卫波, 曾磊, 等. 高超声速飞行器烧蚀防热理论与应用. 北京: 科学出版社, 2019: 112. |

| [25] | DEAL B E, GROVE A S. General relationship for the thermal oxidation of silicon. Journal of Applied Physics, 1965, 12: 3770. |

| [26] | FILIPUZZI L, NASLAIN R, JAUSSAUD C. Oxidation kinetics of SiC deposited from CH3SiCl3/H2 under CVI conditions. Journal of Materials Science, 1992, 12: 3331. |

| [27] | SONG Y, DHAR S, FELDMAN L C. Modified deal grove model for the thermal oxidation of silicon carbide. Journal of Applied Physics, 2004, 9: 4953. |

| [28] | FULLER E N, SCHETTLER P D, GIDDINGS J C. New method for prediction of binary gas-phase diffusion coefficients. Industrial & Engineering Chemistry, 1966, 5: 18. |

| [29] | KNUDSEN M. The laws of molecular flow and of inner friction flow of gases through tubes. Journal of Membrane Science, 1995, 1: 23. |

| [1] | CHEN Yi, QIU Haipeng, CHEN Mingwei, XU Hao, CUI Heng. SiC/SiC Composite: Matrix Boron Modification and Mechanical Properties [J]. Journal of Inorganic Materials, 2025, 40(5): 504-510. |

| [2] | WANG Wenting, XU Jingjun, MA Ke, LI Meishuan, LI Xingchao, LI Tongqi. Oxidation Behavior at 1000-1300 ℃ in air of Ti2AlC-20TiB2 Synthesized by in-situ Reaction/Hot Pressing [J]. Journal of Inorganic Materials, 2025, 40(1): 31-38. |

| [3] | WANG Hongda, FENG Qian, YOU Xiao, ZHOU Haijun, HU Jianbao, KAN Yanmei, CHEN Xiaowu, DONG Shaoming. Microstructure and Corrosion Behavior of Brazed Joints of SiC/SiC Composites and Hastelloy N Alloy Using Cu-Ni Alloy [J]. Journal of Inorganic Materials, 2022, 37(4): 452-458. |

| [4] | LUO Yi, XIA Shuhai, NIU Bo, ZHANG Yayun, LONG Donghui. Preparation and High Temperature Inorganic Transformation of Flexible Silicone Aerogels [J]. Journal of Inorganic Materials, 2022, 37(12): 1281-1288. |

| [5] | LEI Yiming, ZHANG Jie, BAI Guanghai, ZHANG Yanwei, WANG Xiaohui, WANG Jingyang. Influence of Al Content on Oxidation Resistance of Phase-pure Ti2AlC under Simulated Loss-of-coolant Accident Conditions [J]. Journal of Inorganic Materials, 2021, 36(10): 1097-1102. |

| [6] | ZHANG Bingyu,WANG ling,WANG Xiaomeng,QIU Haipeng. Effect of Precursors on Impregnation Behaviors of C/SiC Composites [J]. Journal of Inorganic Materials, 2020, 35(9): 1017-1022. |

| [7] | HUANG Xi-Peng, WANG Bo, YANG Cheng-Peng, PAN Wen-Ge, LIU Xiao-Ying. Evaluating Damage Evolution of Three-dimension Needled C/SiC Composite Based on Acoustic Emission Signal Analysis [J]. Journal of Inorganic Materials, 2018, 33(6): 609-616. |

| [8] | ZHAO Shuang, YANG Zi-Chun, ZHOU Xin-Gui. Fracture Behavior of SiC/SiC Composites with Different Interfaces [J]. Journal of Inorganic Materials, 2016, 31(1): 58-62. |

| [9] | WANG Hao, ZHOU Qing-Jun, JIAN Ke, SHAO Chang-Wei, ZHU Yi-Hua. Preparation of Ordered Porous Ceramic Joint on C/SiC Composites and Its Joining Technique [J]. Journal of Inorganic Materials, 2013, 28(7): 763-768. |

| [10] | MA Qing-Song, LIU Hai-Tao, PAN Yu, LIU Wei-Dong, CHEN Zhao-Hui. Research Progress on the Application of C/SiC Composites in Scramjet [J]. Journal of Inorganic Materials, 2013, 28(3): 247-255. |

| [11] | ZHAO Dan, ZHANG Chang-Rui, ZHANG Yu-Di, CHEN Si-An, HU Hai-Feng. Reactive Preparation and Properties of ZrB2 Coating [J]. Journal of Inorganic Materials, 2011, 26(9): 902-906. |

| [12] | LI Si-Wei, ZHANG Li-Tong, LIU Yong-Sheng, CHENG Lai-Fei, FENG Zu-De, LUAN Xin-Gang, ZHANG Wei-Hua, YANG Wen-Bin. Self-healing Behavior of 2D C/SiC Modified by Partial Boron Carbide Matrix after Annealing at Low Temperature in Wet Oxygen [J]. Journal of Inorganic Materials, 2010, 25(11): 1199-1203. |

| [13] | CHEN Bo,ZHANG Li-Tong,CHENG Lai-Fei,LUAN Xin-Gang. Ablation Characteristic of 3D C/SiC Composite Nozzle in a Small Solid Rocket Motor [J]. Journal of Inorganic Materials, 2008, 23(5): 938-944. |

| [14] | LIU Chi-Dong,CHENG Lai-Fei,MEI Hui,LUAN Xin-Gang,ZHOU Jun. Fatigue Behavior of 2D C/SiC Composites in Water-vapor Containing Environment at 1300℃ [J]. Journal of Inorganic Materials, 2008, 23(4): 729-733. |

| [15] | YAN Lian-Sheng,CUI Hong,LI Ke-Zhi,LI He-Jun,WANG Tao,Song Mai-Li. Preparation and Properties of Carbon Fiber Needling Preform Reinforced Silicon Carbide Composites [J]. Journal of Inorganic Materials, 2008, 23(2): 223-228. |

| Viewed | ||||||

|

Full text |

|

|||||

|

Abstract |

|

|||||