Journal of Inorganic Materials ›› 2022, Vol. 37 ›› Issue (8): 809-820.DOI: 10.15541/jim20220014

• REVIEW • Previous Articles Next Articles

Received:2022-01-11

Revised:2022-03-03

Published:2022-08-20

Online:2022-03-10

About author:WANG Shiwei (1964-), male, professor. E-mail: swwang51@mail.sic.ac.cn

Supported by:CLC Number:

WANG Shiwei. Progress of Spontaneous Coagulation Casting of Ceramic Slurries Based on Hydrophobic Interaction[J]. Journal of Inorganic Materials, 2022, 37(8): 809-820.

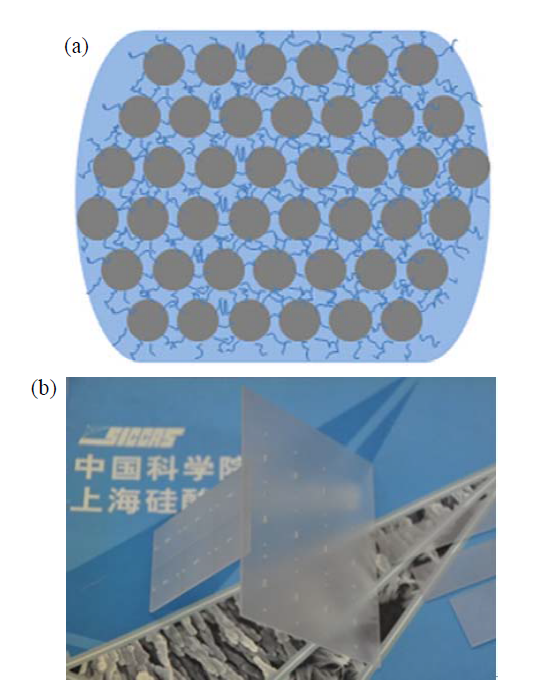

Fig. 1 Schematic diagram of ceramic particles solidified by three-dimensional organic network (a) and photo of translucent Al2O3 sheet (100 mm × 100 mm × 1 mm) (b)

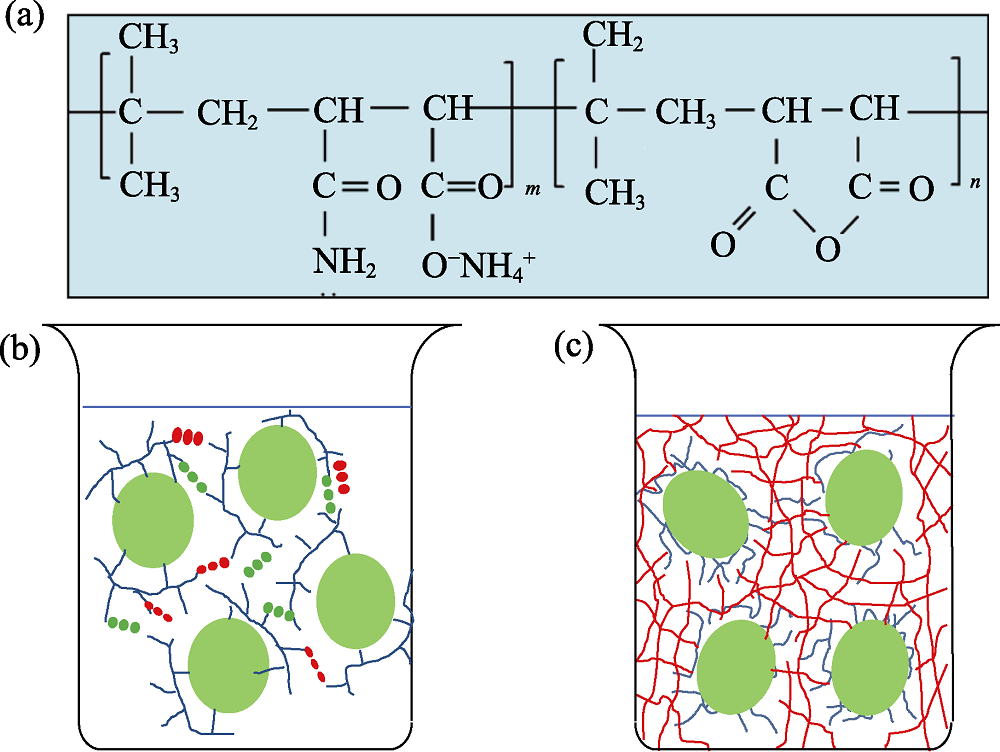

Fig. 2 Simplified structure of PIBM molecule (a) and schematic diagrams of organic network with low and high density by spontaneous coagulation casting (b) and gelcasting (c), respectively

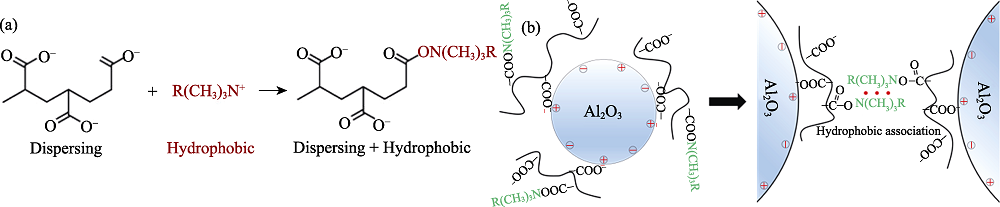

Fig. 4 Effect of hydrophobic groups on spontaneous coagulation (a) Hydrophobic modification reaction; (b) Schematic diagram of ceramic particle dispersion and hydrophobic association curing mechanism

| Organic ammonium salt | Molecular weight | Solubility of Isobam after hydrophobic modification |

|---|---|---|

| TMAC (Tetramethyl ammonium chloride) | 109.6 | Soluble |

| TEAC (Tetraethylammonium chloride) | 165.7 | Soluble |

| MTAC (Methyltributylammonium chloride) | 235.8 | Soluble |

| OTAC (Octyltrimethylammonium chloride) | 207.8 | Insoluble |

| DTAC (Dodecyltrimethylammonium chloride) | 263.0 | Insoluble |

Table 1 Dissolution of Isobam 600 AF after different hydrophobic chain modification

| Organic ammonium salt | Molecular weight | Solubility of Isobam after hydrophobic modification |

|---|---|---|

| TMAC (Tetramethyl ammonium chloride) | 109.6 | Soluble |

| TEAC (Tetraethylammonium chloride) | 165.7 | Soluble |

| MTAC (Methyltributylammonium chloride) | 235.8 | Soluble |

| OTAC (Octyltrimethylammonium chloride) | 207.8 | Insoluble |

| DTAC (Dodecyltrimethylammonium chloride) | 263.0 | Insoluble |

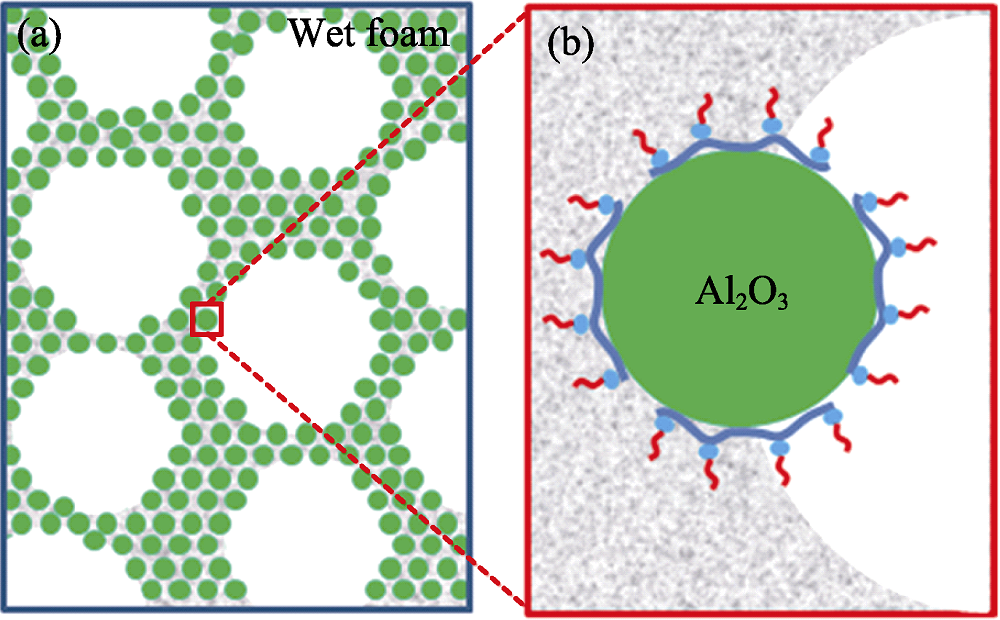

Fig. 7 Schematic diagram of stabilized foam with hydrophobized ceramic particles (a) and corresponding magnification part (showing a modified dispersant on a particle) (b)

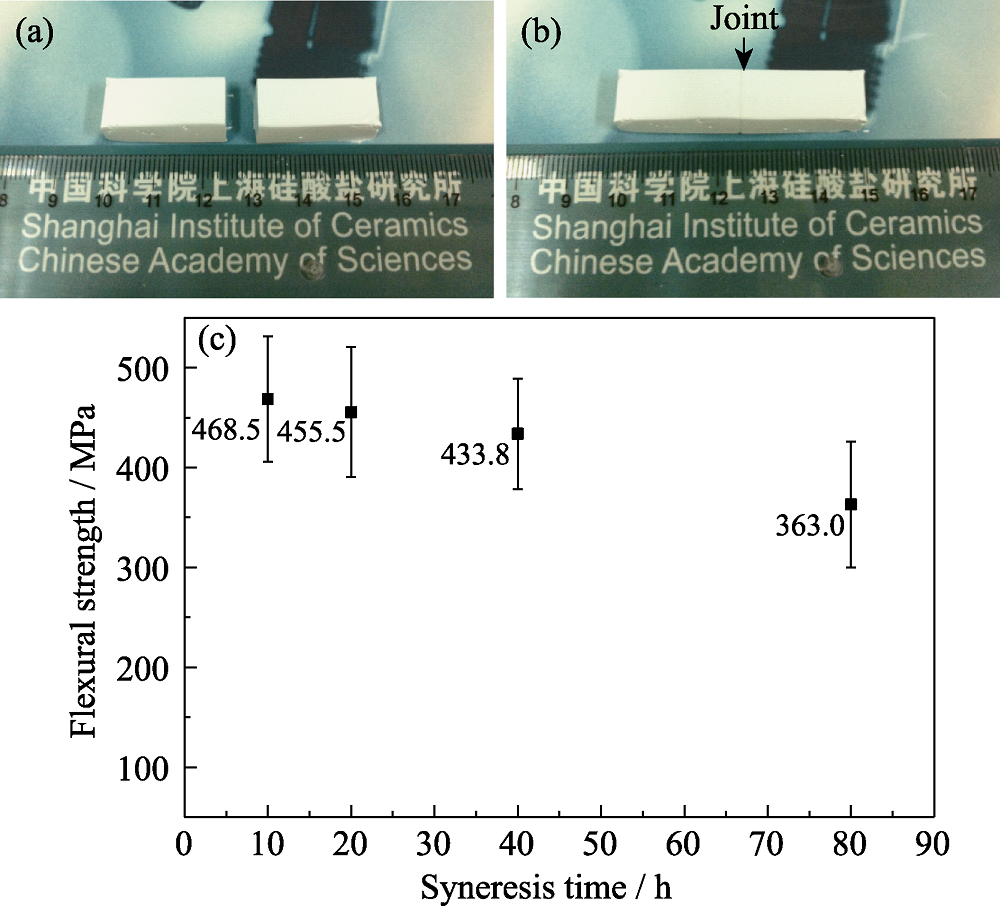

Fig. 8 Pictures of wet green bodies before (a) and after (b) joining, and effect of syneresis time on flexural strength of sintered samples (1600 ℃×2 h) derived from wet green bodies (c) [54]

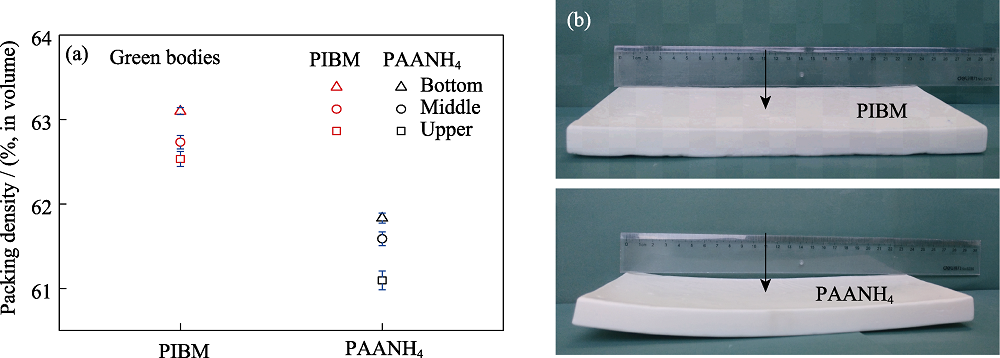

Fig. 10 Density difference of ceramic green bodies prepared by different dispersion systems (a) and photos of sintered samples (280 mm×130 mm×20 mm)(b)[56]

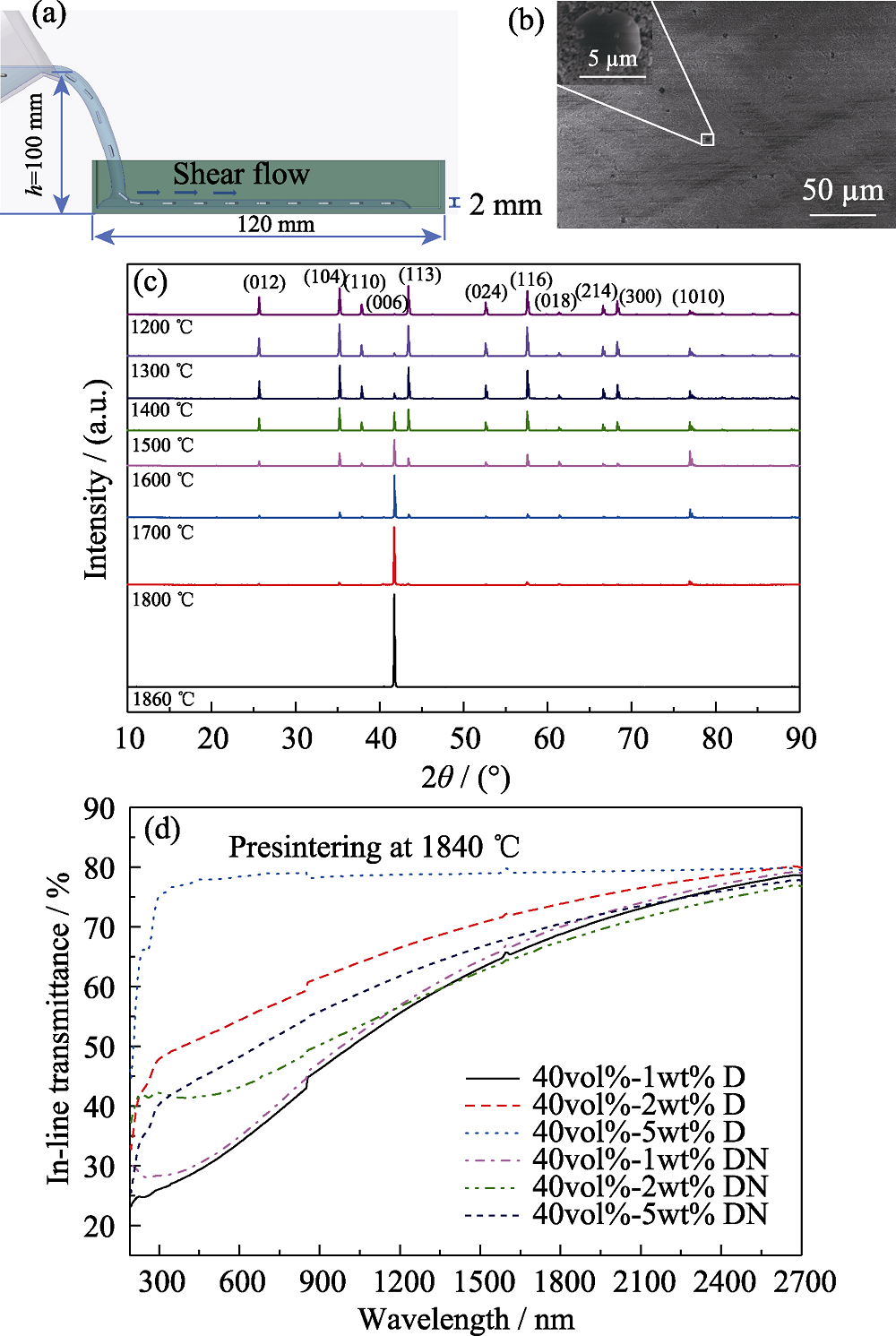

Fig. 12 Schematic diagram of orientation of the platelet under shear flow (a), surface of the green body with platelet (b), XRD patterns of the green bodies sintered at different temperatures (c), and the influence of the content and type of the platelet on the linear transmittance of the ceramic (1 mm thick) (d)[61]

| [1] | 鈴木宏, 内村勝次, 藤原徳仁. セラミックス大型部品用浸透Ⅴプロセスの開発. 素形材, 2007, 12: 21-24. |

| [2] | www.surmet.com/products and applications/Domes and IR optics/ index.php. 2021-12-22. |

| [3] | OMATETE O O, JANNEY M A, STREHLOW R A. Gelcasting-a new ceramic forming process. Am. Ceram. Soc. Bull., 1991, 70: 1641-1649. |

| [4] |

YANG J L, YU J L, HUANG Y. Recent development in gelcasting of ceramics. J. Euro. Ceram. Soc., 2011, 31(4): 2569-2591.

DOI URL |

| [5] |

TALLON C, FRANK G V. Recent trends in shape forming from colloidal processing: a review. J. Ceram. Soc. Jpn., 2011, 119(1387): 147-160.

DOI URL |

| [6] | GRAULE T J, BAADER F H, GAUCKLER L J. Casting uniform ceramics with direct coagulation. Chemtech, 1995, 25(6): 31-31. |

| [7] | 杨燕, 岛井骏藏, 周国红, 等. 一种制备陶瓷坯体的方法. CN103130509B. |

| [8] |

MORISSETTE S L, LEWIS J A. Chemorheoloy of aqueous-based alumina-poly(vinyl alcohol) gelcasting suspensions. J. Am. Ceram. Soc., 1999, 82(3): 521-528.

DOI URL |

| [9] |

CHABERT F, DUNSTAN D E, FRANKS G V. Cross-linked polyvinyl alcohol as a binder for gelcasting and green machining. J. Am. Ceram. Soc., 2008, 91(10): 3138-3146.

DOI URL |

| [10] |

HANSEN E W, HOLM K H, JAHR D M, et al. Reaction of poly(vinyl alcohol) and dialdehydes during gel formation probed by 1H N.M.R.-a kinetic study. Polymer, 1997, 38(19): 4863-4871.

DOI URL |

| [11] |

JOHNSON S B, DUNSTAN D E, FRANKS G V. A novel thermally activated crosslinking agent for chitosan in aqueous solution: a rheological investigation. Colloid Poly. Sci., 2004, 282: 602-612.

DOI URL |

| [12] |

MAO X J, SHIMAI S, DONG M J, et al. Gelcasting of alumina using epoxy resin as gelling agent. J. Am. Ceram. Soc., 2007, 90(3): 986-988.

DOI URL |

| [13] | TALLON C, JACH D, MORENO, et al. Gelcasting of alumina suspensions containing nanoparticles with glycerol monoacrylate. J. Am. Ceram. Soc., 2009, 29: 875-880. |

| [14] |

WIECINSKA P, SZAFRAN M, SAKKA Y, et al. Gelcasting of alumina with a new monomer synthesized from glucose. J. Euro. Ceram. Soc., 2010, 30(8): 1795-1801.

DOI URL |

| [15] |

FANELLI A J, SILVERS R D, FREI W S, et al. New aqueous injection molding process for ceramic powder. J. Am. Ceram. Soc., 1989, 72(10): 1833-1836.

DOI URL |

| [16] |

JIA Y, KANNO Y, XIE Z P. Fabrication of alumina green body through gelcasting process using alginate. Mater. Lett., 2003, 57(16): 2530-2534.

DOI URL |

| [17] |

LYCKFELDT O, BRANDT J, LESCA S. Protein forming-a novel shaping technique for ceramics. J. Eur. Ceram. Soc., 2000, 20(14/15): 2551-2559.

DOI URL |

| [18] |

ADOLFSSON E. Gelcasting of zirconia using agarose. J. Am. Ceram. Soc., 2006, 89(6): 1897-1902.

DOI URL |

| [19] |

CHEN Y L, XIE Z P, HUANG Y. Alumina casting based on gelation of gelatin. J. Eur. Ceram. Soc., 1999, 19(2): 271-275.

DOI URL |

| [20] | 杨金龙, 许杰, 干科. 陶瓷浓悬浮体新型固化技术及其原理. 北京: 清华大学出版社, 2020. |

| [21] | 卜景龙, 刘开琪, 王志发, 等. 凝胶注模成型制备高温结构陶瓷. 北京: 化学工业出版社, 2008. |

| [22] | 杨金龙, 黄勇. 陶瓷新型胶态成型工艺, 2版. 北京: 清华大学出版社, 2010. |

| [23] | 陈大明. 先进陶瓷材料的注凝技术与应用. 北京: 国防工业出版社, 2011. |

| [24] | 王小锋, 王日初. 氧化铍陶瓷的凝胶注模成型. 长沙: 中南大学出版社, 2012. |

| [25] |

MAO X J, SHIMAI S, DONG M J, et al. Gelcasting of alumina using epoxy resin as a gelling agent. J. Am. Ceram. Soc., 2007, 90(3): 986-988.

DOI URL |

| [26] |

MAO X J, SHIMAI S, DONG M J, et al. Gelcasting and pressureless sintering of translucent alumina ceramics. J. Am. Ceram. Soc., 2008, 91(5): 1700-1702.

DOI URL |

| [27] |

MAO X J, SHIMAI S, WANG S W. Gelcasting of alumina foams consolidated by epoxy resin. J. Europ. Ceram. Soc., 2008, 28(1): 217-222.

DOI URL |

| [28] |

JIN L L, MAO X J, WANG S W, et al. Optimization of the rheological properties of yttria suspensions. Ceram. Int., 2009, 35(2): 925-927.

DOI URL |

| [29] |

XUE J F, DONG M J, LI J, et al. Gelcasting of aluminum nitride ceramics. J. Am. Ceram. Soc., 2010, 93(4): 928-930.

DOI URL |

| [30] |

DONG M J, MAO X J, ZHANG Z Q, et al. Gelcasting of SiC using epoxy resin as gel former. Ceram. Int., 2009, 35(4): 1363-1366.

DOI URL |

| [31] |

YANG Y, SHIMAI S, WANG S W. Room-temperature gelcasting of alumina with a water-soluable copolymer. J. Mater. Res., 2013, 28(11): 1512-1516.

DOI URL |

| [32] |

SHIMAI S Z, YANG Y, WANG S W, et al. Spontaneous gelcasting of translucent alumina ceramics. Optical Materials Express, 2013, 3: 1000-1006.

DOI URL |

| [33] |

QIN X, ZHOU G H, YANG Y, et al. Gelcasting of transparent YAG ceramics by a new gelling system. Ceram. Int., 2014, 40(8): 12745-12750.

DOI URL |

| [34] |

ZHANG P, LIU P, SUN Y, et al. Aqueous gelcasting of the transparent MgAl2O4 spinel ceramics. Journal of Alloys and Compounds, 2015, 646: 833-836.

DOI URL |

| [35] |

SUN Y, SHIMAI S, PENG X, et al. Fabrication of transparent Y2O3ceramics via aqueous gelcasting. Ceram. Int., 2014, 40(6): 8841-8845.

DOI URL |

| [36] |

WANG J, ZHANG F, CHEN F, et al. Fabrication of aluminum oxynitride (γ-AlON) transparent ceramics with modified gelcasting. J. Am. Ceram. Soc., 2014, 97(5): 1353-1355.

DOI URL |

| [37] | SHU X, LI J, ZHANG H L, et al. Gelcasting of aluminum nitride using a water-soluble copolymer. J. Inorg. Mater., 2014, 29: 327-330. |

| [38] | MAO X J, CHEN H, ZHAO J, et al. Research progress in spontaneous solidification molding. Modern Technical Ceramics, 2019, 40(6): 398-416. |

| [39] | 美国陆军实验室. http://www.arl.army.mil/arlreports/2016/ARL-TR-7620.pdf. [2021-12-22]. |

| [40] |

YANG Y, WU Y. Tape-casted transparent alumina ceramic wafers. Journal of Materials Research, 2014, 29(19): 2312-2317.

DOI URL |

| [41] |

LU Y J, GAN K, HUO W L, et al. Dispersion and gelation behavior of alumina suspensions with Isobam. Ceram. Int., 2018, 44(10): 11357-11363.

DOI URL |

| [42] |

MARSICO C A, ORLICKI J A, BLAIR V L. Investigation of room- temperature super-stabilized suspension casting system mechanism. J. Am. Ceram. Soc., 2020, 103(3): 1514-1519.

DOI URL |

| [43] | 孙怡. 多官能团一元凝胶体系的改性及应用研究. 北京: 中国科学院大学博士学位论文, 2016. |

| [44] |

CHEN H, SHIMAI S, ZHAO J, et al. Hydrophobic coagulation of alumina slurries. J. Am. Ceram. Soc., 2021, 104(1): 284-293.

DOI URL |

| [45] |

PRABHAKARAN K, RAGHUNATH S, MELKERI A, et al. Novel coagulation method for direct coagulation casting of aqueous alumina slurries prepared using a poly(Acrylate) dispersant. J. Am. Ceram. Soc., 2008, 91(2): 615-619.

DOI URL |

| [46] |

GONZENBACH U T, STUDART A R, TERVOORT E, et al. Macroporous ceramics from particle-stabilized wet foams. J. Am. Ceram. Soc., 2007, 90(1): 16-22.

DOI URL |

| [47] | 陈晗. 类单晶结构氧化铝透明陶瓷的形成机制及制备. 北京: 中国科学院大学博士学位论文, 2021. |

| [48] | ZHAO J, MAO X J, WANG S W. Alumina ceramic foams with controllable cell structure prepared by direct foaming. Journal of the Chinese Ceramic Society, 2019, 47(9): 1222-1234. |

| [49] |

GONZENBACH U T, STUDART A R, TERVOORT E, et al. Macroporous ceramics from particle-stabilized wet foams. J. Am. Ceram. Soc., 2007, 90(1): 16-22.

DOI URL |

| [50] | YANG J L, LIN H, XI X Q, et al. Preparation of particle-stabilized foam slurry and porous alumina ceramics. J. Chin. Ceram. Soc., 2008, 36(2): 220-223. |

| [51] |

YU J L, YANG J L, LI S, et al. Preparation of Si3N4 foam ceramics with nest-like cell structure by particle-stabilized foams. J. Am. Ceram. Soc., 2012, 95(4): 1229-1233.

DOI URL |

| [52] |

CHUANUWATANAKUL C, TALLON C, DUNSTAN D E, et al. Producing large complex-shaped ceramic particle stabilized foams. J. Am. Ceram. Soc., 2013, 96(5): 1407-1413.

DOI URL |

| [53] | 彭翔. 大尺寸氧化铝陶瓷的注凝成型研究. 北京: 中国科学院大学博士学位论文, 2016. |

| [54] |

PENG X, SHIMAI S, SUN Y, et al. Wet green-state joining of alumina ceramics without paste. J. Am. Ceram. Soc., 2015, 98(9): 2728-2731.

DOI URL |

| [55] |

DI Z, SHIMAI S, ZHAO J, et al. Dewatering of spontaneous- coagulation-cast alumina ceramic gel by filtrating with low pressure. Ceram. Int., 2019, 45(10): 12789-12794.

DOI URL |

| [56] |

DI Z, SHIMAI S, ZHAO J, et al. Density difference in pressure- filtrated wet cakes produced from spontaneous gelling slurries. J. Am. Ceram. Soc., 2020, 103(2): 1396-1403.

DOI URL |

| [57] |

CHEN H, SHIMAI S, ZHAO J, et al. Pressure filtration assisted gel casting in translucent alumina ceramics fabrication. Ceram. Int., 2018, 44(14): 16572-16576.

DOI URL |

| [58] |

KRELL A, BLANK P, MA H W, et al. Processing of high-density submicrometer Al2O3 for new applications. J. Am. Ceram. Soc., 2003, 86(4): 546-553.

DOI URL |

| [59] |

MAO X J, WANG S W, SHIMAI S, et al. Transparent polycrystalline alumina ceramics with orientated optical axes. J. Am. Ceram. Soc., 2008, 91(10): 3431-3433.

DOI URL |

| [60] |

YI H L, MAO X J, ZHOU G H, et al. Crystal plane evolution of grain oriented alumina ceramics with high transparency. Ceram. Int., 2012, 38(7): 5557-5561.

DOI URL |

| [61] |

CHEN H, SHIMAI S, ZHAO J, et al. Highly oriented α-Al2O3 transparent ceramics shaped by shear force. J. Europ. Ceram. Soc., 2021, 41(6): 3838-3843.

DOI URL |

| [62] |

CHEN H, ZHAO J, SHIMAI S, et al. High transmittance and grain- orientated alumina ceramics fabricated by adding fine template particles. Journal of Advanced Ceramics, 2022, 11(4): 582-588.

DOI URL |

| [63] |

YANG Y, SHIMAI S, SUN Y, et al. Fabrication of porous Al2O3 ceramics by rapid gelation and mechanical foaming. Journal of Materials Research, 2013, 28(15): 2012-2016.

DOI URL |

| [64] | 赵瑾. 表面活性剂疏水修饰陶瓷颗粒制备泡沫陶瓷. 北京: 中国科学院大学博士学位论文, 2018. |

| [65] |

ZHAO J, YANG C, SHIMAI S, et al. The effect of wet foam stability on the microstructure and strength of porous ceramics. Ceram. Int., 2018, 44: 269-274.

DOI URL |

| [66] |

ZHAO J, SHIMAI S, ZHOU G H, et al. Ceramic foams shaped by oppositely charged dispersant and surfactant. Colloids and Surfaces A: Physicochemical and Engineering Aspects, 2018, 537: 210-216.

DOI URL |

| [67] |

WANG L Y, SHIMAI S, WANG S W, et al. High-strength porous alumina ceramics prepared from stable wet foams. Journal of Advanced Ceramics, 2021, 10(4): 852-859.

DOI URL |

| [1] | ZHU Wenjie, TANG Lu, LU Jichang, LIU Jiangping, LUO Yongming. Research Progress on Catalytic Oxidation of Volatile Organic Compounds by Perovskite Oxides [J]. Journal of Inorganic Materials, 2025, 40(7): 735-746. |

| [2] | HU Zhichao, YANG Hongyu, YANG Hongcheng, SUN Chengli, YANG Jun, LI Enzhu. Usage of the P-V-L Bond Theory in Regulating Properties of Microwave Dielectric Ceramics [J]. Journal of Inorganic Materials, 2025, 40(6): 609-626. |

| [3] | WU Qiong, SHEN Binglin, ZHANG Maohua, YAO Fangzhou, XING Zhipeng, WANG Ke. Research Progress on Lead-based Textured Piezoelectric Ceramics [J]. Journal of Inorganic Materials, 2025, 40(6): 563-574. |

| [4] | ZHANG Bihui, LIU Xiaoqiang, CHEN Xiangming. Recent Progress of Hybrid Improper Ferroelectrics with Ruddlesden-Popper Structure [J]. Journal of Inorganic Materials, 2025, 40(6): 587-608. |

| [5] | WU Jie, YANG Shuai, WANG Mingwen, LI Jinglei, LI Chunchun, LI Fei. Textured PT-based Piezoelectric Ceramics: Development, Status and Challenge [J]. Journal of Inorganic Materials, 2025, 40(6): 575-586. |

| [6] | JIANG Kun, LI Letian, ZHENG Mupeng, HU Yongming, PAN Qinxue, WU Chaofeng, WANG Ke. Research Progress on Low-temperature Sintering of PZT Ceramics [J]. Journal of Inorganic Materials, 2025, 40(6): 627-638. |

| [7] | TIAN Ruizhi, LAN Zhengyi, YIN Jie, HAO Nanjing, CHEN Hangrong, MA Ming. Microfluidic Technology Based Synthesis of Inorganic Nano-biomaterials: Principles and Progress [J]. Journal of Inorganic Materials, 2025, 40(4): 337-347. |

| [8] | ZHANG Jiguo, WU Tian, ZHAO Xu, YANG Fan, XIA Tian, SUN Shien. Improvement of Cycling Stability of Cathode Materials and Industrialization Process for Sodium-ion Batteries [J]. Journal of Inorganic Materials, 2025, 40(4): 348-362. |

| [9] | YIN Jie, GENG Jiayi, WANG Kanglong, CHEN Zhongming, LIU Xuejian, HUANG Zhengren. Recent Advances in 3D Printing and Densification of SiC Ceramics [J]. Journal of Inorganic Materials, 2025, 40(3): 245-255. |

| [10] | CHEN Guangchang, DUAN Xiaoming, ZHU Jinrong, GONG Qing, CAI Delong, LI Yuhang, YANG Donglei, CHEN Biao, LI Xinmin, DENG Xudong, YU Jin, LIU Boya, HE Peigang, JIA Dechang, ZHOU Yu. Advanced Ceramic Materials in Helicopter Special Structures: Research Progress and Application Prospect [J]. Journal of Inorganic Materials, 2025, 40(3): 225-244. |

| [11] | FAN Xiaobo, ZU Mei, YANG Xiangfei, SONG Ce, CHEN Chen, WANG Zi, LUO Wenhua, CHENG Haifeng. Research Progress on Proton-regulated Electrochemical Ionic Synapses [J]. Journal of Inorganic Materials, 2025, 40(3): 256-270. |

| [12] | HAIREGU Tuxun, GUO Le, DING Jiayi, ZHOU Jiaqi, ZHANG Xueliang, NUERNISHA Alifu. Research Progress of Optical Bioimaging Technology Assisted by Upconversion Fluorescence Probes in Tumor Imaging [J]. Journal of Inorganic Materials, 2025, 40(2): 145-158. |

| [13] | SUN Shujuan, ZHENG Nannan, PAN Haokun, MA Meng, CHEN Jun, HUANG Xiubing. Research Progress on Preparation Methods of Single-atom Catalysts [J]. Journal of Inorganic Materials, 2025, 40(2): 113-127. |

| [14] | TAO Guilong, ZHI Guowei, LUO Tianyou, OUYANG Peidong, YI Xinyan, LI Guoqiang. Progress on Key Technologies of Cavity-structured Thin Film Bulk Acoustic Wave Filter [J]. Journal of Inorganic Materials, 2025, 40(2): 128-144. |

| [15] | ZHOU Fan, TIAN Zhilin, LI Bin. Research Progress on Carbide Ultra-high Temperature Ceramic Anti-ablation Coatings for Thermal Protection System [J]. Journal of Inorganic Materials, 2025, 40(1): 1-16. |

| Viewed | ||||||

|

Full text |

|

|||||

|

Abstract |

|

|||||