Journal of Inorganic Materials ›› 2021, Vol. 36 ›› Issue (3): 245-256.DOI: 10.15541/jim20200220

• Review • Previous Articles Next Articles

ZHANG Xiaoshan1( ), WANG Bing1, WU Nan2, HAN Cheng1, WU Chunzhi1, WANG Yingde1(

), WANG Bing1, WU Nan2, HAN Cheng1, WU Chunzhi1, WANG Yingde1( )

)

Received:2020-04-26

Revised:2020-06-09

Published:2021-03-20

Online:2020-09-09

Contact:

WANG Yingde, professor. E-mail: wangyingde@nudt.edu.cn

About author:ZHANG Xiaoshan(1991-), male, PhD candidate. E-mail: zhangxiaoshan15@nudt.edu.cn

Supported by:CLC Number:

ZHANG Xiaoshan, WANG Bing, WU Nan, HAN Cheng, WU Chunzhi, WANG Yingde. Micro-nano Ceramic Fibers for High Temperature Thermal Insulation[J]. Journal of Inorganic Materials, 2021, 36(3): 245-256.

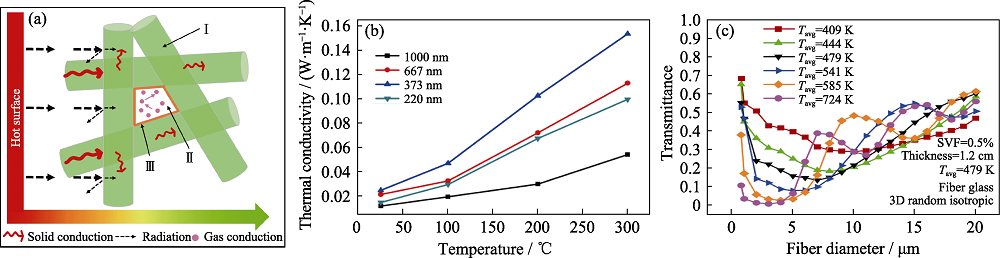

Fig. 2 Schematic of micro-nano fiber heat conduction (a), effect of fiber diameter on thermal conductivity of carbon nanofiber at different testing temperatures (b), and transmittance values for fibers with different fiber diameters at different operating temperatures (c)[13,21]

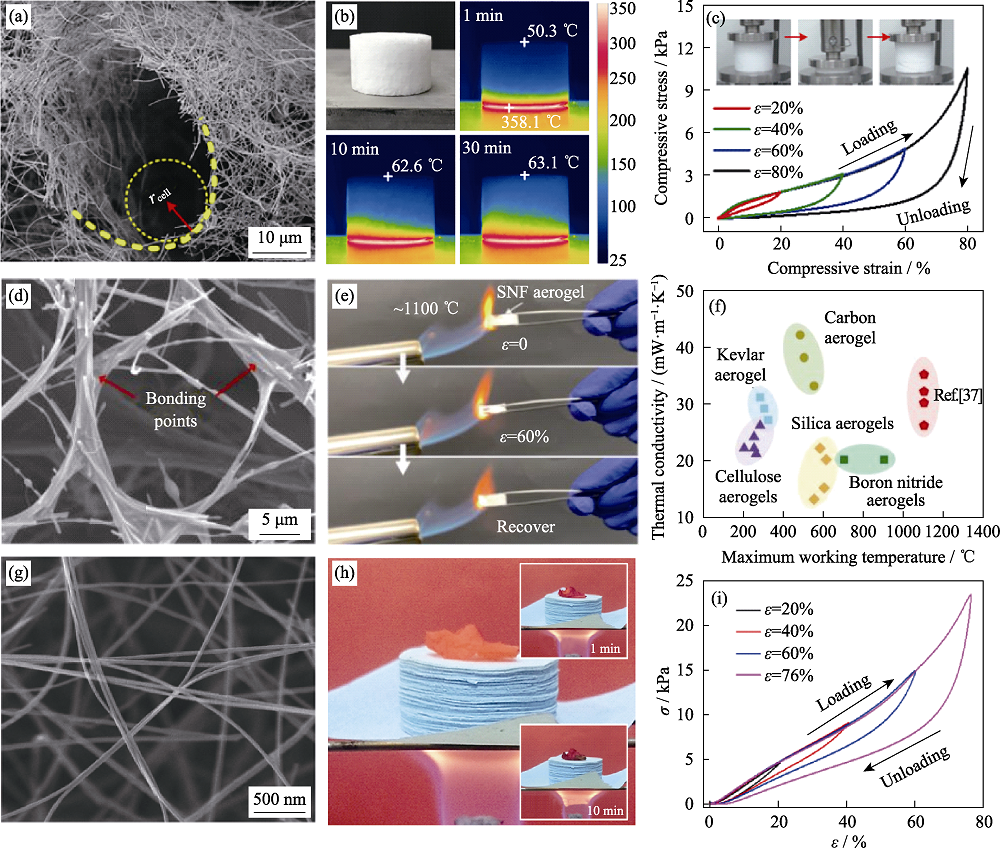

Fig. 3 SiO2 and SiC nanofiber aerogel[7-8,37] (a,d) SEM images of SiO2 nanofiber aerogel; (b) Infrared thermal image; (c) Compression stress-strain; (e) Compression test under high temperature; (f) Thermal conductivity comparison; (g) SEM image of SiC nanofiber aerogel; (h) Optical photo of thermal insulation performance of SiC nanofiber aerogel; (i) Compression stress-strain of SiC nanofiber aerogel

Fig. 5 Hollow micro-nano ceramic fiber[44,48] (a) Surface and cross section SEM images of hollow ZrO2 fiber; (b) Comparison of thermal conductivity between hollow ZrO2 fiber and traditional ZrO2 fiber; (c) Surface and cross section SEM images of hollow Al2O3 fiber; (d) Thermal conductivity comparison among hollow Al2O3 fiber aerogel and other materials

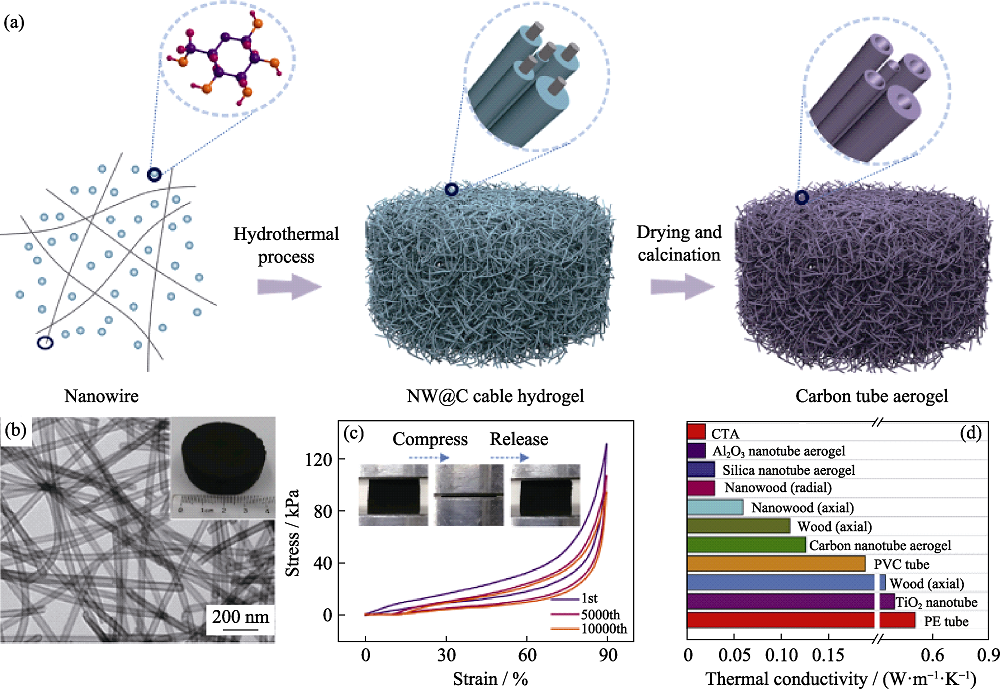

Fig. 6 Hollow carbon micro-nano fiber aerogel[49] (a) Schematic illustration of the fabrication processes; (b) TEM image; (c) Stress-strain curves for 10000 cycles; (d) Thermal conductivity comparison among different hollow-structured thermally insulating materials

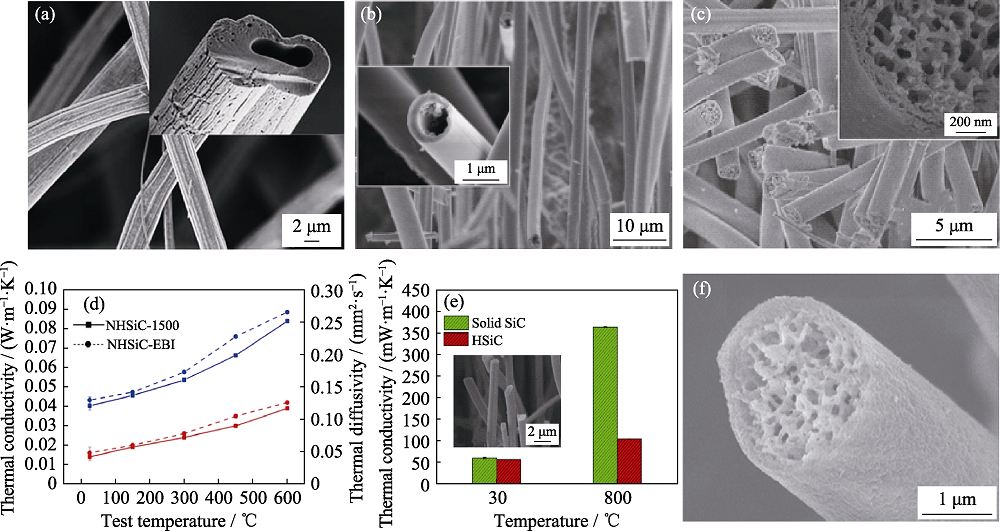

Fig. 7 Hollow and porous micro-nano fiber[51-52,54] (a) SEM image of N-doped hollow SiC fiber; (b) SEM image of hollow SiC fiber; (c)SEM image of porous SiO2-TiO2 fiber; (d) Thermal conductivities and thermal diffusivities of N-doped hollow SiC fiber; (e) Thermal conductivities of solid SiC fiber and hollow SiC fiber; (f) SEM image of SiO2-ZrO2 fiber

| Fiber | Method | Infrared reflectance layer | Coating thickness/μm | Ref. |

|---|---|---|---|---|

| Al2O3 | Dip-coating | TiO2, TiO2/SiO2/TiO2, TiO2-Pt | - | [64] |

| SiO2 | Dip-coating | ITO, ITO/Ag/ITO | ~0.2 | [60,65] |

| ZrO2 | Hydrothermal | CeO2 | 52-214 | [66] |

| Mullite | Hydrothermal | TiO2 | - | [67] |

| ZrO2 | Hydrothermal | TiO2 | 89-236 | [68] |

| Mullite | Dip-coating | SiC | ~0.8 | [69] |

Table 1 Preparation method and coating types of high-reflectivity coated fiber

| Fiber | Method | Infrared reflectance layer | Coating thickness/μm | Ref. |

|---|---|---|---|---|

| Al2O3 | Dip-coating | TiO2, TiO2/SiO2/TiO2, TiO2-Pt | - | [64] |

| SiO2 | Dip-coating | ITO, ITO/Ag/ITO | ~0.2 | [60,65] |

| ZrO2 | Hydrothermal | CeO2 | 52-214 | [66] |

| Mullite | Hydrothermal | TiO2 | - | [67] |

| ZrO2 | Hydrothermal | TiO2 | 89-236 | [68] |

| Mullite | Dip-coating | SiC | ~0.8 | [69] |

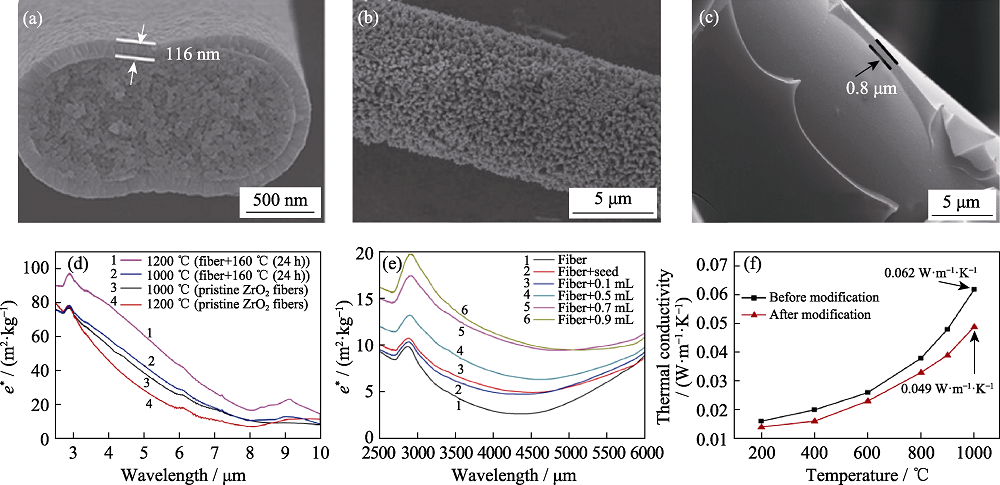

Fig. 9 High-reflectivity coated fiber[66-67,69] (a) SEM image of ZrO2 fiber with CeO2 coating; (b) SEM image of mullite fiber with TiO2 coating; (c) SEM image of mullite fiber with SiC coating; (d) Specific extinction coefficients comparison of ZrO2 fiber and CeO2/ZrO2 fiber; (e) Specific extinction coefficients comparison of mullite fiber and TiO2/mullite fiber; (f) Thermal conductivity comparison of mullite fiber and SiC/mullite fiber reinforced aerogel composite

Fig. 10 Composite micro-nano ceramic fiber[14,70] (a) Schematic illustration of the preparation of ZrO2/SiC fiber; (b) TEM images of ZrO2/SiC fiber; (c) SEM images of SiZrOC fiber; (d) Thermal conductivity comparison of SiZrOC fiber with other ceramic fibers; (e) Schematic illustration of thermal insulation mechanisms of SiZrOC fibers

| [1] | CHEN Y F, HONG C Q, HU C L, et al. Ceramic-based thermal protection materials for aerospace vehicle. Advanced Ceramics, 2017,38(5):311-390. |

| [2] | BEHRENS B, MULLER M. Technologies for thermal protection systems applied on reusable launcher. Acta Astronautica, 2004,55(3-9):529-536 |

| [3] | WANG C A, LANG Y, HU L F, et al. Research progress on lightweight and high strength heat-insulating porous ceramics. Journal of Ceramics, 2017,38(6):287-296. |

| [4] | TERESA L, MARIA T P A, LUISA D. Silica aerogel composites with embedded fibres: a review on their preparation, properties and applications. Journal of Materials Chemistry A, 2019,7:22768-22802. |

| [5] | LUO Y, JIANG Y G, FENG J Z, et al. Progress on the preparation of SiO2 aerogel composites by ambient pressure drying technique. Materials Review, 2018,32(5):780-787. |

| [6] |

XU X, ZHANG Q, HAO M, et al. Double-negative-index ceramic aerogels for thermal superinsulation. Science, 2019,363(6428):723-727.

DOI URL PMID |

| [7] |

SI Y, WANG X, DOU L, et al. Ultralight and fire-resistant ceramic nanofibrous aerogels with temperature-invariant superelasticity. Science Advances, 2018, 4(4): eaas8925.

URL PMID |

| [8] |

SU L, WANG H, NIU M, et al. Ultralight, recoverable, and high-temperature-resistant SiC nanowire aerogel. ACS Nano, 2018,12(4):3103-3111.

DOI URL PMID |

| [9] | SABETZADEH N, BAHRAMBEYGI H, RABBI A, et al. Thermal conductivity of polyacrylonitrile nanofibre web in various nanofibre diameters and surface densities. Micro & Nano Letters, 2012,7(7):662-666. |

| [10] | YAN J, HAN Y, XIA S, et al. Polymer template synthesis of flexible BaTiO3 Crystal nanofibers. Advanced Functional Materials, 2019,29(51):1907919. |

| [11] |

YAN J, ZHAO Y, WANG X, et al. Polymer template synthesis of soft, light, and robust oxide ceramic films. iScience, 2019,15:185-195.

DOI URL PMID |

| [12] | ARAMBAKAM R, TAFRESHI H V, POURDEYHIMI B. A simple simulation method for designing fibrous insulation materials. Materials & Design, 2013,44:99-106. |

| [13] | ARAMBAKAM R, TAFRESHI H V, POURDEYHIMI B. Dual-scale 3-D approach for modeling radiative heat transfer in fibrous insulations. International Journal of Heat and Mass Transfer, 2013,64:1109-1117. |

| [14] | ZHANG X S, WANG B, WU N, et al. Flexible and thermal-stable SiZrOC nanofiber membranes with low thermal conductivity at high-temperature. Journal of the European Ceramic Society, 2020,40(5):1877-1885. |

| [15] | DARYABEUGI K, CUNNINGTON G R, KNUTSON J R. Heat transfer modeling for rigid high-temperature fibrous insulation. Journal of Thermophysics and Heat Transfer, 2013,27(3):414-421. |

| [16] | HU F, WU S, SUN Y. Hollow structured materials for thermal insulation. Advanced Materials, 2019,31(38):1801001. |

| [17] | MACHADO H A. Modeling heat transfer with micro-scale natural convection in fibrous insulation. Journal of the Brazilian Society of Mechanical Sciences and Engineering, 2014,36(4):847-857. |

| [18] | DARYABEUGI K, CUNNINGTON G R, KNUTSON J R. Combined heat transfer in high-porosity high-temperature fibrous insulation: theory and experimental validation. Journal of Thermophysics and Heat Transfer, 2011,25(4):536-546. |

| [19] | SHIN S, WANG Q, LUO J, et al. Advanced materials for high- temperature thermal transport. Advanced Functional Materials, 2020,30:1904815. |

| [20] | GIBSON P W, LEE C, KO F, et al. Application of nanofiber technology to nonwoven thermal insulation. Journal of Engineered Fibers and Fabrics, 2007,2(2):32-40. |

| [21] | WANG B, WANG Y D. Effect of fiber diameter on thermal conductivity of the electrospun carbon nanofiber mats. Advanced Materials Research, 2011,332:672-677. |

| [22] | YAN J, ZHANG Y, ZHAO Y, et al. Transformation of oxide ceramic textiles from insulation to conduction at room temperature. Science Advances, 2020, 6(6): eaay8538. |

| [23] | ZHU W, GUO A, XUE Y, et al. Mechanical evaluations of mullite fibrous ceramics processed by filtration and in situ pyrolysis of organic precursor. Journal of the European Ceramic Society, 2019,39(4):1329-1335. |

| [24] | HE F, LI W, ZKOU L, et al. Preparation and characterization of the three-dimensional network mullite porous fibrous materials by pressure and freeze-casting method. Ceramics International, 2019,45(3):3954-3960. |

| [25] |

XUE J, WU T, DAI Y, et al. Electrospinning and electrospun nanofibers: methods, materials, and applications. Chemical Reviews, 2019,119(8):5298-5415.

DOI URL PMID |

| [26] | WU N, WANG B, WANG Y D. Enhanced mechanical properties of amorphous SiOC nanofibrous membrane through in situ embedding nanoparticles. Journal of the American Ceramic Society, 2018,101(10):4763-4772. |

| [27] | SI Y, MAO X, ZHENG H, et al. Silica nanofibrous membranes with ultra-softness and enhanced tensile strength for thermal insulation. RSC Advances, 2015,5(8):6027-6032. |

| [28] | MAO X, BAI Y, YU J, et al. Flexible and highly temperature resistant polynanocrystalline zirconia nanofibrous membranes designed for air filtration. Journal of the American Ceramic Society, 2016,99(8):2760-2768. |

| [29] | ZHANG P, CHEN D, JIAO X. Fabrication of flexible α-alumina fibers composed of nanosheets. European Journal of Inorganic Chemistry, 2012,2012(26):4167-4173. |

| [30] | LI W, ZHAO X M, WANG Y F, et al. Fabrication and mechanical properties of flexible gamma-Al2O3 nanofibrous membranes. Chemical Journal of Chinese Universities, 2017,38(6):915-921. |

| [31] | YUAN K, WANG X, LIU H, et al. Formation of barium zirconate fibers for high-temperature thermal insulation applications. Journal of the American Ceramic Society, 2016,99(9):2913-2919. |

| [32] | SHI S, YUAN K, XU C, et al. Electrospun fabrication, excellent high-temperature thermal insulation and alkali resistance performance of calcium zirconate fiber. Ceramics International, 2018,44(12):14013-14019. |

| [33] | XIE Y, WANG L, LIU B, et al. Flexible, controllable, and high-strength near-infrared reflective Y2O3 nanofiber membrane by electrospinning a polyacetylacetone-yttrium precursor. Materials & Design, 2018,160:918-925. |

| [34] | SI Y, YU J, TANG X, et al. Ultralight nanofibre-assembled cellular aerogels with superelasticity and multifunctionality. Nature Communications, 2014,5(1):1-9. |

| [35] | DOU L, CHENG X, ZHANG X, et al. Temperature-invariant superelastic, fatigue resistant, and binary-network structured silica nanofibrous aerogels for thermal superinsulation. Journal of Materials Chemistry A, 2020,32(2):1904331. |

| [36] |

DOU L, ZHANG X, CHENG X, et al. Hierarchical cellular structured ceramic nanofibrous aerogels with temperature-invariant superelasticity for thermal insulation. ACS Applied Materials & Interfaces, 2019,11(32):29056-29064.

DOI URL PMID |

| [37] |

WANG F, DOU L, DAI J, et al. In situ synthesis of biomimetic silica nanofibrous aerogels with temperature-invariant superelasticity over one million compressions. Angewandte Chemie International Edition, 2020,59(21):8285-8292.

DOI URL PMID |

| [38] | XIAN L, ZHANG Y, WU Y, et al. Microstructural evolution of mullite nanofibrous aerogels with different ice crystal growth inhibitors. Ceramics International, 2020,46(2):1869-1875. |

| [39] | YU Z L, QIN B, MA Z Y, et al. Superelastic hard carbon nanofiber aerogels. Advanced Materials, 2019,31(23):1900651. |

| [40] | LI C, DING Y W, HU B C, et al. Temperature-invariant superelastic and fatigue resistant carbon nanofiber aerogels. Advanced Materials, 2020,32(2):1904331. |

| [41] | ZHANG J, LI B, LI L, et al. Ultralight, compressible and multifunctional carbon aerogels based on natural tubular cellulose. Journal of Materials Chemistry A, 2016,4(6):2069-2074. |

| [42] | RUCKDESCHEL P, PHILIPP A, RETSCH M. Understanding thermal insulation in porous, particulate materials. Advanced Functional Materials, 2017,27(38):1702256. |

| [43] | BRENDEL H, SEIFERT G, RARTHER F. Heat transfer properties of hollow-fiber insulation materials at high temperatures. Journal of Thermophysics and Heat Transfer, 2017,31(2):463-472. |

| [44] | WANG T C, ZHANG Z, DAI C, et al. Amorphous silicon and silicates-stabilized ZrO2 hollow fiber with low thermal conductivity and high phase stability derived from a cogon template. Ceramics International, 2019,45(6):7120-7126. |

| [45] |

WANG T C, KONG S, CHANG L, et al. Preparation and heat-insulating property of the bio-inspired ZrO2 fibers based on the silk template. Ceramics International, 2012,38(8):6783-6788.

DOI URL |

| [46] |

WANG T C, YU Q, KONG J, et al. Synthesis and heat-insulating properties of yttria-stabilized ZrO2 hollow fibers derived from a ceiba template. Ceramics International, 2017,43(12):9296-9302.

DOI URL |

| [47] | WANG T C, YU Q, KONG J. Preparation and heat-insulating properties of biomorphic ZrO2 hollow fibers derived from a cotton template. International Journal of Applied Ceramic Technology, 2018,15(2):472-478. |

| [48] | XU C, WANG H, SONG J, et al. Ultralight and resilient Al2O3 nanotube aerogels with low thermal conductivity. Journal of the American Ceramic Society, 2018,101(4):1677-1683. |

| [49] |

ZHAN H J, WU K J, HU Y L, et al. Biomimetic carbon tube aerogel enables super-elasticity and thermal insulation. Chem, 2019,5(7):1871-1882.

DOI URL |

| [50] |

DU A, WANG H, ZHOU B, et al. Multifunctional silica nanotube aerogels inspired by polar bear hair for light management and thermal insulation. Chemistry of Materials, 2018,30(19):6849-6857.

DOI URL |

| [51] |

LIU Y, LIU Y, CHOI W C, et al. Highly flexible, erosion resistant and nitrogen doped hollow SiC fibrous mats for high temperature thermal insulators. Journal of Materials Chemistry A, 2017,5(6):2664-2672.

DOI URL |

| [52] |

TIAN Q, WU N, WANG B, et al. Fabrication of hollow SiC ultrafine fibers by single-nozzle electrospinning for high-temperature thermal insulation application. Materials Letters, 2019,239:109-112.

DOI URL |

| [53] | GBEWONYO S, CARPENTER A W, GAUSE C B, et al. Low thermal conductivity carbon fibrous composite nanomaterial enabled by multi-scale porous structure. Materials & Design, 2017,134:218-225. |

| [54] | WANG Y D, HUANG H, ZHAO Y, et al. Self-assembly of ultralight and compressible inorganic sponges with hierarchical porosity by electrospinning. Ceramics International, 2020,46(1):768-774. |

| [55] |

LIU Z, LYU J, FANG D, et al. Nanofibrous Kevlar aerogel threads for thermal insulation in harsh environments. ACS Nano, 2019,13(5):5703-5711.

DOI URL PMID |

| [56] | ZHOU J, HSIEH Y L. Nanocellulose aerogel-based porous coaxial fibers for thermal insulation. Nano Energy, 2020,68:104305. |

| [57] |

YANG H, WANG Z, LIU Z, et al. Continuous, strong, porous silk firoin-based aerogel fibers toward textile thermal insulation. Polymers, 2019,11(11):1899.

DOI URL |

| [58] |

YANG J, WU H, WANG M, et al. Prediction and optimization of radiative thermal properties of ultrafine fibrous insulations. Applied Thermal Engineering, 2016,104:394-402.

DOI URL |

| [59] | YANG L L, GE D, WEI H, et al. Morphology and characterization of ITO-Ag-ITO films on fibers by layer-by-layer method. Applied Surface Science, 2009,255(19):8197-8201. |

| [60] | WANG X D, SUN D, DUAN Y Y, et al. Radiative characteristics of opacifier-loaded silica aerogel composites. Journal of Non-crystalline Solids, 2013,375:31-39. |

| [61] |

LEE S C, CUNNINGTON G R. Conduction and radiation heat transfer in high-porosity fiber thermal insulation. Journal of Thermophysics and Heat Transfer, 2000,14(2):121-136.

DOI URL |

| [62] |

TONG T W, SWATHI P S, CUNNINGTON JR G R. Examination of the radiative properties of coated silica fibers. Journal of Thermal Insulation, 1987,11(1):7-31.

DOI URL |

| [63] | TONG T W, SWATHI P S, CUNNINGTON JR G R. Reduction of radiative heat transfer in thermal insulations by use of dielectric coated fibers. International Communications in Heat and Mass Transfer, 1989,16(6):851-860. |

| [64] | HASS D D, PRASDA B D, GLASS D E, et al. Reflective Coating on Fibrous Insulation for Reduced Heat Transfer. NASA Contractor Report 201733, 1997. |

| [65] |

YANG L L, HE X, HE F. ITO coated quartz fibers for heat radiative applications. Materials Letters, 2008,62(30):4539-4541.

DOI URL |

| [66] |

GAN X, YU Z, YUAN K, et al. Preparation of a CeO2-nanoparticle thermal radiation shield coating on ZrO2 fibers via a hydrothermal method. Ceramics International, 2017,43(16):14183-14191.

DOI URL |

| [67] |

YANG J, ZHANG Y, HONG Z, et al. Preparations of TiO2 nanocrystal coating layers with various morphologies on mullite fibers for infrared opacifier application. Thin Solid Films, 2012,520(7):2651-2655.

DOI URL |

| [68] |

MA D, ZHU L, LIU B. Hydrothermally grown uniform TiO2 coatings on ZrO2 fibers and their infrared reflective and thermal conductive properties. Ceramics International, 2020,46(3):3400-3405.

DOI URL |

| [69] | XU L, JIANG Y, FENG J, et al. Infrared-opacified Al2O3-SiO2 aerogel composites reinforced by SiC-coated mullite fibers for thermal insulations. Ceramics International, 2015,41(1):437-442. |

| [70] |

WANG Y D, HAN C, ZHENG D, et al. Large-scale, flexible and high-temperature resistant ZrO2/SiC ultrafine fibers with a radial gradient composition. Journal of Materials Chemistry A, 2014,2(25):9607-9612.

DOI URL |

| [1] | ZHU Wenjie, TANG Lu, LU Jichang, LIU Jiangping, LUO Yongming. Research Progress on Catalytic Oxidation of Volatile Organic Compounds by Perovskite Oxides [J]. Journal of Inorganic Materials, 2025, 40(7): 735-746. |

| [2] | HU Zhichao, YANG Hongyu, YANG Hongcheng, SUN Chengli, YANG Jun, LI Enzhu. Usage of the P-V-L Bond Theory in Regulating Properties of Microwave Dielectric Ceramics [J]. Journal of Inorganic Materials, 2025, 40(6): 609-626. |

| [3] | WU Qiong, SHEN Binglin, ZHANG Maohua, YAO Fangzhou, XING Zhipeng, WANG Ke. Research Progress on Lead-based Textured Piezoelectric Ceramics [J]. Journal of Inorganic Materials, 2025, 40(6): 563-574. |

| [4] | ZHANG Bihui, LIU Xiaoqiang, CHEN Xiangming. Recent Progress of Hybrid Improper Ferroelectrics with Ruddlesden-Popper Structure [J]. Journal of Inorganic Materials, 2025, 40(6): 587-608. |

| [5] | WU Jie, YANG Shuai, WANG Mingwen, LI Jinglei, LI Chunchun, LI Fei. Textured PT-based Piezoelectric Ceramics: Development, Status and Challenge [J]. Journal of Inorganic Materials, 2025, 40(6): 575-586. |

| [6] | JIANG Kun, LI Letian, ZHENG Mupeng, HU Yongming, PAN Qinxue, WU Chaofeng, WANG Ke. Research Progress on Low-temperature Sintering of PZT Ceramics [J]. Journal of Inorganic Materials, 2025, 40(6): 627-638. |

| [7] | TIAN Ruizhi, LAN Zhengyi, YIN Jie, HAO Nanjing, CHEN Hangrong, MA Ming. Microfluidic Technology Based Synthesis of Inorganic Nano-biomaterials: Principles and Progress [J]. Journal of Inorganic Materials, 2025, 40(4): 337-347. |

| [8] | ZHANG Jiguo, WU Tian, ZHAO Xu, YANG Fan, XIA Tian, SUN Shien. Improvement of Cycling Stability of Cathode Materials and Industrialization Process for Sodium-ion Batteries [J]. Journal of Inorganic Materials, 2025, 40(4): 348-362. |

| [9] | YIN Jie, GENG Jiayi, WANG Kanglong, CHEN Zhongming, LIU Xuejian, HUANG Zhengren. Recent Advances in 3D Printing and Densification of SiC Ceramics [J]. Journal of Inorganic Materials, 2025, 40(3): 245-255. |

| [10] | CHEN Guangchang, DUAN Xiaoming, ZHU Jinrong, GONG Qing, CAI Delong, LI Yuhang, YANG Donglei, CHEN Biao, LI Xinmin, DENG Xudong, YU Jin, LIU Boya, HE Peigang, JIA Dechang, ZHOU Yu. Advanced Ceramic Materials in Helicopter Special Structures: Research Progress and Application Prospect [J]. Journal of Inorganic Materials, 2025, 40(3): 225-244. |

| [11] | FAN Xiaobo, ZU Mei, YANG Xiangfei, SONG Ce, CHEN Chen, WANG Zi, LUO Wenhua, CHENG Haifeng. Research Progress on Proton-regulated Electrochemical Ionic Synapses [J]. Journal of Inorganic Materials, 2025, 40(3): 256-270. |

| [12] | HAIREGU Tuxun, GUO Le, DING Jiayi, ZHOU Jiaqi, ZHANG Xueliang, NUERNISHA Alifu. Research Progress of Optical Bioimaging Technology Assisted by Upconversion Fluorescence Probes in Tumor Imaging [J]. Journal of Inorganic Materials, 2025, 40(2): 145-158. |

| [13] | SUN Shujuan, ZHENG Nannan, PAN Haokun, MA Meng, CHEN Jun, HUANG Xiubing. Research Progress on Preparation Methods of Single-atom Catalysts [J]. Journal of Inorganic Materials, 2025, 40(2): 113-127. |

| [14] | TAO Guilong, ZHI Guowei, LUO Tianyou, OUYANG Peidong, YI Xinyan, LI Guoqiang. Progress on Key Technologies of Cavity-structured Thin Film Bulk Acoustic Wave Filter [J]. Journal of Inorganic Materials, 2025, 40(2): 128-144. |

| [15] | ZHOU Fan, TIAN Zhilin, LI Bin. Research Progress on Carbide Ultra-high Temperature Ceramic Anti-ablation Coatings for Thermal Protection System [J]. Journal of Inorganic Materials, 2025, 40(1): 1-16. |

| Viewed | ||||||

|

Full text |

|

|||||

|

Abstract |

|

|||||