Journal of Inorganic Materials ›› 2023, Vol. 38 ›› Issue (6): 634-646.DOI: 10.15541/jim20220640

Special Issue: 【结构材料】高导热陶瓷(202506); 【结构材料】陶瓷基复合材料(202506)

• REVIEW • Previous Articles Next Articles

CHEN Qiang( ), BAI Shuxin(

), BAI Shuxin( ), YE Yicong(

), YE Yicong( )

)

Received:2022-10-31

Revised:2023-01-18

Published:2023-01-31

Online:2023-01-31

Contact:

BAI Shuxin, professor. E-mail: shuxinde2021@163.com;About author:CHEN Qiang (1992-), male, PhD candidate. E-mail: 13548774386@163.com

CLC Number:

CHEN Qiang, BAI Shuxin, YE Yicong. Highly Thermal Conductive Silicon Carbide Ceramics Matrix Composites for Thermal Management: a Review[J]. Journal of Inorganic Materials, 2023, 38(6): 634-646.

| Producer | Brand | Modulus/GPa | Strength/MPa | Density/(g·cm-3) | Diameter/μm | TC/(W·m-1·K-1) |

|---|---|---|---|---|---|---|

| Nicalon | NL202 | 220 | 3000 | 2.55 | 14 | 2.97 |

| Hi-Nicalon | 270 | 2800 | 2.74 | 12 | 7.77 | |

| Hi-Nicalon-S | 420 | 2600 | 3.05 | 12 | 18.4 | |

| Tyranno | Lox M | 187 | 3300 | 2.48 | 11 | 1.4 |

| ZMI | 200 | 3400 | 2.48 | 11 | 2.5 | |

| SA | 380 | 2800 | 3.10 | 10/7.5 | 65 | |

| Sylramic | Sylramic | 400 | 2800 | 3.05 | 10 | 40-45 |

| Sylramic-iBN | 400 | 3200 | 3.10 | 10 | >46 | |

| KD[ | KD-A | 170 | 2100 | 2.43 | 12.3 | - |

| KD-B | 300 | 3000 | 2.76 | 11.2 | ||

| KD-C | 320 | 2800 | 2.87 | 11.1 |

Table 1 Properties and products of silicon carbide based fibers[21]

| Producer | Brand | Modulus/GPa | Strength/MPa | Density/(g·cm-3) | Diameter/μm | TC/(W·m-1·K-1) |

|---|---|---|---|---|---|---|

| Nicalon | NL202 | 220 | 3000 | 2.55 | 14 | 2.97 |

| Hi-Nicalon | 270 | 2800 | 2.74 | 12 | 7.77 | |

| Hi-Nicalon-S | 420 | 2600 | 3.05 | 12 | 18.4 | |

| Tyranno | Lox M | 187 | 3300 | 2.48 | 11 | 1.4 |

| ZMI | 200 | 3400 | 2.48 | 11 | 2.5 | |

| SA | 380 | 2800 | 3.10 | 10/7.5 | 65 | |

| Sylramic | Sylramic | 400 | 2800 | 3.05 | 10 | 40-45 |

| Sylramic-iBN | 400 | 3200 | 3.10 | 10 | >46 | |

| KD[ | KD-A | 170 | 2100 | 2.43 | 12.3 | - |

| KD-B | 300 | 3000 | 2.76 | 11.2 | ||

| KD-C | 320 | 2800 | 2.87 | 11.1 |

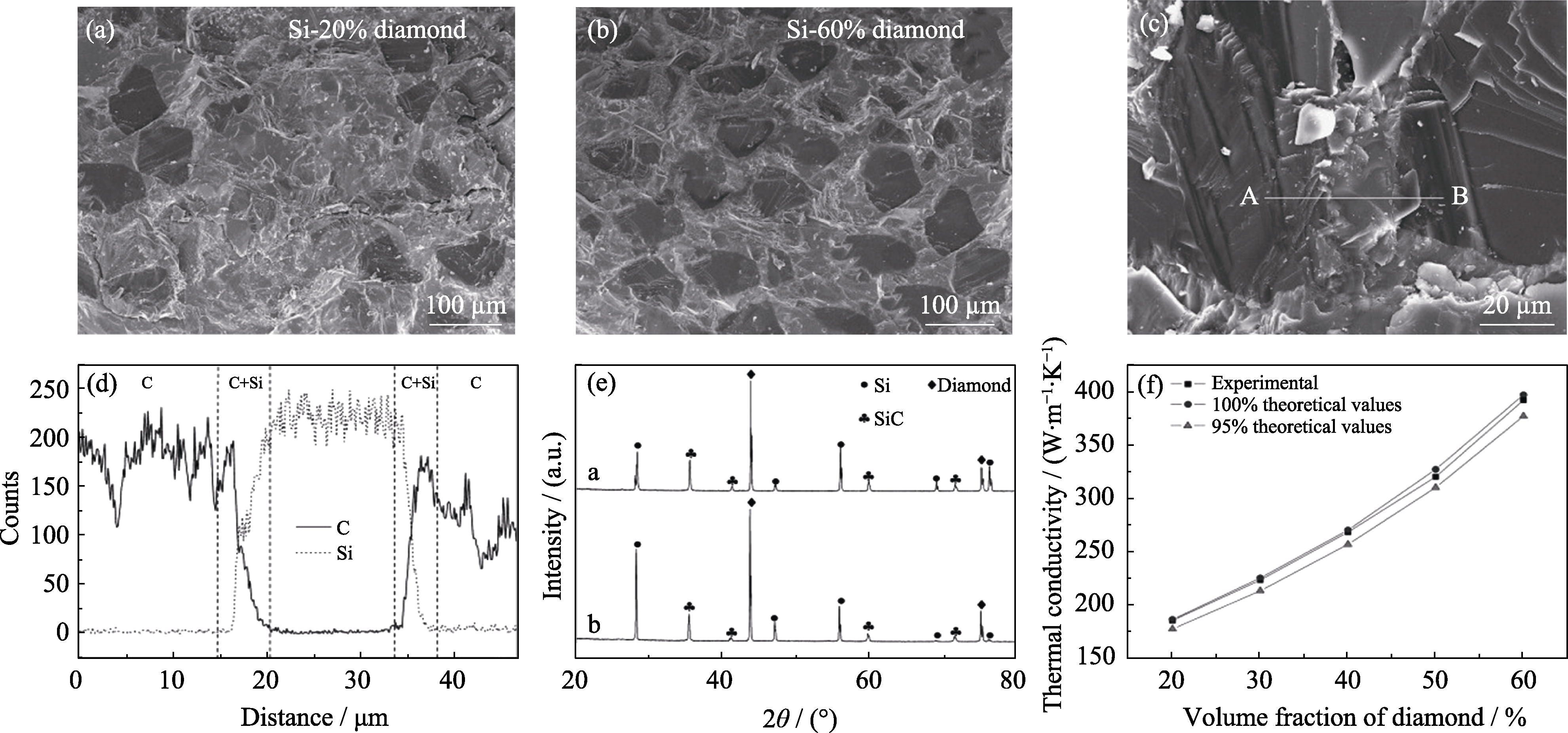

Fig. 1 Microstructures and thermal conductivities of Si-diamond-SiC composites with different diamond volume contents[31] (a) Si-20% diamond (sintered at 1523 K); (b) Si-60% diamond (sintered at 1643 K); (c) Fracture surface of (b); (d) EDX of(c); (e) XRD patterns of (a, b); (f) Experimental and theoretical thermal conductivity of Si-diamond-SiC composites

Fig. 2 Microstructures and thermal conductivities of diamond/SiC composites with different diamond volume contents[32] (a) RBSD1; (b) RBSD2; (c) RBSD3; (d) RBSD4; (e) Diamond/SiC interface; (f) Graphite interlayer in diamond/SiC interfacial region; (g) TEM image of diamond/SiC interfacial region in post-annealing RBSD; (h) Thermal conductivities of RBSDs before and after high temperature annealing

| Producer | Brand | Modulus/GPa | Strength/MPa | Density/(g·cm-3) | Diameter/μm | TC/(W·m-1·K-1) | |

|---|---|---|---|---|---|---|---|

| UCC | P75 | 517 | 2100 | 2.00 | 10 | 185 | |

| P100 | 759 | 2410 | 2.15 | 10 | 520 | ||

| P-120 | 828 | 2410 | 2.18 | 10 | 640 | ||

| Mitsubishi | K-1100 | 931 | 3100 | 2.2 | 10 | 1000 | |

| K13D2U | 935 | 3700 | 2.21 | 10 | 800 | ||

| K13C2U | 900 | 3800 | 2.2 | 10 | 620 | ||

| K63B12 | 860 | 2600 | 2.15 | 10 | 400 | ||

| Nippon | Granoc | 920 | 3530 | 2.19 | 7 | 600 | |

| YS-95A | |||||||

| Granoc | 880 | 3530 | 2.18 | 7 | 500 | ||

| YS-90A | |||||||

| NOCVARB | NM6030-15 | ≥550 | ≥1500 | ≥2.1 | - | ≥250 | |

| NM9050-20 | ≥850 | ≥2000 | ≥2.15 | - | ≥450 | ||

| NM9080-20 | ≥850 | ≥2000 | ≥2.15 | - | ≥750 | ||

| NMA080-25 | ≥950 | ≥2500 | ≥2.15 | - | ≥750 | ||

| TIANCE-TECH | TC-HC-600-S | 750 | 2300 | 2.20 | 13 | 600 | |

| ECO | - | 500-900 | 2500-3500 | 2.2 | 8-12 | 500-800 | |

| TOYI-CARBEN | TYG-1 | 800 | 2300 | 2.2 | 12 | 600 | |

| TYG-2 | 900 | 2500 | 2.2 | 12 | 800 | ||

Table 2 Properties and products of pitch based carbon fibers[42-43]

| Producer | Brand | Modulus/GPa | Strength/MPa | Density/(g·cm-3) | Diameter/μm | TC/(W·m-1·K-1) | |

|---|---|---|---|---|---|---|---|

| UCC | P75 | 517 | 2100 | 2.00 | 10 | 185 | |

| P100 | 759 | 2410 | 2.15 | 10 | 520 | ||

| P-120 | 828 | 2410 | 2.18 | 10 | 640 | ||

| Mitsubishi | K-1100 | 931 | 3100 | 2.2 | 10 | 1000 | |

| K13D2U | 935 | 3700 | 2.21 | 10 | 800 | ||

| K13C2U | 900 | 3800 | 2.2 | 10 | 620 | ||

| K63B12 | 860 | 2600 | 2.15 | 10 | 400 | ||

| Nippon | Granoc | 920 | 3530 | 2.19 | 7 | 600 | |

| YS-95A | |||||||

| Granoc | 880 | 3530 | 2.18 | 7 | 500 | ||

| YS-90A | |||||||

| NOCVARB | NM6030-15 | ≥550 | ≥1500 | ≥2.1 | - | ≥250 | |

| NM9050-20 | ≥850 | ≥2000 | ≥2.15 | - | ≥450 | ||

| NM9080-20 | ≥850 | ≥2000 | ≥2.15 | - | ≥750 | ||

| NMA080-25 | ≥950 | ≥2500 | ≥2.15 | - | ≥750 | ||

| TIANCE-TECH | TC-HC-600-S | 750 | 2300 | 2.20 | 13 | 600 | |

| ECO | - | 500-900 | 2500-3500 | 2.2 | 8-12 | 500-800 | |

| TOYI-CARBEN | TYG-1 | 800 | 2300 | 2.2 | 12 | 600 | |

| TYG-2 | 900 | 2500 | 2.2 | 12 | 800 | ||

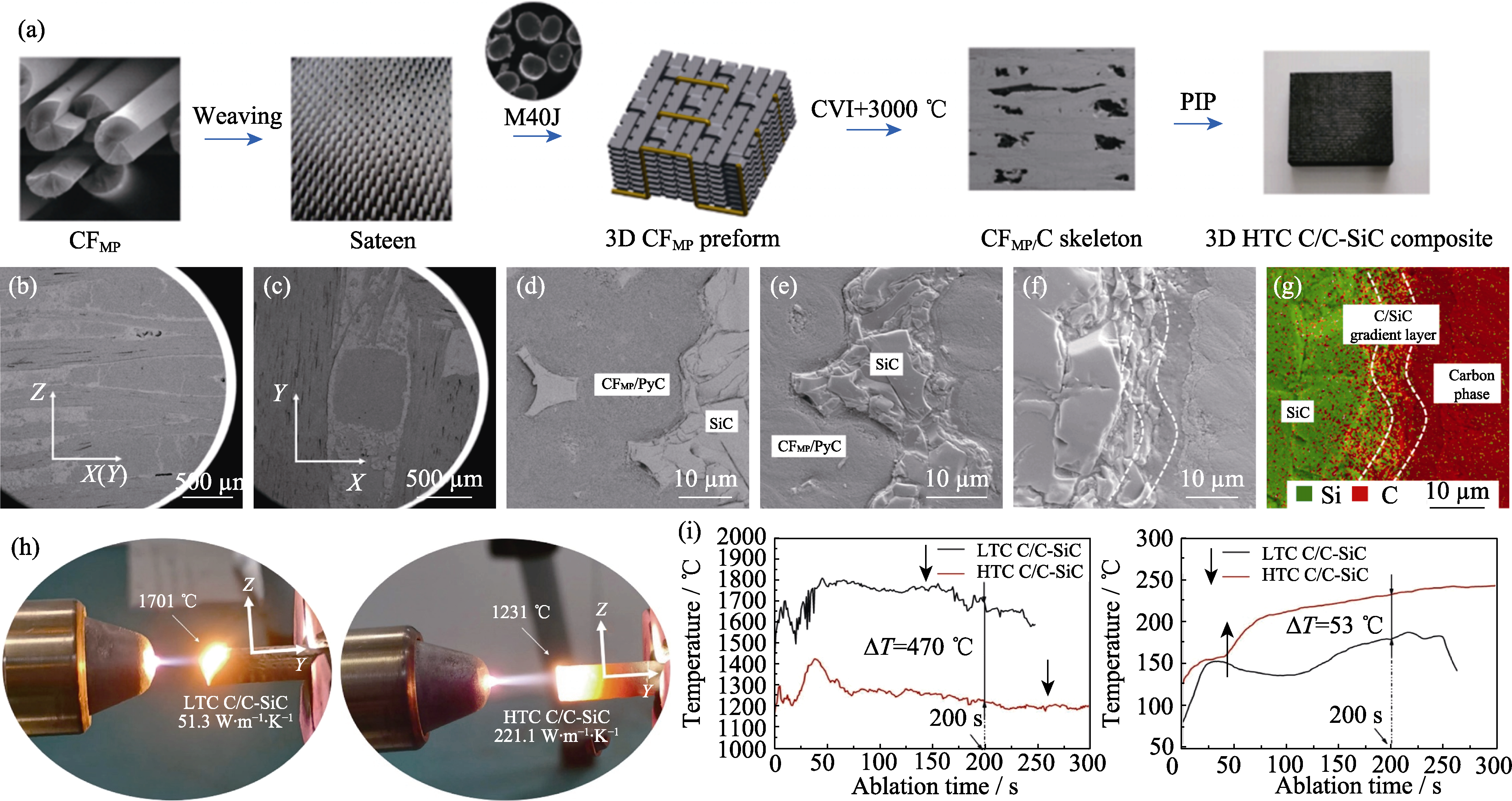

Fig. 3 Diagram of fabrication and microstructure of the 3D HTC C/C-SiC composite[25] (a) Fabrication process of 3D HTC C/C-SiC; (b-f) Microstructures of the 3D HTC C/C-SiC composite; (g) Interface energy spectrum diagram of the 3D HTC C/C-SiC; (h) Ablation tests and (i) temperature curves of the C/C-SiC

Fig. 4 Surface topographies of the as-ablated C/C-SiC[47] (a) Image of the as-ablated C/C-SiC; (b-d) Magnification images of (b) middle region, (c) area “A” and (d) naked fibers in the center region of (a)

Fig. 6 Microstructures of SiC fiber with electrodeposited CNTs and thermophysical properties of SiCf/SiC compersites[57] (a) Surface of SiC fibers with CNTs; (b) Surface of SiC fibers without CNTs; (c) Interface between CNTs and PyC; (d) TEM image of PyC deposited on CNTs; (e, f) HRTEM images of PyC deposited on (e) SiC fibers and (f) CNTs; (g) Bending strength and (h) thermal conductivity of SiC/SiC composites with different interfaces

Fig. 8 Characterization of diamond/SiC interfacial zone[58] (a) TEM image of diamond and SiC separated by a layer of graphite with lighter contrast; (b) HRTEM image of the rectangular region in (a) showing the graphite (G) and diamond (D) zones; (c-e) TEM and HRTEM images of (c, d) graphite layer and (e) reaction formed nano-crystalline SiC with stacking faults; (f) TEM image of Al4C3 formed adjacent to the interface; (g) HRTEM image from the rectangular region in (f); (h) ADF STEM of diamond/SiC interfacial area in (f)

Fig. 9 Microstructures and thermal conductivities of SiCf/SiC composites with different heat-treatment[59] (a) SiC matrix without heat-treatment; (b) SiC matrix with 1700 ℃-2 h heat-treatment; (c) SiC matrix with 1900 ℃-2 h heat-treatment; (d-f) TEM images of SiC matrix corresponding to (a-c); (g) Thermal conductivity of 2D SiCf/SiC after different heat-treatments; (h) Full width at half maximum of (111) diffraction crystal plane after different heat-treatments

| [1] |

PARTHASARATHY T A, PETRY M D, CINIBULK M K, et al. Thermal and oxidation response of UHTC leading edge samples exposed to simulated hypersonic flight conditions. Journal of the American Ceramic Society, 2013, 96(3):907.

DOI URL |

| [2] |

UYANNA O, NAJAFI H. Thermal protection systems for space vehicles: a review on technology development, current challenges and future prospects. Acta Astronautica, 2020, 176: 341.

DOI URL |

| [3] |

NOZAWA T, HINOKI T, HASEGAWA A, et al. Recent advances and issues in development of silicon carbide composites for fusion applications. Journal of Nuclear Materials, 2009, 386-388: 622.

DOI URL |

| [4] |

YAO X M, WANG X J, LIU X J, et al. Friction-wear properties and mechanism of hard facing pairs of SiC and WC. Journal of Inorganic Materials, 2019, 34(6):673.

DOI URL |

| [5] | 肖鹏, 熊翔, 张红波, 等. C/C-SiC陶瓷制动材料的研究现状与应用. 中国有色金属学报, 2005, 15(5):667. |

| [6] |

KRENKEL W, BERNDT F. C/C-SiC composites for space applications and advanced friction systems. Materials Science and Engineering A-Structural Materials Properties Microstructure and Processing, 2005, 412(1/2):177.

DOI URL |

| [7] |

LUO L, WANG Y G, LIU L P, et al. Carbon fiber reinforced silicon carbide composite-based sharp leading edges in high enthalpy plasma flows. Composites Part B-Engineering, 2018, 135: 35.

DOI URL |

| [8] |

WANG X, GAO X, ZHANG Z, et al. Advances in modifications and high-temperature applications of silicon carbide ceramic matrix composites in aerospace: a focused review. Journal of the European Ceramic Society, 2021, 41(9):4671.

DOI URL |

| [9] |

SLACK G A. Thermal conductivity of pure and impure silicon, silicon carbide, and diamond. Journal of Applied Physics, 1964, 35(12):3460.

DOI URL |

| [10] |

ZHOU Y, HIRAO K, WATARI K, et al. Thermal conductivity of silicon carbide densified with rare-earth oxide additives. Journal of the European Ceramic Society, 2004, 24(2):265.

DOI URL |

| [11] |

AN Q L, CHEN J, MING W W, et al. Machining of SiC ceramic matrix composites: a review. Chinese Journal of Aeronautics, 2021, 34(4):540.

DOI URL |

| [12] |

EOM J H, KIM Y W, SONG I H. Effects of the initial α-SiC content on the microstructure, mechanical properties, and permeability of macroporous silicon carbide ceramics. Journal of the European Ceramic Society, 2012, 32(6):1283.

DOI URL |

| [13] | 张立同, 成来飞, 徐永东. 新型碳化硅陶瓷基复合材料的研究进展. 航空制造技术, 2003(1): 24. |

| [14] |

YUAN Q, SONG Y C. Research and development of continuous SiC fibers and SiCf/SiC composities. Journal of Inorganic Materials, 2016, 31(11):1157.

DOI |

| [15] |

LIU G, ZHANG X, YANG J, et al. Recent advances in joining of SiC-based materials (monolithic SiC and SiCf/SiC composites): joining processes, joint strength, and interfacial behavior. Journal of Advanced Ceramics, 2019, 8(1):19.

DOI |

| [16] |

KATOH Y, OZAWA K, SHIH C, et al. Continuous SiC fiber, CVI SiC matrix composites for nuclear applications: properties and irradiation effects. Journal of Nuclear Materials, 2014, 448(1/2/3):448.

DOI URL |

| [17] | XU Y D, CHENG L F, ZHANG L T. Three dimensional textile SiC/SiC composites by chemical vapor infiltration. Journal of Inorganic Materials, 2001, 16(2):344. |

| [18] |

LIU W, WEI Y, DENG J. Carbon-fiber-reinforced C-SiC binary matrix composites. Carbon, 1995, 33(4):441.

DOI URL |

| [19] |

HU C L, HONG W H, XU X J, et al. Sandwich-structured C/C-SiC composites fabricated by electromagnetic-coupling chemical vapor infiltration. Scientific Reports, 2017, 7: 13120.

DOI PMID |

| [20] |

STALIN M, RAJAGURU K, RANGARAJ L. Processing of Cf/SiC composites by hot pressing using polymer binders followed by polymer impregnation and pyrolysis. Journal of the European Ceramic Society, 2020, 40(2):290.

DOI URL |

| [21] |

OKAMURA K, SHIMOO T, SUZUYA K, et al. SiC-based ceramic fibers prepared via organic-to-inorganic conversion process-a review. Journal of the Ceramic Society of Japan, 2006, 114(6):445.

DOI URL |

| [22] | 张建可.树脂基碳纤维复合材料的热物理性能之一——导热系数. 中国空间科学技术, 1987, (3):55. |

| [23] |

MARADUDIN A A. The lattice thermal conductivity of an isotopically isordered crystal. Journal of the American Chemical Society, 1964, 86(17):3405.

DOI URL |

| [24] |

NI Y, XIONG S, VOLZ S, et al. Thermal transport along the dislocation line in silicon carbide. Physical Review Letters, 2014, 113(12):124301.

DOI URL |

| [25] |

HUANG D, TAN R X, LIU L, et al. Preparation and properties of the three-dimensional highly thermal conductive carbon/carbon- silicon carbide composite using the mesophase-pitch-based carbon fibers and pyrocarbon as thermal diffusion channels. Journal of the European Ceramic Society, 2021, 41(8):4438.

DOI URL |

| [26] | SNEAD L L, NOZAWA T, KATOH Y, et al. Handbook of SiC properties for fuel performance modeling. Journal of Nuclear Materials, 2007, 371(1/2/3):329. |

| [27] | GRAEBNER J E. Thermal Conductivity of Diamond. In: PAN L S, KANIA D R. Boston, Diamond:Electronic Properties and Applications. MA: Springer US, 1995: 285. |

| [28] |

YE C, WU H, ZHU S P, et al. Microstructure of high thermal conductivity mesophase pitch-based carbon fibers. New Carbon Materials, 2021, 36(5):980.

DOI URL |

| [29] | 高晓晴, 郭全贵, 刘朗, 等. 高导热炭材料的研究进展. 功能材料, 2006(2): 173. |

| [30] | DONALD T M, GLEN A S. Conductivity of single crystals. In SHINDE S L, GOELA J S. High thermal conductivity materials. New York: Springer, 2006: 21. |

| [31] |

ZHU C X, LANG J, MA N G. Preparation of Si-diamond-SiC composites by in-situ reactive sintering and their thermal properties. Ceramics International, 2012, 38(8):6131.

DOI URL |

| [32] |

ZHANG Y Y, WANG T S, HSU C Y, et al. Thermal transport characteristics in diamond/SiC composites via molten Si infiltration. Ceramics International, 2021, 47(12):17084.

DOI URL |

| [33] | 李亮.碳化硅纤维高温氧化行为研究. 长沙: 国防科学技术大学硕士学位论文, 2016. |

| [34] | EKSTROM T, ZHENG J, KLOUB K, et al. Heat conductive material. United States, Grant, 6914025. 2005.07.05. |

| [35] |

YANG Z L, HE X B, WU M, et al. Fabrication of diamond/SiC composites by Si-vapor vacuum reactive infiltration. Ceramics International, 2013, 39(3):3399.

DOI URL |

| [36] | ZHENG W, HE X B, WU M, et al. Preparation and thermal conductivities of diamond/SiC composites. Applied Physics A-Materials Science & Processing, 2018, 124(12):804. |

| [37] |

YANG Z L, HE X B, WU M, et al. Infiltration mechanism of diamond/SiC composites fabricated by Si-vapor vacuum reactive infiltration process. Journal of the European Ceramic Society, 2013, 33(4):869.

DOI URL |

| [38] |

MATTHEY B, KUNZE S, HORNER M, et al. SiC-bonded diamond materials produced by pressureless silicon infiltration. Journal of Materials Research, 2017, 32(17):3362.

DOI URL |

| [39] |

SHIMONO M, KUME S. HIP-sintered composites of C (Diamond)/ SiC. Journal of the American Ceramic Society, 2004, 87(4):752.

DOI URL |

| [40] | 李子晗. 中间相沥青基碳纤维复合材料研究进展及发展前景. 新型工业化, 2022, 12(8):174. |

| [41] | 宁亮.中间相沥青基碳纤维的制备及其表面处理的研究. 北京: 北京化工大学硕士学位论文, 2009. |

| [42] | 毛德君. 沥青基碳纤维的生产及应用. 炼油与化工, 2002, 13(4):3. |

| [43] | 徐兵.高导热沥青基炭纤维的制备及其在三维炭/炭复合材料中的应用研究. 武汉: 武汉科技大学博士学位论文, 2018. |

| [44] |

CALEBRESE C, EISMAN G A, LEWIS D J, et al. Swelling and related mechanical and physical properties of carbon nanofiber filled mesophase pitch for use as a bipolar plate material. Carbon, 2010, 48(13):3939.

DOI URL |

| [45] |

EDIE D D, FOX N K, BARNETT B C, et al. Melt-spun non-circular carbon fibers. Carbon, 1986, 24(4):477.

DOI URL |

| [46] |

YOON S H, KORAI Y, MOCHIA I, et al. Axial nano-scale microstructures in graphitized fibers inherited from liquid crystal mesophase pitch. Carbon, 1996, 34(1):83.

DOI URL |

| [47] |

FANG D, CHEN Z, SONG Y, et al. Morphology and microstructure of 2.5 dimension C/SiC composites ablated by oxyacetylene torch. Ceramics International, 2009, 35: 1249.

DOI URL |

| [48] |

CAO L Y, WANG J, LIU Y S, et al. Effect of heat transfer channels on thermal conductivity of silicon carbide composites reinforced with pitch-based carbon fibers. Journal of the European Ceramic Society, 2022, 42(2):420.

DOI URL |

| [49] |

CAO L Y, LIU Y S, ZHANG Y H, et al. Thermal conductivity and bending strength of SiC composites reinforced by pitch-based carbon fibers. Journal of Advanced Ceramics, 2022, 11(2):247.

DOI |

| [50] |

GUO S Q. Thermal and electrical properties of hot-pressed short pitch-based carbon fiber-reinforced ZrB2-SiC matrix composites. Ceramics International, 2013, 39(5):5733.

DOI URL |

| [51] |

GUO S Q, NAITO K, KAGAWA Y. Mechanical and physical behaviors of short pitch-based carbon fiber-reinforced HfB2-SiC matrix composites. Ceramics International, 2013, 39(2):1567.

DOI URL |

| [52] |

CHEN S, FENG Y, QIN M, et al. Improving thermal conductivity in the through-thickness direction of carbon fibre/SiC composites by growing vertically aligned carbon nanotubes. Carbon, 2017, 116: 84.

DOI URL |

| [53] |

HU M, YANG Z H. Perspective on multi-scale simulation of thermal transport in solids and interfaces. Physical Chemistry Chemical Physics, 2021, 23(9):5680.

DOI URL |

| [54] |

LI Z X, LI X Q, ZHANG B X, et al. Enhanced thermal and mechanical properties of optimized SiCf/SiC composites with in-situ CNTs on PyC interface. Ceramics International, 2020, 46(11):18071.

DOI URL |

| [55] |

CUI G Y, LUO R Y, WANG L Y, et al. Effect of SiC nanowires on the mechanical properties and thermal conductivity of 3D-SiCf/SiC composites prepared via precursor infiltration pyrolysis. Journal of the European Ceramic Society, 2021, 41(10):5026.

DOI URL |

| [56] |

LI J X, LIU Y S, CHEN C, et al. Effects of phenolic resin contents on microstructures and properties of C/SiC-diamond composites. Journal of the American Ceramic Society, 2021, 104(7):3424.

DOI URL |

| [57] |

FENG W, ZHANG L T, LIU Y S, et al. The improvement in the mechanical and thermal properties of SiC/SiC composites by introducing CNTs into the PyC interface. Materials Science and Engineering A-Structural Materials Properties Microstructure and Processing, 2015, 637: 123.

DOI URL |

| [58] |

ZHANG Y Y, HSU C Y, KARANDIKAR P, et al. Interfacial zone surrounding the diamond in reaction bonded diamond/SiC composites: Interphase structure and formation mechanism. Journal of the European Ceramic Society, 2019, 39(16):5190.

DOI URL |

| [59] |

FENG W, ZHANG L T, LIU Y S, et al. Increasing the thermal conductivity of 2D SiC/SiC composites by heat-treatment. Fusion Engineering and Design, 2015, 90: 110.

DOI URL |

| [60] |

HAN S, LIN J T, YAMADA Y, et al. Enhancing the thermal conductivity and compressive modulus of carbon fiber polymer-matrix composites in the through-thickness direction by nanostructuring the interlaminar interface with carbon black. Carbon, 2008, 46(7):1060.

DOI URL |

| [61] |

ZHANG Y H, LIU Y S, CAO Y J, et al. Effect of well-designed graphene heat conductive channel on the thermal conductivity of C/SiC composites. Ceramics International, 2021, 47(13):19115.

DOI URL |

| [62] |

ZHANG Y H, LIU Y S, CAO L Y, et al. Three-dimensional micro-pipelines high thermal conductive C/SiC composites. Ceramics International, 2021, 47(24):34333.

DOI URL |

| [63] |

PAN Y, WANG J, WANG N, et al. Effects of aligned carbon nanotube microcolumns on mechanical and thermal properties of C/SiC composites prepared by LA-CVI methods. Journal of the European Ceramic Society, 2019, 39(16):5463.

DOI URL |

| [64] |

ZHANG Y H, LIU Y S, CAO Y J, et al. Effect of initial density on thermal conductivity of new micro-pipeline heat conduction C/SiC composites. Journal of the American Ceramic Society, 2021, 104(1):645.

DOI URL |

| [65] |

SNEAD L L, SCHWARZ O J. Advanced SiC composites for fusion applications. Journal of Nuclear Materials, 1995, 219: 3.

DOI URL |

| [66] | NASLAIN R. Hybrid ceramic matrix fibrous composites:an overview. IOP Conference Series: Materials Science and Engineering, 2011, 18: 082002. |

| [1] | ZHU Wenjie, TANG Lu, LU Jichang, LIU Jiangping, LUO Yongming. Research Progress on Catalytic Oxidation of Volatile Organic Compounds by Perovskite Oxides [J]. Journal of Inorganic Materials, 2025, 40(7): 735-746. |

| [2] | WANG Lujie, ZHANG Yuxin, LI Tongyang, YU Yuan, REN Pengwei, WANG Jianzhang, TANG Huaguo, YAO Xiumin, HUANG Yihua, LIU Xuejian, QIAO Zhuhui. Corrosion and Wear Behavior of Silicon Carbide Ceramic in Deep-sea Service Environment [J]. Journal of Inorganic Materials, 2025, 40(7): 799-807. |

| [3] | HU Zhichao, YANG Hongyu, YANG Hongcheng, SUN Chengli, YANG Jun, LI Enzhu. Usage of the P-V-L Bond Theory in Regulating Properties of Microwave Dielectric Ceramics [J]. Journal of Inorganic Materials, 2025, 40(6): 609-626. |

| [4] | HE Guoqiang, ZHANG Kaiheng, WANG Zhentao, BAO Jian, XI Zhaochen, FANG Zhen, WANG Changhao, WANG Wei, WANG Xin, JIANG Jiapei, LI Xiangkun, ZHOU Di. Ba(Nd1/2Nb1/2)O3: Au Underrated K40 Microwave Dielectric Ceramic [J]. Journal of Inorganic Materials, 2025, 40(6): 639-646. |

| [5] | WU Qiong, SHEN Binglin, ZHANG Maohua, YAO Fangzhou, XING Zhipeng, WANG Ke. Research Progress on Lead-based Textured Piezoelectric Ceramics [J]. Journal of Inorganic Materials, 2025, 40(6): 563-574. |

| [6] | ZHANG Bihui, LIU Xiaoqiang, CHEN Xiangming. Recent Progress of Hybrid Improper Ferroelectrics with Ruddlesden-Popper Structure [J]. Journal of Inorganic Materials, 2025, 40(6): 587-608. |

| [7] | WU Jie, YANG Shuai, WANG Mingwen, LI Jinglei, LI Chunchun, LI Fei. Textured PT-based Piezoelectric Ceramics: Development, Status and Challenge [J]. Journal of Inorganic Materials, 2025, 40(6): 575-586. |

| [8] | JIANG Kun, LI Letian, ZHENG Mupeng, HU Yongming, PAN Qinxue, WU Chaofeng, WANG Ke. Research Progress on Low-temperature Sintering of PZT Ceramics [J]. Journal of Inorganic Materials, 2025, 40(6): 627-638. |

| [9] | CHEN Yi, QIU Haipeng, CHEN Mingwei, XU Hao, CUI Heng. SiC/SiC Composite: Matrix Boron Modification and Mechanical Properties [J]. Journal of Inorganic Materials, 2025, 40(5): 504-510. |

| [10] | LI Jianjun, CHEN Fangming, ZHANG Lili, WANG Lei, ZHANG Liting, CHEN Huiwen, XUE Changguo, XU Liangji. Peroxymonosulfate Activation by CoFe2O4/MgAl-LDH Catalyst for the Boosted Degradation of Antibiotic [J]. Journal of Inorganic Materials, 2025, 40(4): 440-448. |

| [11] | TIAN Ruizhi, LAN Zhengyi, YIN Jie, HAO Nanjing, CHEN Hangrong, MA Ming. Microfluidic Technology Based Synthesis of Inorganic Nano-biomaterials: Principles and Progress [J]. Journal of Inorganic Materials, 2025, 40(4): 337-347. |

| [12] | ZHANG Jiguo, WU Tian, ZHAO Xu, YANG Fan, XIA Tian, SUN Shien. Improvement of Cycling Stability of Cathode Materials and Industrialization Process for Sodium-ion Batteries [J]. Journal of Inorganic Materials, 2025, 40(4): 348-362. |

| [13] | MU Shuang, MA Qin, ZHANG Yu, SHEN Xu, YANG Jinshan, DONG Shaoming. Oxidation Behavior of Yb2Si2O7 Modified SiC/SiC Mini-composites [J]. Journal of Inorganic Materials, 2025, 40(3): 323-328. |

| [14] | YIN Jie, GENG Jiayi, WANG Kanglong, CHEN Zhongming, LIU Xuejian, HUANG Zhengren. Recent Advances in 3D Printing and Densification of SiC Ceramics [J]. Journal of Inorganic Materials, 2025, 40(3): 245-255. |

| [15] | YANG Shuqi, YANG Cunguo, NIU Huizhu, SHI Weiyi, SHU Kewei. GeP3/Ketjen Black Composite: Preparation via Ball Milling and Performance as Anode Material for Sodium-ion Batteries [J]. Journal of Inorganic Materials, 2025, 40(3): 329-336. |

| Viewed | ||||||

|

Full text |

|

|||||

|

Abstract |

|

|||||