Journal of Inorganic Materials ›› 2020, Vol. 35 ›› Issue (7): 748-758.DOI: 10.15541/jim20190408

Special Issue: 结构陶瓷论文精选(2020); 优秀作者论文集锦; 2019~2020年度优秀作者作品欣赏(六)

• REVIEW • Previous Articles Next Articles

CHEN Lei1,2,WANG Kai1,2,SU Wentao1,2,ZHANG Wen1,2,XU Chenguang1,2,WANG Yujin1,2( ),ZHOU Yu1,2

),ZHOU Yu1,2

Received:2019-08-12

Revised:2019-10-23

Published:2020-07-20

Online:2019-12-04

Supported by:CLC Number:

CHEN Lei,WANG Kai,SU Wentao,ZHANG Wen,XU Chenguang,WANG Yujin,ZHOU Yu. Research Progress of Transition Metal Non-oxide High-entropy Ceramics[J]. Journal of Inorganic Materials, 2020, 35(7): 748-758.

| Ranking | HEC | EFA/(eV·atom)-1a | Ranking | HEC | EFA/(eV·atom)-1a |

|---|---|---|---|---|---|

| (1) | (VNbTaMoW)C | 125 | (23) | (TiZrNbTaW)C | 59 |

| (2) | (TiZrHfNbTa)C | 100 | (29) | (ZrVNbTaW)C | 56 |

| (3) | (TiHfVNbTa)C | 100 | (33) | (TiZrHfNbW)C | 53 |

| (4) | (TiVNbTaMo)C | 100 | (36) | (TiZrHfTaW)C | 50 |

| (5) | (TiZrNbTaV)C | 83 | (44) | (TiZrTaMoW)C | 48 |

| (7) | (TiVNbTaW)C | 77 | (52) | (ZrHfTaMoW)C | 45 |

| (10) | (TiZrNbTaMo)C | 71 | (55) | (TiZrHfMoW)C | 38 |

| (17) | (TiHfNbTaW)C | 67 | (56) | (ZrHfVMoW)C | 37 |

Table 1 Ranking of some high-entropy carbides based on the EFA values[29]

| Ranking | HEC | EFA/(eV·atom)-1a | Ranking | HEC | EFA/(eV·atom)-1a |

|---|---|---|---|---|---|

| (1) | (VNbTaMoW)C | 125 | (23) | (TiZrNbTaW)C | 59 |

| (2) | (TiZrHfNbTa)C | 100 | (29) | (ZrVNbTaW)C | 56 |

| (3) | (TiHfVNbTa)C | 100 | (33) | (TiZrHfNbW)C | 53 |

| (4) | (TiVNbTaMo)C | 100 | (36) | (TiZrHfTaW)C | 50 |

| (5) | (TiZrNbTaV)C | 83 | (44) | (TiZrTaMoW)C | 48 |

| (7) | (TiVNbTaW)C | 77 | (52) | (ZrHfTaMoW)C | 45 |

| (10) | (TiZrNbTaMo)C | 71 | (55) | (TiZrHfMoW)C | 38 |

| (17) | (TiHfNbTaW)C | 67 | (56) | (ZrHfVMoW)C | 37 |

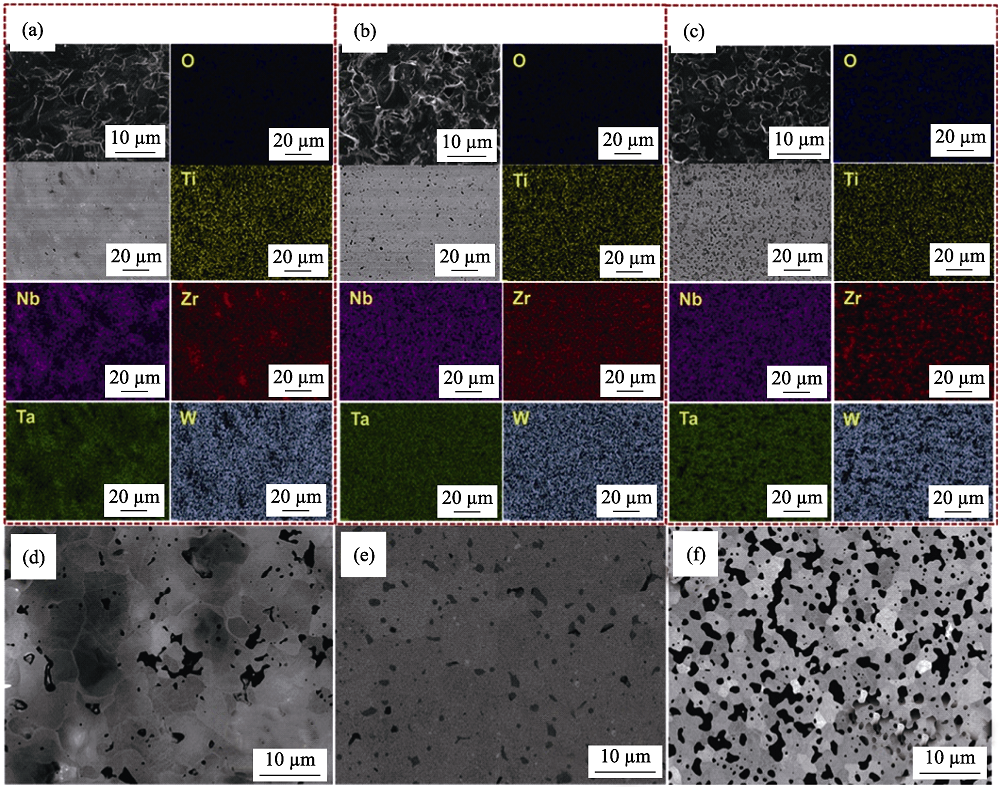

Fig. 2 SEM images of the fracture surfaces, polished surfaces and their corresponding EDS element mappings of (TiZrNbTaW)C using (a) metallic powders and graphite, (b) metal carbides and (c) metal oxides and graphite as raw materials, as well as the back scattered electron images of (TiZrNbTaW)C using (d) metallic powders and graphite,(e) metal carbides and (f) metal oxides and graphite as raw materials[43]

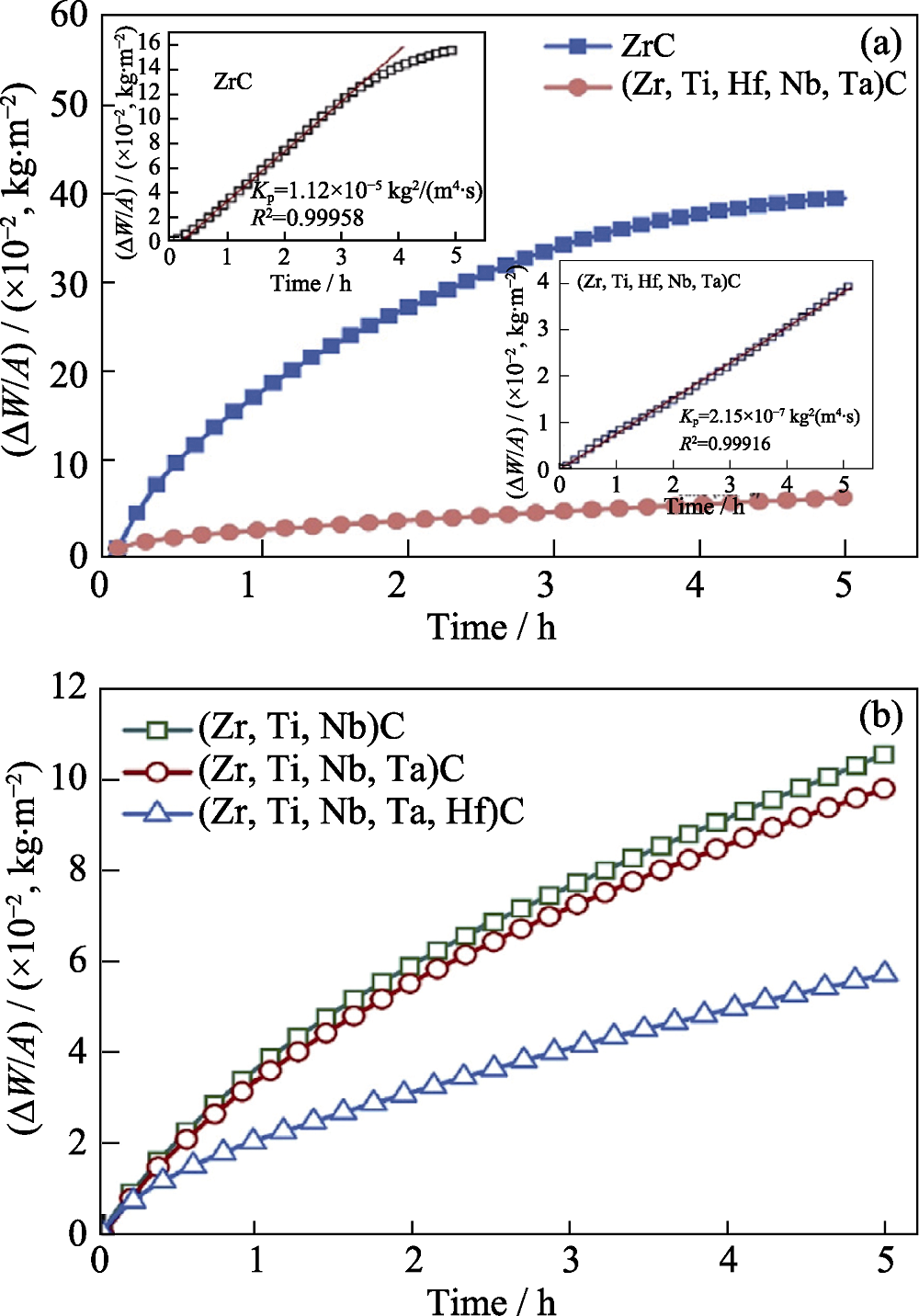

Fig. 5 Comparison of weight gain per unit area as a function of exposure time for (TiZrHfNbTa)C high-entropy ceramic and related (TiZrHNbTa)C, (TiZrNb)C, ZrC ceramic[52]

| [1] |

FAHRENHOLTZ W G, HILMAS G E. Ultra-high temperature ceramics: materials for extreme environments. Scripta Materialia, 2017,129:94-99.

DOI URL |

| [2] |

WEINBERGER C R, THOMPSON G B. Review of phase stability in the group IVB and VB transition-metal carbides. Journal of the American Ceramic Society, 2018,101(10):4401-4424.

DOI URL |

| [3] |

GUO S Q. Densification of ZrB2-based composites and their mechanical and physical properties: a review. Journal of the European Ceramic Society, 2009,29(6):995-1011.

DOI URL |

| [4] |

HUANG P K, YEH J W, SHUN T T, et al. Multi-principal-element alloys with improved oxidation and wear resistance for thermal spray coating. Advanced Engineering Materials, 2004,6(1/2):74-78.

DOI URL |

| [5] |

YEH J W, CHEN S K, LIN S J, et al. Nanostructured high-entropy alloys with multiple principal elements: novel alloy design concepts and outcomes. Advanced Engineering Materials, 2004,6(5):299-303.

DOI URL |

| [6] |

CHEN T K, SHUN T T, YEH J W, et al. Nanostructured nitride films of multi-element high-entropy alloys by reactive DC sputtering. Surface and Coatings Technology, 2004,188-189:193-200.

DOI URL |

| [7] |

CANTOR B. Multicomponent and high entropy alloys. Entropy, 2014,16(9):4749-4768.

DOI URL |

| [8] | CANTOR B, CHANG I T H, KNIGHT P, et al. Microstructural development in equiatomic multicomponent alloys. Materials Science and Engineering: A, 2004,375-377:213-218. |

| [9] |

YEH J W, LIN S J, CHIN T S, et al. Formation of simple crystal structures in Cu-Co-Ni-Cr-Al-Fe-Ti-V alloys with multiprincipal metallic elements. Metallurgical and Materials Transactions A, 2004,35(8):2533-2536.

DOI URL |

| [10] |

TSAI M H, YEH J W. High-entropy alloys: a critical review. Materials Research Letters, 2014,2(3):107-123.

DOI URL |

| [11] |

MIRACLE D B, SENKOV O N. A critical review of high entropy alloys and related concepts. Acta Materialia, 2017,122:448-511.

DOI URL |

| [12] |

WANG Y P, LI B S, REN M X, et al. Microstructure and compressive properties of AlCrFeCoNi high entropy alloy. Materials Science and Engineering: A, 2008,491(1):154-158.

DOI URL |

| [13] |

SENKOV O N, WILKS G B, MIRACLE D B, et al. Refractory high-entropy alloys. Intermetallics, 2010,18(9):1758-1765.

DOI URL |

| [14] |

SENKOV O N, SCOTT J M, SENKOVA S V, et al. Microstructure and room temperature properties of a high-entropy TaNbHfZrTi alloy. Journal of Alloys and Compounds, 2011,509(20):6043-6048.

DOI URL |

| [15] |

SENKOV O N, SCOTT J M, SENKOVA S V, et al. Microstructure and elevated temperature properties of a refractory TaNbHfZrTi alloy. Journal of Materials Science, 2012,47(9):4062-4074.

DOI URL |

| [16] |

GAO M C, CARNEY C S, DOĞAN Ö N, et al. Design of refractory high-entropy alloys. Journal of the Minerals Metals and Materials Society, 2015,67(11):2653-2669.

DOI URL |

| [17] |

LONG Y, LIANG X, SU K, et al. A fine-grained NbMoTaWVCr refractory high-entropy alloy with ultra-high strength: microstructural evolution and mechanical properties. Journal of Alloys and Compounds, 2019,780:607-617.

DOI URL |

| [18] | TUNES M A, VISHNYAKOV V M. Microstructural origins of the high mechanical damage tolerance of NbTaMoW refractory high-entropy alloy thin films. Materials & Design, 2019,170:107692. |

| [19] |

KIM H, NAM S, ROH A, et al. Mechanical and electrical properties of NbMoTaW refractory high-entropy alloy thin films. International Journal of Refractory Metals and Hard Materials, 2019,80:286-291.

DOI URL |

| [20] |

HOU J, ZHANG M, YANG H, et al. Surface strengthening in Al0.25CoCrFeNi high-entropy alloy by boronizing. Materials Letters, 2019,238:258-260.

DOI URL |

| [21] |

HOU L, HUI J, YAO Y, et al. Effects of boron content on microstructure and mechanical properties of AlFeCoNiBx high entropy alloy prepared by vacuum arc melting. Vacuum, 2019,164:212-218.

DOI URL |

| [22] |

BRAIC V, VLADESCU A, BALACEANU M, et al. Nanostructured multi-element (TiZrNbHfTa)N and (TiZrNbHfTa)C hard coatings. Surface and Coatings Technology, 2012,211:117-121.

DOI URL |

| [23] |

LEI Z, LIU X, WU Y, et al. Enhanced strength and ductility in a high-entropy alloy via ordered oxygen complexes. Nature, 2018,563(7732):546-550.

DOI URL PMID |

| [24] | PIERSON H O. Handbook of Refractory Carbides and Nitrides: Properties, Characteristics, Processing and Applications, William Andrew Publishing, Westwood, NJ, 1996. |

| [25] |

YAN X, CONSTANTIN L, LU Y, et al. (Hf0.2Zr0.2Ta0.2Nb0.2Ti0.2)C high-entropy ceramics with low thermal conductivity. Journal of the American Ceramic Society, 2018,101(10):4486-4491.

DOI URL |

| [26] |

YANG Y, WANG W, GAN G Y, et al. Structural, mechanical and electronic properties of (TaNbHfTiZr)C high entropy carbide under pressure: ab initio investigation. Physica B: Condensed Matter, 2018,550:163-170.

DOI URL |

| [27] |

FENG L, FAHRENHOLTZ W G, HILMAS G E. Low-temperature sintering of single-phase, high-entropy carbide ceramics. Journal of the American Ceramic Society, 2019,102(12):7217-7224.

DOI URL |

| [28] |

YE B, WEN T, HUANG K, et al. First‐principles study, fabrication, and characterization of (Hf0.2Zr0.2Ta0.2Nb0.2Ti0.2)C high‐entropy ceramic. Journal of the American Ceramic Society, 2019,102(7):4344-4352.

DOI URL |

| [29] |

SARKER P, HARRINGTON T, TOHER C, et al. High-entropy high-hardness metal carbides discovered by entropy descriptors. Nature Communications, 2018,9(1):4980.

DOI URL PMID |

| [30] | CHEN H, XIANG H, DAI F Z, et al. High porosity and low thermal conductivity high entropy (Zr0.2Hf0.2Ti0.2Nb0.2Ta0.2)C. Journal of Materials Science & Technology, 2019,35(8):1700-1705. |

| [31] |

HARRINGTON T J, GILD J, SARKER P, et al. Phase stability and mechanical properties of novel high entropy transition metal carbides. Acta Materialia, 2019,166:271-280.

DOI URL |

| [32] |

ZHOU J Y, ZHANG J Y, ZHANG F, et al. High-entropy carbide: a novel class of multicomponent ceramics. Ceramics International, 2018,44(17):22014-22018.

DOI URL |

| [33] |

CHICARDI E, GARCíA-GARRIDO C, GOTOR F J. Low temperature synthesis of an equiatomic (TiZrHfVNb)C5 high entropy carbide by a mechanically-induced carbon diffusion route. Ceramics International, 2019,45(17):21858-21863.

DOI URL |

| [34] |

WANG K, CHEN L, XU C, et al. Microstructure and mechanical properties of (TiZrNbTaMo)C high-entropy ceramic. Journal of Materials Science & Technology, 2019,39:99-105.

DOI URL |

| [35] |

DEMIRSKYI D, BORODIANSKA H, SUZUKI T S, et al. High-temperature flexural strength performance of ternary high-entropy carbide consolidated via spark plasma sintering of TaC, ZrC and NbC. Scripta Materialia, 2019,164:12-16.

DOI URL |

| [36] | YE B L, CHU Y H, HUANG K H, et al. Synthesis and characterization of (Zr1/3Nb1/3Ti1/3)C metal carbide solid-solution ceramic. Journal of the American Ceramic Society, 2019,102(3):919-923. |

| [37] |

CASTLE E, CSANADI T, GRASSO S, et al. Processing and properties of high-entropy ultra-high temperature carbides. Sci. Rep., 2018,8(1):8609.

DOI URL PMID |

| [38] |

DUSZA J, ŠVEC P, GIRMAN V, et al. Microstructure of (Hf-Ta-Zr-Nb)C high-entropy carbide at micro and nano/atomic level. Journal of the European Ceramic Society, 2018,38(12):4303-4307.

DOI URL |

| [39] |

YE B, WEN T, NGUYEN M C, et al. First-principles study, fabrication and characterization of (Zr0.25Nb0.25Ti0.25V0.25)C high-entropy ceramics. Acta Materialia, 2019,170:15-23.

DOI URL |

| [40] |

FENG L, FAHRENHOLTZ W G, HILMAS G E, et al. Synthesis of single-phase high-entropy carbide powders. Scripta Materialia, 2019, 162:90-93.

DOI URL |

| [41] |

LI F, LU Y, WANG X G, et al. Liquid precursor-derived high-entropy carbide nanopowders. Ceramics International, 2019,45(17):22437-22441.

DOI URL |

| [42] |

GILD J, KAUFMANN K, VECCHIO K, et al. Reactive flash spark plasma sintering of high-entropy ultrahigh temperature ceramics. Scripta Materialia, 2019,170:106-110.

DOI URL |

| [43] |

WEI X F, LIU J X, LI F, et al. High entropy carbide ceramics from different starting materials. Journal of the European Ceramic Society, 2019,39(10):2989-2994.

DOI URL |

| [44] | ZHANG C. Compressive Creep Properties of (Ta-Hf-Zr-Nb)C HECs Prepared by Spark Plasma Sintering. Advanced Research Workshop on Engineering Ceramics, Slovakia, 2019. |

| [45] |

CSANáDI T, CASTLE E, REECE M J, et al. Strength enhancement and slip behaviour of high-entropy carbide grains during micro-compression. Scientific Reports, 2019,9(1):10200.

DOI URL PMID |

| [46] |

BRAIC V, BALACEANU M, BRAIC M, et al. Characterization of multi-principal-element (TiZrNbHfTa)N and (TiZrNbHfTa)C coatings for biomedical applications. Journal of the Mechanical Behavior of Biomedical Materials, 2012,10:197-205.

DOI URL PMID |

| [47] |

JHI S H, IHM J, LOUIE S G, et al. Electronic mechanism of hardness enhancement in transition-metal carbonitrides. Nature, 1999,399(6732):132-134.

DOI URL |

| [48] |

SANGIOVANNI D G, HULTMAN L, CHIRITA V. Supertoughening in B1 transition metal nitride alloys by increased valence electron concentration. Acta Materialia, 2011,59(5):2121-2134.

DOI URL |

| [49] |

GUO S, NG C, LU J, et al. Effect of valence electron concentration on stability of fcc or bcc phase in high entropy alloys. Journal of Applied Physics, 2011,109(10):103505.

DOI URL |

| [50] |

BALASUBRAMANIAN K, KHARE S V, GALL D. Valence electron concentration as an indicator for mechanical properties in rocksalt structure nitrides, carbides and carbonitrides. Acta Materialia, 2018,152:175-185.

DOI URL |

| [51] |

TAN Y, CHEN C, LI S, et al. Oxidation behaviours of high-entropy transition metal carbides in 1200 ℃ water vapor. Journal of Alloys and Compounds, 2019,816:152523.

DOI URL |

| [52] |

GILD J, ZHANG Y, HARRINGTON T, et al. High-entropy metal diborides: a new class of high-entropy materials and a new type of ultrahigh temperature ceramics. Scientific Reports, 2016,6:37946.

DOI URL PMID |

| [53] |

LIU D, WEN T, YE B, et al. Synthesis of superfine high-entropy metal diboride powders. Scripta Materialia, 2019,167:110-114.

DOI URL |

| [54] |

ZHANG Y, JIANG Z B, SUN S K, et al. Microstructure and mechanical properties of high-entropy borides derived from boro/ carbothermal reduction. Journal of the European Ceramic Society, 2019,39(13):3920-3924.

DOI URL |

| [55] |

ZHANG Y, GUO W M, JIANG Z B, et al. Dense high-entropy boride ceramics with ultra-high hardness. Scripta Materialia, 2019,164:135-139.

DOI URL |

| [56] |

TALLARITA G, LICHERI R, GARRONI S, et al. Novel processing route for the fabrication of bulk high-entropy metal diborides. Scripta Materialia, 2019,158:100-104.

DOI URL |

| [57] |

GU J F, ZOU J, SUN S K, et al. Dense and pure high-entropy metal diboride ceramics sintered from self-synthesized powders via boro/ carbothermal reduction approach. Science China Materials, 2019,62(12):1898-1909.

DOI URL |

| [58] | CHEN H, XIANG H, DAI F Z, et al. Porous high entropy (Zr0.2Hf0.2Ti0.2Nb0.2Ta0.2)B2: a novel strategy towards making ultrahigh temperature ceramics thermal insulating. Journal of Materials Science & Technology, 2019,35(10):2404-2408. |

| [59] |

JIN T, SANG X, UNOCIC R R, et al. Mechanochemical-assisted synthesis of high-entropy metal nitride via a soft urea strategy. Advanced Materials, 2018,30(23):1707512.

DOI URL |

| [60] |

YANG Y, MA L, GAN G Y, et al. Investigation of thermodynamic properties of high entropy (TaNbHfTiZr)C and (TaNbHfTiZr)N. Journal of Alloys and Compounds, 2019,788:1076-1083.

DOI URL |

| [61] |

GILD J, BRAUN J, KAUFMANN K, et al. A high-entropy silicide:(Mo0.2Nb0.2Ta0.2Ti0.2W0.2)Si2. Journal of Materiomics, 2019,5(3):337-343.

DOI URL |

| [62] |

QIN Y, LIU J X, LI F, et al. A high entropy silicide by reactive spark plasma sintering. Journal of Advanced Ceramics, 2019,8(1):148-152.

DOI URL |

| [63] |

ZHANG H, AKHTAR F. Processing and characterization of refractory quaternary and quinary high-entropy carbide composite. Entropy, 2019,21(5):474.

DOI URL |

| [64] |

POGREBNJAK A D, BAGDASARYAN A A, BERESNEV V M, et al. The effects of Cr and Si additions and deposition conditions on the structure and properties of the (Zr-Ti-Nb)N coatings. Ceramics International, 2017,43(1, Part A):771-782.

DOI URL |

| [65] |

POGREBNJAK A D, YAKUSHCHENKO I V, BONDAR O V, et al. Irradiation resistance, microstructure and mechanical properties of nanostructured (TiZrHfVNbTa)N coatings. Journal of Alloys and Compounds, 2016,679:155-163.

DOI URL |

| [66] |

MAYRHOFER P H, KIRNBAUER A, ERTELTHALER P, et al. High-entropy ceramic thin films: a case study on transition metal diborides. Scripta Materialia, 2018,149:93-97.

DOI URL |

| [67] | ZHONG Y, SABAROU H, YAN X, et al. Exploration of high entropy ceramics (HECs) with computational thermodynamics - a case study with LaMnO3±δ. Materials & Design, 2019,182:108060. |

| [1] | ZHU Wenjie, TANG Lu, LU Jichang, LIU Jiangping, LUO Yongming. Research Progress on Catalytic Oxidation of Volatile Organic Compounds by Perovskite Oxides [J]. Journal of Inorganic Materials, 2025, 40(7): 735-746. |

| [2] | HU Zhichao, YANG Hongyu, YANG Hongcheng, SUN Chengli, YANG Jun, LI Enzhu. Usage of the P-V-L Bond Theory in Regulating Properties of Microwave Dielectric Ceramics [J]. Journal of Inorganic Materials, 2025, 40(6): 609-626. |

| [3] | WU Qiong, SHEN Binglin, ZHANG Maohua, YAO Fangzhou, XING Zhipeng, WANG Ke. Research Progress on Lead-based Textured Piezoelectric Ceramics [J]. Journal of Inorganic Materials, 2025, 40(6): 563-574. |

| [4] | ZHANG Bihui, LIU Xiaoqiang, CHEN Xiangming. Recent Progress of Hybrid Improper Ferroelectrics with Ruddlesden-Popper Structure [J]. Journal of Inorganic Materials, 2025, 40(6): 587-608. |

| [5] | WU Jie, YANG Shuai, WANG Mingwen, LI Jinglei, LI Chunchun, LI Fei. Textured PT-based Piezoelectric Ceramics: Development, Status and Challenge [J]. Journal of Inorganic Materials, 2025, 40(6): 575-586. |

| [6] | JIANG Kun, LI Letian, ZHENG Mupeng, HU Yongming, PAN Qinxue, WU Chaofeng, WANG Ke. Research Progress on Low-temperature Sintering of PZT Ceramics [J]. Journal of Inorganic Materials, 2025, 40(6): 627-638. |

| [7] | WAN Junchi, DU Lulu, ZHANG Yongshang, LI Lin, LIU Jiande, ZHANG Linsen. Structural Evolution and Electrochemical Performance of Na4FexP4O12+x/C Cathode Materials for Sodium-ion Batteries [J]. Journal of Inorganic Materials, 2025, 40(5): 497-503. |

| [8] | XUE Ke, CAI Changkun, XIE Manyi, LI Shuting, AN Shengli. Pr1+xBa1-xFe2O5+δ Cathode Materials for Solid Oxide Fuel Cells: Preparation and Electrochemical Performance [J]. Journal of Inorganic Materials, 2025, 40(4): 363-371. |

| [9] | TIAN Ruizhi, LAN Zhengyi, YIN Jie, HAO Nanjing, CHEN Hangrong, MA Ming. Microfluidic Technology Based Synthesis of Inorganic Nano-biomaterials: Principles and Progress [J]. Journal of Inorganic Materials, 2025, 40(4): 337-347. |

| [10] | ZHANG Jiguo, WU Tian, ZHAO Xu, YANG Fan, XIA Tian, SUN Shien. Improvement of Cycling Stability of Cathode Materials and Industrialization Process for Sodium-ion Batteries [J]. Journal of Inorganic Materials, 2025, 40(4): 348-362. |

| [11] | YIN Jie, GENG Jiayi, WANG Kanglong, CHEN Zhongming, LIU Xuejian, HUANG Zhengren. Recent Advances in 3D Printing and Densification of SiC Ceramics [J]. Journal of Inorganic Materials, 2025, 40(3): 245-255. |

| [12] | GAO Chenguang, SUN Xiaoliang, CHEN Jun, LI Daxin, CHEN Qingqing, JIA Dechang, ZHOU Yu. SiBCN-rGO Ceramic Fibers Based on Wet Spinning Technology: Microstructure, Mechanical and Microwave-absorbing Properties [J]. Journal of Inorganic Materials, 2025, 40(3): 290-296. |

| [13] | CHEN Guangchang, DUAN Xiaoming, ZHU Jinrong, GONG Qing, CAI Delong, LI Yuhang, YANG Donglei, CHEN Biao, LI Xinmin, DENG Xudong, YU Jin, LIU Boya, HE Peigang, JIA Dechang, ZHOU Yu. Advanced Ceramic Materials in Helicopter Special Structures: Research Progress and Application Prospect [J]. Journal of Inorganic Materials, 2025, 40(3): 225-244. |

| [14] | MU Haojie, ZHANG Yuanjiang, YU Bin, FU Xiumei, ZHOU Shibin, LI Xiaodong. Preparation and Properties of ZrO2 Doped Y2O3-MgO Nanocomposite Ceramics [J]. Journal of Inorganic Materials, 2025, 40(3): 281-289. |

| [15] | FAN Xiaobo, ZU Mei, YANG Xiangfei, SONG Ce, CHEN Chen, WANG Zi, LUO Wenhua, CHENG Haifeng. Research Progress on Proton-regulated Electrochemical Ionic Synapses [J]. Journal of Inorganic Materials, 2025, 40(3): 256-270. |

| Viewed | ||||||

|

Full text |

|

|||||

|

Abstract |

|

|||||